RIT Scholar Works

Theses

Thesis/Dissertation Collections

1991

Effect of low level radiation on the barrier qualities

of spunbonded olefin

Samir A. Sheth

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu.

Recommended Citation

ON THE

BARRIER QUALITIES

OF

SPUNBONDED

OLEFIN

BY

SAMIR A. SHETH

A

THESIS SUBMITTED TO THE DEPARTMENT OF

PACKAGING SCIENCE

IN THE COLLEGE OF APPLIED SCIENCE AND TECHNOLOGY

OF ROCHESTER INSTITUTE OF TECHNOLOGY

IN

PARTIAL FULLFILLMENT OF THE

REQUIREMENTS

FOR THE DEGREE

OF

MASTER

OF SCIENCE

I

am gratefulto

my

thesis advisor,

Professor Fritz

Yambrach,

whosesupport and guidance

has

madethis

day

cometrue.

I

thankDr. Daneil

Goodwin for

being

a source of encouragement.I

am also gratefulto

Dr.

David Olsson

for his

overall guidance and support throughout theprogram.

I

alsothank

Radiation

Sterilizers

Inc.,

for radiating

the

testmaterials and

Mr.

Bob Reich

andMs. Helen Anderson

ofEthox

Corp

for

their support.

I

wouldlike

to take the

opportunity

to thankMr Alfredo

Marchese for his

help

on theScanning

Electron Microscope

andMr Wick

Smith for his

assistance withMinitab,

a statistical software.I

wouldlike

to

thank

Mr. Reginald Vas for

being

a source of encouragment.Last but

notMedical

packageshave

to

meethighly

specific criteria over andabove other

types

of packages.Protection

of contentsfrom

microbialcontamination and physical

damage

is

a priority.The permeability

to

sterilizing

gas;

retention of properties and appearance aftersterilizing

radiation;

printability

and aseptic presentation allhave

to

be

present atreasonable cost.

The

mostimportant is

maintenance of sterileintegrity.

In

order

to

have

sterileintegrity,

the

medical package musthave high barrier

properties.Sterility

maintenanceis

the

ability

of porouspackaging

materialsto

act as

barriers

to microorganisms.The

random non-woven structure ofspunbonded olefin creates a

highly

complex maze through the sheet.This

torturous

path coupled withinfinitesimally

small openings presentsbacteria

with an

impossible

task topenetrate the spunbonded olefin.Thus

by

virtueof

the

properties exhibited similarto the

"Size

Exclusion"principle,

spunbonded olefin maintainspermeability for

gas sterilizationbut

notfor

microorganisms.

The immediate

consequences ofthis

morphology

are:high

opacity,

high filtration

efficiency,

acceptableto

high

airpermeability

and excellent strength.

Strength

ofa spunbonded sheetis

directly

related tothe

strength ofthe

individual

fibers

andhow

arethey

bonded. It

is

clearthat to

have

an effectivematerial; strength,

permeability

andbarrier have

to

be balanced

in

an optimum structure.Packages

madefrom

spunbonded olefin canbe

sterilizedby ionizing

irradiation

whichis

commercially

exposureto

ionizing

radiation,

high

energy

electronfrom

electronbeams

or gamma raysfrom Cobalt-60

orlevel

ofCobalt

andCesium isotopic

gamma raysdoes

notinduce

any

radioactivity.Although,

irradiation has

the

samesterilizing

effect on spunbonded olefin packages as ethylene oxide gastreatment,

it

does

notappreciably

raisethe temperature

ofthe

medical product asdoes

anEto

cycle.One

ofthe

characteristic advantages ofthe

irradiation

processis

thatthe

medical product canbe

irradiated

even after packagehas been

sealed so recontamination afterprocessing

is

prevented.It

is

not possiblefor

the medical productitself

to

become

radioactive,

and there are no residues ofany kind left

by

this

process.Once

treated,

medical packages areconsidered sterile and

ready for

use.Research Focus:

Irradiation

can cause changesin

the physical properties ofavariety

of plastics.The

effects ofradiation on spunbonded olefin needsto

be

investigated.

Because

a changein

the regulatedpore size couldList

ofTables

ii

List

ofFigures

iv

1.

Introduction

1

2.

General

effects ofirradiation

on plastics7

3. Hypothesis

andTest methodology

14

4. Results

andDiscussion

19

5.

Conclusion

andRecommendation

41

Bibliography

44

Appendix A

51

TABLE

1.

Effect

ofirradiation

onPorosity

ofgroup

treated

with0 Mrads

23

TABLE

2.

Effect

ofirradiation

onPorosity

ofgroup

treated with2.5 Mrads

24

TABLE

3.

Effect

ofirradiation

onPorosity

ofgroup

treated with5.0 Mrads

25

TABLE

4.

Effect

ofirradiation

onPorosity

ofgroup

treated

with7.5 Mrads

26

TABLE 5.

Effect

ofirradiation

onPorosity

ofgroup

treated

with10

Mrads

27

TABLE 6.

Effect

ofirradiation

onWVTR

ofgroup

treated

with0 Mrads

30

TABLE 7.

Effect

ofirradiation

onWVTR

ofgroup

treated

with2.5 Mrads

31

TABLE

8.

Effect

ofirradiation

onWVTR

ofgroup

treated

with5.0 Mrads

32

Effect

ofirradiation

onWVTR

ofgroup

treated

with7.5 Mrads

33

TABLE

10.

Effect

ofirradiation

onWVTR

ofgroup

treated

with10

Mrads

34

TABLE 11

Kruskal

Wallis Analysis

ofPorosity

data

onType 1059B

37

TABLE 12

Kruskal

Wallis Analysis

ofPorosity

data

onType 1073B

38

TABLE 13

Kruskal

Wallis Analysis

ofWVTR data

onType 1059B

39

TABLE 14

Kruskal

Wallis Analysis

ofWVTR data

onType 1073B

40

FIGURE 1.

Effect

ofirradiation

onPorosity

ofType 1059B

28

FIGURE

2.

Effect

ofirradiation

onPorosity

ofType 1073B

29

FIGURE

3.

Effect

ofirradiation

onWVTR

ofType

1059B

35

FIGURE 4.

Effect

ofirradiation

onWVTR

ofType

1073B

36

Packages

are checkedin

orderto

contain, protect,

communicate,

deliver

the

productsafely

to the

consumer.Medical

packages must meethighly

specific criteria over and above othertypes

of packages.Protection

of contents

from

microbial contamination and physicaldamage is

aprimary

concern.The permeability

to

sterilizing

gas,

retention of properties and appearance aftersterilizing

radiation,

andprintability

allhave

tobe

present at reasonable cost(Rudys,1982).

In

orderto

have

sterileintegrity,

the

medical package musthave

high barrier

properties.Sterilization

canbe

stressfullto

packages andmaterials.

Sterilization

canbe

defined

asthe

processby

whichliving

organisms are

removed,

orkilled

to the

extentthat

they

are nolonger

detectable

in

standard culture mediain

whichthey

have previously

been

found

to

proliferate.In

today's

health

careindustry,

the

maintenance ofsterility

is

a significant concern.Meticulous

careis

taken

in

controlling

the

design,

manufacture,

packaging,

and sterilization of medical packages.Validation

procedures and protocols aredesigned

to

ensure probabilites of no morethan

one nonsterile unitin

a million processed units(Reich,1985). The initial

asreaches

its

point of use.The

specificfactors regulating

the

selection of asterilizing

processfor

a given productdepends

onthe

nature ofthe product, the

effect ofsterilization on

the product,

legal

acceptability

or requirementsfor

a producttreated

by

a particularprocess,

economics ofthe

sterilizing

process,

andthe

parameters ofsterility

assurancetests

for

eachsterilizing

procedure(Bruch,

1972).

Each

sterilization processhas its

own advantagesand

disadvantages

and also package requirements.Increase in

the

use ofEthylene Oxide

(EtO)

sterilizationthroughout

the

industry

helped

in

better

understanding

its

characteristics.It

provedto

be

afumigant

with severallimitations.

It

is

usefulonly

as a surfacesterilant and can not

be depended

uponto

reachblocked-off

surfaces.EtO

sterilization requires careful and simultaneous control overdifferent but

interdependent

variables:temperature,

humidity,

gasconcentration,

time

ofexposure,

pressure and vacuum.Consistent monitoring

andintegration

ofthese

important

variables are some ofthe

problemsthat

arise out oflarge

scale sterilization.

For EtO

sterilization,

routine use ofbiological

indicators is

a more criticalvalidationfactor

than

in any

otherprocess.Gas

sterilization requires post-sterilizationtreatment:

sterilized productshave

to

be

aeratedto

removetoxic

residuesbefore

the

products goto

aethylene

glycol(Woodard,

1971). Ethylene

chlorohydrinis formed

whenEtO

reacts with chlorineions

presentin

the

moisture ofthe

polymericmaterials.

This

led

to

a re-evaluation ofthe types

of residue andpotentialhazards from

the

use ofEtO

onMedical

Devices(Wesley,

Rourke

etDabishire,1965).

EtO's

potentialfor toxicity,

carcinogenicity

andmutagenicity

were verified with experiments performed on animal andhuman

subjects(Gammagram#4,

1988).

However,

EtO

sterilization will notbe completely

replacedbecause

certain

products,

including

iodine, lydocaine,

lubricating jelly

and alcohol areincompatible

with radiation.For EtO

sterilization,

questions revolve around potential productresidues,

workerexposure,

environmental emissions andhealth

hazards.

Most

damage

to

package resultsduring

anETO

cycledue

to the temperature

and pressure changes which often causemedical packages

to

burst

open andlose

their sealintegrity. Thus

the

movementfor future

packagedesigns for

medical products anddevices

seemsto

have

potentialfor

radiation sterilization.In

recentyears,

Federal

rulingslimiting

EtO

sterilization coupledwith pressure

from

health

careindustry

to

cut costshave forced

medical product packagersto

increasingly

use gamma radiation as a sterilization method.Competitive

costis

helping

the

growth of radiation sterilization.container

load

of product(2000

cubicfeet)

withdensity

of0.15g/cc,

sterilizedwith a

1.5

megaraddose

would cost about60

cents/cubicfoot,

and at

2.5

megaradsit

would cost about$1.00/cubic

foot.

EtO

sterilizationcosts range

from 90

centsto

$1.20/cubic

foot

(Lodge,

1987).

Availability

of specialized radiation centers aroundthe

country

has helped

promote gamma sterilization.The idea is

to

ship

unsterilized productsto

such centersfor

treatment

en routeto

market.The

cost savings canlargely

be

attributedto the

elimination ofsterility

test costs,

quarantineinventory

costs,

and process rework costs(Gammagram

#5,

1988).

Gamma

rays arevery

penetrating

and allow maximumflexibility

in

product

handling

andpackaging

shapes.A

packageis

not submittedto

rigors of elevated

temperature,

rapid changesin

pressure,

andhigh

humidity,

time

or seal strengthduring

radiation.Hence,

materialscharacteristics such as

heat

resistance,

moisture strength and seal strengthmay be less

critical with radiation sterilization.Simplicity

is

the

key

to

gamma sterilization:

time

is

the

only

variable which requires close control.There

are no product residuesto

deal

with andthere

is

no worker exposureproblem

because

the

science ofworkerprotectionis

wellknown which area

few

attractive aspects of gamma sterilization(Derisio,

Masfield

etParisi,

1990).

barriers

to

microorganisms resultsfrom

the random,

non-woven structureof

the

sheet,

which creates ahighly

complex random mazethrough

the

sheet.

This

torturous

path coupled withinfinitesimally

small openingspresents

bacteria

with animpossible

task to

penetratethe

spunbondedolefin.

Thus

by

virtue ofthe

properties exhibited similarto the

"Size

Exclusion"

principle,

spunbonded olefin maintainspermeability for

gassterilization

but

notfor

microorganisms.Theimmediate

consequences ofthis

morphology

are:high

opacity,

high filtration

efficiency,

acceptableto

high

airpermeability

and excellent strength.Strength

ofthe

spunbonded sheetis

directly

relatedto

the strength ofthe

individual

fibers

andhow

arethey

bonded. It is

clearthat to

have

aneffective

material, strength,

permeability

andbarrier

propertieshave

to

be

balanced

in

an optimum structure.Irradiation

can cause changesin

the

physical properties of avariety

of plastics.

The

effects of radiation onthe

spunbondedpolyolefins needsto

be investigated

because

a changein

regulated pore size could compromisethe

barrier's

effectivenessto

penetration of microorganisms.Radiation

exposuretests

have

been

conducted ondifferent

grades ofspunbonded olefin.

All losses

were within20%

oftheir

strengthpropertiesafter

having

been

subjectedbetween

2.5

and4.0 Mrads

ofradiation.The

barrier

properties of spunbonded materials arevery important

to productquality in

the

medicaldevice industry.

The

amount of researchinvestigating

changesin

the

barrier

propertiesbeing

solimited

makes thistopic

ripefor investigation.

Hence,

this

study

investigates

thefollowing

hypothesis:

"Radiation

causes no changein

the

barrier

properties ofChapter 2. GENERAL EFFECTS OF IRRADIATION ON

PLASTICS

Plastic packaging

materials are synthetic organic materials made ofspecific

types

of moleculesjoined

together

in

multiple repeatunits,

straightor

branched

to

form

ahigh

molecular weight material or amacromolecule.

These

materials aredivided into

two types

based

upontheir

properties:i)

thermoplastics,

materialthat

is

capable ofbeing

repeatedly

softenedby

heating

andhardened

by

cooling.ii)

thermosets,

materialthat

will undergo a chemical reactionby

action ofheat,

temperature,

orpressure,

leading

to

ainfusible

reversible state.Ionizing

radiation affects allpackaging

materials.The

processes ofionization

and excitation of an organic moleculeleads

to

one or more of anumber of effects.

Gas

evolution,

polymerization,

crosslinking,

degradation

anddouble

bond formation

have

allbeen

observed,

and alllead

directly

to

changesin

the

physical properties ofirradiated

plastics(Bolt

etCarrol,

1963).

The

type

of affectdepends

uponthe

specificmaterial, the

dosage

andthe

atmospherein

which radiationtakes

place.The

use of certain additiveshave

adistinct

protective action and can reduceeither

that

of a reactant which combines with radiation generatedfree

radicals withinthe

polymer,

orthat

of aprimary

energy

absorberpreventing

the

interaction

ofthe

gammaenergy

withthe

polymeritself

(Gammagram

#3,

1988). In

particular,

differences

areusually

observedbetween

the

behavior in

the

presence orthe

absence of oxygen.In

someplastics,

degradation is

enhanced,

whereasin

othersit is

reduced.Thin

materials arelikely

to

be

more affectedbecause

oxygenis

morefreely

available;

withbulky

materials,

the

oxidation processis

morediffusion

controlled(Plester,

1972). Post

storage effects ofirradiation

have

alsobeen

notedbecause

ofthe

free

radicals presentin

materialscontinuing

their

action

following

exposure on materials.Although

the

observed affects on plastics arevaried, the

mostimportant involve

changesin

mechanical characteristics such astensile

strength,

elasticmodulus,

impact

strength,

and seal strength.Aromatic

polymers are

very

resistantto

radiationeffects,

whereas aliphaticpolymers -depending upon their

level

of saturation and substitution-exhibitvarying

degrees

of radiation resistance(Skiens,1980).

Radiation

interacts

with polymersin

three

basic

ways.Chain

scissonor radiation

induced

degradation,

which resultsin

alowered

molecularweight and possible

embrittlement,

detracts from

some ofthe

mostthough the

materialmay have become

somewhat softer.Rise in

density

due

to

chain scissonincreases

the

crystallinity

ofthe

polymers(Skeins,

1980).

Cross-linking

induces

polymerization,

increasing

molecular weightand

lowering

the

mobility

ofmolecules,

inhibiting

their

ability

to

flex.

This

raisesthe tensile

strength,

depending

onthe

normal mechanism oftensile

breaking,

andincreases hardness

andbrittleness,

but

reducescreep

and

impact

strength(Bolt

etCarrol,

1963).

Cross-linking

generally

resultsin

increased

tensile

strength,

whileimpact

strength,

elongation,

crystallinity

andsolubility

decreases,

andthe

polymerbecomes

increasingly

brittle

withincreased

cross-linking.Many

plasticsdevelop

colorduring

radiation,

materials willturn

opaque after prolonged exposure.

Most

materialsturn

yellow orbrown,

although

the

dose

at whichdiscoloration

becomes

noticeable varies widely.The

extent andthe

amount of colordevelopment

may vary

on storage afterirradiation,

eitherincreasing

ordiminishing

withtime,

andit is

usually

affected

by

the

presence of oxygen(Charlesby

A.,

1960).

Tests

conducted on polyethylenefilm

afterirradiation up

to

5

Mrads,

showed

it

suitablefor

use as radiation sterilizedpackaging

material.Polyethylene,

in

general,

crosslinks onradiation,

andthere

is

chain scissonas well.

Average

molecular weightincreases

andcrystallinity decreases.

Irradiation

affects mechanical propertiesin

a complex way.First,

the

at

100

-150

Mrad.

The

elastic modulus

behaves in

an oppositemanner,

first

falling

andthen

rising

again.At high dose

rates,

impact

strengthbegins

to

fall,

reaching

a minimum atvery high levels

of radiation(Bopp

et

Sisman,

1951). Changes in

gaspermeability

are negligibleup

to

100

Mrad.

Different

density

polyethylenefilms have

different

changes ofstiffness,

flexural

strength,

andtensile

strength.However,

the

percentage change of ultimate elongationis approximately

the

same(

Hanlon,

1984).

According

to

Killoran's

report onthe

effect of gamma radiation onthe

mechanical properties of

high

density

polyethylene multilayeredmaterial,

there

are no greatdifferences

notedin tensile,

burst,

and seal strengthsbetween

the

control andirradiated

samples(Killoran,

1972).

Irradiating

polypropylene resultsin

chain scisson and crosslinking.Oxidative

degeneration

alsotakes

placein

the

presence of air.At low

doses,

crosslinking

is

a majorfactor because

the

impact

strengthfalls

immediately

followed

by

a slowdecay

over along

time.

Radiation readily

affects polypropylene and

is

borderline in stability

to

singledose

radiation sterilization.Often

a yellow noticeablediscoloration

occursin

polypropylene after single

dose

radiation.The

combination of mechanicalproperties,

low

cost,

and ease offabrication

makes polypropylene usefulfor

medicalpackaging

applications.It

is

one ofthe

moreinteresting

materials

for

consideration(Dammont F.

R.,

Salovey

R.,

1963).

molding

plastics,

andlarge doses

are requiredto

bring

about significanteffects.

Doses

of morethan

100 Mrads may

not cause significantdamage

and multiple sterilization

is

possible.However,

there

is

a slight colordiscoloration.

The

protective actionis

providedby

the

aromatic ringsin

the

structure(Turner J.

O.,

1961).

Radiation

affects acrylic polymersby lowering

their

molecularweight.

Thus,

mechanical properties are affected:tensile

strengthdecreases

by

half

at20 Mrads

andthereafter

decreases

rapidly.Eventually,

the

materialbecomes brittle

and cracks.Upon

irradiation

vinylpolymers cross-linkin

the

absence of air anddegrade

in

the

presence of air.A

moreimportant

affectis

the

liberation

ofhydrochloric

acid withthe

corresponding

production of unsaturation.Interestingly,

polyvinyl chloridediscolors

at quitelow

doses,

anddiscoloration intensifies

over a period oftime.

It is among

the

mostwidely

used vinyl polymers and

finds

applicationin

many

medical products(Charlesby

A., 1953)

Various

types

of polyamideshave

shown no effect onirradiation.

All

are suitablefor

sterilization although notfor

many

repeatdoses.

Upon

irradiation,

polyamides crosslink andlose

crystallinity

whichincreases

their

tensile

strengthbut

decreases

theimpact

strength.Films

andfibers

are more affected

mechanically

than thick

moldingsdue

to

loss

ofincreases

the

effects ofradiation.Polyethylene

terphthalate

in

film

orfiber form

is

suitablefor

irradiation.

Mechanically

it

can withstand atleast 100

Mrads

althoughdiscoloration

occurs atlower doses.

Crosslinking

is

a major affect ofirradiation,

but

radiationinduced

oxidation canbe

observedin

the

presenceof air

(Plester,

1972).

According

to

Killoran's

report onthe

effect of gamma radiation onthe

mechanical properties of polyethyleneterphthalate

multilayered

material, there

was nodifference

notedin tensile,

burst,

and seal strengthsbetween

the

control andirradiated

samples(Killoran,

1972).

Polycarbonate

cansatisfactorily

withstand singledose

exposurebut

tends to

become brittle

above2.5 Mrad

(Broadway,

Palinchak

etKing,

1961).

According

to

generaltests

conductedby

U. S.

Army

Natick

labs

on polymersnormally

usedfor

food

packaging

to

observe substancesmigrating from

plasticpackaging

materials and volatile compoundsproduced

by

irradiation

of plasticfilms,

it

wasfound

that

gamma radiated plasticfilms

in

the

presence offood simulating

solvents producedthe

same chemical extractives asthe

controlsamples,

but in slightly different

amounts.

It

was alsofound that,

uponirradiation,

plasticfilms

emitvolatile compounds.

All

these

differences

were attributedto the

stability

ofthe

films

with regardto their

susceptibility

to

crosslink and/ordegrade

However,

one mechanism willnormally

predominatedepending

uponthe

polymer and additives

involved.

Thus,

the

purity

ofthe

polymer,

stabilizersused, the

fabrication

process,

andthe

shape ofthe

final

article are all relevantto the

suitability

for

radiation sterilization.The

differences

of radiationsensitivity between

the

products ofdifferent

manufacturers andtheir

formulations

of aparticular product can

be

important.

"TYVEK",

a spunbonded olefin madeby

Du Pont

and usedwidely in

the

sterile medicaldevice

industry,

is

madefrom very

fine

inter-connected

strands of

high

density

polyethylenelaid

down in

sheetform

andbonded

together

by

heat

and pressure.Strength

ofthe

spunbonded sheetis

directly

related

to the

strength ofthe

individual

fibers

andhow

they

arebonded. It

is

clearthat,

to

have

an effectivematerial, strength,

permeability

andbarrier

propertieshave

to

be

balanced in

an optimum structure.The

effects of radiation on

the

spunbonded polyolefins needsto

be investigated

because

a changein

regulatedpore size could compromisethe

effectivenessof

the

barrier

to

microorganisms.Radiation

exposuretests

have been

conducted ondifferent

grades ofspunbonded olefin.

All losses

were within20%

oftheir

strength propertiesafter

having

been

subjectedbetween

2.5

and4.0 Mrads

of radiation(Dasgupta,

1973). The

sterilizationindustry

works aroundthis

range.Chanter

3. HYPOTHESIS

"There is

no changein

barrier

qualities of medical gradespunbonded olefin with exposure

to

low level

radiation".The

purpose ofthis

research projectis

to

verify

the

nullhypothesis.The

nullhypothesis is

usedfor any hypothesis primarily

setup

to

see whetherit

canbe

rejected,

andthe

idea

ofsetting up

anullhypothesis

is

to

precisely

confirmbeyond

a reasonabledoubt

that theassumption could

be

accepted or not.Selected

barrier

tests

and statisticalanalysis will

be

conducted as a part ofthe

data

generation and evaluation.Dosage levels in

multiples of2.5

Mrads

have

been

chosen,

sincethe

regular

dose

is 2.5 Mrads in

the medicaldevice

industry.

This

willhelp

verify

whether or notthe

effect on medical grade spunbonded olefinis

related

to

dosage increases.

Two

measures ofbarrier

effectiveness,

porosity

and water vaportransmission rate

(WVTR),

are measuredin

orderto

establish arelationship between

the

barrier

qualities and radiationdose.

These

measures operate on

different

orders of magnitude.Porosity

is

a grossmeasure of gas passage and an

indirect indicator

ofpermeability,

andWVTR

is

afiner

test

and used as a referee methodfor

testing

permeability.Thus

ahigher

porosity

value meansthat the

materialis

less

porous.This

has

important

implications

since the material mustbe

porousfor sterilizing

agent

to

penetrate,

yetlow

enoughto

prevent penetrationby

microorganisms.

It

is

a gross measure of gas passage and anindirect

indicator

of permeability.Water

vaportransmission

rate represents afiner

test which candirectly

relatethe

shelflife

and packaged productstability

by

calculating

the

rate at which moistureis

transmitted through the materialbeing

tested.The

following

two

aspects ofthe

study

willbe

concentratedin

thisreport.

The

first

aspect concentrates on whether or notthere

areany

changes

in barrier quality

of spunbonded olefin uponirradiation.

The

statistical tool used

for

this

purposeis

one-way

variance analysis orKruskal-Wallis

test andis

primarily

setup

to see whether the nullhypothesis

couldbe

accepted or not.The

second aspect concentrates onthe

relationship between

the

dose levels

and their effect onthe

barrier

properties.

The

statistical tool usedfor

this purposeis

regression analysis.TEST METHODOLOGY:

Two commercially

available uncoated medical grade spunbondedolefin are used

for

this

study.Type A

(1059B)

has

basis

weight1.8

oz/yd2determined

by

ounces ofhigh

density

polyethylene per squareyard,

thusgreater

the

basis

weighthigher

the

amount ofhigh

density

polyethylene.-

the

spunbonded olefin are radiated at

four

dosage

levels,

namely 2.5

Mrads,

5.0

Mrads,

7.5

Mrads,

10.0

Mrads.

They

aredivided into

five

groups:

four irradiated

and one nonirradiated group

or control.

-conduct

test to

recordthe

porosity

using

'Gurley Porosity

Tester'by

T-460,

TAPPI

standardtest

method.This

test

is

usedto

measure airresistance of porous paper and

is

anindirect indicator

of permeability.The

test

specimen,

held between

clamping

platesin

a circular orifice ofspecified

area,

is

subjectto

air pressure providedby

the

falling

weight ofthe

inner

cylinder ofthe

porosity

tester.The

time

for

a specific volume ofair

to

pass throughthe

specimenis

a measure ofit's

air resistance.It

is

influenced

by

the

internal

structure whichis

largely

controlledby

the type

and

length

offiber

andthe

surfacefinish

whichis

governedby

the

manufacturing

process(TAPPI,

1988).

The

results ofthis

test,

whenreported as seconds/1

00ml/6.4

cm2are

commonly

referred to as'Gurley

Seconds'.

conduct

test to

recordthe

water vapor transmission rateby

using

infrared

detection

technique,

ASTM

F

1249-89

standardtest

method.The

purposeof

this

test

methodis

to

obtain reliable valuesfor

the

water vaporwet chamber of

known

temperature

andhumidity by

the

barrier

materialto

be

tested.

The

dry

chamber andthe

wet chamber makeup

the

diffusion

cell

in

whichthe test

film is

sealed.The diffusion

cellis

placedin

atest

station where

the

dry

chamber andthe

top

ofthe

film

are swept withdry

air.Water

vapordiffusing

through the

film

mixes with the air andis

carried

into

a pressure modulatedinfrared

sensor.This

sensor measuresthe

fraction

ofinfrared energy

absorbedby

the

water vapor and producesan electrical

signal,

the

amplitude of whichis

proportional to the watervapor concentration.

The

amplitude ofthe

electrical signal producedby

the

measurement of a calibrationfilm

ofknown

transmission

rate.This

information is

then

usedto

calculatethe

rate at which moistureis

transmitted through the

materialbeing

tested

(ASTM,

1989).

It

is

animportant

test

and candirectly

relatethe

shelflife

and packaged productstability.

Data from

this test

is

used as a referee method oftesting.

The

statistical analysis consists of oneway

variance analysis orkruskal

wallistest

depending

on whetheror notthe

data

satisfies a normaldistribution

curveto

accept or reject a nullhypothesis.

The

Kruskal-Wallis

test

offers a non-parametric alternative tothe

usualone-way

analysis ofvariance.

The

test

assumesthat the

data

arise asK

independent

randomsamples

from

continuousdistributions,

allhaving

the

same shape.The

nullhypothesis

of nodifferences among

the

K

populationsis

tested

againstthe

hypothesis

setup

primarily

to

see whetherit

canbe

rejected,

andthe

idea

of

setting up

a nullhypothesis is

to

precisely

confirmbeyond any

reasonable

doubt,

the

assumption couldbe

accepted or not(Freund,

1979).

The

relationship

between

radiationdosage

andthe

barrier

qualitieswill

be

expressedby

the

regression analysis ofthe

data. The

regression coefficient

is

the

percentage ofthe

total variation ofthe

barrier

qualitiesdue

to

different levels

of radiationdosage.

Thus in

this study, the

relationship between

the

barrier

propertiesand radiation

dosage

is

establishedto

confirmthe

effect of radiation onChapter

4.0

RESULTS AND

DISCUSSION

The

quantitative measures used to establish arelationship between

the

barrier

qualities and radiationdosage

areporosity

and water vaportransmission

rate.These

measures operate ondifferent

orders ofmagnitude,

since each measuresdifferent

quantities of gastransmission.

Porosity

quantifiesthe

resistance of a materialto

air.A high porosity

value means

that the

materialis less

porous.Thus

being

a gross measure ofgas

passage,

porosity is

anindirect

measure of permeability.This is

important

to

functional dose

ofthe

materialbecause

'gurley

sees'relate to a

certain amount of air resistance offered

by

a material.Thus

a materialmust

be

porousfor sterilizing

agent topenetrate,

yet provide abarrier

toprevent

re-entry

of microorganisms.The

quantities measured areapproximately

in

cubicinches

per minute.Water

vapor transmission rateis

afiner

measure of water vaportransmission through

the

materials andis

measuredin hundreths

of a gram.Being

afiner test, it

is

used as a referee method oftesting

permeability in

medical products

packaging industry. The

quantities of measurementis

in

tenths

of a gram of water over a twenty-fourhour

period.In

this research,

we arelooking

to

seeif

low level

radiation causesthree

different

measures.The

decision relating differences

between

the

sample means andthe

means of

the

populations sampledwas madeby

utilizing

Kruskal-Wallis

test, because

the

data

values obtaineddoes

notsatisfy

the

parametersfor

one-way

analysis of variance.The

Kruskal-Wallis

test

offers anon-parametric alternative

to the

usualone-way

analysis of variance.To

confirm

the

effectiveness ofirradiation

onthe

barrier

properties ofspunbonded olefins selected

for

this study,

regression analysis wasused,

sothat,

with reasonableassurance,

statistically

significant results canbe

attributed

to

particularcauses,

in

this

study

it

is irradiation dosage levels.

Two commercially

available uncoated medical grade spunbondedolefin:

type

A

(1059B)

and typeB

(1073B)

were selectedfor

this study.Type

A

(1059

B)

has basis

weight1.8

oz/yd2and typeB has basis

weight2.2

oz/yd2.The

basis

weightis

determined

by

ounces ofHDPE/sq.yd.

Thus

greaterthe

basis

weighthigher

the

amount ofHDPE

fibres.

Radiation

of spunbonded olefin was carried out atfour different dosage

levels,

namely

2.5

Mrads,

5.0

Mrads,

7.5 Mrads

and10.0 Mrads.

Dosage

levels

in

multiples of2.5

Mrads have been

chosen,

sincethe

regulardose is

2.5 Mrads in

the

medicaldevice industry.

This

willhelp

verify

whether ornot

the

effect on medical grade spunbonded olefinis

relatedto

dosage

increases.

Each

type

wasdivided into five

groups:four

irradiated

and oneThe porosity

tests

were conductedusing

'Gurley Porosity

Tester'by

T-460

(TAPPI

standardtest

method).The data

collectedfrom porosity

testof

twelve

samples(N=12)

of eachtype

irradiated

at a particulardose

wasused

for calculating

the

averages(refer

to

Table

1-5).

These

averages wereused

to

plot a graphto

illustrate

the

effect of radiation on eachtype

ofTyvek's porosity

atdifferent

radiationdosages (refer

to

figs. 1-2).

The

water vaportransmission test

was recordedusing

theinfrared

detection

technique

by

using ASTM F 1249-89 (ASTM

standard testmethod).

The

data

collectedfrom

vaportransmission test

oftwelve

samples

(N=12)

of eachtype

irradiated

at a particulardose

was usedfor

calculating it's

average(refer

to

Table

6-10).

These

average results wereused

to

plot a graphsto

illustrate

the

effect of radiation on each type ofTyvek's permeability

atdifferent

radiationdosages (refer

to

figs 3-4).

The

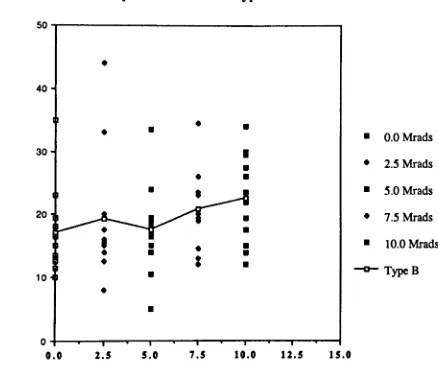

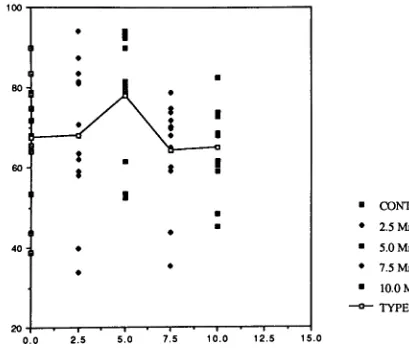

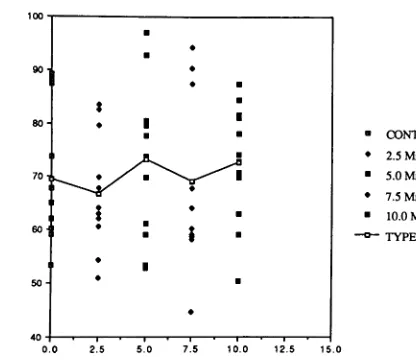

graphs of average

gurley

seconds and water vaportransmission

(figs

1-4)

at

different levels

ofradiationdoes

not show a significant changein

porosity but

when consideredindividually

there

seems tobe

avery

slightchange

in

porosity

andWVTR

values.Statistically

analyzedby

Kruskal-wallis test,

the

Percentile

value orP

value

i.e

the

probability

that

all means are equal wasimportant

in

deciding

whether

the

nullhypothesis

couldbe

accepted or rejected.The porosity

tests

for

typeA

(1059B)

andtype

B

(1073B)

indicated

thatequal

(refer

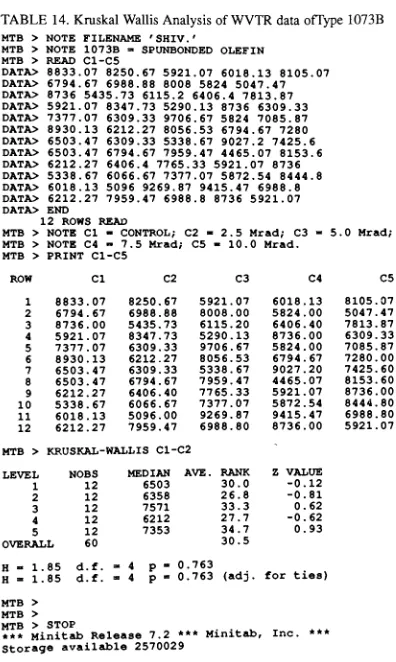

Table 11-12). The

WVTR

tests

for

typeA

(1059B)

and typeB

(1073B)

indicated

that there

is

aprobability

of14.6

%

and76.3%

respectively

that

all means are equal(refer Table 13-14).

It

was not possibleto

rejectthe

nullhypothesis,

orto

derive

arelationship

between

the

rate of water vapor transmission andporosity

andTable

1.

GROUP TREATED WITH

0 Mrads.

Effect

ofirradiation

onPorosity

ofuntreated

1059 B

and1073 B

samples.(

secs/100ml/6.4cmA2)

SAMPLE

#

1059 B

1073 B

1

13.50

18.00

2

9.50

18.00

3

20.00

23.00

4

19.50

13.50

5

9.00

11.50

6

7.00

13.00

7

14.00

15.00

8

18.50

12.50

9

16.50

35.00

10

26.00

10.00

11

14.00

19.50

TABLE 2.

GROUP TREATED WITH 2.5 Mrads

Effect

ofirradiation

onPorosity

of2.5 Mrads

treated

1059 B

and1073

B

samples.(

secs/100ml/6.4cmA2)

SAMPLE

#

1059

B

1073 B

1

15.50

17.50

2

14.50

12.50

3

25.50

20.00

4

13.00

15.50

5

23.00

44.00

6

19.00

8.00

7

20.00

16.00

8

16.50

15.50

9

15.50

33.00

10

13.00

19.50

11

12.00

16.00

TABLE 3.

GROUP

TREATED WITH 5.0 Mrads

Effect

ofirradiation

onPorosity

of5.0 Mrads

treated

1059 B

and1073 B

samples.(

secs/100ml/6.4cmA2)

SAMPLE

#

1059 B

1073 B

1

17.00

10.50

2

20.50

17.00

3

16.50

15.00

4

15.00

12.00

5

14.50

19.00

6

8.00

33.50

7

15.50

16.50

8

9.50

18.00

9

16.50

18.00

10

15.00

14.00

11

14.50

19.50

TABLE 4.

GROUP TREATED

WITH

7.5 Mrads

Effect

ofirradiation

onPorosity

of7.5 Mrads

treated

1059

B

and1073

B

samples.(

secs/100ml/6.4cmA2)

SAMPLE

#

1059

B

1073 B

1

21.00

26.00

2

14.00

23.50

3

11.00

13.00

4

19.50

17.50

5

16.50

20.00

6

20.00

26.00

7

20.50

34.50

8

21.50

19.50

9

27.50

23.00

10

11.00

19.00

11

14.00

14.50

TABLE 5.

GROUP TREATED WITH 10.0

Mrads

Effect

ofirradiation

onPorosity

of10.0 Mrads

treated

1059 B

and1073

B

samples.(

secs/100ml/6.4cmA2)

SAMPLE

#

1059 B

1073 B

1

17.00

19.50

2

16.00

34.00

3

10.00

27.50

4

12.50

12.50

5

14.00

23.50

6

16.00

29.50

7

14.50

22.00

8

12.00

14.00

9

21.50

26.00

10

9.00

15.00

11

7.00

12.00

Figure 1. Effect Of

Irradiation

On

Porosity

Of Spunbonded

Olefin Type 1059B

30

<

E

CA

W5

4>

Column 5

Column 6

Column 7

?

Column

8

Column 9

o-TypeA

10.0

12.5

15.0

Figure

2. Effect Of Irradiation On

Porosity

Of

Spunbonded Olefin Type

1073B

<

E

4>o

aw - 40-II 30-l I 20 -| *I

!

l

Ai ?

:

10H i 0-1

i r| 11 i 1 i i

0.0

Mrads

?

2.5 Mrads

5.0 Mrads

?

7.5 Mrads

10.0

Mrads

"-TypeB

0.0

2.5 5.07.5

10.0 12.5 15.0 [image:40.545.63.501.157.534.2]Table 6.

GROUP TREATED WITH 0 Mrads.

Effect

ofirradiation

onthe

Rate

ofWater

Vapor

Transmission

of untreated1059 B

and1073 B

samples.( Kgs/mA2/day

@

100

degrees

F,

90%

R.H)

SAMPLE

#

1059 B

1073 B

1

53.39

88.33

2

38.83

67.95

3

64.06

87.36

4

74.74

59.21

5

71.83

73.77

6

78.62

89.30

7

43.68

65.03

8

83.48

65.03

9

65.52

62.12

10

78.14

53.39

11

89.79

60.18

TABLE 7. GROUP TREATED WITH 2.5 Mrads

Effect

ofirradiation

onthe

Rate

ofWater Vapor Transmission

of2.5 Mrad

treated

1059 B

andl073B

samples.(

Kgs/mA2/day

@

100 degrees

F,

90%

R.H)

SAMPLE

#

1059 B

1073 B

1

39.80

82.51

2

81.54

69.89

3

70.86

54.36

4

33.97

83.48

5

87.36

63.09

6

63.58

62.12

7

81.05

63.09

8

62.12

67.95

9

94.15

64.06

10

59.21

60.67

11

58.24

50.96

TABLE

8. GROUP TREATED WITH 5.0 Mrads

Effect

ofirradiation

onthe

Rate

ofWater Vapor Transmission

of5.0 Mrad

treated

1059 B

and1073 B

samples.(

Kgs/mA2/day

@

100 degrees

F,

90%

R.H)

SAMPLE

#

1059 B

1073 B

1

80.08

59.21

2

92.70

80.08

3

89.79

61.15

4

78.14

52.90

5

81.05

97.07

6

53.39

80.57

7

61.64

53.39

8

94.15

79.59

9

52.42

77.65

10

81.54

73.77

11

79.11

92.70

TABLE 9.

GROUP TREATED WITH 7.5 Mrads

Effect

ofirradiation

onthe

Rate

ofWater Vapor Transmission

of7.5 Mrad

treated

1059 B

and1073 B

samples.(

Kgs/mA2/day

@

100

degrees

F,

90%

R.H)

SAMPLE

#

1059 B

1073 B

1

78.62

60.18

2

67.95

58.24

3

69.89

64.06

4

70.38

87.36

5

60.18

58.24

6

71.83

67.95

7

59.21

90.27

8

73.77

44.65

9

43.68

59.21

10

65.03

58.73

11

74.74

94.15

TABLE

10. GROUP TREATED

WITH

10.0

Mrad

Effect

ofirradiation

onthe

Rate

ofWater

Vapor Transmission

of10.0 Mrad

treated

1059 B

and1073

B

samples.(

Kgs/mA2/day

@

100 degrees

F,

90%

R.H)

SAMPLE

#

1059 B

1073 B

1

59.21

81.05

2

72.80

50.47

3

45.14

78.14

4

60.67

63.09

5

73.77

70..86

6

48.53

72.80

7

67.95

74.26

8

73.29

81.54

9

61.64

87.36

10

82.51

84.45

11

68.43

69.89

Figure 3. Effect

ofirradiation

onWVTR

Of Spunbonded

olefinType 1059B

100

X

QC

*

et

s

< e "35

CONTROL

?

2.5

Mrad

5.0 Mrad

?

7.5 Mrad

10.0 Mrad

--TYPE A.

0.0 12.5 15.0

Figure

4.

Effect

ofIrradiation

onWVTR

Of

Spunbonded

olefinType 1073B

100 X ec

s

1-4 <s> > ets

< 90II

80-h

50-I

?40

|

i 1 i 1 i 10.0 2.5 5.0 7.5 10.0 12.5 15.0

CONTROL

?

2.5

Mrad

5.0 Mrad

?

7.5 Mrad

10.0 Mrad

--TYPE B.

[image:47.545.65.481.157.517.2]TABLE 11.

Kruskal

Wallis Analysis

ofPorosity

data

ofType 1059B

MTB > NOTE FILENAME 'ELL.COM'

MTB > note 1059B = spunbonded

olefin

MTB > read cl-c5

DATA> 13.5

15.5

1721

17 DATA>9.5

14.5

20.5

14 16 DATA>20

25

16.5

11 10 DATA> 19.513

15

19.5

12.5 DATA>9

23

14.5

16.5

14 DATA> 719

8

20

16

DATA> 14

20

15.5

20.5

14.5

DATA> 18.5 16.5

9.5

21.5

12 DATA>16.5

15.5

16.5

27.5

21.5

DATA>

26

13

15

119

DATA> 14 12 14.5 14 7

DATA> 18.5

21.5

18.5 12.520

DATA> end

12 ROWS READ MTB MTB MTB MTB MTB MTB note CI note C2 note

C3

note C4 note C5 CONTROL2.5

Mrads5

.0

Mrads7.5

Mrads10.0

Mradsprint cl-c5

ROW CI C2 C3 C4 C5

1 2 3 4 5

6

78

9

10 11 12 139

20

19 9 7 14 18 1626

14 18 5 5 05

0

0

0

5 50

0

5

15 14 25 1323

1920

16

15 13 12 21 1720

16 15 148

15

9

16 15 14 18 21 14 11 19 1620

20

0

0

0 5 50

521.5

27.5

11.0 14.0 12.517

16 10 12 14 16 14 12 219

720

MTB > kruskal wallis cl c2

LEVEL

1

2

3

4

5

OVERALL NOBS 12 12 12 12 1260

MEDIAN AVE. RANK Z VALUE 15.25

28.5

-0.4316.00

35.5

1.10

15.25

29.0

-0.3218.00

35.2

1.03

14.25

24.3

-1.3830.5

H - 3.58

H - 3.58

d.f

. d.f. 4 4P

P

0.4670.466

(adj

forties)

MTB >

MTB > STOP

*** Minitab Release 7.2 ***

Minitab,

Inc Storage available2570029

TABLE 12. Kruskal

Wallis Analysis

ofPorosity

data

ofType 1073B

MTB > NOTE FILENAME '

KIN.

COM'

MTB > NOTE 10'3B - ;SPUNBONDED OLEFIN

MTB > READ cl-c5

DATA> 18

17.5

10.5

:26

19.5

DATA>

18

12.5

1723

.534

DATA>23

20

15

13

27.5

DATA>

13.5

15.5

1217.5

12 .5 DATA> 11.544

19

20

23.5

DATA>

13

8

33.5

26

29.5

DATA> 15

16

16.5

34 .5 22 DATA> 12.515.5

18

19.5

14DATA>

35

33

18

23

26

DATA> 10

19.5

1419

15

DATA> 19.5 16

19.5

14.5

12DATA>

16.5

1424

19

30

DATA> note CI CONTROL 12 ROWS READ

MTB > note CI CONTROL

MTB > NOTE C2 -

2.5

MradsMTB > NOTE C3 =

5.0

MradsMTB > NOTE C4 - 7.5 Mrads

MTB > NOTE C5 - 10.

0

MradsMTB > print cl-c5

ROW CI C2 C3 C4 C5

1 18.0 17.5

10.5

26.0

19.52 18.0 12.5 17.0 23.5

34.0

3

23.0

20.0

15.0

13.027.5

4 13.5 15.5 12.0 17.5 12.5

5

11.5 44.0 19.020.0

23.5

6

13.0 8.033.5

26.0

29.5

7 15.0 16.0 16.5

34.5

22.08 12.5 15.5 18.0 19.5 14.0

9

35.0

33.0 18.0 23.026.0

10 10.0 19.5 14.0 19.0 15.0

11 19.5 16.0 19.5 14.5 12.0

12 16.5 14.0

24.0

19.030.0

MTB > kruskal wallis cl c2

LEVEL NOBS MEDIAN AVE. RANK Z VALUE

1

12 15.7523. 5

1 .562

12 16.00 27.6

0 .653

12

17.5027.

3

0 .704 12 19.75

37.

5 1 .565

12 22.7536.

6

1.35OVERALL

60

30.5

H -

6

.09 d.f.-

4

p

=0.

194H -

6

.10 d.f.-

4

p

-0.

193(adj

. forties)

MTB >

MTB ^ STOP

*** Minitab Release 7.2 ***

Minitab,

Inc. ***TABLE 13. Kruskal Wallis Analysis

ofWVTR data

ofType

1059B

MTB > NOTE FILENAME

'RAMA.

rMTB > NOTE 1059B -

SPUNBONDED

OLEFIN

MTB > READ Cl-

C5

DATA>

5338.67

3979.73

8008

7862.4

5921.07

DATA>

3882.67

8153.6

9269. 87

6794.67

7280

DATA>

6406.4

7085.87

8978

.676988. 8

4513.6

DATA>7414.13

3397.33

7813

.877037.

,336066.67

DATA>7182.93

8736

8105.07

6018.13

7377.07 DATA>7862.4

6357.87

5338. 67

7182.93

4853.33

DATA>

4368

8105.07

6163.73

5921.07

6794.67

DATA>

8347.73

6212.27

9415

.477377.

,077328.53

DATA>6552

9415.47

5241.6

4368

6163.73

DATA> 7813.87

5921.07

8153

.66503.47

8250.67 DATA>8978.67

5824

7910.93

7474.13

6843.2

DATA>

6794.67

8347.73

9221

.333542. 93

6794.67

DATA> END12

ROWS READMTB > NOTE CI -

CONTROL;

C2 -2.5

Mrad;

C3 -5

.0

Mrad;

MTB > NOTE C4 -7.5Mrad;

(C5 -10.0

Mrad.MTB > PRINT CI-C5

ROW CI C2 C3 C4 C5

1 5338.67

3979.73

8008.00

7862.40

5921

.072 3882.67

8153.60

9269.87 6794.677280

.003

6406.40

7085.87 8978.676988.80

4513

.604

7414.13

3397.33

7813.877037.33

6066

.675 7182.93

8736.00

8105.07

6018.13

7377 .076

7862.40

6357.87

5338.67

7182.93

4853,.337 4368.00 8105.07

6163.73

5921.076794

.678

8347.73

6212.27 9415.47 7377.077328,

.539

6552.00

9415.475241.60

4368.006163.

,7310 7813.87 5921.07

8153.60

6503.47 8250..6711 8978.67 5824.00

7910.93

7474.136843.

,2012 6794.67

8347.73

9221.33

3542.93

6794,

.67MTB > kruskalwallis C1-C2

LEVEL NOBS MEDIAN AVE. RANK Z VALUE

1

12

6989

29.8

-0.172

126722

30.6

0.02

3

12 805741.5

2.43

4 12 6892

25.2

-1.175

126795

25.5

-1.11OVERALL

60

30.5

H =

6. 83

d.f.

4

p

=o.:

L46H = 6. 84 d.f. -4

p

- 0.146 (adj. forties)

MTB >

MTB > STOP

*** Minitab Release 7.2 ***

Minitab,

IncStorage available

2570029

TABLE

14. Kruskal

Wallis Analysis

ofWVTR data

ofType1073B

MTB > NOTE FILENAME 'SHIV.1r

MTB > NOTE 1073B - SPUNBONDED OLEFIN MTB > READ Cl-C5

DATA>

8833.07

8250.67

5921

.076018. 13

8105.07DATA>

6794.67

6988.88

8008

5824 5047.47DATA>

8736

5435.73

6115.2

6406.4

7813.87DATA> 5921.07

8347.73

5290

.138736

6309.33

DATA> 7377.07

6309.33

9706

.67 5824 7085.87DATA>

8930.13

6212.27

8056

.536794.

67 7280 DATA>6503.47

6309.33

5338

.679027. 2

7425.6

DATA>6503.47

6794.67

7959

.474465.

078153.6

DATA>6212.27

6406.4

7765.:33

5921.07

8736

DATA> 5338.67

6066.67

7377.075872.

548444.8

DATA>

6018.13

5096

9269.879415.47

6988.8

DATA> 6212.27 7959.47

6988

.88736

5921.07DATA> END

12 ROWS READ

MTB > NOTE CI -

CONTROL;

C2 -2.5

Mrad;

C3 -5

.0

Mrad;

MTB > NOTE C4 7.5Mrad;

<2510.0

Mrad.MTB > PRINT CI-C5

ROW CI C2 C3 C4 C5

1

8833.07

8250.67

5921.076018.13

8105,.072 6794.67

6988.88

8008.00

5824.00 5047 .473

8736.00

5435.736115.20

6406.40

7813,.874 5921.07

8347.73

5290.138736.00

6309.

.335

7377.076309.33

9706.67 5824.007085

.876 8930.13 6212.27 8056.53 6794.67 7280 .00 7 6503.47 6309.33 5338.67

9027.20

7425 .608

6503.47 6794.67 7959.47 4465.078153

.609

6212.27 6406.40 7765.33 5921.078736

.00 10 5338.67 6066.67 7377.07 5872.54 8444 .80 11 6018.13 5096.00 9269.87 9415.476988

.80 12 6212.277959.47

6988.808736.00

5921 .07MTB >

KRUSKAL-WALLIS C1-C2

^

LEVEL NOBS MEDIAN AVE. RANK Z VALUE

1 12

6503

30.0

-0.122

12 635826.8

-0.813

12 757133.3

0.62

4 12 6212 27.7 -0.62

5

12 7353 34.70.93

OVERALL

60

30.5

H - 1.

85

d.f. -4p

0.

763H - 1.

85

d.f. =4

p

-0.'763

(adj. forties)

MTB > MTB >

MTB > STOP

*** Minitab Release 7.2 ***

Minitab,

Inc. *** [image:51.545.57.453.54.716.2]Chapter 5.0 CONCLUSION AND

RECOMMENDATIONS

The idea in exploring

possible changesin barrier

properties ofspunbonded olefin was

investigated

because

a changein barrier

propertiescould mean change

in

sterility

whichis

akey

concernin

medicaldevice

packages.

Two

medical grade uncoated spunbonded olefin wereirradiated

atdifferent

dosage

levels.

The

purpose ofirradiating

was tofind

:a)

Is

there

a changein barrier due

to

radiation?

b)

If

thereis

achange,

is

that

change relativeto

dose ?

Three different

sensitivities were usedto

measure changesin barrier

properties :

1)

Gross

visual methodby

taking

pictures onScanning

Electron

Microscope

atdifferent

angles and magnification(refer

appendixA.

)

2)

By

recording

porosity, which quantifiesthe

resistance of a materialto

air.

Thus

being

a gross measure ofgas passage,porosity is

anindirect

measure ofpermeability.

The

quantities ofmeasurement areapproximately

in

cubicinches

per minute.3)

And

by

recording

WVTR,

whichis

afiner

measure of wat