Theses

Thesis/Dissertation Collections

1-1-1988

Optimizing tone production on a 300 spot per inch

laser printer

James R. Hamilton

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion in Theses by an authorized administrator of RIT Scholar Works. For more information, please contactritscholarworks@rit.edu.

Recommended Citation

by

James R. Hamilton

Athesissubmittedinpartialfulfillmentofthe

requirements forthedegreeofMasterofScience inthe

Schoolof

Printing

andManagementSciences intheCollegeofGraphic Arts andPhotography

oftheRochesterInstituteof

Technology

January,

1988School of Printing and Management Sciences

Rochester Institute of Technology

Rochester, New York

CERTIFICATE OF APPROVAL

MASTER'S lHESIS

This is to certify that the Master's Thesis of

James

R.

Hamilton

With a major in Printing Technology

has been approved by the Thesis Committee as

satisfactory for the thesis requirement for the

Master of Science

degree

at the convocation of

January, 1988

Thesis Committee:

Frank Cost

--~~---')=Th::re-s"""'is-A"""""-:-dv--;i"-so-r---Joseph

L. Noga

Graduate

Pro~am Coor~atorMiles Southworth

OPTIMIZING TONE PRODUCTION

ON A 300 DOT PER INCH LASER PRINTER

I, James R. Hamilton, hereby grant permission to the Wallace Memorial Library, of

R.I.T, to reproduce my thesis in whole or in part. Any reproduction will not be for

commercial use or profit.

Iwouldliketo thank the

following

people:Prof. Frank

Cost,

whoseinsightandinterest inspiredthisprojectDr.JosephDeLorenzoandProf. Michael Kleper for

lending

theirexpertisetothisundertaking

RochesterInstituteof

Technology

professorsJosephBrown,

RobertChung,

MarieFreckleton,

C.R.Meyers,

JosephNoga,

MichaelPeres,

Bob TompkinsaswellasDavid CohnoftheT&ECenterwho allhelpedinnumerous stages oftheprojectMark

Curby

andIshmael J. Stevanov-WagneroftheEatonPeabody

Laboratory

foranswerstotechnicalquestions aboutlaser printing

Betty

GreenawaltandPamelaOriansofBoiseCascade,

andJohnGorskiandJudy

PaluckiofHammermillfor arrangingpaperdonations

Lisa DigginsofData

Recording

Systemsfor providingtranscriptsofDavidSpencer'stalksGreg

Haddam,

whoseunderstandingoftheMacintosh greatlyaidedthisprojectList ofTables v

ListofFigures vi

Abstract 1

ChapterOne 1

Introduction 1

Footnotes forChapter One 6

Chapter Two 7

Theoretical Basis 7

TheLaser Printer 8

PostScript 9

Footnotes for ChapterTwo 10

Chapter Three 11

Review oftheLiterature 11

Footnotes forChapter Three 13

ChapterFour 14

Hypothesis 14

ChapterFive 16

Methodology

16TheDevelopmentoftheTests 16

Density

Measurements 21Testing

oftheDensitometer 21Testing

oftheLaser Printer 22Comparing

theStandard Deviations 23Microscopic Studies 23

Footnotes for ChapterFive 24

Chapter Six 25

Results 25

Tone Production 25

Microscopic Studies 26

PaperTests 29

Maximum

Density

Tests 29Gray

Production Tests 30PaperTests 33

Chapter 8 50

Discussion 50

ToneProduction 50

MicroscopicStudies 52

PaperTests 53

Maximum

Density

53Gray

Production 54Chapter 9 56

Summary

56Conclusions 56

Recommendations for Further

Study

57EquipmentUse 57

Bibliography

59Appendices 62

A Tone Production Data 63

Condensed 63

Diamond 67

Open 70

B

-Paper Tests 74

Density

-Part One 75

Maximum

Density

- Part Two. . . . 76

Gray

Production 77Grading

Grays 78C

-Consistency

Tests 79LaserWriter 80

Densitometer 83

D- BartlesonandBreneman 84

E- Spot Sequence 88

Condensed Dot Form Sequence 89

Diamond Dot Form Sequence 90

Open Dot Form Sequence 91

F - Sample Output- 3x3 Condensed 92

3x3 Condensed 93

Pagenumber

Table 1 - Matrix

size,number of grays possible andlinescreenat300spotsperinch. ..11

Table 2

-Summary

of spots in matrix, graylevel, linescreen,

and screen angle 20Table 3 - Comparison

oftestsquareswith 50% spots on 26

Table 4 Dot size measurements 27

Table5

-Testing

the accuracy ofthemicroscopic measurements 28Table 6 Results ofthe firstpapertest 29

Table 7

-Results ofthe second papertest 29

Table 8 - Results

ofthethirdpapertest 30

Table 9 - Overview

of paper characteristics 31

Table 10

-50%spots onwithinformation concerning areabetweenspots 51

Table 1 1

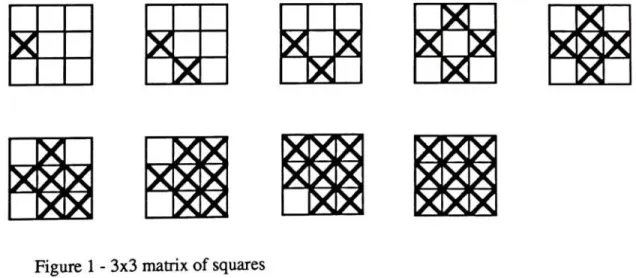

Pagenumber Figure 1 - 3x3

matrix of squares 3

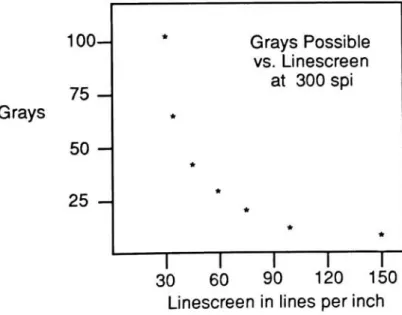

Figure 2 - Grays

possibleversus linescreen at300 spots perinch 11 Figure 3-

Comparison

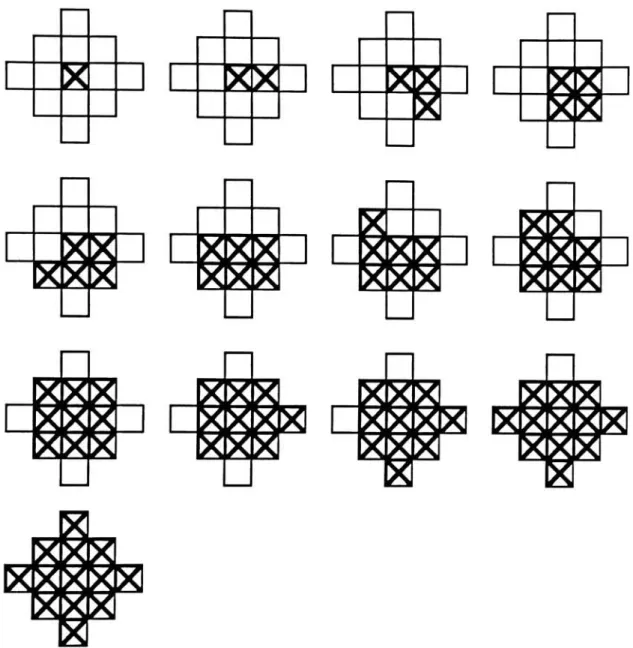

of4x4open and condensed matriceswith eight spots on 14 Figure 4 - 3x3

open matrix 18

Figure 5 - 3x3

condensed matrix 18

Figure 6 - 13

spotdiamond matrix 19

Figure 7 - Spot

sequence in 13 spotdiamond matrix 20

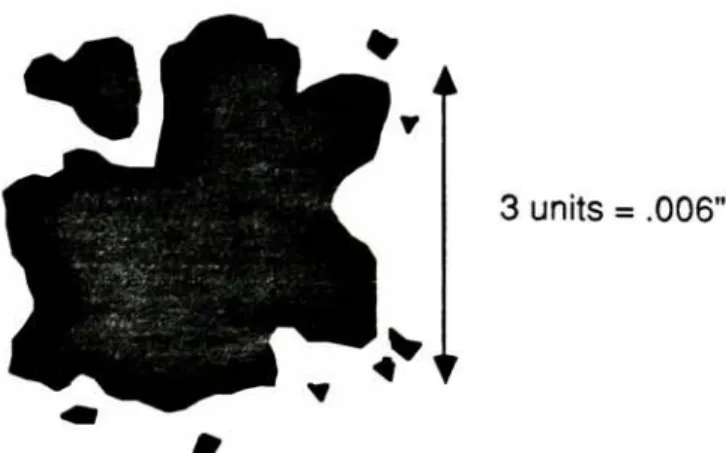

Figure 8 - Irregular

nature ofthe dot 27

Figure 9

Illustrating

dotsize 28Figure 10 Graph of

2x2, 3x3, 4x4,

and 6x6open matrices 35 Figure 1 1 - Graphof2x2, 3x3, 4x4,

and 6x6condensed matrices 36 Figure 12 - Graphof

5,

8, 12,

and24 diamondmatrices 37Figure 13 - Graph of matrices

containing 25 spots 38

Figure 14- Graphof open and condensed 8x8matrices (withcolumn

breaks)

39Figure 15 Graphofidealtonal scale versus 8x8condensed matrix 40 Figure 16 - Microphotoofparallel lines atfinestresolution 41

Figure 17 Microphoto of1/25 5x5 open matrix 42

Figure 18 - Microphoto of6/25 5x5 open matrix

43

Figure 19

-Microphotoof 12/25 5x5 openmatrix 44

Figure 20 - Microphotoof 13/25 5x5 openmatrix 45

Figure 21 Microphotoof 18/25 5x5 open matrix 46

Figure 22 - Microphotoof24/25 5x5 openmatrix 47

Figure23 - Microphotoof 12/25 5x5 condensed matri 48

Figure 24 - Microphotoof 12/25 25 diamond matrix 49

Digitalhalftonesas output on plain paper arethefocusofthisstudy. Anew

terminology

issuggestedtoallow properdescriptionofdigital halftones. Themost importantofthese termsistheuse of"addressability"

toreplacetheoften misusedterm "resolution."

Also important istheuseoftheterm"spot" ratherthan"dot" todescribe addressability. Ameans ofproperly

describing

digitalhalftonesissuggestedtoavoid confusion withanalog(ie.,

conventionalphotographic)halftones.Halftonepatterns were createdto test theefficiencyofdifferent designsat300spot perinch addressabilityon alaserprinter.Thepagedescription language PostScriptwas usedtocreatethehalftonepatternswhichweremodeled onthreebasic designs.

Ithasbeenestablishedthat twohalftone dotpatternsconstructed onthesamematrix andcontainingthesame number of spots will producedifferent densities ifthe

configuration ofthespotswithinthematrixisdifferent This has beentested

by

comparing theresults ofthe toneproductioncurves ofthecondensedand openhalftone dot designs. Thesepatterns were output on alaserprinterand measuredfor density. Toneproduction curves weredrawnand compared.Eventhougheachmatrix containsthesame numberof spots,it hasbeenshownthatdifferent densitiesresult.This is solelya consequence ofthe dotdesign.Microscopicstudies wereconductedtoillustratethenature ofthefilling-in inthe non-image area.Microscopicmeasurements werealso madetoascertainthesize of an individualspotatvarious screen rulings. Itwasfoundthat thespot,whichwasvery irregulartobeginwith,actually begantobreak upasthelinescreenapproached150 lines perinch.

Papertestswere runtogaugethemaximum

density

andthe toneproduction capabilities ofvarious papers.Although theresults wereinconclusive,

they

point out anotherflawofdigital halftoneswhichareoutputon plain paper.Thenumber of grays predictable,givenamatrixsize,isgreaterthanwhatisachievableinpractice.INTRODUCTION

Theideaofcombiningtextandillustrationswithout

having

tocut and pasteisa conceptthathas intriguedtheauthor sincehis daysas a mechanical artist.However,

tobeabletoachievethis goal,both digitaltypeandhalftonesare necessary.Inaddition,a "type-"

or"image-"setterisrequiredthatcan receive and createbothtypesof output

Devicesandtechniqueshave been developedthatcan now achievethesegoals, and what's

more,since

they

output onplainpaper,they

mayevenleadto theelimination offilmas astep intheproduction process.This study investigates digital halftonesandthewaythese

halftones are output onplainpaper. Suggestionsare madetooptimizethedesignanduse

ofdigital halftones.

Consistency

interminology isstrivedforthroughoutthisproject Someofthetermsthatare usedrepeatedlyare:

addressability

-the

frequency

withwhichthelasermarks thephotoconductive surfacedot- theone or more spotsusedtoformthebasicunit of ahalftonepattern

halftone

-atechniqueusedtosimulate continuoustoneimages ina processthatcan

onlyprint or not print at all

latent image- animagethatis

present,butnot yet visible

(ie.,

beforeapplicationoftoner)

linescreen- alsoknownaslineruling; themeasure ofthedistance between halftone

dots inahalftone

linesperinch- thetermusedtodescribethelinescreenof ahalftone

matrix- a

groupingof spots

photoconductivity- the

propertyofconductingelectricityuponexposuretolight

orsharpness

spot

-thesmallest mark alaserprinter can make on paper spots perinch- theterm

usedtodescribe addressability

Toconduct adiscussionoftheissuesinthisthesis, it isoftheutmostimportanceto

maintainconsistencyinterminology. Thereare a number ofmisleading terms which,

poorly

defined,

haveresultedinmuch confusion.Oneofthemostimportantofthesetermsis"resolution."

Resolutionisoften

incorrectly

describedintermsofthenumber of marks that thelasercan makein creatinganinchoflatent image. Thislatentimage, however,

is subsequentlytonedandtransferredtopaper, andany degradationoftheimagethatoccursinthis processisunaccountedfor. Sincethisdegradationtends tobemuchlargerthanina

photographicprocess,itmakestheuseofthe term"resolution" quite misleading. Ifa number valueistobeassigned,the term"addressability" ismore accurate.

Addressability

isthecapabilityofthelasertomark alatent imageonthephotoconductive surface.This canbedescribedmoreaccurately numericallythanresolution sincethereisnodegradation

oftheimagetoaccountfor.

Keep

inmindthataddressability describesthelatentimagewhereas resolutiondescribestheimageonpaper.

Unfortunately,

"resolution" isthe term thatismostcommonly usedtodescribetheimaging

capabilityof aprinter, andit isoftendescribed intermsof "dotsper

inch",

anotherconfusingterm.Printersare accustomedtotheterm"linesperinch" todescribehalftonescreens.

However,

300"dotsperinch" and300"linesperinch"donotmeanthesamething.Inhalftones a300lineperinch linescreen wouldbeof extremefineness. 300 dotsperinchontheother

hand,

producesimagesthatarerelativelycrude

(keep

inmindthat72dotsperinchis dotmatrix printerqualitywhile1000dotsperinch isthe

beginning

oftypesetquality.) Theword"dot" alsoisassociated withhalftonescreens,as in "halftonedot."

Thepotentialforconfusionis

limidess,

andsolelya result of

faulty

terminology.Tounderstandthisproblemitisnecessary tohavea generalunderstandingofthe nature ofhalftones.

They

existtoproduceanillusionofgrayness ina processthatcanonly printblackornot print at all.Halftonescanbe describedasbeing

analogordigital. Inusing theterm

"analog

halftone"

the dots inch. Confused?Youhavea reasontobeconfused sincetheword "dot"

hastwomeanings withinthelastsentence.First it isusedas"halftonedot" which

may vary insize,andthenit isused as"dot" in dotsperinchwhereitmeanstheminimum markablespot(a constant)inalaserprintingsystem.

Toalleviate some oftheconfusionbetween digitalandanalog

halftones,

itwillbenecessarytorevise some commonly-used vocabulary. Theterm"addressability" shouldbe

usedwhennumerically

describing

thecapabilities of a plainpaperprinter."Addressability"

and"resolution"which arevirtually identical inreferencetophotographic processes arein

factquitedifferentwhen usedtodescribeplain paper processes.

Furthermore,

"spotsper inch,"not"dotsperinch," shouldbethe termusedfor

describing

addressability.Theword "dot"simply hastoomanyother connotations."Spotsperinch" willbethe termusedto

describe addressability fortherest ofthisstudy. "Linesperinch" shouldbeusedsolely for

describing

halftones.Analog

halftonesareadequately describedby

thetermlinesperinch;

however,

digital halftonesrequirefurtherexplanation.Abasic descriptionofadigital halftonewill

help

illustratethepointFigure 1illustratesa3x3matrixof squares:

X

m

X

X

X

X

X

X

X

Figure 1 - 3x3matrixof squares

Using

this tobuildadigitalhalftone,

black,

whiteand eight shades ofgraycanbeshades ofgraythantheexample above. In

fact

it'slaughabletotry

and comparethem. Yet ifthedigital screenisdescribed as a100 linescreen,theimmediateassumptionisthatit isequivalenttoa100lineanaloghalftone.

Therefore,

toadequatelydescribeadigitalhalftone,

itisnecessarytostate notonlythelinescreenbutalsotheaddressabilityoftheoutputdevice.

So,

where 100 lines perinchjustly

describesananaloghalftone,

100lines perinchat300spots perinchwouldjustly

describeadigital halftone.This bringsupanother point.Oneofthecharacteristicsthatcanmakeanalog

halftonessuperiortodigitalhalftones isthat

they

are outputonphotographicpaperwhich,ofcourse,hasgreatsensitivitytoverysubtiedifferences. Whenphotographicpaperis

usedtocapturedigital

halftones,

much moredetailcanbe heldthanifthesamehalftone were outputon plainpaper.Thus ifadigital halftonewereoutput onbothplainand photographicpaper,much moredetailwouldbe heldonthephotographic paper. This seems quite obvious.Butitisalsotrue thataslaserprinters gainhigherandhigher addressabilities(intermsofspotsperinch),

themainlimiting

factorwillbethepaper,not thenumberof spots perinch.Theuse ofdigitalhalftones is goingto

increase,

and as aresult,the"look"ofhalftoneswillchange.Digitalhalftonesthatarecreatedforoutput ondotmatrix orlaser

printersalreadystart out at a markeddisadvantagetoanalog halftones:

they

simply fall far short ofphotographic resolution.Even digitalhalftonesthatare output onlasertypesetters havelowerresolutionas comparedtoanalog halftones.There is a simple explanationforthis: thesmallestmarkalaserphototypesettercan createislimited

by

thesizeofthelaserspotwhile,on theother

hand,

lighton photographicfilmorpaperis limited onlyby

the grainsize ofsilverhalidewhichismuchsmallerthan laserspot size(silverhalidecrystalsrangefrom0.05 to2

microns1

whilelaserspot size at300spots perinchis around85

microns.2)Thereisanother complication: thesmallerthelaserspotsize, thelargerthe amount ofinformationtobeencoded,and, thelargerthe amount of

information,

thelarger thecost andtimeinvolved. Forexample, at300spotsperinch,

90,000(300x300)

bitsof informationareneededtoencodea squareinchofimage. At 1000spotsperinch,

1,000,000

(1000x1000)

bits arerequired. Thusthereis atradeoffbetweencost andaddition, there for using digital halftones.

Among

advantages are ease ofdata transmission,electronic storage ofimages,

and electronicdata manipulation.Itshouldbestressedthatalloftheexperimentationinthis studywasdoneona

singleAppleLaserWriter. The limitedscope oftheexperimentswillgive someinsight into

thestrengths and weaknesses oflaserprinting;

however,

these tests are notintendedtobeusedtodrawconclusions about the capabilities ofanymanufacturer'sproduct.Thereis

simplynotenoughdatatosupportthose sorts of claims.Thisisalsotrueofthetestsonthe

X-Rite densitometerandtheHammermillandBoise Cascadepapers. Thesetestshave been

JMcGraw

Hill EncyclopediaofScienceandTechnology. 6thed.S. v."Photography,"

by

Vivian K. WalworthandRobert D.

Anwyl,

p.405.2Author's

calculation:1/300"

THEORETICAL BASIS

In 1937Chester Carlson inventedthefirstelectrostatic process (latercalled xerography.)1

Thiswas thebirthof part of the

technology

forthelaserprinter.Patentswereissuedin 1942and

1944,

andby

1950Xeroxhadthefirstcommercial copieronthe market.The Xerox 914office copier was introducedin1960,

and sincethen,electrostatic copiershavebecomeanintegralpart ofAmericanbusiness life. Inthelate1950's,

Dr. CharlesTownesandDr. Arthur Schawlow laidthefoundations fortheconstructionforthefirstlaser.2

The firstworking laserwas constructed

by

Dr. Therodore Maiman in I960.3 The laserhas broadenedtheapplication ofthecopier.The devicecan nowbeusedas animagesetter/typesetter. Aprime exampleofthisistheApple LaserWriter.The LaserWriter ismorethanalaserprinter;it isacomputing devicewith 1.5megabytes ofrandomaccess memory.Ithasbeen describedasthemostpowerfulcomputerthatApplemakes.4

And

yeteven withthatamount ofmemorytheLaserWriteris limitedtoanaddressabilityof300

spots perinch. This makesitan excellent choicefor business applications,butsubstandard

forthegraphicarts (where 1000spotsperinchis arguablythe standard.)Larger

addressabilityrequires morememory,butthishasnot preventedtherecentintroductionof 400and600spot perinchprinters.Ofcourse,laserphototypesettershave beenused with

great success ataddressabilities of muchhigherthan300spotsperinch

but,

forthemost part,thesesystems usephotographicpaper.5Companiesare anxioustoperfect a plainpapersystemdueto thehighexpense ofphotographicpaper.

Oneofthemost

interesting

developmentshas beenthatofthepagedescriptionlanguage PostScript.

Previously,

eachtypesetting

manufacturerhaditsowncodinglanguage fortheirmachinery.Acomputerfile forone manufacturer'stypesetterwouldbe

useless onanother's.

However,

through theuse ofPostScript,

a single computerfilecan berun on anumberofdifferentoutputdevices attheresolutionofthatoutputdevice. Thisis what

is

knownas deviceindependence.PostScript,

thoughnottheonlypagedescriptionSincethelaserprinter and pagedescription languageare ofimportancetothis

project,

they

willbe discussedinthefollowing

sections.The Laser Printer

Tounderstand whatthelaserprinterdoestoproduce an

image,

it is necessarytohaveanunderstandingoftheelectrostatic process.Inthis

discussion,

theelectrostaticprocess(ormorespecifically,transferxerography)willbe describedas atoner-based

system.Theelectrostaticprocess,as usedinconventionalphotocopiers,isrelatively

simple.Adrumor

belt,

often constructed ofselenium,is charged.This surfaceisaphotoconductor whichloses itscharge when exposedtolight. When oppositelycharged

tonerparticles arebroughtincontact withthesurfaceofthe

drum,

they

adhereto thecharged areas

(ie.,

theareasthathavenotbeenstruckby

light.)

Inthenextstep,a pieceofpaperisbrought incontactwiththedrumatthesametimethata chargeisappliedto the

backside ofthepaper,removingthetonerfromthedrumandpassingitto thepaper. The

toneristhenfusedto thepaper,completingtheprocess.7

Considerfora moment a conventional copier.Toobtain acopy,light isreflectedoff

theimagethatis

being

reproduced.Where light fromthenon-image area reflects ontothesurface ofthe

drum,

thechargewillbelost,

andthereforenotonerwillbeattracted.Thereverseistrueintheimagearea;nolightreflectsfromtheblackoftheimageandtherefore

thedrumstays charged and attractstoner.Inalaserprinter,whereyouare notworking

fromreflectioncopy,thelasercanbeused eithertoerasethenon-image areaintheway

thatlight does in theconventionalcopier,oritcanbeusedtocreate animagearea.Ifthe

laseris usedtoerasethenon-imageareaitisknownaswhitewriting;if itcreatestheimage

areait isknownasblackwriting.The

image-creating

part of alaserprinteriscalledthe"engine."

The CanonengineintheApple LaserWriterusedforthisexperimentis

blackwriting.8

The laser inalaserprinteriscontrolled

by

a polygon-shaped mirrorthataimsthelaser beamatthedrum.Thepathofthebeamishorizontalacrossthedrum

surface.The drum in theLaserWriterischargedandthechargesdissipatewhenstruck

by

thelaser. It becomesclearatthispointthatiftoneristhenattractedto thechargedareas, a

negativeimagewillresult

However,

sincethetonerhas thesame charge asthechargedareas ofthe

drum,

tonerwillonlygotonon-chargedareas(ie.,

wherethelaser has struck.)Thusthe tonersystemsare quitedifferent betweenblack- and whitewriters.

creating finehalftonea similar problem arises.The halftone

dotscreateslittleislandsoflike-chargethatbegintoaffect each other asthelinescreen

increases.

PostScript

In

1982,

ChuckGeschkeandJohn WarnockformedAdobeSystems,

Inc. Their productPostScript

isdescribedas "aprogramming language designedtoconvey a descriptionofvirtually anydesiredpagetoaprinter."9PostScript's syntax resembles the

programminglanguage

Forth,

butthereare also similaritiestoLisp10. The PostScript imageoperator was usedexclusively forthisproject Adescriptionofhow itwasusediscontainedinthe

Methodology

section,page 16. Forthepurposes ofthisproject,FOOTNOTES

FORCHAPTER TWO-J.J.RheinfrankandL.E.

Walkup,

"Current Status ofElectrostaticReproduction Processes,"1961 TAGA Proceedings.TechnicalAssociationoftheGraphic

Arts,

Rochester,

NewYork: n.p.,1961,

p.114.2Allen

Maurer,

Lasers - Light WaveoftheFuture. NewYork: Arco

Publishing, Inc.,

1982,

p.2.-Ibid., p.39.

4Bruce

Blumberg,

"Page Printersfor LowCost ElectronicPublishing,"The Fourth

National Print

Quality

Seminar.Newtonville,

Massachusetts:Datek InformationServices,

Inc., 1985,

p.237.5One

exceptionistheTegraGenesissystemwhichclaimsaddressabilityof1012spotsperhorizontal inchon plainpaper,Tegrapromotional material.

6"...PostScript

hasnow emerged as'the'pagedescriptionlanguage. Atthemoment,AdobeSystems isalmostinamonopoly

position."

TheSeyboldReporton

Publishing

Systems."Competitors for AdobeSystems," 16(May

11,

1987): 49.Encyclopedia

ofPhysicalScienceandTechnology. 1987ed.S. v."PhotographicMaterialsand

Processes,"

by

P.S.Vincent,

pp.484-494.8Personal

letterfrom MarkCurby

andIshmael Stevanov-Wagner.9Adobe

Systems, Inc.,

PostScript Language Tutorial andCookbook.Reading,

Mass.:Addison

Wesley Publishing

Co.Inc., 1985,

p. 1.10Adobe

Systems, Inc.,

PostScript LanguageReferenceManual.Reading,

Mass.:CHAPTER THREE

REVIEWOFTHE LITERATURE

In an articleinthe

February

16,

1987 Seybold ReportonPublishing

Systems1,

David R.

Spencer,

chairmanofDataRecording

Systems,

uses a charttoillustratea pointaboutthe tradeoffsbetweenshades ofgrayandthefinenessoflinescreens. Theresultsfor 300spots perinchare summarizedin Table 1 and shown graphically in Figure 2.

Table 1 - Matrix

size,number of grays possibleandlinescreenat300spotsperinch

MatrixSize 2x2 3x3 4x4 5x5 6x6 8x8 10x10

GraysPossible* 5 10 17 26 37 65 101

Linescreen 150 100 75 60 50 37.5 30

?this isatheoreticalcalculationofgrays,

including

blackandwhiteGrays

100-75

-50

-25

-Grays

Possiblevs. Linescreen

at 300 spi

I

90

T

T

n

r

30 60 90 120 150

Linescreen in lines perinch

Figure2showsthat thelargerthenumber of graysproducible, thefewerthelines in

thelinescreen. Spencergoes ontosaythatat300spots per

inch,

therejust isnotasatisfying tradeoff; hiscutoffis thepoint at which64shades ofgrayareachievable, and thelinescreenis atleast65linesperinch.In

fact,

thiscombination offactors isnot possible untiltheaddressabilityreaches600spots perinch. StephenRoth2 ,intheMay

1987issueofPersonal

Publishing

magazine,makes a similar statement aboutthenumberof grays producible. Bothauthors haveassumedthat theseprojections arein facttrue.

Whilethelinescreen informationisaccurate, thenumber of grays achievableis debatable

(refertodiscussionongrayproductioninthepapertests,page

54.)

Itisthisdiscrepancy

betweenwhatiscalculable and whathappensinreality thatprovidedtheimpetus forthis thesis.

A goodunderstandingofdigital

halftoning

isimportantto thisstudy. SomereferencesthatarehelpfulareJarviset al

(1976),

StoffelandMoreland(1981),

andAnastassiouandPennington(1982).Morerecently,GoertzelandThompsonofIBM

(1987),

havewrittenaboutdigital halftonesontheIBM4250printer.David Spencer(1985, 1987)

andAmnon Goldstein(1985),

bothofDataRecording Systems, Inc.,

havebothpublishedthought-provokingarticlesontheissues

involving

printqualityoflaserprinters.Dr. William White hasalsowritten

lucidly

ontonersand resolutions(ofparticularnotearethemicrophotographs.)His

book,

Laser Printing: TheFundamentals,

has goodbasic informationonlaserprinters.

For informationon

PostScript,

thebooksby

Adobe Systems Inc. formedthestartingpointforthe programmingnecessarytobuildthetestpatterns.PostScripthas been

thefocusof quite alotofinterestrecently,seeDennis Pelli'scontributionto the

Berkeley

Macintosh Users

Group

Newsletter,

Fall1986,

pp.35-44.For informationaboutnumerouspagedescription languagesseetheApril

14,

1986issueoftheSeybold Reporton

Publishing

Systems.ForinformationonBartlesonandBreneman'sdarknessvalues, referto their

originalarticle

(1967),

andalsothoseofArcher(1978)

andR. E. Maurer (1982). Inaddition,anunpublishedhandout

by

Prof. RobertChung

ofRITwas instrumentalinFOOTNOTESFORCHAPTER THREE

!David

R.Spencer,

"OutputTechnologiesandHighResolution,"

The Seybold Reporton

Publishing. 16

(February

16 1987):p.5.CHAPTERFOUR

HYPOTHESIS

Thehypothesisofthisproject canbestated asfollows:

Twohalftonedotpatterns constructed onthesame matrix andcontainingthesamenumber

of spots will producedifferent densitiesiftheconfiguration ofthespotswithinthematrix

is different

Togive anexample, a4x4condensed matrixcontainingeight spotswillproduce a

different

density

than a4x4open matrixcontainingeight spots (see Figure3).Open

Condensed

Figure 3 - Comparisonof4x4openand condensedmatriceswitheight spots on

The 4x4open matrixcontainingeight spotswillproduceadarker

density

becauseofthetendency

oftonertofill inthenon-image area.Whatisofimportance here isthatjudiciousdesignof matrices canbeusedtocontroltoneproduction.

This hypothesiswillbetested

by

comparingtheresults of condensed versus open dot forms. Thenature ofnon-square matrices willbetestedwith thediamond dot forms. Theeffect ofpaper ontheseprocesses willalsobetested.Firstand

foremost,

it istheintentofthisprojecttoshowthatwhatmight appearto beachievablewiththelaserprinterisnot always whathappens inpractice.Theconfusionbetween300spotsperinchaddressabilityand300spots perinchresolutionis an example

mathematicallypossible,but

they

havenottested theactual outputItis theauthor'sbeliefthatfewergrays areactuallypossiblethanSpencerandRothestimate.

Testing

how manygray levelscanbeproduced wouldbeathesisin

itself,

butitwillbeaddressedinsomeCHAPTER FIVE

METHODOLOGY

Abasic method was usedforallthe

testing

inthisproject.First

aPostScript file wascreatedthat,when output onthelaserprinter,would resultinahalftonetestpattern. Thesetestpatternsweremeasuredby

densitometerandtheresults recorded.Inthissection, thenature ofthecreation ofthe testswillbe

discussed,

aswellastests toascertainthevariationinthedensitometerandthelaserprinter.

Finally,

thetechniquesusedforthemicrophotographyand microscopic measurementswillbe discussed.

TheDevelopmentoftheTests

The

feasibility

ofthisprojecthingedonthecreationofthevarioustestpatterns.Prof. FrankCostsuggestedthat thesepatterns couldbecreated on anApple Macintosh personal computerusingthepagedescription language PostScript Continuedresearch

revealedthatthe"imageoperator"

described inthePostScript CookbookandTutorial1

alongwiththesoftware programsJustTextandSendPostScriptwould allowthecreation of theprogramsandtheir transferto theLaserWriter.Thecreationoftheindividualpatterns wastime-consuming.

First,

thedotpatternhadtobe broken downintoa series oflaser spotsthatcouldberepeatedtoproducetheactualdot.Thisseriesthenhadtobetranslatedintoahexidecimalformat foruseintheimageoperator.

Finally,

thehexidecimalnumbers wereinputontheMacintoshand proofedontheLaserWritertoensurethat thecorrectdotpattern was produced.

Aportionofatypicalprogramlooks likethis:

150 650translate 69 69scale

288288 1 [288 0 0288

00]

B6DBB6DBB6DBB6DBB6DBB6DBB6DBB6DBB6DB

B6DBB6DBB6DBB6DBB6DBB6DBB6DBB6DBB6DB

FFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFF

>}imageshowpage

Thisprogram would create a3x3matrix with one spot on out of nine.The firstcommand,

"translate",

determineswheretheimagewillbeplacedusingx andycoordinates.Thesecondcommand,

"scale",

determinesthata squareimage 69x69units willbeproduced(thereare72unitstoan

inch.)

Thenext sevenlinesarethe"image" command.The firstthreenumbers ofthefirst line indicatethat theimagewillbe 288x288pixels wide and each

pixel willberepresented

by

onebit Thesix numbersinthesquarebracketsscaletheimagetofittheunitsquaredescribed inthe"scale" command.2

Thenext sixlinesare a

hexidecimalrepresentation of ahalftone.PostScript hexisthereverse of normalhex so

thatF =0000where0represents non-image area.Thetwolines ofsolidF's (the F's

repeat72

times)

represent onehorizontalscanline.Thesameistrueofthe twolinesofB's,

6'sandD's. The lasttworows ofF's completethe thirdrow ofthe3x3 matrix.Whenthatiscompleted, thecycleisrepeateduntiltheunitsquareis filled.Atthatpoint,

theimageis actuallycreatedusingthecommand

"showpage."

Appendix

F,

page93,

containsa sampleofa3x3condenseddottestpattern.Notethatthe 10squares(oneis

blank)

representthetengray levels. The foursmallblackcornersquares appearin every testimage.

Using

thiskindofprogram,severaldotshapes were produced.They

are categorizedunderthenames

"condensed", "open",

and"diamond".Thefigures thatfollow illustratethedifferences inthevariousdotshapes.Theopendotshapedescribesadotthatis

X

X

X

?x?

X

X

X

X

Figure4- 3x3

open matrix

Thecondenseddotshapedescribesadotthatis builtaround a central spot:

Z

1

Figure5 - 3x3

condensed matrix

Thesquare nature oftheseopenandcondenseddotformsmakesitpossibletostackthem

one on

top

ofanother. Thisallows ascreenangle of zero(therows couldbestaggeredtocreatescreenanglesotherthan zero;howeverthiswasnotdone inthisexperiment.)

Screenanglebecomesafactor inthediamondclassofdotshapes sincethesedots

are notformedonasquare matrixanddon'tstackup neatly like boxes.

However,

inthesensethat

they

buildonacentralspot,they

are similartocondensed spots.Figure6X

EX

*P

KN

X

Hxil^

_*<*i***

Therelationbetweenspotsinthematrix,number ofgray

levels,

and screen angleisshowninthe tablebelow:

Table2

-Summary

of spotsin matrix, graylevels,

linescreenand screen angleCondensed/Open

2x2

3x3

4x4

5x5

6x6

8x8

Diamond

5

8

12

13

24

25

?includesblackand white(rememberthatthis iswhatis mathematicallypossible)

Thespot patternsdescribed inthe chart above canbe described inavisualshorthand

thatdescribesthewaythedotis formed:

Grays+

Linesperinch ScreenAngle

5 150 0

10 100 0

17 75 0

26 60 0

37 50 0

65 37.5 0

6 134.2 63.4

9 106.1 45

13 83.2 33.7

14 83.2 56.3

25 60 36.9

26 60 36.9

13

7 8 9

12

6

1 2 105 4 3

11

Figure7

For informationonthespot sequence of alldot

forms,

seeAppendixE,

pages 88-91.Sincethereare somanypossible combinations ofdot formationsonlyafewcould

bechosenfortesting.Theseparticular condensed and open patterns were chosento

comparetheaffect oftonerspreading intonon-image area.Thediamondpattern was

chosentolookattheeffect of anotherdotform(onewitha non-squarematrixandascreen

angle.)Screenangle couldhavebeenisolatedas afactor

by

creating screen anglesfortheopenand condensed

dots,

butthiswasnotdone inthisstudy.Density

MeasurementsAll

density

measurements were madewithanX-Rite 309reflectiondensitometer.Calibrationwashandledas specified

by

themanufacturer.Measurementswere madeon atablesurface with ablanksheet ofpaper

backing

upthetest.Threemeasurementsweremade on each l"xl"

testsquare.Themeasurementsequencewithinthesquarewas: upper

rightcorner,leftcenterandlowerrightcomer. Thesemeasurementswererecorded

direcdy

onthesheetandlateraveraged.Theseaverages wereusedforanalysis.

Thetestsforthisresearch wererunon anApple LaserWriter. When runninga series

oftests,

they

were rununinterrupted.Paperforthese testshas beensuppliedby

Boise CascadeandHammermill.They

have been labeled "A-E"."A"

representsHammermill

Laser

Copy,

"B"representsHammermillLaserPrint,

"C"

representsHammermill Laser

Plus,

"D"representsBoise CascadeLaserPaperand "E"representsBoiseCascade Cotton

LaserPaper. Paper"C" waschosentobeusedforalltestswhere paper was notthe

variable.

Twoparametersare ofparticularimportanceinthisstudy.The first istheabilityof

the densitometer togivereproducibleresultswithinan acceptabletolerance,andthesecond

istheabilityofthelaserprintertoproducethesamepattern(froma sourcecomputer

file)

within reasonabletolerances. Theresultsforthe

following

sections aretobefound inAppendix

C,

page79.Testing

ofthe DensitometerThe X-Rite309manual3

statesthatmeasurementofthecalibrated reference check

inthisstudy

by

thehalftonenature ofthetestpatterns andthevariationsthatcanoccurwithin a giventestpattern.Measurementswere recordedin

density,

notdotarea. Inan efforttomaintainthehighest accuracywhilekeeping

theprocedurefeasible,

three measurementshavebeenmade on eachtestsquare.Totest therepeatabilityofmeasurements madeinthis manner,an experiment wasconducted.Threetestsquares were chosen andmeasured35timeseach.Thefirstsquarehadan average

density

of.26,thesecond squarehadan average

density

of.78,andthe thirdsquarehadanaveragedensity

of1.13. The standarddeviationsare asfollows: lightpatch .006,medium patch .010and

solid patch.018.Whatthisimplies isthat thelowerdensitiesare measured more

accurately

thanthehigherones.

Testing

oftheLaser PrinterAsingleAppleLaserWriterwasusedforalltests;

initially

itwastestedforconsistency. Theconsistency test(see Appendix

C,

page80)

showedtheextentof variationpossiblewithinrepetitions ofthesamefile. This testhadthirty

solidblacksquares(each

l"xl")

infivecolumns of six squares each.Thissamefilewasprintedthreetimeswiththeresults asfollows.

Density

measurements rangedfrom.88to 1.30 (arangeof.42).Thiswide rangeisaccentuated

by

thevariationsindensity

on a givenpage;however,

ifa squareiscomparedtoa squareinthesamepositiononthefollowing

pagethenthevariations wentonlyas highas.26.

Following

inthismanner ofonly comparingthesame square ondifferentpages showsthat 100%ofthemeasurementsfallwithin.243

ofthemean. Inotherwords,there isastandarddeviationof.081.

Itwasdiscoveredthat thereisa

tendency

fortheprintertoprintdarkerontheleft handside ofthepage(thisisclearlyshownby

theaverages of pages1-3,

AppendixC,

page

81.)

Thetop

was alsoslighdy darkerthanthebottom. Generalobservations revealedthatsheets were oftenmarked withtracesofapreviousimage. Inaddition,adarkimageon

a single sheet could affectthedarknessachievableinother areas ofthesheet.It became clearthatseveral stepswouldhavetobetakentoadjustforthesevariations.

First,

corner testsquares wereincludedoneachimagesothatageneral comparisoncouldbemadebetween any twotestsheets.

Secondly,

thepositioningofthesquares was reconsidered. Greaterspace wasleft betweentestimages,

fewer imageswereincludedon apage, andtestimageswerekept away fromtheedge areas of pages wherevariationwasgreatest.

Thirdly,

whenanumberoflike-tests weretoberun,a"sample"

theghosting effect of a previousimage.Evenwiththeseadjustments,itwas clearthata

certain amount ofvariationwasinherentintheprocess which could notbeavoided.

Comparing

theStandard DeviationsItfollowsthata comparison canbemadebetweenthedensitometerandthelaser

printer.Thedensitometermeasured a solidtestsquarein35trialswitha standarddeviation

of.018(mean

density

= 1.13). The LaserWritercreatedthesame solidtestsquare90timeswitha standarddeviationof.081 (mean

density

=1.14.) Althoughit istruethatthevariationcaused

by density

measurementwillbereflectedinthis .081 standarddeviationforthe

LaserWriter,

it isstill quite clearthat thevariationintheLaserWriterisof amuchgreatermagnitudethaninthedensitometer.

MicroscopicStudies

Themicrophotos were shotusinganOlympus BH-2microscopewith

Tungsten-Halogen

lamp

and aNikonMultiphotphotographic attachmentThemagnification was80x (Vonthephotograph = onthe

original.) Allphotographs

representPaperC. Polaroid Type 55 Positive/Negative Instantsheetfilmwasused.

Exposuretimewasfourminutes anddevelopmentwas handledas prescribed

by

Polaroid.These4x5negatives werethencontact printedforreproductioninthis thesis.

They

havebeenmounted on a grid

illustrating

thematrix.Microscopicmeasurementsweretakentodeterminetheactualsize of adot

consistingofonespot.The instrumentused wasaBauschandLomb lightmicroscope

witha lOx

lens,

zoom adjustmentand acalibratingeyepiece.Theeyepiecewascalibratedtoan etched slidewithdivisionsof.001".Themarkingsintheeyepiece were adjustedto

FOOTNOTESFOR CHAPTERFTVE

1Adobe

Systems, Inc.,

PostScript LanguageTutorial andCookbook.Reading,

Mass.:Addison

Wesley Publishing

Co, Inc., 1985,

p.l1 1-116.2Surprisingly,

whenthescale was setto72x72and a300x300pixelimagewascreatedtheresultingtestpatterndisplayed repeatingpatternsthatstreakedtheimage vertically

andhorizontally. Trial and errortestsconfirmedthat thecombination of69x69

scalingplus a288x288pixelimageresultedinnon-streakedtestpatterns.288 is a

multiple of72whichmay be whyiteliminatesthe streaking,althoughno

explanationfora unit square of69x69was everdetermined.

CHAPTERSIX

RESULTS

Besidestheconsistencytests(referto the

Methodology

section),a numberofdifferenttests were conducted.

They

canbe divided intogroups: tone production,microscopicstudies,and papertests. Alldata forthe toneproduction and papertestsare

includedintheAppendices.Theresults ofthemicroscopic studies areincludedinthis

chapter(withtheexception ofthemicrophotographs.)

Tone Production

Toneproduction curves were producedfor

2x2, 3x3, 4x4, 5x5, 6x6,

and8x8matrices.Withineach ofthesematrix structurestwodotformswerecompared: open and

condensed.Thesetests were run onPaperC. Thegraphs ofthese testsappearonpages35

to40intheAnalysissection. (Thegraphs record

density

onthey-axisandnumberofspots ondivided

by

totalspotsinthematrix onthex-axis.)Severaltrends becomeclear.Thecondenseddot

forms,

Figure11,

tend toproducea slight s-shaped curvethatbecomeslessandlessaccentuated as thematrix sizeincreases.

Conversely

theopendotforms,

Figure

10,

produces an exaggerated s-curvethatactually developsahump

nearthe50%spots on region.

Density

continuestodrop

untilaround70%. Thiscurvebecomesmoreexaggeratedas matrix sizeincreases.

Toneproductioncurves were alsoproducedforthediamond dot forms. These dot

forms(see Figure

12)

produced curves quitesimilarinshapetothecondenseddotforms(ie.,slightly

s-shaped.)Themidtones(fromapproximately 30%to70%)

are coveredby

lowerandlower densitiesasthenumberof spotswithinthediamondmatrixincreases.

Wheredirectcomparisonispossible(see

below)

itcanbeseenthateventhoughthesamepercentageof spots are oninthematrix,alarger

density

is achievedwherethematrixTable 3 Comparisonoftestsquares with50%spots on

Spotson

Density

MaximumDensity

AdjustedDensity*2/4 .71 .93 .76

4/8 .63 .85 .74

6/12 .56 .95 .60

8/16 .49 .89 .55

12/24 .47 .94 .50

18/36 .42 .91 .46

32/64 .45 1.15 .39

?Forthepurpose ofcomparison,the

density

isadjustedto themaximumdensity

achieved

by

theLaserWriteron a givenday.Allofthedensitieshave beenadjustedtoa maximum

density

of1.00. Inthecase of2/4spots onthismeansthatthedensity,

.71,ismultipliedby

1.00/.93togive an adjusteddensity

of.76.Theassumption madehere isthatifthe

density

had been1.00,

the2/4 stepwouldhavebeen.76.Yeteven withoutadjustingthe

density

thereisa gradualdeclineindensity

asthenumber of spotsincreases.

Thedotshapes usedforthis testwerethe

8,

12 and24 diamondshape,andthe2x2, 4x4,

6x6and8x8condenseddotshapes.Theopendotshapes at

50%,

sincethey

are allcheckerboards,are all quite similar.

They

averageat about.82adjusteddensity.Microscopic Studies

Microscopicmeasurements weremadetodeterminetheactual size ofthedot. The

markingsin theeyepiece were adjustedtobeequalto through theuseofthe zoom

adjustment. Theactualdotsare quiteirregular innature(see

below),

sothesediameter3 units =

Figure8- Irregular

nature ofthedot

Thecriterion used wasthatthebulkofthedotshouldfallwithinthestated

measurementMeasurements weremade on

2x2, 3x3, 4x4, 5x5, 6x6,

and8x8 matricesusingthe testsquare whereonlyonespotinthematrix was on.Inthismanner,thevariable

betweenthe testsisthedistancebetweenadjacent spots. Itshould alsobenotedthatasthe

dotscome closer and closertogether,the

irregularity

inthedotshapeincreases. Themeasurementsfortheindividualspots are asfollows:

Table 4- Dot

size measurement

Matrix

2x2

3x3

4x4

5x5

6x6

8x8

Diameterofthedot

Ameasurementwas also made ofthe2x2opendot formwheretwoout offourspotsare

oninthematrix.Thischeckerboardpatternhasquite anirregulardotwhichmakesexact

measurement

difficult

howeverthediameterisnogreaterthan.003".Graphically

thedata5x5 4x4 3x3 2x2 2x2

*

?

Side

of boxequalsFigure9

-Illustrating

dotsize(Thesecond2x2matrix representsthe twospots on situation.Ineach case thenearest

adjacentdotsare alsoshown.)

The accuracyofthemeasurements wastested

by

measuringthedistance betweenthedotsandcomparingitwiththeknown linescreenvalues:

Table5

-Testing

theaccuracyofthemicroscopic measurementsDistance betweenspots(midpointto midpoint)

Matrix Measured Calculated

2x2

3x3

4x4

5x5

6x6

8x8

Microphotographs weretakentogive avisualillustrationofwhatis

happening

atthelevelofasinglespot.Thephotos areshownon pages41 to49.

They

have beenmountedon a gridtoillustratetherelationship between thespot andthematrix. Thephotos were

shot at amagnificationofapproximately80x (one inchonthephotographisequalto

.0125").Thephotos willbe

discussedintheanalysissection,butpleasenotetwo things:

first

therelativesize of anindividual spotandsecond, therelationofthematrixtothePaperTests

Twofactorsrelatingtopaper weretestedas part ofthisresearch.The firstisthe

ability toachieve ahighmaximumdensity.Thesecondistheabilitytoproduceatonal

curvethrough a range of grays.

Maximum

Density

Tests- Thedensity

testconsisted oftakingdensity

measurementsfrom 12solidblackpatches,aswellasrecordingthe

density

ofthewhite ofthepaper.Threesheets were runforeach paper sample.Theresults werethenaveragedand shown

below (rankingsareinparentheses):

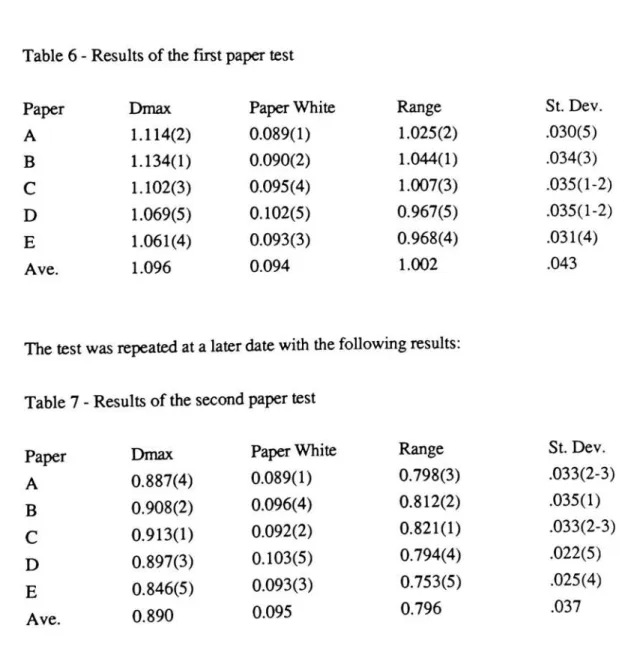

Table6- Resultsofthefirstpapertest

Paper Dmax Paper White Range St. Dev.

A

1.114(2)

0.089(1)

1.025(2)

.030(5)B

1.134(1)

0.090(2)

1.044(1)

.034(3)C

1.102(3)

0.095(4)

1.007(3)

.035(1-2)D

1.069(5)

0.102(5)

0.967(5)

.035(1-2)E

1.061(4)

0.093(3)

0.968(4)

.031(4)Ave. 1.096 0.094 1.002 .043

Thetestwas repeatedat alater datewiththe

following

results:Table 7- Resultsofthesecond papertest

Paper Dmax PaperWhite Range St. Dev.

A

0.887(4)

0.089(1)

0.798(3)

.033(2-3)B

0.908(2)

0.096(4)

0.812(2)

.035(1)C

0.913(1)

0.092(2)

0.821(1)

.033(2-3)D

0.897(3)

0.103(5)

0.794(4)

.022(5)E

0.846(5)

0.093(3)

0.753(5)

.025(4)Ave. 0.890 0.095 0.796

Itis

interesting

tonotethat themaximumdensity

achieved ontheday

ofthefirsttestis 1.096comparedto0.890onthesecondday. Eachtestrepresents,inthecase of maximum

density,

36measurements(gleaned from 108 actual measurements onthe36squares.)

Gray

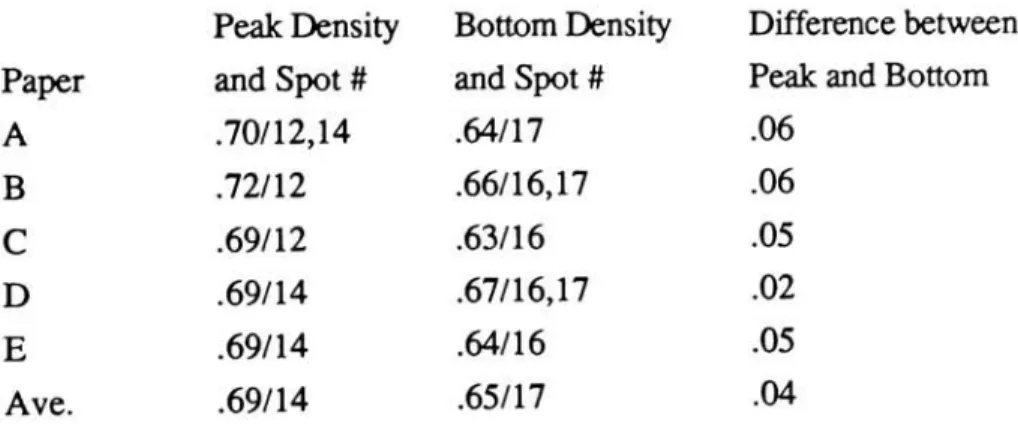

Production Test- Totest theabilityof a papertoproduce grays(andalsoto

gaugetheamount of

filling in)

anothertestwas run. The 5x5open matrixpatternwasrunthreetimeson each paper.

Density

measurements weretakenand averaged. Sincethisparticulardot formationformsa characteristichump-shapedtoneproductioncurve, itwas decidedtocomparethepoints wherethecurve peaks and whereitreachesthebottom. Thesepeaks,bottomsandcorrespondingspot numbers are recordedbelow:

Table8- Resultsofthethirdpapertest

Peak

Density

BottomDensity

Difference between Paper andSpot # andSpot # PeakandBottomA .70/12,14 .64/17 .06

B .72/12 .66/16,17 .06

C .69/12 .63/16 .05

D .69/14 .67/16,17 .02

E .69/14 .64/16 .05

Ave. .69/14 .65/17 .04

Thisparticulartestwillbeofimportancenotonly in

determining

a paper'sabilitytoreproduceatonecurveaccurately, butalsotoget alookatthenature ofthis hump/bottom

phenomenon. Thisis becausetheaverages oftheresultsof all papersshowthat

steps 14

and 17arethekeysto solvingthepuzzle.Thenatureofthegrayproduction willbe discussed

by

theuseofseveral methodstogradetheproductionofgrays.Referto the Analysis section,page32 foranexplanationofthesemethods.Table 9- Overview

of papercharacteristics

A B C D E

Weight(in

lbs.)

20 24 24 20 20Opacity

87 90 92 86+ 85+Brightness 89 89 90 85.5 91

Brightness* 89

93 89.5 85 90

?brightnessmeasurements made on aPhotovolt Model 670reflection meter(the

CHAPTER

SEVENANALYSIS

Thissectionis divided intothreeparts: toneproduction,microscopicstudies,and

papertests.The datafromtheResultssectioniscontainedintheAppendices.The data has

beenusedtocalculatemeans andstandarddeviations. Theraw

data,

alongwiththemeansand standarddeviations isshownintheseAppendices. Graphs havebeen drawnto

illustratesome ofthedata. Thegraphs are on pages35 to40attheend ofthischapter.

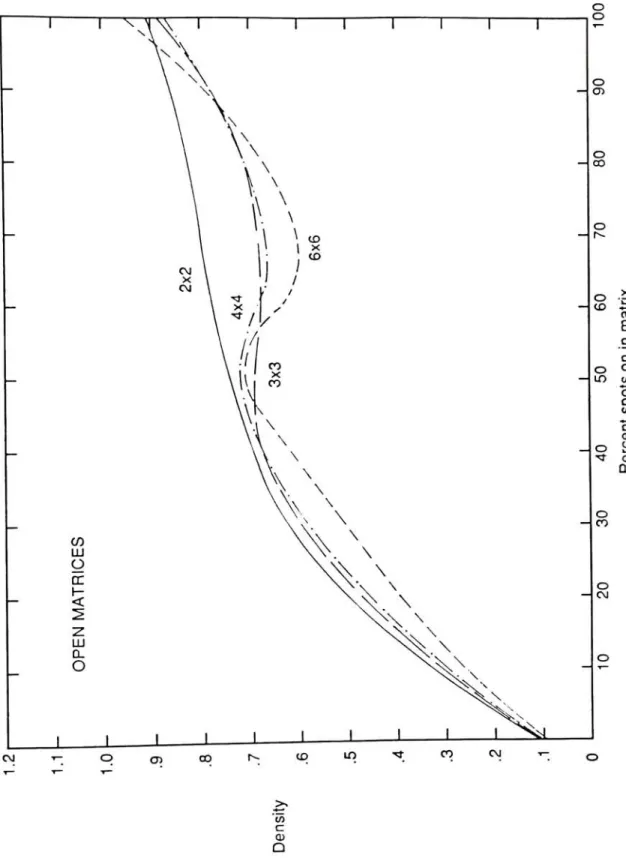

ToneProduction

Thebulkofthissection consists ofthegraphical representation oftheResults

section. Figures 10through 15are graphs ofthetoneproduction curves.

Density

isrecorded onthey-axis while percent of spotsoninthe matrixisrecordedonthex-axis.

Percentof spots on inthematrixsimplyisa calculation of spotsondivided

by

spotsinthematrix. Forexample,one spot onina25spotmatrixyieldsa valueof4%spots oninthe

matrix.Wherecertain curveswithinacategory showed greatsimilarity (asis thecaseinthe

diamondmatrixforexample)onlyone curvewas showntopreservetheclarityofthe

graph.Forexample, the 12 diamondand 13 diamondareverysimilar andthereforeonly

the 12diamondisshown on the graph (thesameistruefor 24and

25,

only 24 diamond isshown.) This adjustmenthas beenmadein figures 10through 12.

Agoodcomparisoncanbemadeofthe25

diamond,

5x5condensed andthe5x5open matrices since

they

allcontain25 spotswithinthematrix. Forthisreasontheyhaveallbeenshowntogetherin figure 13. Thecurvesinthegraphs havebeen drawnto

representthedatapoints.Itshouldbenotedthatinthematricescontaining fewspots

(ie.,

2x2, 3x3,

5diamond)

thismeansthat thecurvehas been drawn using relatively few datapoints.Nocurves aredrawn in figure 14. Allthedatapoints are showntoillustratethe

unevennature ofthedata. Column breaksare showntoshowtheeffectthatpagelocation

hasonthetest.Inthe8x8 test, 24testsquaresfiton a pagein fourcolumns of sixsquares

each. Threepageswere requiredtofitalltestsquares. 8x8openisrepresented

by

and8x8condensedisrepresented

by

"c's". Wherethevalues arethesame an"x"

appears.

BartlesonandBrenemanvalues were usedtocreatetheidealtonalscalein Figure

15. Thissystem relateshumanperceptionto

density

values.Inthismanner,stepsofequalvisualdifferencecanbecreated.

Therefore,

ifthemaximumdensity

ofthe8x8condensedmatrixis 1.

15,

anidealcurve of65steps canbecreatedusing 1.15as the maximumdensity

and0.10astheminimumdensity. See AppendixD,

page84 forcalculations andanin-depthexplanation.

MicroscopicStudies

Themicroscopic measurement results are shownintheresults sectionintheir

entirety.No furtheranalysishasbeenperformed onthisdata.

Themicrophotographs have beenmountedongridswhichrepresentthematrices on

which

they

arebuilt The"x's" representthespotswhichare on. Figure 16 includesamicrophotograph of parallellinesattheirfinestresolution(thereisnounderlyingmatrixfor

this.)

Figures 17through22shouldbeviewedas a series.They

allrepresentthe5x5openmatrix with anywherefromoneto24spots on. Figures 18and21 are remarkablefortheir

similaritythough 18 has six spots on while21 has 18spots on. Figure 23representsthe

12spots on square ofthe5x5condensed matrix.Figure 24represents 12 spotson,inthis

caseinthe25 spotdiamondmatrix.Both23and24shouldbecomparedtoFigure

19,

sinceineach ofthesecases 12out of25 ofthespots areoninthematrices.

Paper Tests

Appendix

B,

page74,

givesthefullextent ofdataand calculations.The grayproduction part ofthepapertestsrequiresan analysis todetermine how manygrayswere

produced.Therearecertainly many waystodothiskindof analysis.Theauthorhas developedthreemethods of

doing

thisand eachwillbe lookedat separately.First,

it ispossibletomeasurethenumberoftimes thatavalueofagivenstepislessthanor equalto theprevious value.

Certainly

ifavalue inanascending gray scaledoesnotexceedtheprevious valueitcannotbeconsideredaseparategray. ThismethodwillbecalledMethod

One.Anothermethod wouldbetocountthenumberoftimes that thevalue of a givenstep

doesnotexceedthehighestpreviousvalue.Thismethod will accountfor dips ina curve

(likeintheopencurves) where valuesmay be ascending but have actuallybeenexceeded

countingthenumber oftimesthat thevalue ofanystep inthe testisrepeated.Thismethod

willbereferredtoasMethod Three.Toreview:

MethodOne

-thenumber oftimesthatthevalue ofa givenstepislessthanorequal

to thepreviousstep

MethodTwo

-thenumber oftimesthat thevalue of a givenstepis lessthanorequal

to thehighestprevious value

MethodThree- the number oftimes that thevalue of a

steprepeats

Thesecalculations havebeenmadenotonly forthepapertests,butalsoforthe tone

LU

o

DC

h-<

LU

D-O

o o

o a.

o CO

o

o (o E c c o o ID W O Q. l/>

OJ O ^r cj 0_

o co

o CO

rtJ I

CM

t-<J> 00 to to CO CJ

to QJ

D

Figure 10 - Graphof

2x2, 3x3, 4x4,

and6x6co hi o cn h-< D LU CO -z. LU D O o

J I I L

o a. o oo o X to -rt rt* ro E c c o o u. to c> Q. to c OJ o y rtf OJ 0-o CO o C\J CJ

T-Oi CO to io CO CM

-to c

OJ O

Figure 1 1 - Graphof

2x2, 3x3, 4x4,

and 6x6CM PcDooi^-to-O'-;

c0.CN.,r"-cz

CD D

Figure 12- Graphof

5, 8,

12,

and24diamondo Q-00 in CM CD 2 2 O O C/0 LU o cc h-< o o CD O CO o to ~ ro o o -m o Q. V) C CD O ^ ^ CD CL O CO o CM

1 I I L

CM

t-CD oo r^ co io CO CM

to c CD Q

Figure 13 - Graph

o u o CO O O o o o o o o o o CJ o O o o o u o u u o CJ o o o o u o u o cj o o o u CO o CJ o o u o o CJ o o o o o u <J o o o D LU

00 . .

7- c

III rti

Q or

S <<o O C/J UJ o V) O ro z cc OJ

<. < c z rt E

UJ m 3

LL V O

u oo u

o o u o u o o o o CO "o CJ u Irt) o o o o o o OO CO -CD Ol ro CL CM CD ro Crtrtl. <D O) ro a. CJ o o OO CO OO o o o o o 05 o CO o o co o CO o CM ro E o <r> O Q. to CD CJ krt Q) 0. CM

t-O) oo CD IO CO CM

to c

CD Q

Figure 14- Graph

-O

LU 00

z

UJ UJ _J Q

< z

o

00 o

o

_l

<

z

oo

X

CO

u

1- 00

rtrt-J

<

LU

Q

00

cc

UJ

>

1 I

CM cn oo to m CO CM

c CD

O

X

X

X

it

<

X

X

X

X

X

X

X

x:

e

E

x

k. ^rtk. rtrtAk.__*^ ... ^rtrtrtrtirtk.^^^fc.^^rtrtirtk.^'_ k.^jLrt<rtk^rtirtL^ikv. .^^rt*rtk.^^rtrt*k.^"rt^fc.^F^W^^rti rtk.^^rtrtrtk^^^fc.^ik.VAl^^r.

***

?!-?!

?>:

?>T.tt.>:

.*T<iT

*_;?::?:

*l*

?!<>*.**>*

a<

?X*>>5

&2&3Z

CHAPTEREIGHT

DISCUSSION

Thischapteris divided intothreesections:tone production, microscopicstudies and

papertests.

ToneProduction

Forthisdiscussionplease refertoFigures 10through 15on pages35to40. An

inherentcharacteristic ofthecurves oftheopen matricesbecomesclearin Figure 10. The

curve (of6x6 forexample)reaches aninitialpeakatabout50% spots on andthendrops

until 70%spots on at which pointitincreasesagain.This isapparentin Figures 13and 14

as well.Thecurves ofthecondensed matrices ontheother

hand,

tend towardan s-curveshapewhichisrelatively flat inthe midtones.The diamondmatricesare quite similarto the

condensedas agroup (seeFigure 12).Thethree typesofcurves canbecomparedin

Figure 13.

Clearly

themoststriking aspectofthisgraphisthehumped-shapeofthe5x5opencurve.Itmightbesurmisedthat theopenmatriceswouldfill in causingtherapidrise

indensitiesshown;howeverit iscuriousthatthedensities decreasepast50%as more

spots are added. Thisquestionisanswered

by

themicrophotographs andwillbe discussedinthemicroscopic studiessectionofthis chapter.Rememberin

looking

atFigure 13 thattheopenand condensed5x5 matricesdiffer only inthewaythespots are configured.

Thegeneralshape of open versus condensed curvesiswelldocumented in Figure

14.Inaddition, theinfluenceof pagelocationisindicated

by

themarkingofthecolumnchanges.The datapointsdonotformaperfecdy smoothcurve.Inpartthisiscaused

by

thecolumn changes.

Note,

inparticular,page3,

column 1 wherebothopen and condensedrise

by

considerable amounts.Thesameistruetoa somewhatlesserextentinpage3,

column2. This emphasizesthepoint madeinthe

Methodology

section, thatis,

thatpagelocationplays alargeroleinthe

density

ofagiventestsquare.Thefinalgraph,Figure

15,

comparesanideal BartlesonandBrenemancurveto thefacts

shouldbenoted.First,

the8x8

condensedmatrix represents alinescreenof37.5which while

affording

numerous grays,sacrificesdetail. Secondofall, the8x8curveistoosteep inthe

highlight

andshadow,andtooflatinthemidtone.Thismeansthat themidtoneareafromabout.3to.6in

density

(

a range of.3)iscovered

by

moregrays thantheentire rest oftherange(about.75).Lastofall,duetothedigitalnature ofdigital

halftones,

thefirst few steps are of greater magnitude thantheonesthatfollow. Thevaluesof

0/25,1/25,2/25,3/25

and4/25 are asfollows:0.10, 0.14,

0.17, 0.19,

and0.20.Ideally

thesteps mightbe

0.10, 0.12,

0.14, 0.16,

and0.18. Ifthiswerethecase, therewouldnotbesuch alarge

jump

fromthepaper whitetothefirstgray.In addition,itwouldfacilitatethespreadingout oftheflatareainthemidtone.Theseconditions,

however,

aredifficulttoachieveinadigitalhalftone.Rememberthat theaddition ofa spotwithinthe

matrix will make a greaterdifferenceif very fewspots arealreadythere.Forexample,

fromoneto twospotsthereis a100% increaseinthenumber ofspots,fromtwo tothree

onlya50% increase and so on.

Pulling

data fromthevariouscurvesthefollowing

comparison canbemadebetweenall ofthedatapointsatwhich50%ofthespots are on(see

Results,

page26):Table 10- 50%spots onwithinformation concerningareabetweenspots

Spotson Area betweenspots Docomerstouch? Adjusted

density

2/4 2units Yes .76

4/8 4units Yes .74

6/12 6units Yes .60

8/16 8units No .55

12/24 12units No .50

18/36 18 units No .46

32/64 32units No .39

Eventhoughthesame percent of spots areon,itisclearthatthe

density

increasesas theareabetweenthespotsincreases.

Why

shouldthisbe? Therearecertainly manyfactorsatplay

here,

twoofthembeing

laserspot size andtheamount of overlap. Onepossibleexplanationis thatastheline ruling

increases, toning

willbelesslikely

inthenon-imageMicroscopic Studies

Themicroscopicmeasurementsrevealthat thediameterof adot consistingof a

single spot remains at aconstant untilthematrix sizeisreducedto4x4.Atthatpoint

thedotcontinuestoshrink untilit

becomes

soirregularthatit is difficulttomeasure.Thisdestruction

oftheunitbuilding

blockof ahalftone

isof utmost concerntodesignersofdigital

halftones.

Forthe

following

discussionofthemicrophotographsplease refertoFigures 16through

24,

pages41 to49. Figure 16isa goodillustrationofthemannerinwhichtonerfillsinthenon-imagearea.ThesearethefinestparallellinesthattheLaserWritercan

create.Ina unit

inch,

onehundredandfifty

oftheseblacklineswouldbe borderedby

onehundredand

fifty

whitelines.Ifitwere possibletooutputthis imagetophotographic paperthenature oftheimagewouldbemuchdifferentThespread oftonerwould notbea

problem andthedefinitionoftheedge wouldbemuchfiner. Thishigherresolutionis

reflectedinthehighercost of photographic paper andfilm.

Thenextsequence,Figures 17through

22,

isofinterestforseveral reasons. Notethedecreaseinspot sizebetween Figure 17and 19. The individualspots are visiblein

Figure 19andhaveshrunkenremarkablyas comparedtoFigure 17. Figures 18and 21

make another

interesting

comparison.Ineffect, six spots (in Figure18)

dotheworkof18spots(in Figure21).This isdueto toner

filling

inthenon-image areainFigure 18. Tonerfalls intothenon-imagearea;however becauseit issurrounded

by

moretonerthathasalreadymadeits wayto theimagearea,itcan't makeitswayoutandisultimatelytrapped.

The

hump

shaped curvein Figure 13canbeexplainedwiththe microphotographs.Figure 19representsthepeakofthe curve,Figure 20representsthepoint

immediately

after.Figures 19and20illustratethedecrease in

density

thatoccurs.Notehow Figure 20appearslighterthanFigure 19eventhoughan extra spothasbeenadded. Whatappearsto

be

happening

hereis that theextraspot,whichissurroundedby

fourotherspots,forms alargecharged areawithitsneighbors.Thischarged areaappearstodrawthetonerfromthe

non-image area

thereby

creatingahigher density. Thisextraspothastheeffect ofcleaningupthenon-image area ofstray toner; howeveritalsoappearstomakeitmoredifficultfor

tonertobeattractedto theimageareasthatareisolated.Thisprocess continuesuntilthis

largecentral charged areahasbecome largeenoughitselftobeginanincreasein

density

(seeFigure

21.)

ItissurprisingthattoreachFigure21 it is necessarytopass throughtoeach otherinsequence, andyet, thecentraldot in Figure 18 virtually decomposes before

being

built

upagain in Figure 21.Figure

22represents one spot short of a solidblack.Notethat thesize oftheopen

(non-image)

areais quite similarinsizetothatoftheimageareain Figure 17.

Figures

19,

23 and24make aninteresting

comparison of25 spot matriceswith 12spotson. The resulting densities (.42

diamond,

.53 condensed,and.88open,refertoAppendix

A)

show adifference

thatisalso quite visible onthemicroscopiclevel. In Figure19,

theopen areas betweenspotshave filledintoa great extent In Figure23thegreatestamount offilling-intakesplace atthepoint wherethehalftone dotsare endtoend. In

Figure24the

halftone

dots onlyapproach each other atthecomers andit isatthesecornersthatsomefilling-intakesplace.This limited filling-inthat takesplaceinFigure24isa

result ofthescreen anglethatexistsinthe25diamondmatrix. Thisisanimportant factor

to

keep

inmind whiledesigning

matrices sinceitcanbeusedtocontrolfilling-in. Thesemicrophotographsshowthatconfigurationwithinthe matrix, and, theshape ofthematrix

itselfplayalargeroleintheresultingdensities.

Paper Tests

Maximum

Density

-Achieving

ahighmaximumdensity

isimportantintoneproductionsinceitallows a greater range of valuestobecovered

by

various grays. Alowmaximum

density

willcompress thegrayscale sothatadjacent graysbecomemore similar.Theotherfactorinrangeistheminimumdensity. What is

being

comparedinthispapertestistherangefrommaximumtominimumdensity. InthefirsttestTable

6,

page 29thepapers are ranked

by

rangeinthefollowing

order: BthenA,

C, E,

andD. Itwouldbestatisticallypossibletojudgetheaccuracyofthisrankinggiventhemeans and standard

deviations.

However,

thesecondtest,Table7,

page29,

gives arankingofCthenB, A,

D,

andE. This rankingthrowssomedoubtontoanyjudgementsof orderthatmightbedrawn fromtheserankings.Itshouldbenotedthatonthe

day

ofthefirst test,theaveragemaximum

density

was 1.096while ontheday