Investigation On The Effect Of Cutting Parameters On Machining Of Aluminium Using 5-Axis Machining

Full text

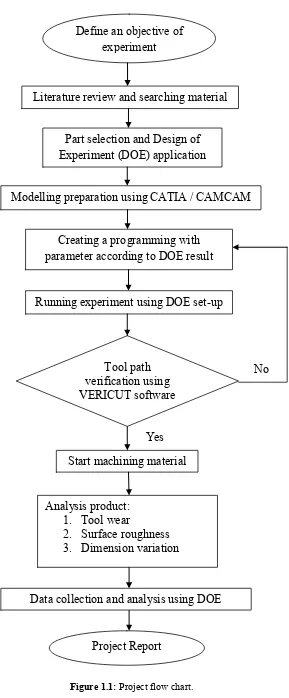

Figure

Related documents

This project is analysis the effect of cutting parameters like cutting speed, feed rate, and depth of cut on surface roughness for different type of material using CNC

The use high of cutting speed in industry has become more prevalent in recent year. In most manufacturing industries, the smooth surface is usually the objective in machining

The experiments were done to find out the better surface roughness and tool wear generated during machining of required Aluminium samples by using cutting

This work outlines the effect of grinding cutting parameters on the surface integrity namely surface roughness and the surface hardness of AISI 1148 steel

In this study, the Taguchi optimization method was applied to find the optimal process parameters, which minimizes the surface roughness during the dry turning of AISI 6061

The complete machining process is performed on cnc lathe machine Hence the intention of this project is to minimize the surface roughness, tool wear, machining

The aim of the investigations is the determination of appropriate machining parameters for slide diamond burnishing of AMCs considering surface roughness, imperfections and

The effect of the control factors laser power, cutting speed, assist gas pressure and standoff distance on the cut quality characteristics surface roughness and