DESIGN AND DEVELOPMENT OF

CARBON FIBER DOUBLE WISHBONE SUSPENSION ARM FOR

UTeM FORMULA STYLE RACE CAR

MOHD IZAMUDIN BIN ITAM AHMED

I have read this thesis and from my opinion this thesis

is sufficient in aspect of scope and quality for awarding Bachelor of Mechanical Engineering (Automotive)

Signature :…….………

Supervisor : Muhd Ridzuan bin Mansor

DESIGN AND DEVELOPMENT OF CARBON FIBER DOUBLE WISHBONE SUSPENSION ARM FOR UTeM FORMULA STYLE RACE CAR

MOHD IZAMUDIN BIN ITAM AHMED

This report is presented as a requirement for a degree undergraduate in Bachelor of Mechanical Engineering (Automotive)

Faculty of Mechanical Engineering Universiti Teknikal Malaysia Melaka

“I declare this report is on my own work except for summary and quotes that I have mentioned its sources”

Signature : ……….

iii

To my family

for their support and love.

Together with supports from friends,

ACKNOWLEDGEMENT

Praise to Allah SWT to who seek help and guidance and under His benevolence we exist and without His help this project could not have been accomplished

I would like to take this opportunity to express my gratitude to my supervisor, Mr. Muhd Ridzuan bin Mansor for his constant guidance and encouragement during the past one year. He always appreciated whether little progress I have achieved and continuously give me so much inspiration by sharing his precious knowledge and experiences. Although there were so many weaknesses in myself, he never shows the negative attitude and always thinks positive about his student.

Not forgetting, my dedication to the members of the academic and technical stuffs that continuously support and guiding me directly and indirectly to complete this project in time. The sharing of experiences helps me to overcome the obstacles encountered during completing this project

v

ABSTRACT

The one of most important factors in racing car is weight of car. This can reduce the performance of the car due to unnecessary weight. This study will reduce the weight by replacing their suspension system. By choosing current UTeM Formula Varsity racing car as a reference and FSAE rules as our guidance, a development of composite suspension has taken place. Most of racing car use double wishbone suspension link as their suspension system due to its advantages. The design of this suspension system involved the calculation of load transfer during cornering and braking condition. Then followed by the force acting on the link suspension is calculated by using matrix vector unit. After that, the strength of the composite is calculated by using stiffness matrix equation which it determines the strength of the composite layers according to its orientation. The value of composite must greater than value of force acting on the suspension system in order to prevent failure when it operating in certain condition. Then, the fabrication process of component will take place using carbon fiber polymer with polyester resin matrix using conventional hand lay-up technique. Final finished product will undergo compression testing using INSTRON Universal Testing Machine to determine the maximum compressive strength.

.

ABSTRAK

Salah satu faktor penting dalam sesebuah kereta lumba adalah berat kereta tersebut. Keupayaan kereta tersebut akan berkurang disebabkan berat yang berlebihan. Kajian ini akan mengurangkan berat kereta tersebut dengan menggantikan sistem suspensinya. Dengan mengambil kereta lumba UTeM Formula Varsity sebagai contoh dan peraturan FSAE sebagai petunjuk, pembangunan sistem suspensi berasaskan komposit telah dibuat. Kebanyakkan kereta lumba menggunakan penyambung suspensi tulang selangka berdasarkan kelebihannya. Rekabentuk sistem suspensi ini melibatkan pengiraan pemindahan beban ketika dalam keadaan membelok dan membrek secara mengejut. Diikuti dengan daya yang bertindak terhadap penyambung suspensi tulang selangka dikira dengan menggunakan persamaan unit vektor matrik. Kemudian, kekuatan komposit dikira dengan menggunakan persamaan matrik simpulan yang akan menentukan kekuatan lapisan-lapisan komposit berdasarkan orientasinya. Nilai komposit mesti melebihi nilai daya yang bertindak terhadap sistem suspensi supaya dapat mencegah kegagalan semasa ia sedang beroperasi dalam keadaan tertentu. Kemudian, proses pembuatan komponen suspensi telah dilakuknn dengan menggunakan serat karbon bersama

vii

CONTENTS

CHAPTER TITLE PAGE

NUMBER

DECLARATION ii

DEDICATION Iii

ACKNOWLEDGEMENT iv

ABSTRACT v

ABSTRAK vi

CONTENTS vii

LIST OF TABLES xii

LIST OF FIGURES xiii

LIST OF APPENDIX xv

CHAPTER 1 INTRODUCTION

1.1 Background Study 1

1.2 Problem Statement 2

1.3 Project Objectives 2

1.4 Project Scope 2

1.5 Project Outline 3

CHAPTER 2 LITERATURE REVIEW

2.1 Overview Suspension System 4

2.2 Types of Suspension System 6

2.2.1 Non-Independent Suspension System

CHAPTER TITLE PAGE

NUMBER

2.2.2 Independent Suspension System

7

2.2.3 Double Wishbone Suspension Arm

8

2.2.4 Suspension Geometry 10

2.2.5 Suspension Kinematics/ Load Transfer

11

2.2.6 Suspension Loading and Dynamics

13

2.2.6.1 Tire Loads 13

2.2.6.2 Suspension Forces 15

2.3 Composite 16

2.3.1 Fibres 16

2.3.2 Resins 18

2.3.3 Process 20

2.3.3.1 Prepregging Process 20

2.3.3.2 Wet Filament Winding 21

2.3.3.3 Hand Lay-Up of Prepreg Process

22

2.3.3.4 Automated Tape Placement Process

23

2.3.3.5 Resin Transfer Molding

23

2.3.3.6 Pultrusion 24

2.3.3.7 Injection Molding 24

2.3.3.8 Vacuum Bagging, Autoclave Cure

25

2.3.3.9 Machining Finishing 26

ix

CHAPTER TITLE PAGE

NUMBER

2.4.2 Bonded Joining 27

2.4.2.1 Adhesive Material 27

CHAPTER 3 METHODOLOGY

3.1 Introduction 29

3.2 General Methodology 30

3.3 Load Calculation Methodology 31

3.4 Composite Calculation Methodology 32

3.5 Fabrication Methodology 33

3.6 Methodology Details in PSM 1 34

3.6.1Problem Statement Identification 34

3.6.2 Literature Review 34

3.6.3 Calculation 35

3.7 Methodology Details in PSM 2 36

3.7.1 Fabrication Process 36

3.7.2 Testing 36

3.7.3 Discussion and Conclusion 36

3.8 Suspension Design 37

3.8.1 Concept Design 37

3.9 Introduction to Calculation Theory 40

3.10 Members Nomenclature 41

3.11 Suspension Link Calculation 43

3.12 Composite Laminate Analysis 46

3.13 Introduction to Fabrication Process 47 3.14 Fabrication of Suspension

Component

48

3.14.1 Preparation before Component Fabrication

48

3.14.2 1st Stage Component Fabrication (Lay-Up)

CHAPTER TITLE PAGE

NUMBER

3.14.3 2nd Stage Component Fabrication

54

3.15 Construction of Testing Jig 56

3.16 Compression Test for Composite Suspension

58

3.16.1 Compression Test for Composite Suspension in Longitudinal Direction

59

3.16.2 Compression Test for Composite Suspension in Lateral Direction

60

CHAPTER 4 RESULT AND DISCUSSION

4.1 Introduction 61

4.2 Suspension Members Calculation 62

4.3 Composite Calculation Analysis 64

4.4 Calculation Theory Summary 65

4.5 Experimental Result 66

4.6 Discussion 69

CHAPTER 5 CONCLUSION

5.1 Conclusion 71

5.2 Recommendation 72

REFERENCE 73

xi

LIST OF TABLES

NO. TITLE PAGE

NUMBER

2.1 Double Wishbone Arrangement (Mark Wan, 1998-2000)

9

6.1 Suspension Labelling Coordinate Points 62

6.2 Wheel Centre Loading for Front Right Corner of the Suspension (Borg, 2009)

63

6.3 Wheel Centre Loading for Front Right Corner of the Suspension

LIST OF FIGURES

NO. TITLE PAGE

NUMBER

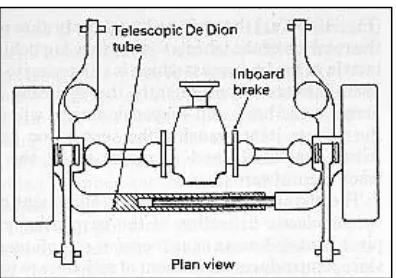

2.1 De Dion Axle Suspension System (Mark Wan, 1998-2000)

7

2.2 Double Wishbone Suspension System (Longhurst, 2006)

8

2.3 Suspension Geometry Factors (Milliken, 1995) 10 2.4 Variable and Dimension Associated with lateral

Load Transfer (Milliken, 1995)

12

2.5 Calspan TIRF Tire Measurement Machine (Borg, 2009)

13

2.6 Tire Contact Patch under Slip Angle and Effects of Pneumatic Trails (Gillepsie, 1992)

14

2.7 Example Graph of Lateral Force versus Vertical Load (Milliken, 1995)

14

2.8 Prepregging Schematic (Milauskas, 2010) 20

2.9 Filament Winding Schematic (Milauskas, 2010) 21

2.10 Hand Lay-Up of Prepreg (Milauskas, 2010) 21

2.11 Automated Tape Placement (Milauskas, 2010) 22

2.12 Resin Transfer Molding (Milauskas, 2010) 23

2.13 Pultrusion Processing (Milauskas, 2010) 23

2.14 Injection Molding (Milauskas, 2010) 24

2.15 Vacuum Bagged Part Place in Autoclave for Cure (Milauskas, 2010)

25

xiii

NO. TITLE PAGE

NUMBER

3.2 Load Calculation Methodology 31

3.3 Composite Calculation Methodology 33

3.4 Fabrication Methodology 33

3.5 Aerodynamic Drag Coefficient (www.ceepo.com, 2010)

37

3.6 Final Design of Upper Arm Wishbone Suspension 38 3.7 Engineering Drawing for Upper Arm Wishbone

Suspension

39

3.8 SAE Car Coordinate System (Gillespie, 1992) 40 3.9 3D Graphic Modelling for Front Right Suspension

Assembly with Point Label

42

3.10 Mould made from box for Lower Arm 48

3.11 Grinded Metallic Ball Joint 49

3.12 Carbon Fiber Woven Roving 49

3.13 Mold Release Wax 50

3.14 Mold Release Wax Being Applied 50

3.15 Hardener Being Added At Ratio 99:1 into Setup Resin

51

3.16 The First 4 Plies Applied To the Mold with Matrix Resin

51

3.17 The Metallic Ball Joint Has Been Positioned 52 3.18 Finished Lay-Up Component Consist Metallic Ball

Joint and Eight (8) Plies of Carbon Fiber

52

3.19 The Component Already Cured 53

3.20 Trimming Process Using Grinder (The Box Will Remove When We Get Necessary Shape after Trimming)

54

3.21 Our Final Product after Trimming Process 54

NO. TITLE PAGE

NUMBER

3.23 Mild Steel Rectangular Have Been Cut Into Needed Dimension

56

3.24 The Jig Members Being Welded According To Specification

56

3.25 50% Complete Jig Construction 57

3.26 Composite Wishbone Assemble Together With Its Testing Jig

57

3.27 Assembled Composite Wishbone Has Been Placed In INSTRON Universal Testing Machine

59

3.28 Buckling Behaviour on Composite Wishbone 59

3.29 Upper Arm Has Been Placed in Lateral Direction 60

3.30 Buckling Behavior in Lateral Direction 60

6.1 Stress – Strain Graph for Composite Wishbone - Upper Arm in Longitudinal Direction

66

6.2 Stress – Strain Graph for Composite Wishbone - Lower Arm in Longitudinal Direction

66

6.3 Stress – Strain Graph for Composite Wishbone - Upper Arm in Lateral Direction

67

6.4 Stress – Strain Graph for Composite Wishbone - Lower Arm in Lateral Direction

67

xv

LIST OF APPENDIX

NO. TITLE PAGE

NUMBER

A Current Design on UTeM Formula Varsity Race Car

75

B Full Result of Suspension Link Calculation 77

C Composite Properties 78

D The Assembly Design of Double Wishbone Suspension Arms

79

E Detail Drawings of Double Wishbone Suspension Arms

80

F LOCTITE Adhesive 81

CHAPTER 1

INTRODUCTION

1.1 Background Study

The objective of this study is to design and develop a racing car suspension system based on composite materials. The main goal is to decrease the weight of suspension but in the same time, it provides strength beyond metallic material.

In recent event, Universiti Teknikal Malaysia Melaka has participated in the Formula Varsity race event and secured second place during the competition. Improvements on the vehicle were later carried out in order to sustain the good performance and achieve better results for similar future races.

Suspension is one of important part in vehicle. The main purpose of suspension is to absorb vibration and impacts come from road profile due to load transfer and extreme manoeuvres. Sneaking into race car world, the suspension will hold the tyres to its maximum area contact with road profile in order to maximize its grip. The suspension design also affects the chamber gain in tyres and further information will explain in Chapter 2.

2

1.2 Problem Statement

The current UTeM racing car used double wishbone suspension arm built from mild steel and it can affect the weight of vehicle. In addition, according to the racing team, they do not have conducted any strength analysis regarding the vehicle in extreme manoeuvre in racing circuit.

Therefore, in order to make new improvement and overcome this problem, a study about racing car suspension has been carry away and it involving composite material. Carbon fiber polymer has proven for it strength beyond the steel and provide less weight. By apply this fact; the study about racing car suspension in composite form has taken place.

1.3 Project Objective

The main purpose of this project is to design and develop the suspension arm for UTeM Formula Style Racing Car using carbon fiber polymer composite.

1.4 Project Scope

This study focuses on new composite racing car suspension. Before composite laminate analysis can be undergo, the analysis on load acting must done following the UTeM 2nd Formula Varsity Regulation and International FSAE Racing Event. Thus, the analysis has taken place.

In short the project scope is listed as follow:

i. To calculate the load acting on the component during operation. ii. To perform composite laminate analysis.

iii. To produce detail design of the component using 3D CAD software. iv. To fabricate the component using carbon fiber-polyester matrix.

1.5 Project Outline

This report on “Design and Development Carbon Fiber Double Wishbone Suspension Arm for UTeM Formula Style Race Car” is divided into several chapters. Chapter 1 introduces the audience to the general background of this research, the problem statement, project objectives, as well as the project scope. Also, it offers an overall view of the project outline.

Chapter 2 is a literature reviews and background study gathered from electronic media, published journals, and books. This chapter will elaborate about this project briefly.

Chapter 3 explains about the methodology used in this project pictured as flow chart along with explanation of every stage process. This chapter also explains the theoretical calculation of load acting on component followed by composite laminate analysis calculation along with the new double wishbone suspension design. The fabrication process along with components fabrication using carbon fiber and polyester matrix as resin including the design of testing jig and its fabrication process will be included in this chapter In addition; the testing procedure also will be explained in this chapter.

Chapter 4 indicates the results of the calculation and compared with actual value (experimental data). This chapter also will discuss on the difference of the value obtained in this project with previous researcher.

4

CHAPTER 2

LITERATURE REVIEW

2.1 Overview Suspension System

The main functions of a vehicle’s suspension systems are to isolate the structure and the occupants from shocks and vibrations generated by the road surface. The suspension systems basically consist of all the elements that provide the connection between the tires and the vehicle body. According to Gillepsie (1992), the primary functions for suspension systems are;

Provide vertical compliance so the wheels can follow the uneven road, isolating the chassis from roughness in the road.

Maintain the wheels in the proper steer and camber attitudes to the road surface.

React to the control forces produced by the tires-longitudinal (acceleration and braking) forces, lateral (cornering) forces, and braking and driving torques.

Resist roll of the chassis.

Keep the tires in contact with the road with minimal load variations

These forces may be in the longitudinal direction such as acceleration and braking forces, in the lateral direction such as cornering forces, and in the vertical direction.

6

2.2 Types of Suspension System

Suspensions basically can be identify into two main groups-non-independent and independent suspensions. Each group carried different functions and therefore, this differentiation will be discussed generally in this chapter.

2.2.1 Non-Independent Suspension System

In non-independent suspension systems (known as solid axle suspension system), wheels are mounted at the ends of a rigid beam so that any movement of one wheel is transmitted to the opposite wheel causing them to steer and camber together.

Solid drive axles are used on the rear of many cars and most trucks and on the front of many four-wheel-drive trucks. Solid beam (non-driven) axles are commonly used on the front of heavy trucks where high load-carrying capacity is required.

Figure 2.1: De Dion Axle Suspension System (Mark Wan, 1998-2000)

2.2.2 Independent Suspension System

In contrast to non-independent suspension system, independent suspensions allow each wheel to move vertically without affecting the opposite wheel. Nearly all passenger cars and light trucks use independent front suspensions, because of the advantages in providing room for the engine and the better resistance to steering vibrations. The independent suspension also has the advantage that it provides inherently higher roll stiffness relative to the vertical spring rate. Further advantages include easy control of the roll centre by choice of the geometry of the control arms, larger suspension deflections, ideal chamber control and greater roll stiffness for a given suspension vertical rate.