Geometric Optimization Of LED Heat Sink For Cooling Of LED Lighting

Full text

Figure

Related documents

To reduce the maximum temperature and increasing the heat flux in copper source microchip cooling system different cross sections of the fins are used without adding the number

HoSung Lee [3] provides his insights into the general approach towards Heat Sink Design with derivations of relations between various parameters like Heat flow

HoSung Lee [3] provides his insights into the general approach towards Heat Sink Design with derivations of relations between various parameters like Heat flow

The result of thermal analysis for proposed design-1 indicates the temperature distribution of Northbridge continuous heat sink the maximum temperature is 100 o C

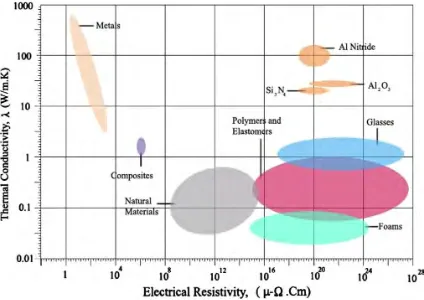

Plate Pin-fin heat sinks obtain higher heat transfer rate, lower pressure drop and low thermal resistance than the finned or unfinned channel heat sink.. Copper and Aluminium are

In the present work, based on the theory of heat transfer enhancement, a film cooling method with chemical sink is proposed to improve the film cooling effectiveness of gas

The modern design incorporates the heat sink directly into the unit for heat transfer to prolong LED life.. This reliable unit has a 50,000 hour rated life, significantly

It can be observed from the figure that using a heat sink of optimum design can help in reducing the temperature of PV panel thus affecting the