Investigation of influence of tool rake angle in single point diamond turning of silicon

Full text

Figure

Related documents

Hence in this research work, apart from the cutting parameters like cutting speed, feed rate and depth of cut, the cutting tool geometry like nose radius, rake angle and

The Modal and Harmonic analysis gives some useful results in relation to change in rake ANGLE and FREQUENCIES for different work material while machining with

The predicted deflections in axial, radial, tangential directions by FEA are compared with Beam model results at different side cutting edge angle and increasing

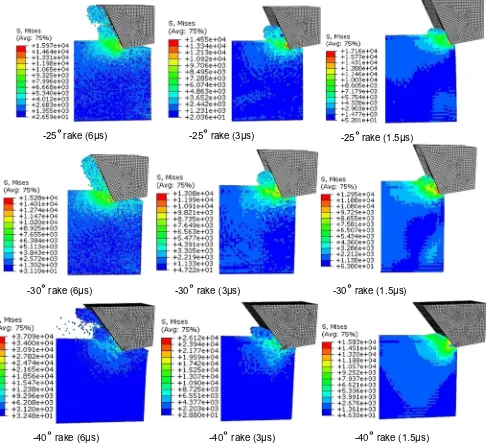

have studied the finite element analysis of the influence of cutting tool geometrical parameters: nose radius, rake angle and clearance angle – on the some evaluation

In this work, deflection of a T-42 CT H.S.S single point cutting tool is investigated by varying rake angle, cutting feed and tool extension length during turning operation

The research indicate that the cutting forces are directly depends on the cutting parameters like cutting speed, feed rate, depth of cut, work piece material, tool

1. Type of the material being cut: A harder material like cast iron may be machined by smaller rake angle than that required by soft material like mild steel or aluminum. Type

In plunging cut, due to full tool edge contact, the frictional resistance superimposes the effect of contact pressure reduction and hence the cutting forces continuously