Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

11-3-2009

Investigation of tetrahedron elements using

automatic meshing in finite element analysis

Gordon Bae-Ji Tseng

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu.

Recommended Citation

Investigation of Tetrahedron Elements

Using Automatic Meshing in

Finite Element Analysis

Gordon Bae-Ji Tseng

A Thesis Sllmmitted in partial fulfillment

of the

Requirments for the degree of

Master of Science

in

Mechanical Engineering

Rochester Institute of Technology

Rochester, New York

August 1992

Approved by:

Dr. Joseph S. Torok (Advisor)

Dr. Rober Hefner

Dr. Mark Kempski

Acknowledgment

I

dedicate

this

workto

my Mother

andFather,

whohave

providedsupport and encouragement

to

allowmeto

accomplishthis

achievement.I

wouldlike

to

thank

Dr. Joseph

Torok,

my

advisor,

for

guidance ,valuable suggestions and

for

alwaysbeing

availablefor

assistance.He is

a great professor andfriend.

I

wouldlike

to thank

allthe

members ofthe

RIT

Mechanical

Engineering

Department

whohave

been very helpful working

with methrough

the

schoolyears.

Thesis

Outline

Abstract

Table

ofContents

Chapter

1.

Introduction

Geometric

Modelers

1)

Wire

frame

modelers2)

Surface

modelers3)

Solid

modelersConstructive Solid

Geometry

(CSG)

Boundary

Representation

(bRep)

Cell

Decomposition's

andSpatial

Enumeration

Approaches

to

mesh generationLaplacian

methodMapping

methodsAutomatic

meshgeneration1. Point

placementfollowed

by

domain

triangulation

2.

Mesh

generationbased

on sub-domain removal3. Mesh

generationby

recursivesubdividing

4.

Spatial

decomposition followed

by

sub-domain meshControl

ofthe

elementdistribution

Chapter 2.

Test Problems

Static State

Modal

analysisChapter 3.

Analytical

Solutions

Cantilever

(square)

beam

Cantilever

(round)

beam

Square

flat

plate all edgesfixed

Circular

flat

plate with a edgefixed

Chapter 4.

FEA

Results

Cantilever

(square)

beam

Cantilever

(round)

beam

Square

flat

plate all edgesfixed

Circular flat

plate with a edgefixed

Chapter

5.

Discussion

ofResults

Cantilever

(square)

beam

Cantilever

(round)

beam

Square

flat

plate all edgesfixed

Circular

flat

plate with aedgefixed

Chapter

6.

Conclusion

Chapter 7.

Summary

Abstract

This investigation

examinesthe

quality

offinite

element analysis(FEA)

resultsbased

onthe

use oftetrahedron

elements.For

some classes of problems analyzedby

the

finite

element method(FEM),

the

use of various polynomial ordertetrahedra

is

consideredquite acceptable.However,

in

other classes ofproblems,

particularly

stressanalysis,

usershave

astrong

bias

againstthese types

of elements.Various

case studiesare

performed,

comparing

resultsbased

on severaltypes

ofthree-dimensional

elements.Page11

Table

ofContents

List

ofFigures

Pg-

iv

List

ofTables

Pg.

ix

Chapter 1.

Introduction

Pg-

1

Chapter 2.

Test

Problems

Pg-

21

Chapter 3.

Analytical Solutions

Pg.

23

Chapter 4.

FEA Results

Pg-

29

Chapter

5.

Discussion

ofResults

Pg-

314

Chapter 6.

Conclusion

Pg-

342

Chapter

7.

Summary

Pg-

371

List

ofFigures

Figure 1.1 Wire

frame

representationFigure 1.2 Constructive Solid

Geometry

modelerFigure 1.3

Boundary

representation modelerFigure 1.4

3-dimensional

octree modelerFigure 1.5 A

3-dimensional

mapping

mesh generationFigure 1.6 Dirichlet

tessellation

andDelaunay

triangulationFigure 1.7

Watson's

Algorithm

Figure 1.8 A way

to

define

the

node pointsin

spaceFigure 1.9 The

distorted

Delaunay

tetrahedron,

"silver"

Figure 1.10

Surrounding

algorithmFigure 1.11 The flow

chart ofthe

3-dimensional

surrounding

algorithm

Figure 1.12 The

"Ghost"pointfor

boundary

definition

Figure 1.13 Subdivision

of a multilateraldomain

Figure

1.14.

Nodal

levels

Figure 1.15

Element

removal operatorsFigure 1.16

Cutting

concave polygonusing splitting line

Figure 1.17 chopping

offlayers

yield elementsFigure

1.18

The

quadtree and modified quadtree representationsFigure

1.19

Examples

of cut octants usedin

the

modified octree algorithmFigure 1.20 A

overview of octree/Delaunay

triangulation

methodFigure

2.1 Cantilever

(square)

beam

Figure

2.2 Cantilever

(round)

beam

Figure

2.3 Square flat

plate all edgesfixed

Figure

2.4 Circular flat

plate with a edgefixed

Figure

3.1 Cantilever

(square)

beam

Figure

3.2 Cantilever

(round)

beam

Figure

3.3

Square

flat

plate all edgesfixed

Figure

3.4

Mode

1

Figure

3.5

Mode

2&3

Figure

3.6

Mode

4&5

Figure

3.7

Mode

6

Figure

3.8 Circular flat

plate with a edgefixed

Figure

3.9

Mode

1

Figure

3.10

Mode

2&3

Figure 3.11 Mode 4&5

Figure 3.12 Mode

6

Figure

4.1 Type

of elementsFigure

4.2

Maximum

displacements

w/

40

LQ

elements.Figure

4.3

Maximum

displacements

w/

320

LQ

elements.Figure

4.4

Maximum

displacements

w/

40

Figure

4.5

Maximum

displacements

w/

320

Page

iv

Figure 4.6 Maximum

displacements

w/

71 LT

elements.Figure 4.7 Maximum

displacements

w/

532 LT

elements.Figure 4.8 Maximum

displacements

w/

703 LT

elements.Figure 4.9 Maximum

displacements

w/

4095 LT

elements.Figure 4.10 Maximum

displacements

w/

7947

LT

elements.Figure 4.11 Maximum

displacements

w/

71 QT

elements.Figure 4.12 Maximum

displacements

w/

532

QT

elements.Figure 4.13 Maximum

displacements

w/

703 QT

elements.Figure 4.14 Maximum displacements

w/

65

LQ

elements.Figure 4.15 Maximum

displacements

w/

221

LQ

elements.Figure 4.16 Maximum displacements

w/

432

LQ

elements.Figure 4.17 Maximum displacements

w/

703

LQ

elements.Figure 4.18 Maximum displacements

w/

48

Figure 4.19

Maximum

displacements

w/

192

Figure 4.20 Maximum displacements

w/ 77

LT

elements.Figure 4.21

Maximum

displacements

w/

328

LT

elements.Figure

4.22 Maximum

displacements

w/

659

LT

elements.Figure 4.23

Maximum

displacements

w/

1937 LT

elements.Figure 4.24 Maximum

displacements

w/

5977 LT

elements.Figure 4.25 Maximum

displacements

w/

77

QT

elements.Figure

4.26

Maximum

displacements

w/

328 QT

elements.Figure 4.27-4.32

Square

flat

plate model and mode1-5

mode shapew/

25

LQ

elements.Figure

4.33-4.38 Square

flat

plate model and mode1-5

mode shapew/

100

LQ

elements.Figure

4.39-4.44 Square

flat

plate model and mode1-5

mode shapew/

225

LQ

elements.Figure 4.45-4.50 Square flat

plate model and mode1-5

mode shapew/

400

LQ

elements.Figure

4.51-4.56 Square flat

plate model and mode1-5

mode shapew/

2 5

Figure

4.57-4.62 Square flat

plate model and mode1-5

mode shapew/

100

Figure

4.63-4.68 Square flat

plate model and mode1-5

mode shapew/

225

Figure 4.69-4.74

Square

flat

platemodel and mode1-5

mode shapew/

176

LT

elements.Figure

4.75-4.80 Square flat

plate model and mode1-5

mode shapew/

626 LT

elements.Figure

4.81-4.86 Square

flat

plate model and mode1-5

mode shapew/

2567 LT

elements.Figure 4.87-4.92 Square flat

plate model andmode1-5

mode shapew/

19320

LT

elements.Figure

4.93-4.98 Square flat

platemodel and mode1-5

mode shapew/

Figure 4.99-4.104

Square

flat

plate model and mode1-5

mode shapew/

626 QT

elements.Figure 4.105-4.110 Square

flat

plate model and mode1-5

mode shapew/

2567 QT

elements.Figure 4.111-4.117 Circular flat

plate model and mode1-6

mode shapew/

20

LQ

elements.Figure 4.118-4.124 Circular flat

plate model and mode1-6

mode shapew/

40

LQ

elements.Figure 4.125-4.131 Circular flat

plate model and mode1-6

mode shapew/

100

LQ

elements.Figure 4.132-4.138 Circular flat

plate model and mode1-6

mode shapew/

140

LQ

elements.Figure 4.139-4.145 Circular flat

plate model andmode1-6

mode shapew/

300

LQ

elements.Figure 4.146-4.152 Circular flat

plate model andmode1-6

mode shapew/

600

LQ

elements.Figure 4.153-4.159 Circular flat

plate model and mode1-6

mode shapew/

20

Figure

4.160-4.166

Circular

flat

plate model and mode1-6

mode shapew/

40

Figure

4.167-4.173 Circular

flat

plate model and mode1-6

mode shapew/

80

Figure

174-4.180 Circular flat

plate model and mode1-6

mode shapew/

140

Figure 4.181-4.187

Circular flat

plate model and mode1-6

mode shapew/

600

Figure 4.188-4.194

Circular

flat

plate model and mode1-6

mode shapew/

141 LT

elements.Figure

4.195-4.201

Circular flat

plate model and mode1-6

mode shapew/

209

LT

elements.Figure

4.202-4.208 Circular flat

plate model and mode1-6

mode shapew/

729 LT

elements.Figure 4.209-4.215 Circular

flat

plate model and mode1-6

mode shapew/

2300

LT

elements.Figure 4.216-4.222

Circular

flat

plate model and mode1-6

mode shapew/

16088

LT

elements.Figure

4.223-4.229 Circular flat

plate model and mode1-6

mode shapew/

141

QT

elements.Figure

4.230-4.236 Circular

flat

plate model and mode1-6

mode shapew/

209 QT

elements.Figure

4.237-4.244

Circular

flat

plate model and mode1-6

mode shapew/

729 QT

elements.Figure 4.245-4.251

Circular

flat

plate model andmode1-6

mode shapew/

2300 QT

elements.Page vi

Figure 4.252-4.258

Circular

flat

plate model and mode1-6

mode shape w/3055QT

elements.Figure 4.259-4.265 Circular

flat

plate model and mode1-6

mode shapew/

11021 QT

elements.Figure 6.6 Type

ofelementsFigure 5.1 Cantilever

(square)

beam

#

of elements vs.%

of errorFigure 5.2 Cantilever

(square)

beam

#

of nodes vs.%

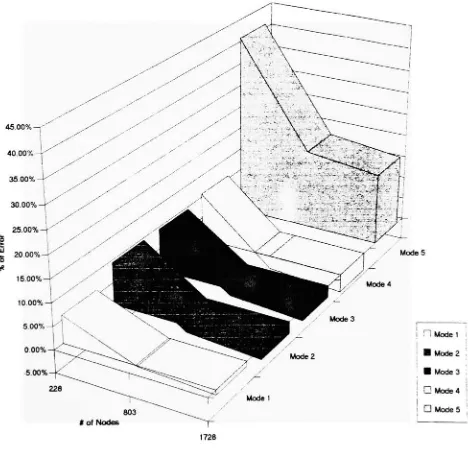

of errorFigure 5.3

Cantilever

(round)

beam

#

of elements vs.%

oferrorFigure 5.4 Cantilever

(round)

beam

#

ofnodes vs.%

of errorFigure 5.5

LQ

element#

of elements vs.%

of errorFigure 5.6

LQ

element#

of nodes vs.%

oferrorFigure 5.7

#

of elements vs.%

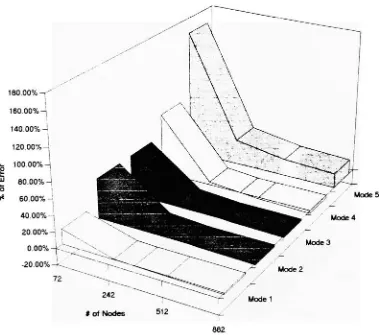

of errorFigure 5.8

#

ofnodes vs.%

of errorFigure 5.9 LT

element#

of elements vs.%

of errorFigure 5.10

LT

element#

of nodes vs.%

of errorFigure

5.11

QT

element#

of elements vs.%

of errorFigure 5.12 QT

element#

of nodes vs.%

of errorFigure

5.13

LQ

element#

of elements vs.%

of errorFigure 5.14

LQ

element#

of nodes vs.%

of errorFigure

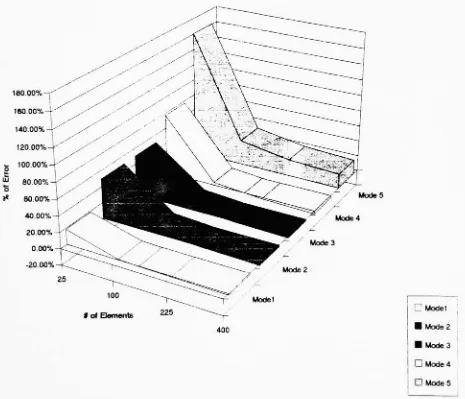

5.15

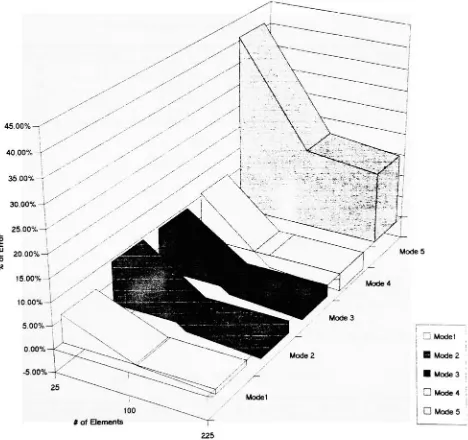

#

of elements vs.%

of errorFigure

5.16

#

of nodes vs.%

of errorFigure 5.17

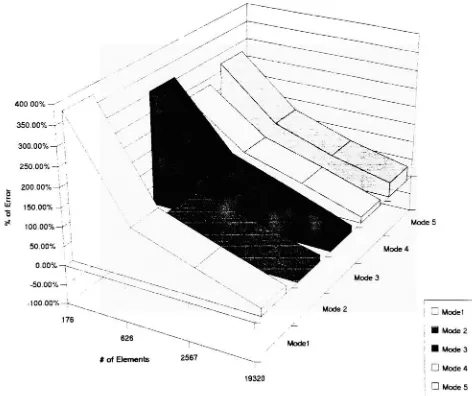

LT

element#

of elements vs.%

of errorFigure 5.18

LT

element#

of nodes vs.%

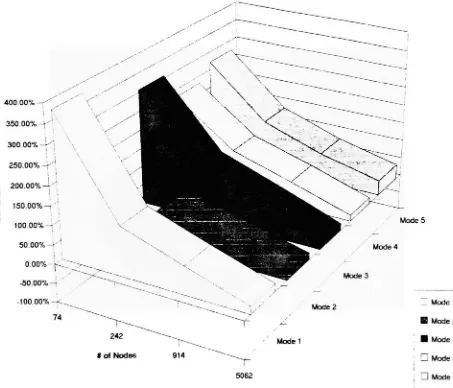

of errorFigure 5.19 QT

element#

of elements vs.%

of errorFigure

5.20 QT

element#

of nodes vs.%

of errorFigure

6.1

Displacement

of cantilever(square)beam

withLQ

elementsFigure

6.2

Displacement

of cantilever(square)beam

with wedgeelements

Figure

6.3

Displacement

of cantilever(square)beam

with wedge elementsFigure

6.4

Displacement

of cantilever(square)beam

with wedge elementsFigure

6.5

Displacement

of cantilever(square)beam

with wedge elementsFigure

6.6

Type

of elementsFigure

6.7

Mode

1

of circular plate#

of elements vs.%

oferrorFigure

6.8

Mode

1

of circular plate#

of nodes vs.%

oferrorFigure

6.9

Mode

2

of circular plate#

of elementsvs.%

of errorFigure

6.10

Mode

2

of circular plate#

of nodes vs.%

oferrorFigure 6.11

Mode

3

of circular plate#

of elements vs.%

of errorFigure 6.12

Mode

3

of circular plate#

of nodes vs.%

of errorFigure

6.13

Mode

4

of circular plate#

ofelements vs.%

of errorFigure

6.14 Mode 4

of circular plate#

ofnodes vs.%

of errorFigure

6.15 Mode 5

of circular plate#

of elements vs.%

of errorFigure 6.17 Mode 6

ofcircular

plate#

of elementsvs.%

of errorFigure 6.18 Mode 6

of circular plate#

of nodes vs.%

oferrorFigure 7.1

Housing

FEA

results withQT

elementsFigure 7.2

Housing

FEA

results withQT

elementsFigure 7.3

Housing

FEA

results withQT

elementsFigure 7.4

Housing

FEA

results withQT

elementsFigure 7.5

Housing

FEA

results withLT

elementsFigure 7.6

Housing

FEA

resultswithLT

elementsFigure 7.7

Housing

FEA

resultswithLT

elementsFigure 7.8

Housing

FEA

resultswithLT

elementsPageviii

List

ofTables

Table 4.1

#

of elements&

nodesvs.%

of errorTable 4.2 #

ofelements&

nodesvs.%

of errorTable 4.3

#

of elements&

nodesvs.96

of errorTable 4.4 #

of elements&

nodes vs.%

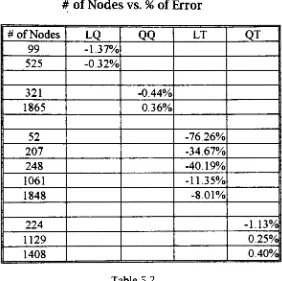

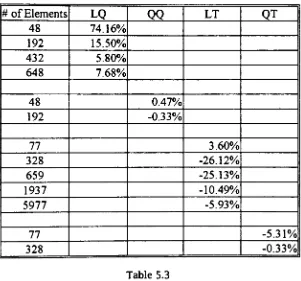

of errorTable 5.1

#

ofelementsvs.%

of errorTable 5.2 #

of nodes vs.%

of errorTable 5.3 #

of elementsvs.%

of errorTable 5.4

#

of nodesvs.%

oferrorTable 5.5

#

of elements&

nodes vs.%

of errorTable 5.6 #

of elements&

nodes vs.%

of errorTable 5.7

#

of elements&

nodes vs.%

of errorTable 5.8

#

of elements&

nodesvs.%

of errorTable 5.9

#

of elements&

nodes vs.%

of errorTable 5.10

#

of elements&

nodes vs.%

of errorTable

5.11 #

of elements&

nodes vs.%

of errorTable 5.12

#

of elements&

nodes vs.%

of errorTable 6.1

Mode

1

of circular plate#

of elements vs.%

of errorTable

6.2

Mode

1

of circular plate#

of nodes vs.%

of errorTable

6.3

Mode

2

of circular plate#

of elements vs.%

of errorTable

6.4

Mode 2

of circular plate#

of nodes vs.%

of errorTable 6.5

Mode

3

of circular plate#

of elements vs.%

of errorTable 6.6

Mode

3

of circular plate#

of nodes vs.%

of errorTable 6.7

Mode 4

of circular plate#

of elements vs.%

of errorTable

6.8

Mode 4

of circular plate#

of nodes vs.%

of errorTable

6.9 Mode 5

of circular plate#

of elements vs.%

of errorChapter

1.

Introduction

The

finite

element methodis

one ofthe

numerical techniques usedfor

the

approximate solution ofengineering

problems.The

proceduresfor FEA

canbe divided

into

three

stages:1.

Pre-processor

2. Processor

3. Post-processor

The Pre-processor

is

the

stageto

makegeometry

(model),

createelements

(mesh)

andapply

the

boundary

conditions.The

processoris

a numerical solver which solvesthe

FEA

model.The

post-processoris

atool

which allowsthe

userto

seethe

results.Once

the

FEA

modelis

finished,

the

user canonly

sendit

to the

solver(processor)

and checkthe

result(post-processor)

afterthat.

The

userhas

no control atthe

processor andthe

post processor stages.The

most critical stageis

the

pre-processor.At

this

stage,

the

user mustfully

understandthe

problem and use allthe tools

which are providedby

the

FEA

program.A

single mistake canadversely

effectthe

FEA

result.If

the

userfully

understandsthe

problem,

the

only

thing

that

canimpede

the

results arethe tools

of pre-processor which are providedby

the

program.Finite

element solvers can give solutionsto

rather complexproblems and

have

traditionally

been

usedfor

analysis ofcomponents with complicated shapes andboundary

conditions(loads

andconstrains).Various

solvers exist which will givereasonably

accurate and reliable resultsfor

these

problems.All

the

finite

element computer packages require aninput

of afinite

elementmesh,

loads,

boundary

conditions(constraints)

and material properties.The

finite

element meshdescribes

to the program, the

discrete geometry

ofthe

domain

to

be

analyzed.Communicating

this

meshto the

finite

element solverhas normally been

done

manually

andthus

has been

time-consuming

and error-prone.The

usefulness ofgeometric modelersfor finite

element mesh generationis readily

apparent.Since

afinite

element meshcommunicates

the

geometry

ofthe

domain

to

be

analyzed, it

seems appropriatethat

it

couldbe

constructedfrom

the

geometry

ofthe

domain in

question.The geometry

of parts and assemblies are stored on computersusing

programs calledgeometric modelers[1,2].

Page

1

Geometric

modelers

The

geometric modelerscanbe

classifiedinto

varioustypes

according

to the

way

they

storethe

geometry

of a object.1)

Wire

frame

modelersThe

objectis

representedby

its

edges.Imagine putting

a wirefor

every

edgein

the

object.The resulting

representationis

a wireframe. No

information is

presentregarding

the

surface.Because

it

does

notcompletely

represent an object with asurface,

it

couldlead

to

an ambiguousobject,

a exampleis

givenin

Figure 1.1.

^^

y

/

/

^s

/s

Toptobottom? Fronttoback?

&

w

Wireframe

Figure 1.1 Wire

frame

representation2)

Surface

modelersThe

objectmay

be

representedby

its

surfaces, curved surfaces canbe

represented and objects are unambiguous.There

is

noinformation

regarding

whatis inside

or outsidethe

object.Thus

it is

not possibleto

computethe

volume or other properties ofthe

object.3)

Solid

modelersThe

objectmay

be

representedin

various waysbut

it is

defined

unambiguously

andit

shouldbe

possibleto

computevolume, mass,

etc.There is

information

regarding

the

inside

and outside ofthe

object.In

ambiguity.

Most

solid modelers storethe

geometry

data in

away

that

canbe

classifiedin

one ofthe three

categories ortheir

combinations.Constructive

Solid

Geometry

(CSG)

The

objectis

built

by

performing

Boolean

operations(union,

difference,

andintersection)

onsimple pre-defined objects calledprimitives,

such asblocks,

cones, cylinders,

tube,

spheres,

etc.The

actualboundary

ofthe

objectis usually

notstoredbut

canbe

computed atany

time.

An

exampleis

givenin Figure 1.2.

Figure 1.2

Constructive Solid

Geometry

modelerBoundary

Representation

(bRep)

The

boundary

ofthe

objectis

storedin

whatis

calledboundary

file

in

a structured manner suchthat

it

is

possibleto

identify

the

regionsinside

or outsidethe

object.The

boundary

ofthe

boundary

ofthe

body

willusually

be

an ordered set ofsurfaces,

faces,

loops

edges and vertices.An

exampleis

givenin Figure 1.3.

Cell

Decomposition's

andSpatial Enumeration

The

objectis

representedby

decomposing

it into

abunch

ofcells,

cubes or

blocks,

which canbe

thought

of asbuilding

up

the

object.The

domain

ofthe

objectsis

representedby

atree

structure,

quadtreein

2-Page

3

dimension

and octreein

3-dimension,

with status ofthe

cells(partial,

full

andempty),

seeFigure 1.4.

for

example.The

boundary

of an objectcan

be

approximatedby

the

cells.Object

Figure

1.3

Boundary

representation modelerThe

early

systemsthat

simply

computerizedthe

drafting

process

do

not contain allthe

geometricinformation

neededto

allow applicationsto

operate automatically.Therefore

,the

more recent solidmodeling

systemsemploy

complete and unique geometricrepresentations.

These

systems contains allthe

geometricinformation

neededto

allowany

finite

element mesh generationtechniques to

automated.Z

1

o

0

Figure

1.4 3-dimensional

octree modelerapplications

to

operate automatically.Therefore

,the

more recent solidmodeling

systemsemploy

complete and uniquegeometricrepresentations.

These

systems contain allthe

geometricinformation

needed

to

allowany

finite

element meshgenerationtechnique to

be

automated.

Approaches

to

mesh

generationThe

problemofmeshgeneration[3]

is

to

convertthe

geometry

from

one ofthe

geometric modelersto

aform

understoodby

afinite

element

solver, in

a manner as automatic as possible.The

increase

in

the

level

of automationwill allowthe

finite

element methodto

be

usedby

engineers

to

provide reliable analysis resultsto their

problem.There

are various popular ways ofgenerating

these

meshes andthey

canbe

classified

into

the

following

categories.1. Laplacian method,

2.

mapping

methods,

3.

point placementfollowed

by

triangulation,

4.

removal ofindividual sub-domain,

5.

recursive subdivision ofthe

domain,

and6.

spatialdecomposition followed

by

subdomain

meshing.An

automatic mesh generatoris

an systematic procedure capableof

producing

a validfinite

element meshin

adomain

ofarbitrary

complexity

given noinput

pastthe

computerized geometricrepresentation of

the

domain

to

be

meshed.The Laplacian

method andmapping

method are notthe

real automatic mesh generationtechniques.

But

both

two

methods arewidely

used(especially

for

quadratic

brick

(Hex)

element orlinear brick

element)

in

the

finite

element method.Laplacian Method

A

set ofsimultaneous nonlinear equationsfor

the

position vectorsof

the

interior

nodes with respectto the

neighboring

nodesis

solvedusing

iterative

techniques.A starting

gridis

required.The

laplacian

methoditeratively

replacesthe

interior

nodePj

Page 5

NJ

Pi

="Pj

Eq. 1.17=1 ;'*i

where

Nj

is

the

number of nodesto

whichPj

is

connected andPj

arethe

nodepoints of

the

connectednodes.The

processhas

proven usefulin

mesh generation algorithms and smoothes

the

meshinto

one withbetter

proportioned elements.

This may

be

usedto

smooth meshes createdusing

other methods.Mapping

Methods

A

function

is

usedto

map

the

givengeometry

into

a simplegeometry,

usually

a squarein

two

dimensions

and a cubein

three

dimensions.

This

simplegeometry is

meshed and allthe

node points aremapped

back

to the

originalgeometry.Various

mapping functions have

been

used, the trans-finite

mapping

are mostcommonly

usedfor

mappedmesh generation.

Mapping

methodsdo

impose

a number of restrictions onthe

geometry

ofthe

object.When

mapping

methods areused,

the

geometry

ofthe

objectis

constructedby

gluing

together the

individual,

fixed

topology,

mesh patches(see Figure 1.5).

Therefore,

the

geometric representationis

explicitly defined

in

terms

of meshpatches.The

useris

responsiblefor

defining

a valid set of meshpatches,

whichimplicitly

define

the

geometric representation andexplicitly

providethe

geometry necessary for meshing

to

occur.The

mesh generatorsare,

therefore,

not concerned withthe

actualgeometry

a.

Body

coordinateb. Mapped

on a unit cubec.

Mesh

generatedof

the

object.This is

however,

notthe

casefor

an automatic meshgenerator which

is

given a complete geometricrepresentationofthe

domain

ofinterest

andis

responsiblefor

decomposing

it

into

a valid set of elements.This

paperwill notdiscuss

this

otherthan to

say

that the

mapping

techniques

have been

found

to

be

ratherinadequate

for

automatically generating

meshes onarbitrary

complex geometry.Automatic Mesh Generation

Techniques

The

other mesh generation methods arefully

automatic mesh generationprocedures,

which arefully

3-dimensional

orthe

extensionfrom

2-dimensional

to

3-dimensional

mesh generation appears possible.Currently,

these

mesh generationtechniques

only

use tetrahedron elementsin

3-dimension;

no othertype

of elements are available.1. Point

placementfollowed

by

domain

triangulation

This

type

of mesh generatorinvolves

two

independent

process[6,7,8,9].

First,

node points mustbe

inserted

within and onthe

boundary

of

the

structureto

be

meshed.Secondly,

the

node points areautomatically

triangulated to

form

a network of well-proportioned elements.The

triangulated

algorithmsfunction

in

both

2- and3-dimensional

settingsproducing

meshes oftriangular

andtetrahedral

elements,

respectively.These

two

algorithmsfunction

independently

of eachother,

sothat there

aremany

waysto triangulate

the

elements.For

ease of

exposition,

wefirst discuss

a meshtriangulation

algorithm.Recent

efforts[6,10,11,12]

employ

the

properties ofthe

geometricconstructs of

Dirichlet

tessellation

and moreimportantly

for

meshgeneration, the

Delaunay

triangulation

of given set of points, considerfirst

the

2-dimensional

case.Let

Pj,

P2,...,Pn

be distinct

pointsin

the

plane,

anddefine

the

setsVi(

l<i<N,

whereVr{X:

IX-Pil

<IX-Pjl

for

allj*i}

Eq. 1.2

where

|.|

denotes

Euclidean

distance

in

the

plane.Vj

represents aregion ofthe

planewhose points are nearerto

nodePj

than to

any

other nodes.Thus

Vj

is

an open convex polygon(usually

called aVoronoi

polygon)

whoseboundaries

are portions ofthe

perpendicularbisectors

ofthe

lines

joining

nodePj

to

nodePj

when%

andVj

are contiguous.The

collection of

Voronoi

polygonsis

calledthe

Dirichlet

tessellation.

In

general,

a vertex of aVoronoi

polygonis

sharedby

two

other polygons soPage

7

that

connecting

the

three

generating

points associated with suchadjacent polygons

form

atriangle,

say T^.

This

set oftriangles

n_}

is

calledthe

Delaunay

Triangulation. See

Figure

1.6

for

example.Figure 1.6 Dirichlettessellationand

Delaunay

triangulationThe

construct canbe

shownto

be

atriangulation

ofthe

convexhull

ofthe

node points.An

important

property

of2-dimensional

Delaunay

Triangulation

which makesit

suitablefor

use as afinite

elementthat

its

triangles

are as close or equilateral as possiblefor

the

given set ofnodes.Consequently,

ill-conditioned

andthin triangles

are avoided whenever possible.There

aremany

approachesto the

construction of a

Delaunay

triangulation.

A currently

popular approachis

a version proposedby

Watson[8].

In

two

dimensions,

Watson's

algorithmturns

uponthe

simpleobservation

that three

given node points willform

aDelaunay

triangle

if

and

only

if

the

circumdiskdefined

by

these

nodes contains no other node pointsin

its interior.

The

algorithmis

initialized

by

calculating

the

coordinates ofthree

nodepoints whichform

atriangle

Tq

that

surrounds all

the

node pointsto

be

inserted. The

circumcentrecoordinates and circumradius of

the

circumcircledefined

by

T0

are also calculated and recorded.The

node points arethen

introduced

one at atime.

The

algorithm operatesby

maintaining

alist

oftriplets

of node points which represent completedDelaunay

triangles.

Associated

with each suchtriangles

arethe

coordinates ofits

circumcentre andcircumradius.

For

each new nodepointentered,

a searchis

made ofall currenttriangles to

identify

those

whose circumdisks containthe

new point.For

suchdisks,

the

associatedtriangles

areflagged

to

indicate

removal.

As

shownin Figure

1.7,

the

union of all suchtriangles

forms

be

shownthat

nopreviously inserted

nodeis

containedin

the

interior

ofthe

polygon andthat

eachboundary

node ofthe

polygonmay

be

connected

to the

new nodeby

astraightline

lying

entirely

withinthe

polygon.Thus,

a newtriangulation

ofthe

region enclosedby

the

polygonis

formed.

Repeated

use ofthis

insertion

algorithm permits all nodepoints

to

be

entered,

while ensuresthat

at eachstep

the

triangulation retainsits

Delaunay

properties.a.

New

pointinsertion

b.

Element deletion

c.New

mesh generatedFigure 1.7 Watson's Algorithm

In

three

dimensions,

Watson's Algorithm

starts with atetrahedron

To

containing

all pointsto

be

inserted,

and newinternal

tetrahedron

areformed

asthe

points are entered one at atime.

At

atypical

stage ofthe

process,

a new pointis

tested to

determine

which circumspheres ofthe

existing

tetrahedron

containsthe

point.The

associatedtetrahedra

areremoved,

leaving

aninsertion

polyhedroncontaining

the

new point.Edges connecting

the

new pointto

alltriangular

faces

ofthe

surface ofthe

insertion

polyhedron arecreated,

defining

tetrahedral

whichfill

the

insertion

polyhedron.Combining

these

withthe

tetrahedral

outsidethe

insertion

polyhedron produces a newDelaunay

triangulation

whichcontains

the

newly

added point.There

are a number of waysthat

node points canbe

inserted

within

the

domain. For

instance,

one ofthese

methods usedin

[6]

is

to

cut planesthrough the structure,

say P1,P2,...,Pn. It

is

within each ofthese

cross-sectionsthat

nodepoints willbe defined.

Figure

1.8

illustrates

the

stepsto

define

the

node pointsin

a space.In

summary

,node points are

defined

interactively

aplane-at-a-time.Within

eachplane, the

userhas

control overlocal

nodedensities.

It is

possibleto

automatethis

nodeinsertion

processfurther.

Page

9

Figure

1.8

A waytodefine

thenodepointsinspaceAlthough

Delaunay

triangulation

performsvery

wellin

two

dimensions,

several problems exist withWatson's

approachin 3-D.

The

first

oneis

the

existence ofdegenerate

cases.These

occurin

practicewhen a

newly inserted

node appearsto

he

onthe

surface of acircumsphere associated with some

existing

tetrahedron.The

problembecomes

apparent wheneverthe

distance from

anewly

enterednodalpoint

to

anexisting

circumsphereis less

than

e,

where eis

the

expectedaccumulated computer

truncation

error.This in

turn

producesstructural

inconsistencies in

the

triangulation,

that

is

overlapping

tetrahedral

orgap

in

the

mesh.Delaunay

tedrahdron

circumsphere

Figure 1.9 The

distorted

Delaunay

tetrahedron,

"silver"Another

serious problem which arisesin

the three

dimensions,

and which also requires modification of

the

Delaunay Triangulation,

occurs with

the

creation oftetrahedron

we call"silver".

In

this

case(see

Figure

1.9),

"silver"

will

defines

abadly

distorted

Delaunay

tetrahedron

made

arbitrary

small.Therefore,

these

methods which useDelaunay

Triangulation

needchecking

criterionto

eliminatethose

ill-shaped

elements after

the

mesh elementshave been

generated.i

-_--->

4.1

!

Figure

1.10

Surrounding

algorithmOther

rule-based procedures oftriangulation

have been developed

[7,8].

For

instance,

in

two

dimensions,

a methodbinges

onthe

principle offully

surrounded points.Starting

with node1,

each nodeis

surrounded

in

turn

withtriangular

elements.When

a nodeis

being

surrounded,

newtriangles

areonly formed

with nodes ofhigher

node number whichis

registeredby

a specialscanning

procedure.This

automatically

ensuresthat

triangles

do

not overlap.The

process startsby

selecting

the

nearestpoint

to

node1

andthus

estabkshing

a sidelj

wherej

is

the

nodenumber of

the

nearest point.When surrounding

another pointi,

the

first

side

is

establishedonly

afterchecking

whetheri is

already

part of anexisting

triangle.If

this

is

the

case,

the

existing

triangle

is

usedto

provide

this

starting

side.The

sideij

is

then

usedto

seek a nodek

suchthat the

anglei-k-j

is

maximum andi-j-k is

an anti clockwise sequence.This

new pointk

becomes

j

andthe

processis

repeated and so on.If

a node1

is

found

suchthat

triangle

ikl already

existsthis

routineis

omitted and

1

becomes

the

new pointi.

The

process stopswhen atriangle

is

obtainedcontaining

the

sidefrom

whichthe

processbegan

and

the

pointis

thus

completely

surrounded(see Figure

1.10

for

detail.)

The

extensionto

3-dimension

couldbe in

[9].

In

this

approach,

the

surrounding

a given point withtriangular

elementis

replaced withsurrounding

aline between

two

points with elements andthen

move onto

anotherline

untilthe

meshis

complete.A

flow

chart ofthis

routineis

shown

in

Figure 1.11.

Page

llSTART

Determingtheline

tobesurrounded[1-2]

Determingthebasic

triangle[1-2-3]

<r

Lookingfortheoptimum point[4]andformingthe the tetrahedron[1-2-3-4]

>1

|3]=[4]

End

=Surroundingangle

Figure 1.11 The flow chart ofthe

3-dimensional

surroundingalgorithmThe

nodeinsertion

ofthe

surrounding

algorithm mentioned above usesa

slightly

different

scheme.The

node point numberis

recordedin

sequence

by

a specificscanning

procedure.When

allthe

"true" node pointshave

been

recorded, the

number ofthe

last

nodeis

noted andthen

startto

record"ghost"

points outside

the

boundaries

ofthe

structure,

seeFigure 1.12

The

use of"ghost"

points removes

the

needfor

the

identification

ofnodes on externalboundaries.

Ghost

points mustbe

placed so

that

each element side whichis

on an externalboundary

canform

atriangle

with a ghost point.Otherwise,

the

mesh generationprogram will

form

atriangle

whichdoes

not exist onthe

structurebetween

the

boundary

node points.These

"ghost"

triangles

willbe

removed after

the

mesheshave

been

generated.Though

these

algorithms useproperly

constructed set of rulescapable of

producing

a well-conditioned meshwithin adomain,

they

require extensivesearching

andlarge

number ofchecks,

suchasdegenerate

andoverlapping

cases,

many

morethan

other meshtriangulation

rulesthat

wouldinsure

the

elements generatedsatisfy

a givenshape criterion.Ghost

points

/

Figure

1.12The

"Ghost"pointfor

boundary

definition

2. Mesh

generationbased

onSub-domain

removalAutomatic

mesh generation proceduresin

this

method[13,14,15,

16]

operateby

removing

individual

piecesfrom

the

domain

one at atime

until

the

domain

is

reducedto

oneremaining

acceptable piece.Element

removal

meshing

proceduresemploy

a specific set of element removal operatorsthat

are capable ofremoving

a single elementfrom

anobject.They

operateby

first examining

the topological

features

ofthe

objecttesting

a specific set of geometric measuresto

seeif

any

ofthe

element removal operators canbe

applied.There is

a pre-specifiedhierarchy

in

which

the

various operators are applied.They

typically

employ

aboundary

representation ofthe

domain

and operateby

searching for

entities of specifictype that

satisfy

a set ofconductivity

and geometricrequirements.

Two

examples ofthis

kind

are represented asfollowed.

Figure

1.13

Subdivisionof a multilateraldomain

The

first

approachis

an subdivision ofaplanar polygonby

triangular

elements[13].

Given

a certaindomain

with a number of nodes Page13

around

its

boundary,

we startby deterrmning

the

most well-conditionedelements which can

be

formed

at each corner ofthe

domain.

Having

finished

this

step,

the

elementsformed

are consideredto

be

cut outfrom

the

original area andthe

same conceptis

appliedto the

remaining

area and so on.

The

level

equals unity.Subdivision

at a corner node oflevel

equalsunity

generates nodes oflevel

equalsto two

and so on.The

subdivision

ofdomain

is

performed

in

successive stages.In

eachstage,

A

continuous

boundary

layers

is

cut out.This is

shown(Ungrammatically

in

Figure 1.13 & 1.14.

Starting

withthe

nodes aroundthe

originalboundary,

Triangular

elements are generated anda new set of nodes oflevel

equalstwo

are obtained.The

first

stageis

known

to

be

completewhen all

the

nodesbounding

the

areato

be

subdividedbecome

oflevel

equals

two.

Again,

starting

withthese

nodes,

a new set of nodes oflevel

equalsthree

are generatedand so on.The

mesh generation processis

known

to

be

complete whenthe

number of nodes aroundthe

boundary

of

the

remaining

area reachthree.

This

meansthat the

remaining

areais

one single

triangular

element andhence

no more subdivisionis

required.

Contour |

Figure

1.14.

Nodallevels

The

second approach[14]

is

a3-dimensional

subdivision ofobjectwhich

is

extendedfrom

an2-dimensional

procedure.Consider

the

basic

element removal operators used

to

mesh a3-dimensional

subdivisiondomain

without void.The first

operator,

VERTEX_REMOVAL

is

appliedby

searching

the

objectfor

verticeswithonly

three

edgescoming into it.

Any

such vertex satisfies a set of geometricinterference

requirements

canbe validly

removedfrom

the

object.The

removal ofvertex carves atetrahedron

from

the

object.In

cases where allverticeshave

morethan

three

vertices,

a secondoperator,

EDGE_REMOVAL,

is

applied.In

this

case,

tetrahedron

containing

the

selected edgeis

carvedfrom

the

object.the

verticesby

oneofeach,

it

eventually

reducesthe

complexity

ofthe

object untilthe

first

operator canbe

applied again.In

case where neither ofthe

first

two

operators canbe

appliedathird operator,

FACE_REMOVAL,

canbe

applied.In

this

case,

a tetrahedroncontaining

aface

ofthe

object andconnecting

the three

verticesthat

bound

the

face

being

removed.These

operators areillustrated

in

the

Figure 1.15.

(A) VERTEXJIEMOVAL

(B)

EDGE_REMOVAL(C)

FACE_REMOVALFigure 1.15

Elementremoval operatorsA

topological-based

elementby

element removal procedureappears

ideally

suitedfor

the

construction of optimalh-p

(

HEX

element)

finite

element meshes wherecoarse,

exponentially

graded meshes aredesired. Since

the

amount ofcomputationrequiredfor

the

application of each removal operationis

high,

these

procedures are notcomputationally

efficientfor

the

creation of afine

mesh.The

development

of an algorithmthat

decomposes

the

domain

into

large

chunks

by

removing

them

one at atime

is

an attractiveway

to

considerthe

automation ofthe

current methods of mesh generation wherethe

user

interactively

decomposes

the

domain

ofinterest into

mappable regions andinvokes

amapping

mesh generator which wehave

mentioned at

the

beginning

[4,5].

The

difficulty

in

developing

such an approachis

the

identification

andimplementation

of a set of rulesthat

would examine a

geometry

to

determine how

to

decompose

it into

mappable regions

that

will yieldthe type

of mesh generationsdesired

aswell as

providing

asatisfactory

meshtopology.

3.

Mesh

generationby

recursive subdivisionThe

recursive subdivision mesh generators[17,18,19]

operateby

the

repeatedsplitting

ofadomain

into

simplerparts untilthe

individual

parts are single

elements, or,

possibly,

simple regionsin

which elements canbe quickly

generated.The Triquamesh

technique

is

one ofthe

wide used recursive subdivision methodin

this

area.The

Triquamesh

technique

is based

onthe

surface/volumetriangulation.

It

canbe

usedto

create

triangular

or quadrilateralmeshes on surface.It

can alsobe

broken

up

into hexahedrons.

The

wholetechnique

is

based

ontwo

basic

laws

of analyticgeometry

atthis time:

Page

15

Every

polygonis

divisible

into

triangles.

Every

polyhedronis

divisible

into

tetrahedron.

It

follows

that

we willbe

ableto

create a meshconsisting

oftriangles

ofany

surface.Also,

wewillbe

ableto

create a meshconsisting

oftetrahedral

in any

volume.To

explainthe

working

ofthis

method,

we startwith adescription

in

2-dimensions [18].

The

extensionto

3-dimension

is

then

straightforward.

Any

area canbe divided

by

the

userinto

a certain number ofsub-area.

Each

sub-areaneedsto

be

coherent,

that

is,

a closedloop. An

area with n-foldincoherence

canbe

made coherentby

n-1 cuts.The

first step

involves obtaining

a convex polygon.So,

if

the

polygonis already

convex,

we moveto the

next step.Otherwise,

This

polygonis

successively

subdivided,

until abunch

of convex polygons are obtained.This

process ofsubdividing

a concave polygoninto

morethan

one convex polygonsis

controlledby

certainheuristics,

whichhave

essentially been

obtainedby

trial

and error.The

aimis

to

get a splitline

which will passthrough

aconcavity

in

the

concave polygon and whichis

likely

to

yield good elements.These

splitlines have

to

be

chosen rathercarefully because

these

later

become

the

boundaries

ofthe

elements.Once

a polygonis

divided

into

two

by

using

a splitline,

seeFigure

1.16,

we needto

createnodes on

the

splitlines.

The

problem now reducesto

meshing

two

polygons.

This

processis

continued aslong

as wehave

polygons.Once

we

have

convexpolygons,

they

aretaken

up

oneby

one.An

attemptis

madeto

chop

offlayers from

the

polygon,

wherethe

polygonhas

asharp

angle.These

layers

yield elements.These

layers

are choppedsuccessively,

suchthat

each ofthe

layers

yields good elements.Again,

this

is

done using

certainheuristics. Once

no moresharp

corners arefound,

the

polygonis

again cutinto

two

by

use of a splitline

asplitline

Figure 1.16

Cutting

concave polygonusingsplitting line

Figure 1.17 chopping

offlayers

yield elementsThe

same concepts are extendedto

3-dimension A

surfacein

3-dimension

is

projected(or transformed)

to

2-dimension

andthe

abovemeshing is

done.

For

solidelements, tetrahedron

are generated.These

can

later be

subdividedinto

hexahedrons.

We

will nowbe

dealing

withconvex polyhedra

instead

ofpolygons and split planesinstead

of splitlines

then

same proceduresfrom 2-dimensional

meshapplied untilthe

mesh complete.

As in

the

sub-domain removalprocedures,

this

class of meshgenerator

typically

operates off aboundary

representationofthe

domain

to

be

meshed,

looking

for

candidatetopological

features

meeting

specificconductivity

and geometric requirements.Some

structures whichthis

method cannot split shouldbe

transformed

or sub-dividedto those that

can

be

split.4. Spatial

decomposition

followed

by

sub-domainmeshing

The

basic

idea

behind

this

approach[10,11,14,19,20,21,22,23]

is

use an efficient procedure

to

decompose,

in

acontrolledmanner,

the

domain

ofinterest

into

a set of simple cells andto then

meshthe

individual

cellsin

sucha mannerthat the

resulting

meshis

valid.The

one spatial

decomposition

approachthat

has been

appliedto

meshgeneration

is

the

quadtreein

2-dimensions

andthe

octreein

3-dimensions. The

entire structureis

storedin

ahierarchic

tree

as shownin

figure

1.18.

One

algorithmto

building

a3 dimensional

meshgeneratorusing

this

basic

tree

representationis

the

modified-octree(modified-quadtree

in

2-dimension)

[21,22,23].

the

basic

stepsin

the

modified-octree meshgenerating

processes are :a.

Set

up

aninteger

coordinate systemthat

containsthe

objectto

be

meshed.Page 17

b.

Generate

the modified-octree

representation ofthe

objectaccounting

for

the

mesh gradationinformation

specified withthe

geometricmodel.

c.

Break

the modified-octree

up into

avalidfinite

element mesh.d.

Pull

the

nodes onthe

boundary

ofthe

modified-octreeto the

appropriate

vertices,

edges andfaces

ofthe

original geometry.e.

Smooth

the

locations

ofthe

node pointsto

create abetter

conditioned

finite

element mesh.iff

%

m

%

m s_r QUADTREEREPRESENTATIONTOP FOUR

LEVELS

OFTREE

FULL

EMPTY

PARTIAL

MOOlflEO

OUAOTREE

REPRESENTATION

Figure 1.18 Thequadtree and modified quadtree representations

The

essentialdifference

between

an octree and amodified-octree

is

that the

modified-octree allowsfor

the

definition

of a cut octant.Since

the

size of octree cubesdesired for

usein

the

finite

element meshgeneration are

large

with respectto the

geometricdetails

ofthe

object, it

is necessary

to

deal

in

a specific manner withthose

octree cubesthat

containthe

boundary

ofthe

object and are neitherfully

inside

nor outsidethe

object.The

cutoctants,

whichis

the

octantscontaining

the

boundary

ofthe object,

is

completedby

qualifying

which side ofthe

discrete

boundary

existing

in

the

octantis inside

the

object.To

maintainthe

integer

tree

storage andto

limit

the

number of cutoctant casesto

amanageable

number,

only

the

corners andhalf-points

ofan octant casesare used

in

the

cutting

process.This

operationrequires a specific set of geometric checks[23].

With

IN/OUT information

ofthese

points,

the

sharp

offaces

ofthe

octantthat

are cutby

the

cutting

surface aredefined. One

approachto

define

the

cutting

surfaceis

to

allowonly

when

the

cutting

surfacepoints

arenot coplanar.In

these

situations,

the

surface

representation

willhave

adiscontinuity,

which willlead

to

problems when

the

final

mesh modifications are performed.Therefore,

it

is

necessary

to

include

amore extensive set of octantcutting

surfaces.The IN/OUT

information

canbe

properly

represented with an addition of a set oftwo

planar cut octants andalimited

number ofthree

planarcuts,

seeFigure 1.19. After

the

octant onthe

boundary

aredefined,

the

interior

octants withinthe

boundary

arethen

quickly filled

by

a simpletree traversal

process.

Once

the

modified-octreeis

available,

it is broken

into

a set of validfinite

elements.After

aninteger

finite

element meshis

available,

the

final

stepsinclude pulling (or

assign)

nodesto the

boundary

andsmoothing

the

nodallocations

to

ensurethe

best

possible element sharpsfor

the

given elementtopology.

One

planar cut octant examples

Two

planar

cut octant examples

Figure 1.19 Examplesofcut octants usedinthemodified octree algorithm

Another

approachbased

onspatialdecomposition

usesthe

combination of

Octree

andDelaunay

Triangulation

[10,11,12].

The

basis

of

the

scheme areintroduced

briefly

asfollows

(see

figure

1.20

for

details):

a.

Tree building. Given

a geometricmodel,

generateits

octreerepresentation.

Each

octantis

classifiedinside,

outside,

or onthe

boundary

ofthe

object.An

octantis

classified onthe

boundary

whenany

ofits

features

(vertices,

edges,

orfaces)

is

classified on orintersects

the

boundary.

b.

Octree

triangulation.Each

octant classifiedinside

or onthe

boundary

is

triangulated

using

templates

orDelaunay

procedure.c.

Intersection

point triangulation.The

octreetriangulation

serves asthe

initial

triangulationfor

the

intersection

pointtriangulation

.In

Page

19

this

step

the

intersection

points

generatedduring

tree

building

areincorporated into

the

triangulation using

the

Delaunay

property.Classification

and compatibility.The

geometrictriangulation

requiresthat

the

mesh entities are classified againstthe

modelgeometry

andthat topological

compatibility is

assured.If

anincompatibility

is

identified,

it

resolved eitherthrough

alocal

resolution procedure orby

refining

the

octree.Mesh

improvements.

A

point repositionprocedure,

such asLaplacian

method, may

be

usedto

improve

the

quality

ofthe

mesh elements.Rg

_:?"^

\\

\y*OriginalGeometry TreeBuilding Octreetriangulation Intersectionpoints Classification& Triangulation Comparability

Figure

1.20 A

overview ofoctree/DelaunaytriangulationmethodControl

ofthe

elementdistribution

In

additionto the

ability

to

generate a valid meshfor any

geometry,

automatic mesh generators must permitthe types

of mesh gradationsnecessary

to

produce efficientfinite

element models.Ideally,

the

mesh controldevice

should allowfor

the

convenient specification ofboth

a priori and a posterior mesh generationinformation.

A

priorimesh control

device

are usedto

specify

the

distribution

of elementsin

the

initial

finite

element model.Since

the

basic

input

to

an automaticmesh generator

is

a geometricrepresentation.,

any

priori mesh controldevice

mustbe

tied to the

geometric representation.This

meansthat

apriori mesh control can also

be

afunction

ofthe

particular geometricmodeling

approach used.A

posterior mesh controldevices

are used an adaptive analysis processto

improve

the

mesh asindicated

by

the

resultson

the

overalldiscretization

errorin

one or more solution norms.The

primary function

of a posterior error estimators areto

provide aconvergent and accurate measure of

the

discretization

error of agivenfinite

element solution.To

used mosteffectively, the

mesh generationprocedures must

be

coupledwith adaptive analysisprocedurethat

caninsure that the

final

mesh yieldsthe

requesteddegree

of accuracy.Without

adaptive analysisproceduresbased

on reliable aposterior errorestimators, the

analyst will needto

use a priori mesh controltechniques

Chapter

2. Test Cases

The

benchmark

is

based

ontwo types

of analyses(static

state andmodal

analysis).

Each

type

of analysis willgiventwo

geometries andmeshes

by

linear

and quadratictetrahedron

and quadrilateral elements.All

the

FEA

results willbe

comparedwithhand

calculation.Static State

Cantilever

(square)

beam

1000 lbf

10"xl"xl"

Material :Steel E= 3e7psi u =

.3

Figure2.1

Cantilver

(round)

beam

1000 lbf

D=1",L=10"

Material:Steel - E= 3e7psi u =

.3

Figure 2.2

Page 21

Modal Analysis

Square

flat

plate all edgesfixed

10"

x

10"

x

0.5"

Material :Steel - E= 3e7psiu = .3 Figure2.3

All edgesfixed

Circular

flat

plate with a edgefixed

Edges fixed

OD

= 10"t = 0.5"

Chapter 3.

Analytical Solutions

Cantilever

(square)

beam

smmmmmm

;'-;.>:";"-'::*':-"'a";v" :;"

::: ';'':-::;

1000 lbf

10"

x

1"

x

1"

Material:Steel

-E= 3e7psi o =

.3

Figure3.1

I

=-- =-- =0.08333

in* Eq.3.112

12

37

lOOO(lO)3

3H

= -0.1333

in

Eq. 3.2Page

23

Cantilver

(round)

beam

:^:v^^^^->^ -^ '^A^^^^^^v.^^^s\^^^^^s<^s^^^'.^<;";^^s^^<s^^<^^^W;^...,

;^;->X^:^: -^^^^v^v.^^^^^^^^^^^^^v^A^^^<sW^6^^^s^s^Ww^S^^^^v..,

^^:^^^^^:>- ^^^^^^^^^^^^v.^v.-.^^^^^^<^.^W:0^<4s^vvl.^^ss.,

'^^^^^^^^;-^-^^^^.^^^v^.,.iA^^^.^^^^s^v^.v^.^^*-^v.X<.vA^^^y^v^^^X^.^^J^^v.,

....-...v.s.