Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

4-30-1962

Production Sensitometric Testing of Lithographic

Films Correlated with Customer Quality

Acceptance

Lawrence Albertson

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu

.

Recommended Citation

Lawrence

P.

Albertson

Abstract

Various

methods ofproduction

sensitometrictesting

oflithographic

films

areinvestigated

to

establish correlationbetween

atesting

parameter and customer acceptance ofline

copy

reproduction

in

the

field.

The

chosenparameter,

"gamma,"is

comparedstatistically

for

acceptable and unacceptable reproduction

based

onfield

appraisals.Results

indicate

that

nocorrelation exists

between

the

chosentesting

parameter andfield

acceptance.Information

is

also obtainedconcerning

the

development

and exposure conditions which yield acceptableline

copy

reproductionin

the

field.

Introduction

It

is

desirable

in the manufacturing

of all photo-sensitivematerials

to

have

correlationbetween

production sensitometricparameters and customer

acceptability

ofthe

product.In

otherwords,

the

ideal

situationis

one where customer acceptanceis

predicted

by

parametric values obtainedduring

production.In

the

manufacturing

of most photographic materialsthere

is

atleast

somedegree

of correlationin

this

respect.Many

materialshave

production sensitometric systems which correlatevery

highly

with consumer acceptance.

Photographic

papers aregenerally

very

good examples ofthis

type

of situation.However,

Graphic

Arts

materials,

in

particularhigh-contrast

lithographic

films,

seemto

lack

this

correlation.The

litera

manufacturers

certainly have

production sensitometric systemsin

effect.

Whether

or notthese

systemshave

any

correlation withcustomer

acceptance

is

notknown.

An

Investigation

was madeto

obtainInformation

in

th6

Graphic

Arts

field

ofline

copy

reproductionconcerning

the

degree

ofcorrelation

between

a production sensitometric parameter andcustomer acceptance of

the

product.Also

ofinterest

werethe

conditions of exposure and

development

under whichline

copy

reproduction

is

acceptable.Chosen

for

this

experiment werethree

methods of

measuring

the

"gamma" oflithographic

films

taken

from

published material

in the

field.

It

is

notknown

definitely

that

these

methods areactually

usedin.

industrial

applications.It

should

be

notedthat

"gamma"in

referenceto

lithographic

films

does

nothave

the

conventionalmeaning

ofthe

slope ofthe

straight-line

portion ofthe

characteristiccurve,

but

ratherthe

slope ofa

line

connecting

two

arbitrarily

defined

points onthe

characteristic

curve.It

is

in

this

latter

sensethat

the

term

"gamma"will

be

usedin

this

paper.An

explanation andillustration

ofthe

three

methods ofmeasuring

gammafollows;

V) Z

D-

0.1

net

LOG EXPOSURE

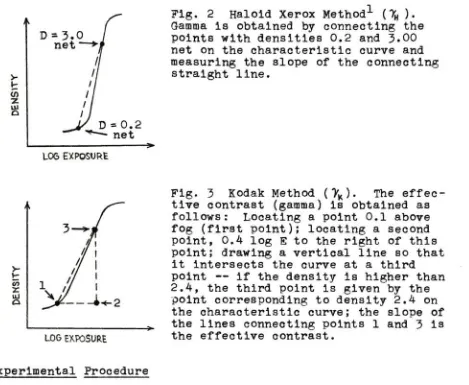

Fig.

1

Ansco

Method

(%).

The

averagegradient

(gamma)

is

obtainedby

connecting

the

points withdensities

0.1

and2.5

net onthe

characteristic curveand

measuring

the

slope ofthe

connecting

straightline.

If

this

line

intersects

the

characteristic curveat a

density

below

2.5

net,

it

is

tilted,

using

the

point withdensity

0.1

as apivot,

untilit

becomes

atangent

to

the

characteristic curve.In

this

case,

the

tangent

slopeis

tk

D

=3.

net

0_

/

//

Ul1

t1

ll lI

y

D

=0.2

"*- net

-.

-

3

-Fig.

2

Haloid

Xerox

Method1(

?H

)

.Gamma

is

obtainedby

connecting

the

points with

densities

0.2

and3.00

net on

the

characteristic curve andmeasuring

the

slope ofthe

connecting

straight

line.

LOS EXPOSURE

t

CO r UJ L06EXPOSURE

Fig.

3

Kodak Method

(?K).

The

effective

contrast(gamma)

is

obtained asfollows:

Locating

a point0.1

abovefog

(first

point);

locating

a secondpoint,

0.4

log

E

to

the

right ofthis

point;

drawing

a verticalline

sothat

it

intersects

the

curve at athird

point

if

the

density

is

higher

than

2.4,

the

third

pointis

givenby

the

point

corresponding

to

density

2.4

onthe

characteristiccurve;

the

slope ofthe

lines

connecting

points1

and3

is

the

effective contrast.Experimental

Procedure

Basically

the

procedurefor

this

experimentinvolved

photographing

atest

copy

containing

representative samples of variousline

originals;

exposing

sensitometricstrips;

andcomparing

statistically

gamma valuesfor

acceptable negatives with gammavalues

for

unacceptablenegatives,

negativeacceptability

being

determined

by

field

appraisal.To

test

the

three

methods of gamma measurement asoutlined

above,

two

films

known

to

have

different

performance characteristics

in

the

field,

Kodak

Kodalith

Ortho

Type

3

andHaloid

-*-The names attached

to

the

methodsindicate

the

source ofthe

[image:5.558.38.507.87.472.2]Halolith,

were selected.Kodak Kodalith

Developer,

whichis

widely

usedin field

applications withthe

abovefilms,

waschosen

for

developing

all negatives and sensitometric strips.The

test

copy

was composed of representativeline

copy

samples suggested

by

Graphic

Arts

field

personnellocated

withvarious

printing

establishmentsin

Rochester.

Included

in

the

test

copy

were samples of registermarks,

typing

material,

vari-type,

phototype,

pen andink

drawings,

serifs,

letterpress,

anda

resolving

power chart.In

attempting

to

encompassthe

rangeof conditions which produce acceptable negatives an exposure

time-development

time

matrix wasdesigned using

practicallimitations

of

both

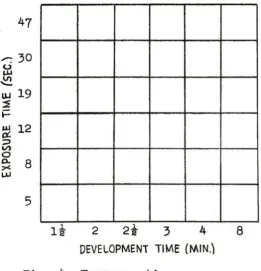

variables as extreme values.Figure

4

showsthe

matrixform.

o

U-oi

o o. m

47

30

19

12

8

5

li

2

2i

3

4

DEVELOPMENT

TIME

(MH)

Fig.

4

Exposure

time-development

time

matrix [image:6.558.151.413.419.690.2]

-5

-In

order

to

performthe

statistical correlation a sensitometric

strip

was neededfor

each negative.To

minimize variability,

sensitometric

strips were exposedin the

camera withthe

negatives.

Thus

each11

x14

sheet offilm

contained a negativeof

the

test

copy,

and a sensitometricstrip

exposedfrom

a0-3.0

density,

continuous wedge placedin

contact withthe

film

in

the

camera.

The

continuous wedge allowed sensitometric curvesto

be

traced

with a continuousrecording

densitometer.

Statistical

considerations

indicated

that

the

matrix shouldbe

twice

replicated

for

eachfilm,

resulting

in

atotal

of144

negatives and144

corresponding

sensitometric strips.In

exposing

the

negatives and sensitometric strips a processcamera

utilizing

a vacuumcopy

board,

a vacuum cameraback,

anelectric

timer,

and a voltage-regulatedtungsten light

source wasmade available

through

Graphic

Arts

Research

andDevelopment

atRochester

Institute

ofTechnology.

Although

the

tungsten light

source

did

notcompletely

conformto

practice,

it

offereddistinct

advantages

In minimizing light

source variation and was of considerable

importance

in

assuring

consistent results.The

negatives and sensitometric strips were exposed andde

veloped as

indicated

in

the

matrixin Figure

4.

The

matrix wastwice

replicatedfor

eachfilm.

To

minimizethe

effect oftest

time

the

test

order was establishedby

use of atable

of randomnumbers.

The

negatives werethen

taken

into

the

Graphic

Arts

field

as

being

either acceptable or unacceptable.Sensitometric

curveswere prepared

from

the

sensitometric stripsby

use of a continuous

recording densitometer.

The

three

methods of gamma measurement were

then

appliedto

each sensitometric curve.Results

The

data

from

the

evaluations offive

appraisersin

the

field

appears

in

Figure

5.

Each

ofthe

matricesin

Figure

5

is

a combination of

the

appraisal resultsfrom

the

twice

replicated matricesfor

eachfilm.

The

numbersin

the

boxes

indicate

the

number oftimes

the

negativesfrom

corresponding

boxes

in the

twice

replicated matrices

wereJudged

as acceptable.Since

there

weretwo

matricesfor

each

film

andthese

were shownto

five

appraisers,

the

maximum number

of acceptable appraisalsis

ten

for

eachbox

in

Figure

5.

Haloid

Halolith

Film

Kodak

Kodalith

Ortho

Type

3

Film

r-r47

0

1*2

0

0

0

47

&

30

|19

^12

3

g

8

X u.5

0

9

4

2

0

0

Hi

>-630 ID

^19

12

0

0

1

0

0

0

0

9

9

10

0

0

0

0

4*1

0

0

0

0

1

10

0

0

0

0

0

5*2

0

0

0

1

6

9

0

3

o o

0

0

0

0

5* 1*0

0

0

0

6

1

m

5

0

0

0

0

1*0

0

0

0

0

1* 1*2

2i

3

4

8

DEVELOPMENT

T\ME

6*1*0

Is

li

2

2i

3

4

8

DEVELOPMENT

TIME

(MIN.)

Fig.

5

Appraisal

Data

*The

asteriksindicate

occurrences of acceptable negativequality

where gamma values could not

be

obtainedfrom

the

corresponding

sensitometric strips

by

one or#ore

ofthe

methods of gamma measurement.

Comparison

ofthe

matricesin

Figure

5

withthose

in

Figure

6

will point out which ofthe

methods of gammameasurement

[image:8.558.53.504.423.647.2]Kodak

Kodalith

Ortho

Type

3

Film

(%)

tt

47

tfN^

UJ

30

2

h

19

lu

12

(D

8-8

>< Ul

5

5.610

7.710

9.245

14.680

4.660

7.890

7.975

9.660

8.140

4.175

7.740

10.065

8.900

4.105

10.000

10.065

9.750

4.215

12.050

3.940

ii

2

2i

3

4

DEVELOPMENT TINAE

(MIN)

8

Haloid

Halolith

Film

(

?A)

U*7

Hi

42.30

Ui

w

5

3.200

4.355

5.060

4.950

3.120

4.440

4.670

4.360

3.020

4.800

4.700

2.840

3.810

4.320

2.800

4.440

2.730

ii

8

Kodak

Kodalith

Ortho

Type

3

Film

(Tfe)

o47

40-30

u_

Il9

2

12

2

8

us

5

2.900

5.450

7.425

9.130

14.925

4.160

7.870

7.945

9.335

8.760

3.810

7.600

9.930

9.1303.835

9.910.

10.170

10.720

3.875

13.025

3.510

3.385

ii

2

2i

3

4

DEVELOPMENT

TIME

(MIN.)

8

Haloid

Hal

ollth

Film

(

7K

)

^47

<n19

ul a

12

/>

2

8

X

UJ _

3.350

4.535

5.165

5.065

1.800

3.875

4.850

4.050

1.730

4.550

4.450

3.485

1.450

4.370

4.110

1.745

4.220

1.650

4.050

1.050

ii

2

2i

3

4

DEVELOPMENT

TIME

(MIN.)

8

[image:10.558.69.462.99.570.2]Kodak

Kodalith

Ortho

Type

3

Film

(%)

d47

UJ

HI

30

h9

*12

tn

2

8

x

UJ

6.590

9-560

11.535

17.775

4.790

9.040

10.605

13.860

8.005

4.445

8.750

10.760

9.065

4.245

10.000

9

.515

9.505

4.340

9.380

4.150

li

2

2i

3

4

DEVELOPMENT

TIME

(MIN.)

8

Haloid

Halolith

Film

(7M)

o

UJ

Ui

47

30

pl9

ul a

12

3

2

8

X Ui r

4.420

5.160

5.135

3.640

4.370

4.795

4.745

3.545

4.830

5.000

3.360

4.635

3.360

li

2

2i

3

4

DEVELOPMENT

TIME

(MIN.)

The

gammadata

obtainedfrom

applying

each ofthe

three

methods of gamma measurement

to

each sensitometric curve appearsin Figure

6.

As

withthe

appraisaldata,

the

gamma measurementshave

been

combinedfrom

the

twice

replicated matricesfor

eachfilm

into

a single gamma matrixfor

eachfilm

containing

averagegamma values.

There

are no gamma valuesfor

someboxes

because

of gross underexposure and/or underdevelopment which prevented

measurements

from

being

made.There

were alsoborderline

caseswhere,

because

ofthe

criteria

for

a particularmethod,

only

one gamma value couldbe

obtained

for

corresponding

boxes

from

the

twice

replicated matricesfor

eachfilm.

In

these

cases ajudgment

had

to

be

made asto

whether

the

situation was a result of errorin

the

experimentalprocedure or variation

in

the

process,in

the

cases of an errorjudgment

the

data

wasdiscarded;

in

the

cases of a variationjudgment

the

single value wastaken

as anindication

ofthe

average value.

Average

gamma valuesfor both

films

andthe

three

methodsof gamma measurement were calculated

for

acceptable and unacceptable negatives.

In

all casesthe

acceptable negative averagegamma was a weighted calculation

based

on appraisaldata

eachgamma value

being

used oncein

the

calculationfor

each acceptableappraisal

(i.e.,

if

a negative was appraised as acceptablefour

times,

than

the

corresponding

gamma value was usedfour

times

in

calculating

the

average valuefor

acceptable negatives.)

Using

the

samedata

in

the

similarmanner,

standarddeviations

(s)

werealso calculated.

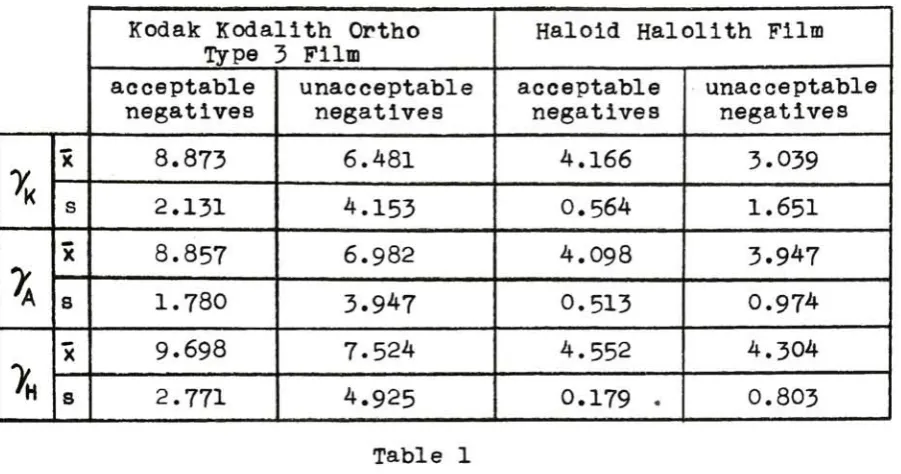

Table

I

lists

the

calculated values of average

-9

-Kodak Kodalith

Oftho

Type

3

Film

Haloid

Halolith

Film

acceptable negatives unacceptable negatives acceptable negatives unacceptable negatives

Ic

X

8.873

6.481

4.166

3.039

S

2.131

4.153

0.564

1.651

/a

X

8.857

6.982

4.098

3.947

s

1.780

3.947

0.513

0.974

J,

X

9.698

7.524

4.552

4.304

s

2.771

4.925

0.179

.0.803

Table

1

The

valuesfor

average gammas and standarddeviations

ofacceptable and unacceptable negatives were compared

statistically

for

eachfilm

and each methodto

determine

significantdiffer

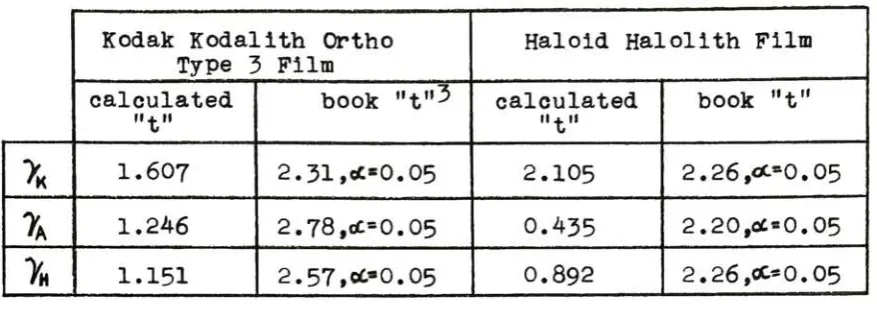

ences.

An

"f"test

was runcomparing

variances(s2)

and a "t"test

was runcomparing

average gamma values.The

results ofthese

tests

are shownin

Table

2

andTable

3.

Kodak Kodalith

Ortho

Type

3

Film

Haloid

Halolith

Film

calculated

11fii

book

"f"2 calculated11fti

book

"f">K

3.789

3.09,<**0.001

8.600**3.46,*o.01

X

4.918***4.37,<**0.001

3.608*2.64,ed0.05

X

**3.159

3.12,cc0.01

20.156

10.3,OL*0.01

Table

2

"f"Test

onVariances

^Duncan,

Ache

sonJ.,

"Quality

Control andIndustrial

Statistics,"1952,

p.878,

Table

J.

*The

asteriksindicate

the

valuesfound

to

be

significant.One

asterik represents significance with

the

probability

ofbeing

wrong

onetime

in

20;

two

asteriks,

onetime

in

100;

andthree

[image:13.558.45.496.56.293.2] [image:13.558.32.496.327.691.2]Kodak Kodalith

Ortho

Type

3

Film

Haloid

Halolith Film

calculated "t"

book

"t"3 calculated"t"

book

"t">K

1.607

2.31,cC0.05

2.105

2.26,0^0.05

?A

1.246

2.78,oc=0.05

0.435

2.20,ot0.05

>

1.151

2.57,ct0.05

0.892

2.26,eC*0.05

Table

3

"t"Test

onAverage

Gammas

Analysis

ofResults

From

Table

3

it

canbe

seenthat

there

are no significantdifferences

between

the

average gammas of acceptable negativesand

those

for

unacceptable negativesfor

any

ofthe

three

methodsof gamma measurement with either of

the

two

films.

It

canbe

seen

from

Table

2

that

the

variances(s2)

were allsignificantly

different.

From

this

fact

aloneit

appears asif

this

parametermay

be

a usefulindication

of customeracceptability,

ratherthan

gamma.

Closer

examination ofthe

standarddeviations,

however,

shows

that

the

data

overlapsfor

acceptable and unacceptablenegatives.

Because

ofthis

overlapping

ofdata

it

wouldbe

impossible

to

clearly

separatethe

distributions,

andit

wouldtherefore

be

unwiseto

determine

the

acceptability

ofthe

productin

the

field

by

this

measurement.The

fact

that

there

were occurrences of acceptable negativeswhere gamma measurements could not

be

madehelps

to

supportthe

above analysis.

Further

examination ofthis

point revealsimpor

tant

information

and a possible cluetowards

the

solution

ofthe

[image:14.558.48.487.80.245.2]

-11

-problem of

lack

of correlationbetween

production sensitometrictesting

and customer acceptance ofthe

product.Inspection

ofthe

characteristiccurves,

for

the

occurrences of acceptable negatives

where gamma measurements could notbe

made,

indicate

one ofthe

shortcomings ofthe

various gamma measurement methods.Although

peoplein

the

Graphic

Arts

field

maintainthat

a minimumbackground

density

of about2.5

is

necessary

for

acceptableline

copy

reproduction,

the

sensitometric curves of acceptable negatives

indicate

that

this

value couldbe

aslow

as1.8.

It

is

easily

seenwhy

two

ofthe

methods of gammameasurement,

7^

andO^

fail

to

measure gammasfor

acceptable negatives withlow

back

ground

densities,

orin

the

case of sensitometricstrips,

low

maximum

densities,

y^

and*Vh

require maximumdensities

of atleast

2.5

net and3-0

net,

respectively,

before

the

methods canbe

applied,"V.

is

not aswholly

dependent

on a mimimum value ofDmax

asthe

othertwo

methods,

but

this

factor

is

stillextremely

important

withthis

method also.A

method of gamma measurementwhich

is

going

to

satisfy

the

desired

correlation as stated previously

must,

then,

be

ableto

makethe

measurementfor

the

entirerange of possible maximum

densities

for

acceptableline

copy

reproduction.

Figure

5

contains considerableinformation

concerning

the

range of exposure and

development

conditions which will produceacceptable

line

copy

reproduction.From

these

two

matricesit

is

easily

seen which combinations of exposuretime

anddevelopment

time

produce acceptable negatives, whatthe

ranges of each varifilms

the

area of acceptable negatives appearsto

lie

along

adiagonal

with slopeapproximately

equalto

-1.In

producing

acceptable

line

copy

reproductionKodak

Kodalith

Ortho

Type

3

Film

appears superior

to

Haloid

Halolith

Film.

Conclusions

Using

just

the

measurement of gammaby

any

ofthe

three

methods and with either

film

it

is

not possibleto

predictacceptability

ofthe

productby

the

customer.For

Kodak

Kodalith

Ortho

Type

3

Film

the

optimum exposuretime

appearsto

be

30

seconds underthe

experimentalconditions,

with

development

variedfrom

two

to

three

minutesfor

maximumnumber of acceptable negatives.

For the

samefilm

optimumdevelop

ment

time

appearsto

be

three

minutes under experimental conditionswith exposure varied

from

12

to

30

secondsfor

maximum number ofacceptable negatives.

For

Haloid HalolithFilm

there

does

not appearto

be

clear-cut optimum exposure and

development

times

for

maximum productionof acceptable negatives.

However,

the

area of acceptable negativesin

the

experimental matrix appearsto

coincide quiteclosely

withthe

areafor

the

Kodak

film.

The

minimum backgrounddensity

for

acceptableline

copy

reproduction

appearsto

be

1.8.

With

the

information obtainedin

this

experiment,

especially

that

concerning

the

backgrounddensity

of acceptablenegatives,

amethod of

measuring

gamma which would correlate with acceptable

-13

-Acknowledgments

The

author wishesto

acknowledgethe

kind

assistance ofthe

following

people:Professor

Hollis

M.

Todd

andProfessor

Albert

D.

Rickmers,

Rochester

Institute

ofTechnology;

Mr.

Robert

P.

Smith,

and

Dr.

Chung

Wei

Chen,

Xerox

Corporation;

Mr.

Warren

Rhodes,

Graphic

Arts

Research

andDevelopment,

Rochester

Institute

ofTechnology;

Mr.

Anson

Halsey,

Mr.

C.

Peterson,

andMr.

John

Schoonhagen,

Case-Hoyt

Corporation;

Mr.

Fred

Hess,

Stecher-Traung

Lithographic

Corporation;

andMr.

E3

Potter,

Smith-Hart

Printing