Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

1999

Performance study of the 1911 Wright Brothers

model B aircraft and propeller

Robert Egenolf

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

Recommended Citation

PERFORMANCE STUDY OF THE 1911 WRIGHT BROTHERS

MODEL B AIRCRAFT AND PROPELLER

Robert Egenolf

Mechanical Engineering Department

Rochester Institute of Technology

Rochester, New York

A Thesis Submitted in

Partial Fulfillment of the

Requirements for the

Degree of

MASTER OF SCIENCE

In

Mechanical Engineering

Approved by: Professor

_

Kevin Kochesberger, Thesis Advisor

Professor

_

Dr Alan Nye, Professor

Professor

_

Dr. Ali Ogut, Professor

Professor

_

PERMISSION

TOREPRODUCEThesis Title.

PERFORMANCE

STUDYOF THE 1911 WRIGHT BROTHERSMODELBAIRCRAFTAND PROPELLER

I,

RobertEgenolf,

hereby

grant permissionto theWallace MemorialLibrary

oftheRochesterInstituteof

Technology

toreproducemythesisinwholeor part.Any

reproduction can notbe usedforcommercial use or profit.

FORWARD

Iwouldliketo take thisopportunityto thank thepeople whohave helpedme

throughout mycollege career andin reaching mygoal ofgraduation.

To my advisor,Kevin

Kochesberger,

Iwouldliketoextendmythanksinthe timeand efforthe putforward

helping

me conceivethisproject andbring

ittofruition. Iwould alsoliketo thankhim fortheplane ridesdownto thewindtunnelat

Langley,

Virginia.

To Ken

Blackburn,

Iwouldliketoextendmygratitude andthanksforall ofhishelp

withsortingouttheinputs forthe softwareprogramand all ofhisadviceregardingthis thesis.Withouthistremendous effort,Iwouldstillbe inthedarkonmanyofthese

issues.

To my

family, Joyce, Bruce,

andEric,

Iwouldliketoextendmygratitudefortheirconstantsupportthroughoutmyeducation,hereatRITand evenbeforehand. Icould

nothaveaccomplishedmygoals withouttheirencouragementand confidencein my

ABSTRACT

Aperformance evaluation ofthe 1911 WrightBrothers Model B aircraftand

propelleristobepresented.

Background,

contemporaryaviationhistory,

andtheWrightanalysis will precedetheevaluationinordertorecreatethesituation inwhichthe

Brotherswere operating.

Following

thisbriefhistory,

theories regardingpropellers willbeexaminedinordertounderstandbetteranefficiencyevaluation.

Finally, theoretically

generateddatawillbecomparedto theknownvaluesatthetimeoftheModel B's flight.

Theoretical datawillbegatheredfromtwosources;

(1)

a software programdedicatedto theefficiencypredictionofpropellers,and

(2)

adrag

studyconductedontheModel B aircraftitself. The inputs forthe software programwillbe discussedaswellas

theprocedurefor operatingthe software.Outputswillinclude graphs,specifically

efficiencyandavailablepoweratcertainspeeds.

Following

thischapterwillbeadrag

studyoftheModel B aircraft, which willincorporatethesoftware graphs and producethe

aircraft's cruise speedandclimbrate.Afinalchapter will discusstheseresults and

recommendfurtheravenues of study.

Finalresults ofthe performanceevaluation ofthe 1911 Wright Model B aircraft

haveshownrelativelyclosecorrelationtotheoriginal numbers measured and calculated

by

theWright Brothersthemselves. Cruisespeed and overallefficiencyas predictedby

TABLE OF

CONTENTS

PagesI. GreekLetters 7

II. Dimensionless Parameters 7

III. Variables 7-8

IV. ListofTables 9

V. ListofGraphs 9

VI. ListofFigures 9-10

Chapter 1- Introduction

1.1

Contemporary History

11-121.2 Background 12-13

1.3 Wright Brothers ExperimentsandAnalysisofthePropeller 14-18

1.4Objective 21-22

Chapter 2- Propeller

Theory

2.1 Simplified Momentum

Theory

23-282.2 Blade Element

Theory

28-34Chapter 3- PropellerSoftware Program InputsandResults

3.1 Propeller Software Background 35-39

3.2 Selected Inputs forthePropellerProgram 41-43 3.3 Output Results fromtheSoftware Program 44-49 Chapter4- Performance EvaluationoftheWright Model B Aircraft

4.1

Drag

Analysis ProcedureoftheWright Model B 50-55 4.2Drag Study

NumericalAnalysisandResults 56-65Chapter 5- DiscussionofResults

6.1 Climb SpeedandClimbRate 66

6.2 Performanceat

CL

Max 666.3 Cruise Speed 66

6.4 Propeller Performance 66-67

Chapter6- ConclusionsandRecommendations

6.1 Conclusions 68-70

6.2Recommendations 70-72

VII. References 73-74

I. Greek

Letters:

Q : angularvelocity

p:

density

r\ : efficiency

-: pi

u. : axialvelocity

a : angle ofincidence

O :blade angle

cj) :bladeangle

-angleofincidence

y:effect of profile

drag

ofthebladeII.Dimensionless Parameters:

J : advanced ratio of a propeller

III.Variables:

V: freestream velocity

v : incrementalvelocity

pA : initialpressure

p'

: incrementalpressure

HA

:initial head flowA: area

E :energy

T: torque

Ta

: torqueavailablePa

:power availabler : radius

a'

: rotational interference flow

Cd

: coefficient ofdrag

Cl

: coefficient ofliftM : resultantvelocity

c : chord oftheairfoil shape

s : solidityofblade

N :number ofblades

n :

frequency

L:thrust(Wright Brothers

Theory)

K: airpressurecoefficient

SWing

: totalwingareaS :reference area

A=AR : geometric aspect ratio

Ai :effective aspectratio

e : correctionfactor

b : wingspan

h : height betweenwingson abi-plane

W : weight

Q

: torqueCT

:coefficientofthrustIV. ListofTables: page

Table 1 :TableofSoftware Inputs 42

Table 2 :Flyer

Drag

Coefficients

60Table3 : B

Drag

Coefficients

61Table 4: B

Velocity/Drag

Force 63Table5 :B PowerRequired 64

V.ListofGraphs

Graph 1 :

Efficiency

vs. Speed 44Graph 2 : HPvs. Speed 45

Graph 3 :

Efficiency

vs. Advanced Ratio 46Graph 4: Thrustvs. Speed 47

Graph 5 :

Cp

vs. Advanced Ratio 48Graph 6 :Ct vs.Advanced Ratio 49

Graph 7 : Flyer CLvs.

Cd (induced)

59Graph 8 :B

CL

vs.Cd (induced)

59Graph 9 :Flyer

CL

vs.Cd (induced/total)

60Graph 10:B

CL

vs.Cd (induced/total)

62Graph 1 1 :Power Requiredvs. Power Available 65

VI. ListofFigures:

Figure 4 :Blade Element

Theory

Diagram 31Figure5 : Software Program Diagram 36

Chapter

1

:Introduction

1.1

Contemporary

History

Inordertounderstandthemagnitudeofthe accomplishmentthat theWright

Brothersset outto achieve,abrief descriptionofcontemporary

history

in aviation willbedivulgedtothe reader.Atthe timeofthe

Brothers,

no onehadyetdeterminedtheforcesin action on aerial propellers. Inmarinepropellers,mostknowledgewas empiricaland

needed experimentationtoreach perfection.

Transferring

marineknowledge intoaerialpropellerknowledgewouldbe impossibleand not reasonable.

Up

tothispointinaviation,propellers wereonlyabout40%efficient with someofthebetter designs andbettercraftworkreachingashighas55%. Thesenumbers might

seem

high,

buttheWright Brotherswishedto gohigherand surpasstheprevious designsand goals.

Settling

forwhat other peoplehadconstructed was unacceptableto theBrothers. Forexample, Santos-Dumont's Bird of

Prey,

required50 HPtobecomeairborne. This relatively highpower numberindicatedthat thepropellers musthave been

inefficientandtheplane wasprobablyoverweight.The goal oftheBrotherswastouse a

motorcapableofonly 8 HP Thistremendousdifference inrequirements exhibitsthe

ambition andengineeringskillpossessed

by

theBrothers.More horsepowerinstantly

meant alargerandbiggerengine.

This,

in turn,meantthat theplane wouldautomaticallygainin weightfromthemotor alone.Thepredicted weight oftheFlyer onlyallowedfora

smallmotor,light inweight.

Casting

processesoftheday

also preventedthelargermotorsfrom

losing

alotofweight.Propellershadtobe more efficientthanthosecentralhubwithout

taking

intoconsiderationthecurvatureoftheupper surface whichdictates theliftandinthe case of apropeller,the thrust.

Fortheirachievementinaviation,

including

theplane andthe propellers, theWrightBrothers were considered pioneers andinnovators intheirfield. Nowthat the

readerhas abetterunderstanding ofthetimeperiod,amorein depth lookattheWright

Brothers willbe

discussed,

asthey

arethe mainfocusofthisdocument.1.2Background

Intheearly 1900'sateamoftwobrotherswouldbethefirsttoachievethe

unreachable goal of sustainable poweredflight. OrvilleandWilbur Wrightwould

revolutionizethe

industry

with ahomemadeplane and onehistoric flightatKitty

Hawk.Butthis tremendousaccomplishment was not withoutits obstacles andtechnical

challengesthat

they

wouldencounteronmorethenoneoccasion,bothanticipated andunforeseen. The lastaspect oftheplanetobedesigned beforethe flightwasthe

propulsion system,

including

theengine/motoritselfandthemeansby

whichtheenginepower wouldbetransformedintothrustorforwardmovement. Bothofthesecomponents

would provetobethelargestobstaclesofthemall.

Ownersandoperators of abicycleshop,theWright Brothers had littletono

experienceintheengine

building

business.They

hadconstructed aone-cylinder enginetopowertheequipmentintheirshop butthatwastheextent oftheirexpertise. When

they

firstconsidered powerplantsfortheir plane,

they

contactedautomobile enginemanufacturersand gavethem their specifications,whichhadbeencalculated and checked

manufacturer atthe timecould meetthedemandsofthebrothersand;therefore, the

engine wouldhavetobeconstructedfromscratch andbepurpose-builtfromtheonset.

Luckily

one oftheir employees,CharlieTaylor,

hadabitmoreengine experienceandalmost single

handedly

builtthebrothersafourcylinder enginefortheir plane,andtotheirspecifications.

However,

oncethisproblem wasovercome,aseeminglypremature assumptionmade

by

thebrothers wouldturnintoarevolutionary ideaanddesigninthearea offlightpropulsion. Thepropellers requiredtotransformtheenergy atthe outputshaft ofthe

engineinto forwardmotionthrough theair wouldbereinvented,in everysense ofthe

word.Noonepriorto theWright Brothers hadunderstoodthedynamicsanddesignof

propellers.

"

Maxim/Langley

developed great motorsbutterribly

inefficientflat-bladedpropellers

"

Mostofthework completedinthisareaexistedonly inthearea of marinepropellersand

not airplane propellers.The brothers believed

they

couldjustsubstitute air pressureinplacewater pressureandachieve propeller performance predictions.Aquicklook into

thisassumption provedthis

theory

would notbeapplicableto theirsituation. Withallpreviouswork

being

entirelyempirical and nottheoretical,theWright Brotherswereforcedto

develop

theirown equations andcalculations inordertoconstructthecorrectpropellersonthefirstattempt(Notethat

they

didnothavethecapitaltorelyon the"cutand try"

methodemployed

by

othercontemporaryinventors.).With onlyone attempt attheir grasp, theircalculationshadtobecorrect andpredictingtheefficiencyofthe

1.3 WrightBrothers'

Experiments

andAnalysisofthe Propeller(Flyer)

Before completingtheirdesign fortheairfoilpropeller, theWrightBrothers

conducted various experiments to

help

themdetermineshapes, sizes,and speedsfortheirdesign.

Specifically

they

conductedfanscrew and propeller experimentsina scaled windtunnel

they

hadcustombuilt forthisspecific purpose.These,

alongwiththe analysis oftheireventual propeller willbeundertakeninthisportion ofthechapter.

Forthefirstoftheirexperiments,

they

employedfan bladesand a motor(themotor wasprobablytaken fromtheirbicycle shopwhere

they

usedittodrivesome oftheirpower equipment).

During

theseexperimentsthebrotherspaid close attentiontotheCenterof

Pressure,

which is defineddifferently

fromthemeaningassociated with ahorizontalwing. This

they

defined as ablade sectionlocated 5/6oftheradiusaway fromthehub. There

they

measuredor estimatedbladeangle,camber,rotationalvelocity, andangleofattack.

They

usedthesecrudebladestocreateearlymodels ofthepropellerbladesand

help

themvisualizehowthepropshouldfinally

appear. Thesewereonly earlyexperimentsand so

they

moved ontopropellersthateventually becamealotmoresophisticatedand alotcloserto theirultimategoal.

Thepropeller experimentsagain usedthesame motor asthefanscrew

experiments,mainly duetoafailureofthelargermotor.Thepropellers were similarin

lengthto thefanscrewbut differed in bladewidth andbladeangle.The Brothersaltered

these twovariablestogain thebestthrust/liftdesignthatwould suit theirneeds.

They

determinedthatasthelengthoftheblade

increased,

theblade sections nearthehubbecame.The Brothers developedanequationforthethrust/liftofthepropeller andit

appears as follows:

L

=KxVxSxCL

(D

whereLis thrust, A"

isan air pressurecoefficient, Vis thevelocity inmph,S isthetotal

blade area,andC/,is theliftcoefficient.

By

simply understanding thatliftforawingcorrespondstothrustforapropeller,theBrotherswere abletoapplythisequation

directly

to theirdesigns.Once

they

had finishedthese experiments,they

coulddeterminethecorrectpropellerfortheplane

they

werebuilding

basedon some assumptionsthey

hadmade attheonset oftheprojectregardingtheirFlyer.These included:

Planeweight=755lbs

Min velocity for flight=23 mph

Engine & propweight=200lbs

Total wingarea=500 ft2

They

above mentioneddesignrequirementsdictatedthepropeller'sdesignanditsperformanceaswell asthemotor and othernecessarycomponents. The Wright Brothers

keptnotebooksontheprogressionoftheirdesignandanalysisandthe

following

analysishas beenexcerpted from Wilbur'snotebook

H,

1902-1905.Efficiency,

asdefinedby

theWrights,

becamethefollowing

equation:___ . PowerOutput

(2)

Efficiency

=Knowing

this relationship,one candeterminethe inputby

multiplyingthe torqueandvelocityof rotationtoobtain:

40lb

xl2lft/

s=4,

S40ft

-lb/s

4,840

550=

S.13hp

This givesthefirstpart oftheefficiencyequation.Now

by

understandingthat thepoweroutputisproduct ofthethrustandforwardvelocity, the second portionbecomes:

90lbx24

mi/

'hr

=2,160/m-Ib/hr

2,160

375

=

5J6hp

where 375mi-lb/hris equaltoonehorsepower. Oncetwoout ofthreevariables have

been

determined,

the efficiencyequation cannowbeusedtodeterminetheperformanceofthepropeller asfollows:

__, . PowerOut 5.76

n ,,

Efficiency

= = x1 00=66% Powerln 8.73Thiswasthe theoretical number associated withthepropellers used onthe

Brothers'

Flyer.

According

tocalculationsthey

hadsurpassedtheachievements of pastaviatorsandbroughtthepropellerintoanewera.Theiranalysis would serve asthebasis

for

designing

propellers for decadestofollow. Neverbefore inaviationhadsuch anundertakingbeen acceptedandthenovercome. The Brothers hadthelastpiece fortheir

year. Someothercritical numbers associatedwiththepropellers oftheFlyer

andtheB

were asfollows:

Flyer Data

Speedof machine=23mph

Grossspeed(forward velocityofproprelative to theair)=44 ft/s

Thrust=90 lbs

Areaofblades=5.4 sq ft

RPM=330

SpeedofCenterofPressure (locatedat5/6ofthe totalradius)= 121 ft/s

Angleofincidence=7

deg

Normalpressure=25.3 lbs

Weight :755 lbs (withonepilot)

Wing

area:500ft21911 Model B Data

Speedof machine :40mph

Grossspeed: 58.6 ft/s

Weight: 1250 lbs (withtwopilots)

Wing

area : 472ft2RPM :428

where gross speedisthe freestream velocitywithouttheadded"suck"velocityand90lbs

ofthrustistheestimated

drag

oftheFlyer accordingtotheBrothers.Along

withthesenumberswere also quite afew tables, graphs,anddiagrams fromwhichtheBrothers

propeller

design,

inanengineeringsense ofthe word. The figures (1 and2)

onthe-L..A_i...L.,

\

i

./,LU.-._/

. I--1 a sy 1 i i f1 I1

, ^*i_ II "^Vi 1 >_______!$ l i i i \

n

r-#v\i j _/

1

^

--f-h. . -.-__

09

-. pa CO .

"

-8I

I

_. On

5

~z o

CN

U

00

1.4 Objective

Nowthatthebackground forthestudy has been

documented,

the main purpose ofthestudywillbediscussed. Theoverall objective ofthisstudywastoemploycurrent

techniques of propellerdesignandefficiencycalculationin ordertopredicttheefficiency

ofthepropeller used ontheWright Model Baswell asthecruise speed oftheplanein flight. Thisprediction wouldbecarried outinanumberof variousways,bothwith a

computertool andanalytically inordertocapture arangeof sources andtechniques.

The firstofthesemethods wastoemploya propeller performance software

packagein

determining

theoverallefficiency and poweroftheWright Brothers design.Having

propellerdrawings available wouldallowdatatobe inputteddirectly

intothesoftware. Oncethisis complete, thesoftware program wouldbeabletorunthroughits

calculations andsimulationsand output sixperformance graphs(canbe seeninthe

ResultsandConclusionssection)

Thesecondmethod ofanalyzingperformancewouldbetoconduct a

drag

studyofthe overallplane anduseavailable equationsto transform

drag

numbersintoanoveralldrag

force. Thedrag

forcewouldthenbe plottedintheformof power required againstpower available.Fromthe thrust numbers,powercanbe derivedandthiscanbeusedto

directly

determinetheperformanceand cruise speed ofthe aircraft,including

maxlevelThethirdsource ofdatawouldbetheWright Brothers themselves.

They

conducted an extensive analysis priortoconstructingtheFlyerandthepropeller

efficiencywas a critical part ofthis analysis.Theremethodofanalysisandresulting

numbers willbeused as a comparisontothe two aforementioned methods.

Following

datacollection, theefficiencyand powernumbers were compiledandcomparedtothenumber obtained

by

theWright Brothersatthetime theFlyer B wasChapter

2

:Propeller

Theory

In orderto better understand how the efficiency of a propeller is

determined,

a morein depthexplanation ofthe employed theories will nowbe given. The first two theories are used in

determining

the ideal efficiency of a propeller. This explanation is necessarytounderstandhowthesoftware program operatesinthenext chapter.

2.1 SimplifiedMomentum

Theory

(Rankine andFroude)

Asevidencedin thenamealone,this

theory

of airscrewsdependson a consideration ofthemomentum aswellasthekinetic energyofthe systembeing

studied. Before goingin depth intoadetailedanalysis ofthis

theory however,

it is necessarytostatetheassumptions attachedto the theory.

Assumptions:

1. the airscrewisconsideredtobe adisc

(spinning

inthe air) 2. thegeneratedthrustis distributed evenlyoverthedisc3. anyrotationoftheslipstreamdueto theaction ofthe torque isignored

Nowthat the assumptionshave been categorically

described,

thetheory

canthenbesetforth. Asthe fluidpassesthrough the

disc,

anincrementalpressureis added whichis equalto the thrustper unit area ofthedisc. Thiscanbeseenin Figure 3 onthe

following

page.Anothereffect ofthe disc istoformaslipstreamofincreasedaxialvelocitybehindthedisc. The fluid flow frompointAtopointB isregarded as

irrotational,

aspreviously statedinthe assumptionsassociatedwiththis theory.Oncetheseideas have beenestablished, it isnow properto apply Bernoulli's Equationtothe

fluid flow. Bernoulli's Equationappliedto thediagrammed fluid flowyields anequation

for dynamicpressure as follows:

nA=pA+y2pv2=p+y2p{v+v)2

(3)

where V isthefreestream velocityandvistheincremental velocityadded oncethe

stream passesthroughtheairscrew.p0istheinitialpressurebefore

being

effectedby

theairscrewandp isthepressurejustpriortopassingthrough thescrew.

Further,

afterpassingthroughthe prop,H

=P,+/2P(V+\f

=P+P+/2P(V+vf

(4)

where p'

istheincrementalpressureadded

by

theairscrew.And,

Ap-HB-HA_p(v+

^/vB)vB

(5)

By

consideringthisAp,

thethrust,T,

thenbecomesthefollowing

withA=area ofthedisc. This isalso anexpression fortherateof changeinaxial momentum:

T

=A/7(V

+Figure3

[image:25.538.30.509.139.460.2]Andthisindicatesthathalfofthe addedvelocityoccursbeforetheairscrew andhalfofit

afterthe airscrew.

Therefore

equation(6)

canberewrittentaking

thisintoconsideration,T

=2Ap(V

+ v)v(7)

HereVcanbeconsideredthefreestreamvelocityor grossvelocity and v canbe takenas

the"suck"velocityorthevelocityadded

by

theairscrew.Anexamination ofthekineticenergyofthesystemreveals anincreaseovertime

inthefluidsystemcorrespondingto the

following

equations:E^A^V+v^V+vJ-V2)

(8)

Whichreducesto

E=2Ap(V+v)2v

(9)

Whichyieldsthe

following

afterusingequation(7)

E_T(V+v)=QQ

(10)

whereQ isequated toangularvelocityoftheairscrew

(27if)

andQ

isthetorqueoftheairscrew.Nowthisexpression canbeusedtodefine the totalworkdoneonthefluid

by

the thrust.Oncetheactual andidealwork areboth

known,

an expressionfortheefficiencyofthe system canbewritten asfollows:

TV

n=^Q

<>

and wherethe total workdoneis

nQ

=T(V

+And if

y=aV

(13)

where ahereisusedtosymbolizea multiplier

Thentheideal efficiency isthensaidtobe:

V V 1

rj= = =

V+ v V+ aV 1+ a

(14)

By

constructingthisequationtheassumptionismadethat theonly loss inthesystemis dueto thekinetic energyofthe axialvelocity intheslipstream.Butthereare

otherlosses inthe system,which areignored inthis

theory

aslisted below.a) nofriction

drag

ofthebladesb)

nokinetic energy loss intherotationoftheslipstreamc) noloss ofthrust towardsthebladetips

Themostinfluential ofthelistedlosseswouldbe

(a)

becausethereexists alarge amountoffrictionalloss here

depending

onthebladesurfacematerial. Fora quick anddirty

estimate oftheefficiencyof apropeller, one can predictwithsomecertaintythat the

actualefficiencywillbealmost85% thatoftheideal efficiency

(#4,

H.Glauert)

fromtheaboveequation, whichindicatesthatastudyoftheideal efficiency isa good guideto

determining

actual efficiency.Anotherversionoftheefficiencyequationinvolving

power, speed,andthe airscrewdiametercanbe derivedwhen one considers power output

versus powerinputtoapropeller,withthefinalresult

being

thefollowing

1-7

2Prj npND

Itcanbe deduced fromthisequationthatthe

efficiency falls quicklyasthepower

coefficient

increases,

such asattemptingtoput alotof powerthrougharelativelysmallpropeller.

2.2 Blade Element

Theory

(ExtensionofMomentumTheory)

Asa continuation ofthesimplified momentumtheory,thebladeelement

theory

providesfora moredetailedanalysis ofthepropeller

by

exploringtheforcesexperiencedby

theairscrewblade. Aswiththemomentumtheory,thereare several assumptions madeby

thistheory

inordertoconduct an analysis andthey

are asfollows:1. Therotationalvelocityofthe tipsoftheblade doesnot approachthe

speedofsound.

2. The blade isplacedinauniform streamofvelocity Vparallelto the

axis ofrotation.

Thereexistalso someterms thatneedtobedefined inorderforafullexplanationto

becomeuseful in

helping

oneanalyze a propeller.Inflow- Flow

immediately

in frontofscrewOutflow- Flow

immediately

behindthescrewWake- Flow inslipstreamfar behindthe screw

Interference Flow

-Velocity

fieldof system oftrailing

vortices which acts as aninterference ontheblade elements

Nowthatsomeimportanttermshave been defined forthe reader, a morein depthlookat

theactivity surroundingapropellerblade canbe discussed. Inthis theory,asinthe

timeitissubjecttointerference flowrepresented

by

helicalvorticescreatedby

tip

androotblade elements. (Inthis case, theexact effect ofthevorticesis difficulttoanalyze

andthemean valueisgenerallysubstituted.)

To begintheanalysis,thetorqueofthe airscrew mustbeexaminedand

understoodtocreate rotation abouttheaxis offlow intheslipstream. Notethatthis

rotationdoesnot occurinfrontoftheairscrew or outsidethe

boundary

layer. Thisrotationthen transformsintovortices and circulation aroundtheblades. Dueto the

trailing

vortices,theflow intheplane ofthe screwwillhavean angularvelocity inthesame sense astherotation ofthescrew. Thecirculation aroundthe screwbladeswill

cause equal and opposite angularvelocities oftheinflowandoutflow.Oncethe flow

motionis understood, theangular momentum oftheoutflow can beexaminedandknown

tobe closelyrelatedto the torqueofthe screw.

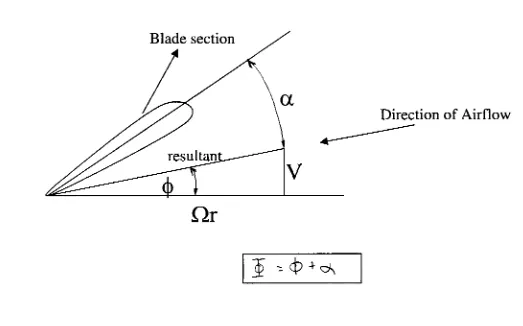

Consider bladeelementdrat radialdistancerintheFigure 4. Fromthis figurethe

following

variables andequationscanbe derived. Equation(16)

showsthattheaccelerationoftheflow inthe directionofthebladetravelresultsintorque.Equation

(17)

isthentheincrementalthrustforanelementalongthepropellerblade.

dQ

=torque of this elementu=axial velocity thru the airscrew annulus

torque=rate of increase of angular momentum

dQ

=2-xp

u-2--r2dr

(16)

^

=4-r> VQ(l+

a)a'

(17)

andais theaxialinterferenceflowwhile afistherotationalinterference flow.

Theaxialvelocity isconsideredtobecontinuousthrough theairscrew and ubecomes the

axialvelocityattheinflowand outflow. In estimatingtheaxialinterference flow

magnitude one importantassumption mustbe made:the

trailing

vortices movein helices.Theinterference flowexperienced

by

thebladesatdistancerfrom theaxisdoesn't dependonbladeelements at otherdistances. Forthisstatementtobe true,

considerthebladeelementdratrfromthecenter whentheremainderoftheairscrewis

not present. The

trailing

vortices which spring fromtheends oftheelementlieon thesurfaces ofthe twocircular cylinders of radius randr+dr. The vorticity isresolvedinto

twoparts:

1. Axis paralleltothescrew axis

2. Circumferential

The firstoftheseparts acts as a

bearing

betweentherollingshell of airboundedby

thecylindrical surfacesandthe generalair.Thistranslates intothe factthat thegeneral mass

of aircannot acquire circulationabouttheaxis andhencetherotationduetothetorqueof

theblade elementis confinedto theregionbetweenthe twocylinders.Thereforethe

rotational interference duetothevortexsystemisexperiencedonly

by

thoseblades thatcausethevorticity.

Discovering

thisfact,

ageometricanalysisofthevelocities andtheoverall effectFigure4

Blade

Element

Theory

DiagramResultant Force

rQ(l-a').

Rotational velocity

M

Resultant

velocity

V(l+a).

[image:31.564.22.519.133.458.2]where

a V (1+a) tand=

-(20)

rQ(l-a')Cl

andCo

aredefinedastheliftanddrag

coefficients, respectively.These applytoairfoilintwo-dimensionalmotion.Thesecanberesolvedintothrustandtorqueaccordingto the

following

equations:\

=CLcost#-CDsin^

(21)

/*2 =

CL

sin<p+CD

costp(22)

Theelements ofthrust andtorquegiven

by

thebladeelement of areacdr,wherecisthechord oftheairfoil shape,thenbecome:

dl=AiyipM1cdr

(23)

Theseexpressions arethenmultiplied

by

the numberofbladestoobtaintheelements ofthrustandtorquefortheentire airscrew. Inplace ofc,sisusedforthepropellerblades

whichisequaltofollowing:

Nc

(25)

s= 2-r

whereN isthenumberofblades inthe airscew. srepresentstheratio ofbladeelementsto

Andthe advanceratioforthescrew canbegivenas:

. V r V r

1-a'

,

(26)

rjD R rQ R 1+ a

There existtwoextremities forthisanalysisthefirstof whichis thefollowing:

(27)

sCL=4^2

where

C_

istaken atanangle ofincidenceequalto 0-<f>. Thiscorrespondstoa normal

positive value of</>forapropulsive screw. Thesecondextremityoccurs whenthe thrust

disappearsatapoint given

by

thefollowing:CL=CDtan<*

(28)

Thetorqueispositivebutvanishes at ahigherrate of advancewhen

(29)

CL

CD

cot<j>Betweenthesetwopoints, theairscrewis actingas abrakeandbeyondthepoint where

torqueis negative, theairscrew isthenactingas a windmill.

For efficiency utilizingthemethodfound intheNotesinthe appendix and

correspondingtoanincrementalelementat

dr,

theequationbecomesthe following:VdT

_

V

\

tan^

(30)

T,~

where

CD-CLtanr

(31>

Note : yis definedas theeffect of profile

drag

oftheblades and

a1

is theeffect of rotation onthe slipstream.

Profile

drag

is definedastheskinfrictionandinduceddrag

on an airfoil shaped section.Inthefirstoftheseequationstherearetwoadditional sources ofenergy loss andthese are

thefollowing:

1.

a'

: effect of rotation ontheslipstream

2. y: effect of profile

drag

oftheblades. The first loss issmall overthe

workingrange ofthepropeller,butthe secondloss

becomes importantwhenthebladeelement approachestheattitudeofnolift.

Nowthat thebladeelement

theory

has been introducedandexplained,showingthateachbladeelementcontributesto theperformanceofthepropeller, anothertechnique

employingtheuse of a computer softwareprogramwillnowbecovered. Thissoftware

programtakesinto account a numberofbladeelements andthedesignofthepropellerin

ordertopredicttheperformance andefficiencyoftheoverall prop.This eliminatesthe

needtoperformtedioushandcalculationsinorderto get afasterestimate oftheprop

performance without construction ofthepropelleritself. As

long

asgeometryat certainChapter

3

:Propeller Software

Program

3.1 Propeller

Software

BackgroundModern

Prop

andDuctDesign, by

Martin HollmannandMarkBettosini,

is awritten guide thatfirstexplainsthe

theory

ofdesign behindpropellers and ductsandthenproceedsto analyze potentialdesigns with anincludedprogram.But beforetheprogram

canbeproperlyutilized,a generalunderstandingoftheauthors'

knowledge concerning

thesubject mustbe undertaken.Tothisend,the

theory

inthemanualwillbeexplainedindetailandthentherelativeinputsrequiredfornumeric predictionswillbe divulged.

Thetheoreticalbackgroundon whichthesoftwareprogramis basedwillnowbe

discussed. The geometryofthebladetobeusedonthe aircraftmustbe

fully

described inordertoderivemathematicequationsthatpertaintothrust,power,and efficiency.The

mostbasicofthesequantitiesincludethebladepitch angle 0,theradius ratwhicha

bladesectionis described alongthe

blade,

the totalradiusRoftheblade,

andtherotational speedoftheblade Q. IfoneconsultsFigure 5on thenextpage, these

quantitiesare moreeasilyreferenced. It isalsonecessarytoknoworhave an

understandingoftherelativewind speedseen

by

boththeplane andthepropeller.Thisquantity isgiven

by

:v

=Vv>(nr)!

<32>

where

V_

is thefreeairflow,

whichin anycaseisthesamefortheprop andtheplanebeing

that thepropellerisattachedto theplane. Itcan alsobeseenthat thepitch angleisthesumoftwootheranglesasfollows:

0

=a+O

Figure5

Blade Element Diagram

for Program Input

Blade

sectionQr

J

- <> +<^

[image:36.584.28.551.179.505.2]where

O =

tan"1

-z-(34)

ClrIt isobviousthat thepitch ofthebladevaries alongtheradius and so O is determinedat

eachbladesection alongtheradius(note thatit isrecommendedtousetensectionsfora

betteranalysis),fora certain speed,and certainfree flowof air. Thevariablea however

remains a constantbetween 2and4 degreeswhich givesthemostlift forthe leastamount

of powerforcertainwingsections.

Onceanunderstandingofthesequantitieshas beenacquired,it isnowrelevantto

discuss efficiency 7ofapropeller which canbe definedas :

P 77=7"

(35)

Inthis equation, theefficiency is simply describedasthepower availablefromthe

propellerovertheshaftbrakepowerdeliveredto thepropeller

by

the engine orthedrivesystemitself. Butthisequationneedstobe broken down intoa moredescriptiveequation

withknownquantities andmeasurablevalues such as:

TV

77

"p

(36)

wherethepower available attheprop has beenequatedto thefreestreamflowmultiplied

by

theavailablethrust. Frompasttheory

andextensiveexperimentation,it has beendeterminedthat theefficiencyisafunctionof adimensionless quantity

J,

theadvancedwhere nisthe

frequency.

Agraph canbegenerateddepicting

theefficiencyversusvarious values ofJ in orderto

directly

readtheefficiencynumber,butthis techniquecannotbeusedforbladesthatdonothaveafixedpitch. Inthiscase a more complex

techniquemustbe employed whichiswherethe software programbecomesmostuseful.

Twoother quantities ofinterest are also analyzed and graphed

by

thesoftwareprogram. Theseinclude

Ct,

thecoefficient ofthrust, andCp,

thecoefficientof power.Thecoefficient ofthrustfora propellerdependsonthreeseparatefactorswhichinclude

theshape ofthepropeller, the advanceratio, andtheReynold'snumber.Thepropeller

thrustisequalto thefollowing:

T

=pnld*CT

(38)

whered isthediameterofthepropeller andn istherotationalspeed ofthepropellerin

revolutionsper second. Thepower coefficient alsodependsonthesamefactors affecting

the thrustcoefficientanditcanbeequatedto thefollowing:

CP

=2nCQ

(39)

where

Cq

isthecoefficientoftorque. Thepower equationstarts asthefollowing:P

=pn3d527rCQ

(40)

and canbereducedtothefollowing:

P =

Whencallingupontheaid of a softwareprogramfor

help

inanengineeringproblem,it isalways good practicetounderstandtheinputsrequiredoftheuser andthe

correspondingoutputstobeinterpreted

by

theuseraswell.Forthisparticular programthereare alargenumber ofinputsneededinordertocorrectly describethepropeller

geometricallyas well astheenvironmentinwhichitwilloperate. This assiststhe

computerin

determining

a more accurate resultintheschemeofthings.The listofinputvariables canbefound intheNotessection.The otherinputsrequiredforthecorrect

analysis ofthepropeller canbe foundwiththeTableofInputs inthenext section.These

3.2 Selected InputsForthePropellerProgram (withcollaborationfrom Ken

Blackburn)

After

defining

andlisting

the inputsto thesoftwareprogram,one mustbe abletoinputthecorrect valuesfortheparticulartypeofpropeller

being

usedfortheevaluation.This willtell thepotential propellerdesignerandbuilderwhetherthebladesare adequate

enough forthepurpose intended. Forthisparticularanalysis, reverseengineering isused

todeterminetheefficiencyoftheWrightBrothers'

propeller. Sincethebladeis already

inexistence, thevalues mustsimply be determined fromthesectionsprovidedonthe

propeller

drawing

itself.Inordertoacquirethenecessary inputsrequiredforthesoftware program, the

propellerandinturn eachbladesectionmustbe carefullyanalyzed.Forthistask, an

Eppler

boundary

layerprogramisemployed. Informationonthedrawing

is transferred tothisprogramfortheanalysis whichoccursintwosteps. The firstofthesestepsis an

inviscid flowanalysiswhichlooksattheairflowaroundthe airfoil. Itproduces avelocity

distributionandpressuredistribution tobeusedinthe second step.Importanttonoteis

thatthisprogram assumes no

boundary

layer. Thesecond stepoftheprogramis anintegral

boundary

layersolverthatintegratesindividualeffects on small sections oftheairfoil. Thisis apiecewiseintegratorand,intheend, this program can producethe

requiredinputs forthe analysisofthepropellerusingtheefficiencyprogram.

Analyzing

thesesectionsaccordingtoKen

Blackburn,

thefollowing

values wereinputted intotheM: 10

THETA75: 28.875

RPM: 428 rpm

VMPHBEGIN:0

VMPHEND: 50

VMPHSTEP: 1

D: 8.5'

N:2

RHO: .002378

CLP: 2.0

MINCL: 1.2

ALPHAMINCL: 22

Theaforementionedvariablesdescribetheoperatingconditions fortheWrightBrothers'

propeller.Thevariable THETA75 specificallyrefersto theangle of attack atthespan

75%outfromthe centerhubofthepropeller. Thesoftwareprogramusesthisvlaueto

determine allothervalues,

by

assumingtheangle oftwistas afunctionof radiusis ideal.Anothernoticeable variableis theRPMofthepropeller.The value of428 rpm was

retrievedfroma

drawing

oftheWrightpropeller.Thisrpm waskeptconstantthroughoutthe analysisbecausethepropellerturnedata constant rpm ontheModel B.

Nowadays,

propeller rpm canbe altered

during

flight butthisis notthecase withtheModel B. Thenextset ofvariables takesintoaccountthesections oftheblade andtheirspecific

characteristics andproperties.Thiswillensuretheprogramhasthecorrect propeller

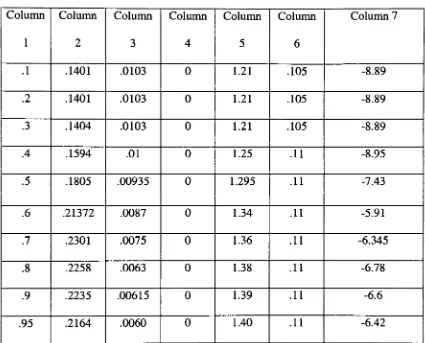

Table 1

TableofInputs

Column 1 Column 2 Column 3 Column 4 Column 5 Column 6 Column 7

.1 .1401 .0103 0 1.21 .105 -8.89

.2 .1401 .0103 0 1.21 .105 -8.89

.3 .1404 .0103 0 1.21 .105 -8.89

.4 .1594 .01 0 1.25 -8.95

.5 .1805 .00935 0 1.295 .11 -7.43

.6 .21372 .0087 0 1.34 -5.91

.7 .2301 .0075 0 1.36 -6.345

.8 .2258 .0063 0 1.38 -6.78

.9 .2235 .00615 0 1.39 -6.6

.95 .2164 .0060 0 1.40 -6.42

Column 1 : Midelement spanwiselocationasa percent ofthe total

Column 2: Widthofthebladeairfoilsection as given

by

thefollowing

Width=Chord/Radius

Columns 3 & 4: Coefficientsofthefollowingequation

CD

=A,

+A3

xa2

whereA*isobtainedbysettingtheangle of attacktozero andreadingthecorrespondingCDandA3is obtained

by

readingtheCDcorrespondingtoaknownangle of attack.

Column5: MaxCLforeach section

Column6: Liftcurve slopeforeach section(enteredperdegree)

Thetableontheprecedingpage completestherest oftheinputs necessary forthe

output ofthegraphs andefficiencynumbers

by

thepropeller program.By

alteringthesenumbers, one can changetheperformance characteristics ofthepropellerandinturnthe

plane towhichthepropeller will beattached.Thesenumbers werecarefullycalculatedin

ordertoobtainthecorrecttraitsoftheWrightBrothers'

propeller. Graphical

3.3 Output

Results

from

Software

Program

Graph1- 428

rpm

Efficiency

vs.Speed1 1

09

-OR^

07

-o

n r

-_.

i>

>>

c

05-0)

'5

m

04-i>

no

-0<?

10 15 20 25

Speed(mph) 30

?Efficiency

Graph2- 428

rpm

HPvs.Speed

18

16

14

12

10

a.

z

<>

n

o

<>

o

10 15 20 25

Speed(mph)

?HP

Graph3- 428rpm

Efficiency

vs.Advanced Ratio0.9

0.8

0.7

^0.6

>>

c 0.5

a,

'5

UJ

0.4

0.3

0.2

0.1

?

?

?

?

<> 1 1

0.2 0.4 0.6

AdvancedRatio

0.8 1.2

Graph4- 428 rpm

Thrustvs.Speed

120

100

80

|

6040

20 o

V. a

<?

o

10 15 20 25

Speed(mph)

?Thrust

Graph 5- 428rpm

Cp

vs, Advanced Ratio0.3

0.25

0.2

0.15

0.1

0.05

?

?

?

_

0.2 0.4 0.6

Advanced Ratio

?Cp

0.2

0.18

0.16

0.14

0.12

0.1

0.08

0.06

0.04

0.02

0.2

Graph6- 428rpm

CTvs.Advanced Ratio

?

? ?

?

<

0.4 0.6

AdvancedRatio

0.8

?CT

These graphscannowbeusedinan overall performance evaluationoftheWright

ModelB aircraftin Chapter 4. Notethat thediscussionofthesesix graphs willbeundertaken

Chapter

4

:Performance

Evaluation

ofthe

Wright

Model

B

Aircraft

Nowthat thecomputer software programhas beenutilized and produced

performancegraphs, a

drag

studywillbeconductedtobeusedinconjunction withtheperformance graphsin ordertopredictthecruise speed oftheWright Model B aircraft. In

this section,datafromtheWright Flyer willbe usedand correctedtofittheWright

Model B. Thismethod was chosendueto thelackofdata inexistence ontheModel B.

4.1

Drag

AnalysisProcedureoftheWright Model BThe first step in conductinga

drag

studyoftheWright Model B wastoobtain anydrawingsavailable oftheplaneinordertoaidinthecalculationoftheequivalentfrontal

area oftheplane. Inthis caseboth drawingsfortheFlyerandtheBwere obtained(for

reasonstobe discussed later). These drawingswere presented asFigures 1 and2 inorder

forthereadertobetterviewthe available material. Oncethescale ofthe

drawing

wasestablished, measurementsweretakenof cable

length,

strutlength,

approximate enginesize,and approximatepilotsize.

Following

the measurements,adrag

coefficientforeach separate piece wasdeterminedwith

help

fromaFluid DynamicDrag

textbook(Hoerner,S 1965). Cableandstrutcoefficientsweretaken

directly

fromthebook,

while aCd

forthepilothadtobecalculatedusingejection seatdataprovidedinthebook (Note:thefrontalarea ofthepilot

wasassumedtobe equivalenttotheejectionseatbecausebothwerein asittingposition.

Thisanalysis willbeshowninthenumerical results section.).Inthe end,thetotal

equivalentflatplatearea, theoverall

drag

coefficient oftheplane wasthencalculatedaccordingtothefollowing:

(42)

C.plane=

S.

wmg

where

Swing

is thetotal area ofthewing,notjustthefrontal area.Now eventhiscoefficientis not

totally

accurate so thata correctionfactormustbeappliedtoboostthecoefficienttomatch windtunneldata. Becausea

l/8th

scalemodel oftheFlyer hasbeen

inthewindtunnel,thetotal

drag

coefficients oftheplane arealready known. Thesewillbeusedto

help

determinethedrag

coefficients ofthemodelB.Theinherentassumption isthat theplanes arerelativelysimilarin flight. Basedondatato

date,

thisappearstobe agood assumptiondueto thefactthat theplaneswere nottoodifferent in design. There

wassome differenceinthenumberofpilots,

landing

gear,andtailbooms buttheoverallplaneappeared similarenoughtomakethis assumption.

The first stepwastodeterminethe totalcoefficientof

drag

oftheplaneinordertofurther carryontothefinal stepof

determining

thepowerrequiredtokeep

theplaneinflight. Thetotalcoefficientof

drag

canbe determined accordingto thefollowing:(43)

C Total =C'Parasitic+C. Inducedda a

whereparasitic

drag

is due to theflatplate areaandtheinduceddrag

is duetoliftgenerated

by

thewingsandtheangle of attack oftheplane.Sinceparasiticdrag

is merelytheonlypartrequiring furtheranalysis.The

following

equation canbedirectly

appliedtodeterminetheinduced

drag

coefficient:C2

C'induced=

(^4)

-e

(AR)

where

Cl

is theliftcoefficient,eisa correctionfactor(approximately

equalto0.9fortheWrightaircraft), andAR istheaspect ratio fortheplane. Since

Cl

willbeplotted againstCd,

Cl

isthengiven andisnot neededtobecalculated.As withCl,

eand ;rarealreadyknownvalues

leaving

ARtobe determined foreach respectiveplane.Theaspect ratiowouldbe easily determined foramonoplane,butchanges forthe

case oftheWrightplaneswhichwerebi-planes. Inthiscasethewingspan andheight

betweenwings mustbe known. Oncetheratio ofheighttowingspan was

determined,

itwasfoundon agraph(canbeseenintheResultsandDiscussion

Chapter)

andtracedoverto thecorrespondingAi/A value.Thiswasmerelyanintermediate step in

determining

theultimate aspectratio- Ai.The valueARwasthencalculatedby

thefollowing:

b2

(45)

AR

=wing

wherebis thewingspanand

Swing

isthetotalarea ofthewings.Oncethiswasdetermined,

theoverallAi foreachplanewasfinalized.This stepwas repeatedfor boththeFlyerandtheBmodels. (Notethatseparate plots

were created andthesewillbeshownintheResultsandDiscussion

Chapter.)

TheinducedplotfortheFlyerwasthencombined withtheoverall

Cd

fortheFlyer. Thismeansthatthe inducedplot couldbe subtractedfromtheoverall plotinordertoisolate

theparasitic

drag

only,which wasdoneaccordingto thefollowing:Cd

parasitic=Cdoverall-Conduced

The resultingnumbers werethenadjusted

by

multiplyingthemby

thefollowing

correctionfactor: (Thecorrectionfactor accountsforalloftheparasiticdifferences

betweentheFlyerandBso

CdB(parasitic)

canbefound.)

cf=

Y,CdS(B)

(47)

Y^CdS

(Flyer)

CdB(

parasitic)=cfxCdFlyer{

parasitic)(48)

where

CjS(B)

isthe totalequivalent flatplate area ofB aircraft andCdS(Flyer)

is the totalequivalentflatplate areaforthe Flyer. Thesenew numbers, alsoknownastheparasitic

drag

fortheBplane,werethenaddedto theinducedcurvefortheB inordertogetthecombined

drag

coefficient fortheB planeaccordingto thefollowing:Cd

(B total)=Cd

(B induced)+cf*Cd(flyer

parasitic)'4")

Anew curvewas thenplottedtodepictthe

Cl

vs.Cj

totalfortheB plane.ThiscanbeOneofthelaststeps ofthisanalysis wastodetermine the

drag

force atcertainspeeds ontheplane.Thiswas conducted

by

firstdetermining

thevelocityat whichtheplane was

flying

accordingto thefollowing

equation:CL=

, W

(50)

y2pv2swing

where Wisthe weight oftheplane,p istheair

density,

V isthevelocity,andSWig

is thetotal wingarea.

Knowing

Cl, W, S,

andp, theonlyunknown valueis thevelocity.After rearrangingtheequationthevelocitycanbe found from:

W

(51)

V C S1

wing

Knowing

thisquantityandthecoefficient ofdrag

at eachCL,

thedrag

forcewasthencalculatedasfollows:

1/ 2

(52>

Drag

Force =C,

x V,'

xpxV x5

whereall oftheabove quantities have been previously definedand areknown inthe

equation. From heretotherequiredpower was onlya matter ofplugging intothe

following

equation:Powerrequired=

Drag

ForcexVelocity

(")

Thiswasthenconvertedinto horsepowerthrough a series of conversions which were

ontheplot of power available vs. speed obtainedfromthesoftware analysis. Thepower

obtainedfromthesoftware program neededtobe doubledinordertoaccountforthe two

propellers present ontheplane.

The finalstepwasto determinetheclimb speed

by

readingthespeedoff ofthegraphthatcorresponds to theleastamount ofHPrequired.Thentherate ofclimb,

R,

canbefoundaccordingto thefollowing:

P -P

R=

(54)

Weight K }

where

Pa

is theavailable power andPr

istherequired power attheclimb speed.4.2

Drag Study

Numerical

AnalysisandResultsAccording

to theanalysisdescriptiongivenintheTheory

Chapter,

thefollowing

drag

studyoftheWright BrothersPlanes,

the FlyerandtheB,

was undertaken andcompletedand exhibitedtheproceedingresults.

Total Equivalent FlatPlate Area

Flyer: 2.69

(cables)

+ 13.54(struts)

+ 1.8 (chaintubes)+2.205(engine)

+7.65(wing)

+6.48 (person+ radiator +fueltank)=34.365Model B :

(1.91+.32) (cables)

+ 12.85(struts)

+2.21 (chaintubes)+ 1.42(motor)

+.385

(wheels)

+7.08(wing)

+ 12.96 (pilot+ radiator +fuel tank)=39.135Cd

ofPerson inSitting

Position (from Fluid- DynamicDrag

Book)

Thefirst step in

determining

theequivalentflatplate area oftheWrightplaneswas tofindthe totalprojectedfrontal areafromthedrawings. Thenthe

Cd

wasfound intheFluid Dynamic

Drag

bookand appliedto thefrontalarea. Inthecaseofthepilottherewasnoclear-cut

drag

coefficient.The frontalareahadtoassumedandthe

drag

coefficient wascalculatedaccordingto theinformationfoundinthebook (theexample was foran ejection seatbutthe

drag

coefficientwas appliedtotheWrightpilot).

=

V~oV2SC

(55)

Drag

force=where

5 =

6ft2(asumed)

V=500 knots=843.9-^/

p=.00238

Drag

force=5500lbsKnowing

thisinformation,

theCd

oftheejection seat/personisequivalentto 1.08.Aspect Ratio Determination (from Fluid- Dynamic

Drag

book)

Figure4 :AspectRatio Diagram

ATA (C^ ()

> ae a (e,) ()

A C II (C,) (<)

A> k/l m

Gap

Ratio=h/bEffectiveAspect Ratio =Ai

GeometricAspect Ratio=A=

y^

[image:57.538.113.444.296.626.2]Flyer Analysis:

B Analysis:

Plotof

Cd

InducedGap

Ratio=h/

=6/A

n=0. 15

40

A=

40Xio

=3-137Ai=1.25x3.137=3.921

Gap

Ratio=h/b=

5'4%s

5=0.141

A/A

=l.23A= =3.140

'472

Ai=1.23x3.140=3.8622

C 2 C,induced = , .

d

n{0.9)Ai

Oncetheaspectratiohas been determined fromtheprevious analysis,theinduced

drag

coefficientcan beplotted versusthecoefficientoflift. Theresults canbeseenintheFlyer

induced

drag

plotC C.induced = , .

'

^-(0.9)3.921

Graph7- Flyerinduced

drag

CL

vs.Cd

Flyer

n

(

1 <

) 8 ?

<

<

1 R ?

1 A. ?

1*? ?

n i?

-0.01 0.01 0.03 0.05 0.07 0.09 0.11 0.13 0.15

Cd

?Cd induced

B induced

drag

plotC

C,

induced=-, .

'

^-(0.9)3.3.8622

Graph 8-- Model B induced

drag

r>

CL

vs.Cd

B

(

(

I

i ?

i p ?

J.Q

1fi ?

1 A ?

\i ?

J.c fl .

*

-0.01 0.01 0.03 O.I35 0.07 0.09 0.11

Cd

0.13 0. 15

PlotofFlyer

Induced

Drag

+ParasiticDrag

(takenfromexistingdata)

Graph9- Flyer induced

andtotal

drag

CL

vs.Cd

Ryer 1.2 0.8 0.6 0.4 0.2 ? ? ? *t

1

?,, B

0.05 0.1 0.15

Cd

0.2 0.25 0.3

?Cd induced Cd induced+parasite

Parasitic

Drag

CoefficientDeterminationoftheFlyerCdparastic=

Cd

(measured)

-Conduced

Using

theabovedescribedequationandthecurves presentedintheprevioussection,theparasitic

drag

coefficient oftheFlyerwasdeterminedat eachdatapoint and [image:60.538.101.463.92.332.2]placedintothe

following

table:Table 2- Flyer

Drag

CoefficientsCd

inducedCd

totalCd

parasite0 0.13 0.13

0.000902009 0.12 0.119097991

0.003608035 0.11 0.106391965

0.008118079 0.11 0.101881921 0.014432141 0.11 0.095567859

Determination

oftheParasiticCd

fortheBNowthat theparasitic

drag

coefficienthas been determined fortheFlyer,

itcanbeappliedtotheB with afewadjustments as follows usingacorrectionfactor:

YC.S(B)

39.135 cf =__^

d v J

= =1.1388

2^CdS

(Flyer)

34.365Thetotalcoefficient of

drag

fortheB isasfollows:Cd(B total)=Cd(B

induced)

+cfx.Cd(flyer

parasitic)

[image:61.538.185.352.379.569.2]This yieldsthe

following

tableof values andthegraphonthefollowing

page:Table 3- Model B

Drag

CoefficientsCdinduced Cdtotal

0 0.148044522

Graph 10- Model B induced

andtotal

drag

CLvsCd

B

O

1

1 _ ??

Ofi

?

\J.KJ

04

ut

OP

A?\J.C

n;

\

.0

?

Cd

induced

Cd

irduced+parasite

Drag

ForceDetermination

fortheBOncetheabove plothasbeencompleted, a

drag

forcecanbeobtainedby

applyingthe

following

equationsin theorder presented:V =

W

/9 L wing

Drag

Force =C.x]/xpxV2xS

Inthiscasetheunknownvelocity is found first

by

pullingCL

valuesfromthegraphs andthenapplyingthe second equationfor

drag

force. Fromthese twoequations thefollowing

tablewas produced:

Table4- Model B

Velocity

/Drag

Forcecd

Total

Velocity

ft/s

drag

forceLbs

CL

0 0.148045 471.747814 18505.51

0.1 0.136545 149.179757 1706.808

0.2 0.124823 105.486018 780.1388

0.3 0.124265 86.1289731 517.7702

0.4 0.123485 74.5898787 385.8893

0.5 0.125329 66.7152157 313.3209

0.6 0.12695 60.9023809 264.4775

0.7 0.131194 56.3846484 234.2751

0.8 0.14091 52.743009 220.1719

0.9 0.156098 49.7265858 216.8015

1 0.193838 47.1747814 242.2965

[image:63.538.168.374.351.562.2]Power Required for Flight

Nowthat the

drag

forcehas beencalculated, theoverall power requiredtokeep

theplanein flightatdifferentvelocities canbe determined. Oncethishas been

found,

itcanbeplotted onthe same graph as power available produced

by

the softwareprogram.Thepower required canbefoundviathefollowing:

Power required =

Drag

ForcexVelocity

Aftertheequation was appliedto thedata intheprevioustableand

following

someconversionstogetto theultimate goal,

HP,

thefollowing

tablewas produced:Table 5- Model B Required Power

Velocity

Ft/s 471.747814 149.179757 105.486018 86.1289731 74.5898787 66.7152157 60.9023809 56.3846484 52.743009 49.7265858 47.1747814 44.9793892 295.255drag

force Lbs 18505.51 1706.808 780.1388 517.7702 385.8893 313.3209 264.4775 234.2751 220.1719 216.8015 242.2965 powerreq HP 15872.63 462.9482 149.6252 81.08196 52.33359 38.00599 29.28605 24.01734 21.11372 19.60148 20.78236 24.14619ThisshowstheHPrequiredagainst speed and

drag

force. Inthenext section theplot ofHPrequiredvs. Speed

(mph)

willbe presentedalongwiththeHPavailable vs. SpeedHP

Required/Available

vs.Speed

This isthelast step intheoverall

drag

studyoftheWright Bplane. Fromthisgraphthestall speed canbedeterminedas well as regions ofliftandsinking.The

following

graph willbe further discussedinthenext section ofthis chapter.60

50

40

_ 30

20

10

Graph11

Power Required/ Power Available

'*-7<21.1vi.vc--.

A

A

/

/

/

*

10 20 30

Speed(mph)

40 50

PowerRequiredB

-Power Available

60

ClimbSpeedand Climb Rate

According

tothegraphabove, theclimbspeedisapproximately 34mph andtheclimb rateisthefollowing:

,,06107-107")

,,

Chapter

5

:Discussion

ofResults

5.1 Climb Speed

andClimb Rate

Fromtheprevious chapteritwas shownthat thebestclimb speed occurred at34

mph andthiscorrespondedtoa climb rate or almost4.26ft/sor255 ft/min. These values

comparecloselywiththeknowndata fromtheModel Bperiod of200 ft/min. Theclimb

in ft/sisoften referredtoasthespecific excess energy. Atsealevelanaircraftperforms

differently

thenathigheraltitudes. Ascomparedtosealevel,

anaircraft'sengine losespower athigheraltitudesdueto the thinnessoftheair. Theenginecannotingestenough

airtomaintain performance andthereforeitcannot climb over a certain altitude.

5.2

Performance

atCL

Max

Theaircraft specific excessenergyatCLmaxis 2.26 ft/s . This indicatesthat the

aircraft canstillclimbwhileontheedge of astall,whichisadesirabletrait. Apilot can

usethisadvantagewhenabortinga

landing

orclearing highterrain.5.3 Cruise Speed

Thecruise speed was readfromthepowercurve whichdepictedtheavailable

powerandtherequired power atspecificvelocities. Thetwocurvesintersectedat41

mph. This becomesthecruisespeed oftheaircraft. Availabledata fromthe period ofthe

ModelB aircraftindicatethatitscruise speedwas around40mph.This comparesvery

closelyto thatofthedatagenerated

by

thesoftwareprogram andthedrag

study.5.4 Propeller Performance

Efficiency

of apropellerisvital to theperformanceof an aircraftinflight bothinistoproducethrustand act against a

body

of airin ordertopropeltheplanein aforwarddirection. Thepropellersatthe timeoftheWrights were

hardly

efficient andthereforetheirgoal of66%seemed out ofreach,butthroughperseveranceandhardwork

they

succeeded.Theanalysis ofthepropeller conductedhere wastoconfirmtheirdesignand

theirnumerical outputs. Becausethepropellerturnedat one speed most ofthetime,the

analysis was run at a constant rpm of

428,

being

thisis a published numberlinkedtotheModel B aircraft.

Thehorsepowergraph

(2)

fromthesoftware programindicatethepowerinputtopropeller(which ismultiplied

by

2forthedualpropellerset-up) and should notbeconfused withthepowerresulting fromthe thrust.The efficiency factorreducesthe

powerpropellingthe aircraftforward.

Asitturns out,the428 rpm resultsin 28 totalHPrequired atthepropellers, which

isaboutrightforthevertical4engine.Thisenginewascapable of35

HP,

butthetransmissionlossesand

density

of air will reducethispower.SincetheWright Brothers first designedtheirpropeller,therehave been

enormousimprovements andrefinementsmadeon propellerdesign

itself,

andinturntheefficiencyofthepropeller. As a result ofthese

improvements,

today'spropellers canbeChapter 6

:Conclusions

&

Recommendations

6.1

Conclusions

Inthepreviouschapter,the results obtainedthrough thesoftware analysis andthe

drag

studywere presented and discussedasfarastheircorrelationto thedataormeasurements obtained

by

theWright Brothers. Thischapterwill attempttodrawconclusionsfromtheseresults andthe

following

chapter willmake recommendationsinordertoeasefurther studyofthissubject matter. Fromthefirstchapter, theobjective of

thisresearch wastodetermine theaccuracyand correctness oftheWright Brothers in

theirquesttodesignapropellerfortheirairplane.

Thefirstareaof concern was theefficiencyofthepropelleritself. From observing

the presenteddataand graphsintheResultsandDiscussion

Chapter,

it isclearthatbothstudies producesimilar enoughresultstoconcludethattheir theorieswere correct and

theirpropeller performedinthemanneritwasintended.

Taking

thecross sections andinputting

theircorrespondinggeometricaldataintothesoftware program wastheultimatetestofthepropeller.Thesoftware wasdesignedtoconductefficiencystudies giventhe

shape ofthepropelleras well astheoperatingcircumstances ofthepropeller, orinthis

casetheplaneitself. Thistranslatesintoarelativelyprecise physical model ofthe

propellerandtheresults canbeconsideredasaccurateastheinputtedmodel. Outofthe

softwarecame anefficiencyof70%thatis notfaroff ofthe66%predicted

by

theWrightbe acceptable

including

theavailablehorsepoweratdifferentspeeds(

agraphthatwaspresented intheResultsandDiscussionChapter). Thenextstepoftheanalysiscouldbe

completed

knowing

thisinformation.Thesecond objective ofthisresearch wastodeterminepower requiredto

keep

theplaneinflight.Thecalculated powerdatacouldbeplotted againstthepredicted power

dataretrieved fromthesoftware and a cruise speed couldbe determined. Fromscale

drawingsofboththeFlyerandthe

B,

adrag

studywas conductedaccordingtotheprocedureinthe

Theory

Chapter (theresults of whichcanbeseenintheResultsandDiscussion Chapter). This

drag

studyyieldedbothspeeds andthedrag

forcepresent ateach speed.

Using

thisdataandthepowerequationpresented, thepower-requiredcurvewasthendiscovered.

Overlaying

bothplots yieldeda cruise speed of around42mphwhichcloselymatchesthatgivenatthe time theplanewas constructed. Thecombined

powercurvefulfilledthis objectiveintheresearchand showedthat the technique

employedtoconductthe

drag

studycouldactuallyproduceviable numbers with arelativelysmall amountofknowledgeatthe start. Evenwithonlycrude scaledrawingsof

the planes, thefinalnumberswereonlyafewunitsofffromtheirsupposedtargets(as set

by

theWright Brothers).Asmentionedpri