Fault detection and diagnosis of a plastic film extrusion process

Full text

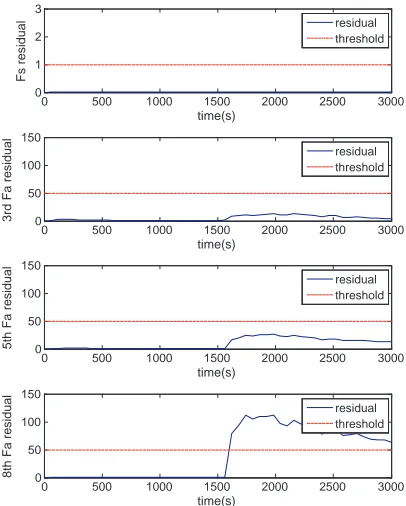

Figure

Related documents

Mining has been criticized for using vast quantities of underground water and for discharging toxic waste into freshwater sources.. Indigenous groups have organized protests

• Lubrication System: Test & Assembly Modification and Using Extra SOS • Hot Gas Path Development: HPT Blade Design and its Coating Modification Services Offered After

and hockey following training sessions the athletes perceived to be easy, moderate or 86 hard.. 87 88 METHOD

In collaboration with the client, his/her support system and the health care team, monitors client’s response to intervention and modifies/grades treatments, care plan, and

We could also use larger markers closer to the virtual building location, but the marker size can get quite unpractical in large range tracking, and occlusion of the markers will be

Whether your continuity arrangements include a commercial third-party recovery centre, or utilize alternate space within your own corporation, it is critical for the resources that

The new method is based on the reconstruction of evolutionary fitness using underlying equations for population dynamics and it can be applied to self-reproducing systems

It also requires minimal coordination ahead of time, since all you really need is a list of identifiable songs that you think most of your team would know. Time investment