Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

2003

Carbon nanotube catalysts: an approach toward

nanodimensional reactions

Mindy Gordon

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu.

Recommended Citation

Carbon Nanotube Catalysts: An Approach Toward Nanodimensional Reactions

Mindy Gordon

July 2003

A thesis submitted in partial fulfillment of the requirements for the degree of

Master of Science in Chemistry

Approved:

Santhanam K.S.V.

Thesis Advisor

Terence C. Morrill

Department Head

Department of Chemistry

Rochester Institute of Technology

Copyright Release Form

Carbon Nanotube Catalysts: An Approach Toward Nanodimensional Reactions

I, Mindy Gordon, hereby grant permission to the Wallace Memorial Library, of

RIT, to reproduce my thesis in whole or in part.

Any use will not be for commercial use

or profit

.

Signature

Mindy Gordon

Table

ofContents

Abstract

i

Acknowledgments

iii

Publications

iv

List

ofFigures

vList

ofSchemes

viiList

ofTables

viiiList

ofEquations

viii1.

Introduction

1

1

.1

Structural Aspects

ofCarbon

1

1. 1. 1 Graphite

(amorphous)

1

1.1.2 Diamond

2

1. 1. 3 Carbon Nanotubes

2

1. 1.4 Synthesis of

Carbon

Nanotubes

3

1. 1.5

Structural

Representations

6

1

.2Electrical

Properties

9

1

.3Mechanical Properties

9

1

.4Purification

andFunctionalization

ofCarbon Nanotubes

10

1.4. 1 Chemical Properties

12

1.4.2 Applications

13

1.5 Nanoscience

15

1.5.1 Nanodimensional

Reactions

16

2.

Experimental

19

2.1

Chemicals

19

2.2 Instrumentation

19

2.2.1

UV-VIS Analysis

of

the

Reaction

19

2.2.2

GC/MS

Characterization

of

theProducts

19

2.2.3

FT1R of

Carbon

Nanotubes

andProducts

20

2.2.4

TGA of

Carbon

Nanotubes

20

2. 2. 5

Fluorescence Spectra

ofAzobenzene

andProducts

21

2.2.6

Atomic Absorption of Carbon Nanotubes

21

2.2.

7

pHof

theCarbon Nanotubes

21

2.3 Procedures

21

2. 3. 1

Functionalization of Carbon Nanotubes

21

2.4

Oxidation

ofAniline

22

2.5

Oxidation

ofp-Toluidine22

2.6

Oxidation

ofMethylamine

23

2.7

Oxidation

ofDiphenylamine

23

3. Results

andDiscussion

23

3.1

Characterization

ofCarbon Nanotubes

23

3. 1. 1 Fourier Transform

Spectroscopy

Studies

23

3. 1.2 Thermogravimetric

Studies

25

3. 1. 3

Scanning

Electron

Microscopic Results

26

3.

1. 4 Transmission

Electron Microscopic Studies

27

3.3

Atomic Absorption

ofFunctionalized Carbon Nanotubes29

3.4

Oxidation

ofPrimary

Amines

30

3. 4. 1

Aniline-Discovery

of

theEffect of

Carbon

Nanotubes

30

3. 4. 2

Influence of

Hydrogen

Peroxide Concentration

31

3.4.3

Role

of

Solvent

onOxidation

32

3. 4. 4

Test For Hydrogen Peroxide Inside

theNanotube

34

3.4.5

Possible Mechanisms

34

3.4.6

Catalysis

of

Carbon

Nanotubes

37

3.4.6.1

Estimation

ofAzobenzene Concentration

38

3.4.6.2

Azobenzene Diffusion Profiles

40

3.4.6.3

Suggestive Evidence For Reaction Inside

theNanotubes

42

3

.4.6.4Stereospecificity

ofAzobenzene

43

3.4.6.5

Oxidation

underInert

atmosphere43

3.4.6.6 Formation

ofNASH Product

44

3.5

Analytical Applications

46

3.6 Experiments

withRPI Carbon Nanotubes

50

3.7

Effect

ofSilica

andLight

52

3.8 Degradation

ofCarbon Nanotubes

52

3.9

Oxidation

ofp-Toluidine53

3.9. 1

Spectral

andKinetic

Features

57

3.10

Oxidation

ofMethylamine

67

4. 1

Principle

67

4.

1. 1

Proposed

Construction

68

4.2

Preliminary

attempts andResults

69

4.

2. 1

Simulation

of

theNanosynthetic Machine

69

4.2.2

Aniline

Oxidation

Reaction

71

4.2.2.1

Concentration

Dependence

ofAniline

90

4.

2. 3

p-ToluidineOxidative

Reaction

90

4.2.4

Methylamine Reaction

101

4.2.5

Oxidation ofDiphenylamine

101

4.3

Relevance

ofNanosynthetic Machine Concept in

Relation

to theExisting Technology

103

5.

Conclusions

1 04

Abstract

The

oxidations of aromatic and aliphatic amineshave

been

investigated

to evaluatethe

catalytic effect offunctionalized

multiwalled carbon nanotubes.

Aniline

oxidationby

hydrogen

peroxide produces

very low

yields ofazoxybenzene; similarly,

p-toluidine

oxidation produces azoxytoluene afterlong

time periods.When

functionalized

multiwalled carbon nanotubes are presentin

these

reactions,

the above oxidations produced unique productssuch as azobenzene or azotoluene within a short period.

The

course ofthe reaction

has been followed

by

GC/MS

that showed amass number of

198

corresponding

to

azoxybenzene(without

carbon

nanotubes)

or182 corresponding

to azobenzene(with

the

nanotubes).

The

first

stage of the oxidationis identified

asnitrosobenzene

formation

whichsubsequently

couples with theparent molecule to produce the azo compound.

UV-VIS

absorption

spectroscopy

showed no peakin

the

absence ofthe

carbon

nanotubes;

in

contrastto adistinct

peak at347

nmwhenthe

reaction

is

catalyzedby

carbon nanotubes.The

GC/MS data for

the/7-toluidine oxidation showed a mass spectral peak at a mass

number of

226,

corresponding

to

azoxytoluene,

whichis

replacedby

210,

corresponding

toazotoluene,

whenthe

reactionis

the

UV-VIS

absorptiondata

showed an azotoluene peak at464

nm.To

reduce the unwanted product contributioncoming

from

the

outer

solution,

a carbon nanotube column was configured.In

this

situation

100%

azobenzeneformation

was obtained when anilinewas oxidized.

The

efficiencies ofthedifferent

columnsrangefrom

50-97%

for

the

p-toluidine oxidation reaction.The

oxidations ofdiphenylamine

and methylaminehave

alsobeen

carried outin

the

column configuration to understand the mechanisms.

The

resultssuggest

the

feasibility

ofconstructing

a nanosynthetic machinefor

Acknowledgments

My

advisor,

Dr. KSV

Santhanam,

for his

ideas,

patienceanddirection

My

committee:Dr. T.C.

Morrill,

Dr.

G.

Takacs

andDr. M. Miri

for

theirguidanceand encouragement

Tom Allston

for

alwaysbeing

aroundto

help

The RIT

Chemistry

Department for providing

thefunding

for

theresearchDr. P. Ajayan

atRPI

for

carbonnanotubes andallowing

usto

usetheSEM

andTEM

Dr. D.D.L.

Chung

attheUniversity

ofBuffalo

for

the

honeycomb

graphiteMy family

andfriends for

all oftheir support-1

couldn'thave

made

it

withoutany

ofPublications

(Refereed

Journals)

M.

Croston,

J.

Langston,

R.

Sangoi,

andK.S.V.

Santhanam,

"Catalytic Oxidation

ofp-Toluidine

atMultiwalled

Functionalized Carbon

Nanotubes",

J. Internal

Nanoscience,

1(3-4),

277-84

(2002)

-A

special

issue

oncarbon nanotubes.M.

Croston,

J.

Langston,

G.

Takacs,

T.

Morrill,

M.

Miri,

K.S.V. Santhanam

andP.

Ajayan,

"Conversion

ofAniline

to

Azobenzene

atFunctionalized Carbon Nanotubes: A

Possible

Case

of aNanodimensional

Reaction",

J. Internal

Nanoscience, 1(3-4),

285-94

(2002)

-A

special

issue

on carbon nanotubes.Posters/Presentations

M.

Croston,

J.

Langston,

G.A.

Takacs,

T.C.

Morrill,

M.

Miri,

andK.S.V.

Santhanam,

Oxidation ofAniline

Catalyzed

by

Multiwalled

Carbon

Nanotubes,

poster,

ACS meeting

-

Rochester

division,

October 2001

M.

Croston,

J.

Langston,

R.

Sangoi,

andK.S.V.

Santhanam,

Catalytic Oxidation

ofp-Toluidine

by

Multiwalled Carbon

Nanotubes,

presentation,

201stECS

meeting,

Philadelphia, PA

May

2002

M.

Croston

andK.S.V.

Santhanam,

Concept ofNanosynthetic Machine

withFunctionalized

Carbon

Nanotubes,

poster,

ACS meeting

-Rochester

List

ofFigures

Figure

1.

MWCNT

carbon arcsetup

3

Figure 2.

Apparatus for

thepreparation ofMWCNT

by

pyrolysis4

Figure 3. Laser

ablation apparatusfor

the

preparationofSWNTs

5

Figure 4.

Single-walled

carbon nanotube6

Figure 5. Multi-walled

carbon nanotube7

Figure 6.

Helicity

of a carbon nanotubes7

Figure 7.

Helicity

of carbon nanotubes8

Figure 8. Apparatus for

the thermalannealing

ofCNTs

11

Figure 9. Irradiation

apparatusfor

purifying

nanotubes12

Figure 10. Carbon

nanotubetransistorfrom IBM

14

Figure 11. Reaction

inside

a carbon nanotube16

Figure 12. FTJR

analysis ofcarbonnanotubes priortofunctionalization

24

Figure 13. FTIR

analysis ofcarbonnanotubesfollowing

functionalization

24

Figure 14. TGA

graph ofCNT

priortofunctionalization

25

Figure 15. TGA

spectrum ofCNT

afterfunctionalization

26

Figure 16. MWCNT

carbon arc methodsetup

27

Figure 17. TEM

analysisofclosed carbon nanotube28

Figure 18. TEM

analysis of afunctionalized

carbon nanotube28

Figure 19. Photograph

of reactionin

cuvettes31

Figure 20.

1:1 Aniline:hydrogen

peroxidein

acetone reactions33

Figure 21. Azobenzene

in

acetonitrile reference spectrum37

Beer's

Law

plotfor

cis-andtrans-azobenzene39

Figure

24.

trans-Azobenzene

concentrationvs.time

for

varying

amounts of

CNT

40

Figure 25.

Simulation

ofFick's

Law

errorfunction

curvefor

the

diffusion

of reactants

into

the

nanotubes and products out ofthe

nanotubes41

Figure 26. Extraction

ofthe solutioninside

the

nanotubes42

Figure 27.

1M

aniline and1M

hydrogen

peroxidein

acetonitrile monitoredevery

five

minutesfor

onehour

-convection method

46

Figure 28. Breakdown

ofCNTs

in

hydrogen

peroxide53

Figure 29. Simulation

ofp-toluidine reaction54

.Figure

30.

/?-Toluidinewithhydrogen

peroxide controlsolution(0-50min)

58

Figure 31. Time-dependent

absorbance ofp-toluidinereaction withCNT

59

Figure 32.

Linearity

ofthe

growthof p,p'-dimethylazobenzenewithtime60

Figure 33. Comparison

ofGC/MS

results of1

:1

p-toluidinereactionwith

hydrogen

peroxide61

Figure 34.

p'p-Dimethylazobenzene reference spectra62

Figure 35. Kinetic study

of1

:1

/?-toluidineto

hydrogen

peroxidereaction66

Figure

36. Proposed

construction of nanosynthetic machine68

Figure 37. Product

of aniline reactionfrom

simulatednanomachine

-first

collection72

Figure 38.

GC

spectrum of nanotube column collection80

Figure

39. Mass

spectrum ofthe

first

collectionfrom

the

nanotube column81

Figure 41.

UV-VIS

analysis of nanomachine product83

Figure

42.

Analysis

ofO2

saturation of acetonitrile88

Figure 43.

Analysis

ofN2

saturation of acetonitrile89

Figure 44.

UV-VIS

spectra ofp-toluidinecollection vs. controlfor

1

M

:1 M

solution94

Figure 45. UV-VIS

spectra of/?-toluidine collection vs. controlfor

2M: 1M

solution95

Figure 46.

p-Toluidine concentrationdependence

on azotoluenepeak96

Figure 47.

%Conversion

ofp-toluidine296nm

peak99

Figure 48.

Azotoluene

formation in

nanomachine99

Figure 49.

Nanomachine

collectionfrom diphenylamine

reaction102

List

ofSchemes

Scheme 1.

Outline

of reaction mechanismfor

thecontrol solution.35

Scheme 2.

Side-product formed

whenaniline andperoxide reactin

acetone.35

Scheme 3.

Outline

ofthe carbon nanotubereaction36

Scheme 4. Reaction

mechanismforp-toluidine

in hydrogen

peroxidecontrol solution

56

Scheme 5. Side-product

of/?-toluidinereacting in

acetone56

Scheme 6. Mechanism

of/?-toluidine reactionin

the

presence ofFMWCNT

57

Tables

Table

1.

pH ofFunctionalized

Carbon Nanotubes

29

Table 2. Aniline Detection

Limits

47

Table 3.

GC/MS

Data

ofthe

Catalysis

ofCNTs

48

Table 4.

GC/MS

Data

from Aniline

Reaction

49

Table 5. Comparison

ofRPI

andDEAL Nanotubes

51

Table 6. Comparison

ofKinetic

vs.Convection Method for

/j-Toluidine

Reaction

63

Table 7. Measurements

for

Carbon Nanotube Columns

70

Table 8.

Specifications

for Aniline Reaction

73

Table 9.

GC/MS Analysis 22h

afterCollecting

from

Nanomachine

75

Table 10.

Specifications for

/?-ToluidineReaction

90

Table 11. GC/MS Analysis

ofp-ToluidineCollections

92

Table 12. Concentration

ofAzotoluene

in Samples

withVarying

Concentrations

of^-Toluidine97

Table 13. Concentration

ofAzotoluene from 0. 1M

/?-ToluidineSamples

98

Table 14.

Efficiency

ofCNT Column

100

List

ofEquations

Eq. 1 Beer's law

equation39

Eq. 2 Fick's Law

ofDiffusion

41

1.

Introduction

The

synthesis offullerenes

and carbon nanotubesmay

be

considered as one ofthe

important discoveries

ofthe 20thCentury.

Kroto,

Curl

andSmalley (1)

pioneered theeffort when

they

began studying

a new allotrope ofcarbon calledthe

fullerene.

Another

turning

pointin

the

history

ofthe

chemistry

of carbon came with thediscovery

ofthe

tubular structure of carbon

by

Iijima

[2],

whichis

rapidly

being

investigated

for

materialstructure,

strength and catalytic properties.This

thesisis devoted

to theunprecedentedstudy

of catalytic properties of carbon nanotubes sin organic oxidative reactions whichmay

be

amenablefor

the

construction of nanosynthetic machinesfor

organicpreparations.

1.1

Structural Aspects

ofCarbon

There

arefour different

types

of graphite structures that willbe discussed:

diamond,

planargraphite,

buckminsterfullerenes

and carbon nanotubes.Diamond

existsas a

face-centered

cubic unit cellconsisting solely

of carbon atoms.Planar

graphiteconsists of planes of carbon atoms arranged

in

hexagons

whichlayer

each other.Graphite

seems tobe

"slippery"because

the planes canbe easily

separatedfrom

andmoved across each other.

This

is

why

graphiteis

usedin

pencils.The

buckminsterfullerene

is

spherically

shaped withthe

carbon endsforming

a pentagon toclose

the

sphere.Nanotubes

areformed in

somewhatthe

samefashion,

either single ormultiple graphitic planes are rolled

into

atube

with carbon pentagonsexisting

asthe

end1.1.1

Graphite

(amorphous)

Graphite

bonding

is

sp2hybridized

and exists as aflat

plane andhas

a3-fold

coordination system

[3].

1.1.2

Diamond

Whereas

graphiteis

sp2hybridized,

diamond

existsassp3

hybridized

carbonin

afour-fold

coordinated structure[3].

The C-C

bond distance

for diamond

is

larger

thanthatof graphite

due

to theweakerforces

between

the

atoms[3].

1.1.3

Carbon

Nanotubes

Multiwalled

carbon nanotubeshave diameters

from 10-50

nm and canbe 10

urnin length

orlonger.

Multiwalled

nanotubeshave

adensity

of1-2

g/cm3and a

very large

surface areaof

10-20

m2/g.Single

walled nanotubeshave

diameters

ofl-1.4nm

and canbe

aslong

as100

urn.Whereas

multiwalled nanotubebundles

arestraight,

singlewallednanotube

bundles

are curled andlooped.

Carbon

nanotubes can existin

threedifferent

orientationsthat affect their electrical properties:

zigzag,

armchair andchiral,

orhelical

[4].

Zigzag

nanotubes can either act as semiconductors ormetals,

armchair tubes aremainly

semiconductors and chiraltubes

areprimarily

metallic.One

ofthe

mostpromising

characteristics of carbonnanotubes,

other thanthat

they

canbe

conducting

is

that

they

canbe ballistic

conductors,

which meansthat there

willbe

noscattering

ofelectrons

[5].

They

alsohave

the

highest

currentdensity

ofany

known

material at 108A/cm [6].

Carbon

nanotubes areapproximately

100

times

stronger than steel with astrength of

60,000

psi.They

are alsovery

light

with adensity

of1.33-1.4

g/m3

Nanotubes

canbe

very

elastichaving

aYoung's Modulus

of1500

GPa

[7].

They

alsohave

ahigh

thermalconductance,

whichhas been

measured at -2000W/mK

at roomtemperature

[8]

and,

they

have

electrical conductance properties comparableto that

ofcopper

(5.9x1

07Qm)

[9].

When

nanotubes aremade,

they

form bundles

ofthemselvesthat

contain allthree

orientations ofthenanotubes.Researchers

atIBM

have developed

amethod of

separating

the

metallicCNT

from

thesemiconducting

CNT for

usein

singlecarbonnanotube

transistors

[10].

1.1.4

Synthesis of

Carbon

Nanotubes

There

are nowmany

different

waysin

which carbon nanotubes canbe

synthesized.

The

single walled tubesaregenerally

madeby

laser

ablation of a graphiterod

using

anickel or palladium metal catalyst.MWCNTs

aregenerally

preparedby

thecarbon arc method

in

the presence ofhelium

orhydrogen

gas.In

thiscase,

no metalcatalyst

is

needed.A. Anode B: Caihooe C:Collarette I): Deposit I 11eh-like\ul F.Soul (': DCpower

supph H Walcr-cooled

[image:18.484.94.389.416.630.2]doublewall reav'Un

The

carbon arc methodfor

producing

nanotubesis

shownin

Figure 1 [11].

The

cathodeand

the

anodearehoused in

adouble-walled

water-cooled condenser.When

a20-25

V

DC

arc currentis

passed acrossthe

anode to the cathodein

the

presence of30-500 Torr

of

H2

orHe2

gas,

at2500-3000

C,

the

cathodelength

begins

to

decrease

andCNT

areformed

[11].

Soot

is

collecteddown

atthebottom

ofthe

vessel.The

cathodeis

removedand

the

multiwalled carbon nanotubes are collected.MWCNT

can alsobe

formed

by

pyrolysis.

Quartztube

Furnace

Bubbler

&

[Thermocouple

ICA

[image:19.484.144.341.278.421.2]t

Figure 2.

Apparatus

for

thepreparation ofMWCNT

by

pyrolysis 12This

apparatus shownin Figure 2

consists of a quartztube with aninner

diameter

of20

mmand a

heating

zone of200

mm[12].

Acetylene

is

passedthrough

aliquid

Fe(CO)s

bubbler

at300

seemusing

argon as a carrier gasflowing

at30

seem[12].

The

gases andthe

catalyst are thenintroduced into

the

quartztube

andheated

at750-950

C for

30

minutes

[12].

The

furnace

is

then cooledto

roomtemperature

atanAr

flow

rate of500

seem

[12].

The

nanotubes arethen

collected.SWCNT

can alsobe

producedby

the

arcThis

metal canbe in

the

form

ofCo, Co/Ni,

Co/Y, Co/Fe, Ni/Y,

Ni/Fe

withNi/Y giving

the

best

results.These

catalysts promotethe

growthofthe

singlewalled structures.The

most common methodof

preparing SWNTs is

by

laser

ablation.Figure 3

showsthe

laser

ablation

apparatus,

which consists of a60

cmlong

quartztubewith an outerdiameter

of3.6

cmand aninner diameter

of2.7

cm[12].

A

target

(~5um

in

diameter)

consisting

of acompressed

graphite, Ni

andCo

powderis

placedinside

the

quartztube

at atemperatureof

1200

C

[12].

Argon

gasis introduced into

thequartztubeat a rate of0.2

L/min

and apressure of

700 Torr.

A Nd:Y

pulsedlaser beam

is

then shown ontothe

target andbombards

the

target surfacewith150

pulses oflight

[12].

The laser

has

awavelength of532

nm with a pulsewidth of6-7

ns and afrequency

of10

Hz

[12]. The beam

currentis

2 J/xm

with adiameter

of2

mm[12].

Once

thelaser

ablates thetarget,

the nanotubesare collected on awater-cooledcopper collector.

hjmaceat

1,200' Celsius

\

water-cooled^^^ copper co&edor all / "

\

1

argon gasm#>-:

*S^^^" ~Tfi^A^^*..V

' '""zniHcT{^sS***^ft P|P\

\ narwtube leH" growingetongfipof collector

grapfaletarget

neodymkjm-vflnunv

sJuminum-gamellaser

Fig. h.\. Singl'--wallednanotu!**>procuced in a quartz luhr-hcai.-d"

U, 1200'C hj the as^r vapor12 ation method, using a

fcraphit.*-larjl<Mandarooli-dcollectorfornanoubcs[95].

Figure 3. Laser

ablation apparatusfor

the

preparation ofSWNTs

12an

iron

oxide catalystis

prepared.Methane

is

decomposed

in

afurnace

at1000

C in

thepresence of

the

iron

oxide catalyst[12].

The

iron

oxide catalystis

preparedby

impregnating

alumina nanoparticlesin

methanol withFe(N03)2-9H20

at roomtemperature

for 1 hr [12]. The

solventis

then evaporatedat80C

andthe catalystis

thenheated

and groundinto

a powder.The

alumina/iron oxide catalystis

then placedin

aquartztube and

heated

at1000

C

with anAr flow [12]. Methane

is

thenintroduced into

the

quartztube

at aflow

rate of6150

cm3/min at1.25

atm pressure[12].

After

lOmin,

the methane

is

thenpurgedbe

reintroducing Ar [12]. The CVD

processhas

been

studiedto provide the optimum conditions

for

CNT

growth.Other

carrier gas/catalystcombinations

have been

usedincluding

n-hexane/ferrocenethiocene

used atRPI

[13].

1. 1. 5 Structural

Representations

Single-walled and multi-walled carbonnanotubes are shown

in Figures 4

and5.

Single-walled nanotubes consist of carbon atoms arranged

in

ahexagon

and rolledinto

atube.The

multiwalled carbon nanotubein Figure 4

consistsbasically

of concentricsingle-walled nanotubes.

R

i^t i^^i^^ i^%i^i i^i i^Qii^^i iSFigure 5.

Multi-walled carbonnanotube.15If

the

nanotubein

Figure 5

was opened andlaid

on aflat

surface,

it

wouldlook like

Figure 6 (a

andb),

aflat

graphene sheet.Figure 6

(b)

showshow

thehelicity

of acarbonnanotube

is

determined.

(ah.

(b)

-^. . , , A

_' .}

M a a. ,jfc _a

> a m a a >^c-50

"/'

^ * a 5 . l7i-.q:

:

! I J IS .17! SO

'

15 1 ?2ik7 ->k> f:metal '^enucorxJuctor

Figure

6.

Helicity

ofacarbon [image:22.484.132.359.342.634.2]The

helicity

is defined

by

the

m and nindices in

parenthesesonthe

diagram

(n,m)

[11].

When

m and n areequal, the

nanotubes are saidto

be

in

armchair[11]

configuration.When

mis

equal tozero,

thenanotubes areconsideredtobe

zigzag [1 1].

If

n and m aredifferent from

each other and mis

not equalto zero,

the nanotubesare chiral[11].

All

armchairnanotubes are metallic as shownonthe

diagram

andzigzag

tubes can eitherbe

[image:23.484.93.392.252.550.2]metals or semiconductors

[11].

Figure 7.

Helicity

ofcarbonnanotubes.nFigure 7

shows nanotubesofdifferent

helicities:

(a)

represents an armchairnanotube,

(b)

zigzag

tubes

areperfectly

symmetrical throughout the nanotubewhereas chiraltubes

arenot as can

be

seenin Figure 7 [1 1].

When

nanotubes areformed,

they

have

endcaps onboth

ends ofthe tube.

Once

they

arepurified,

the

endcaps arebroken

off asis

shownin

Figure 7. This

concept willbe discussed in

moredetail

in

anupcoming

section.1.2

Electrical Properties

Carbon

nanotubes can act either as metallic orsemiconducting

tubesdepending

on their geometry.

For

typical metallicsystems,

electrons can movefrom

one metalto

the next quite easily.

In

the case ofCNT; however,

because

they

possess suchdifferent

electrical

properties,

electrical current will not alwaysflow easily from

onetube to

the

next

[3].

Introducing

aSchottky

barrier

into

the nanotube(bending

the

nanotube at onepoint),

allowsthe

flow

of electrical currentto

continue[3].

Nanotubes

possessthese

defects

whenthey

are made andthey

can alsobe

formed

by inducing

a rotation ofbonds

between

twohexagons

to

form

afive-fold

ring

and anadjacent seven-foldring

[3].

This

allows a single nanotube

to

possessboth semiconducting

and semi-metallic character[3].

1.3 Mechanical Properties

Carbon

nanotubeshave

excellent mechanical propertiesdue

to

theirlow

density

of

defects [16].

The Young's

modulus ofCNTs (reported

previously)

is higher

than

tubes

composed of otheratoms[16]. This

valueonly slightly

depends

onthe

diameter

ofthe

nanotubes anddepends

on thedegree

ofsp2

hybridization

[16].

The Young's

modulus

is

highest

for

aflat

graphene sheetdue

to the

fact

that

folding

the

sheetinto

ananotube would

distort

sp2

ratio

(v)

of a nanotube alsodepends

onits

diameter,

but

is

dependent

onchirality

aswell[16].

Planar

graphitehas

aPoisson

ratio of v=0.

17,

armchairtubeshave

a v=0.

14,

andother chiralities range

from

v=0.18-0.19

[16].

When

stressis

appliedto nanotubes,

both

thin and thick-walled nanotubes exhibit compressive strengths one order ofmagnitude

higher

thanany known

fiber [16].

Zigzag

and armchairnanotubes arethe stiffest at0

K

[16].

Nanotubes

are alsovery

flexible [16].

When

subjectedto

large

amounts ofdeformation,

the nanotubes switchinto different

shapesreleasing

energy [16].

This

canbe

reversed andis

causedby

the

ability

ofsp2

hybridized C-C

bonds

toreversibly

changehybridization,

to sp3in

thiscase,

whendeformed

out ofa plane[16].

1.4

Purification

andFunctionalization

ofCarbon Nanotubes.

There

aremany

different

methodsfor purifying

andfunctionalizing

CNTs.

No

matter what method

is

used to produceMWNT

orSWNT,

the sootis

not100%

nanotubes.

As

a matter offact,

thepurity

ofthe sample canbe

between 10-90%.

The

CNTs in

the sample comein

threedifferent forms.

They

can eitherbe completely

closedtubes,

have

oneend open orhave both

ends open.The

purposeofpurifying

theCNTs is

toremovemost orall ofthe excessamorphous graphite material and

to

openboth

ends ofall of

the

nanotubesthat

arepresent.This

is

usually

done

in

the

presence of astrong

acidfor

approximately

12

hrs.

The

acidsinvolved

canbe

hydrochloric,

nitric and sulfuricacid.

In

most ofthese cases,

the ends are openedby

oxidating

the

carbonsin

the

pentagon

rings

of the endcaps asthey

canbe

easily

oxidizeddue

to

their geometry.When

this occurs,

carbonyl groupscanbe

found

atthe

dangling

carbonbonds

left

onthe

[17].

thrraoooupk

team

Intolute

<

lt

/heitar 1

TtnrMWNTi wtrrhite

r

(4K)

Figure

8.

Apparatus for

the

thermalannealing

ofCNTs.17

The

apparatusin Figure 8

represents onethatis

usedtopurify

thenanotubesby

thermalannealing.

The

cathodedeposit is

placedin

theinner

tube of thefurnace

andis

constantly

rotated at30

rpm.The

temperature

is fixed

at760

C

throughout.In

thiscase,

most ofthe carbonaceous material was removed and theweight was reduced

to

40%

ofthe original

[17].

Purification

ofMWNT

by

intercalation

ofCuCh

[18]

has

alsobeen

reported.

Nanotubes

can alsobe

purified and oxidizedusing

ozone[19].

In

gas-phaseozone

oxidation,

CNTs

are placedinto

a vertical reactorcontaining

a mixture of ozoneand oxygengasesand

heated

at150-200

C

for 30-90

min[19]. Liquid

phase oxidationsperformed

by

suspending

the

CNTs in

an acidic solution(CIO4",

Mn04*

or

H2O2)

along

with the oxygen/ozone gas mixture and

heated

at60-70

C

for 24 hrs [19].

In

both

ofthese cases,

theendcaps,

andany

kinks

or steps thatmay

occurin

the nanotubesthemselves,

arethefirst

tobe

oxidized andthebonds broken. Other

purification methodsw aler

IN

S=3

Figure 9. Irradiation

apparatusfor

purifying

nanotubes.20Figure 9

showsthe apparatusfor

thistype

of purification.The

cathodedeposit

from

thecarbon arc method

is

placeddirectly

in

the path ofthe

infrared beam.

Here,

it is

irradiated

for 30

min at500

C

in

air.The

productwasaspongy

square ofMWNTs

witha surface area of

10

mm2

and

0. 1

mmthickness[20].

1.4.1 Chemical Properties

The

chemical properties of carbon nanotubes are nowbeing

extensively

explored.Only

oneendof acarbonnanotubeis

openasit

exists afterit is

made.The

other end canbe

opened, exposing

the

nanotube to thepossibility

offilling

it

with moleculesthereby

acting

as a vessel.They

alsohave

ahigh

specific area which suggeststhat

many

molecules can

be

adsorbed ontothe surface ofthe

tubes.As

the

nanotubes areopened,

they

can alsobe

functionalized

-other molecules can

be introduced

to the

ends ofthe

carbon chains.

Carbon

nanotubes can also act aselectrodes,

increasing

the

rate of1.4.2

Applications

The

potential applications are numerousbased

onthe

extraordinary

electrical andmechanical properties

that

carbon nanotubes possess.Some

recent advances andimportant

research areas arediscussed

here.

It

has been

notedthat

CNTs have

the

ability

to

conductwaterby

capillary

action,

thesame

way

that

kidneys

and other smallblood

vessels movewater[22]. There

aretwomajor

implications

here.

First,

nanotubes wouldbe

extremely

valuablein

biological

systems.

This

providesthe

potentialfor

artificialorgans,

such askidneys,

andrecently,

scientists

have

been

determining

whetherCNTs

canbe

used as artificial muscles[23].

This

alsoimplies

that

CNTs

can act as carrier vessels or"nano

test

tubes"

Small

molecules

in

solution can enterinto

the

CNTs,

ashas already been

shownby

de

Heer,

etal.

CNTs

werefilled

with gaseous or solution-phase metals which weredecomposed

to

solid metals

inside

the

CNTs

[24].

CNTs

can alsobe

usedin

transistors

anddiodes.

They

arevery

small andthe

electronic properties are perfectfor

these types ofdevices

because

electrons can movefreely

within them withlittle

or no scattering.IBM

has

drain

electrode source

electrode

' (SO

.

^

WaWr^

i

t

fe

F

^^L^g,e

^

Figure 10.

Carbon

nanotubetransistorfrom

IBM

10They

canalsobe

used asfield

emittersfor flat-panel

displays.

Many

scientists,

recently,

have

been

testing

nanotube/polymer composites.Nanotubes

have

superior mechanicalproperties compared

to polymers,

sothe

addition ofCNTs

should provideincreased

strength and

hardness.

They

have

alsobeen

addedto

conducting

polymersto

increase

the

electrical properties ofthepolymers.

In

the

US,

we are alwayslooking

for

ways toincrease

energy efficiency

andto

eliminate pollution.

Recently,

the

presidenthas

granted abill

that providesmoney for

hydrogen

fuel

cell research.CNTs

play

abig

rolein

this

category.They

have been

shown

to

be

highly

efficientfor

the

storage ofhydrogen

gas.A

single gram of carbonnanotubes can absorb

>3

wt%hydrogen

under290 K

and -10MPa

[25]

whichis

potentially

usefulfor

fuel

cell applications.Purified MWNTs

have

alsobeen

usedto

electromechanically

catalyzeoxygen reductionin fuel

cells.Batteries

canbe

madeusing

CNTs

that

willhave

animproved

lifetime

overtraditionalmetal catalyzedbatteries

[26].

gases or

for

chemical analysis.Conducting

polymer/CNT compositeshave

already been

used

in

gas-detection sensors.The

hope is

that

we willbe

ableto

useCNTs

in

avery

small apparatus

that

couldbe

remotely

operatedto

areas wherehumans may

be in

harm.

These

small sensors couldeasily be

undetected and couldtransmitinformation regarding

the

purity

ofthe

air or water.CNTs

can alsobe

usedin

microscopy.Recently,

atomicforce

microscopeshave

been developed

that

use a carbon nanotube as atip

ratherthana gold electrode[27].

We

are

moving

toward smallerdimensional

particles and we needto

be

able to analyzesurfaces

in

the

smallestdimensions.

Using

a single carbon nanotube atthe

tip

ofanAFM

allows us

to

analyze surfaces on the order ofnanometers,

whichhas

neverbeen

done

before. Thus

the

foundation

for

thedevelopment

of nanosciencehas

emerged.1.5

Nanoscience

Nanoscience

is

mostwidely defined

asthe

phenomenon associatedwithstructuresroughly in

the1-100

nm range wherethe properties are ofinterest due

to

the sizeofthestructure,

and aretypically

different

than those of a molecule or a comparablebulk

material.

We

planto

prove that whena reactionis

confined to nanodimensional carbonstructure, the

products aredifferent

thanin

the

bulk

solution.Basically,

any

chemicalobject ofsubmicrometer

dimensions

orwith submicrometerfeatures

canbe

considered apart ofnanoscience.

Why

is

nanoscienceimportant? When

matteris

confinedto

a smallspace,

as willbe

provenin

this

thesis,

phase transitions can occurthat

cannotbe

observedin larger

This

will allow usto

getinformation faster

than

ever.Resist layers may

be

deposited

monomolecularly

which will allowfor

the

smallestdevices

possible.Research

in

nanoscience

has

allowedfor

the

development

ofconducting

polymers as thinfilm

transistors.

Chemical

applicationsin

nanoscienceinclude

building

moleculesfrom

the

bottom

up.

We

may be

ableto

build

a molecule pieceby

piece with specific stereochemistry.The

possibility

ofdeveloping

monodisperse assemblies of clustersto

form

high

molecular weight units

has

alsobeen

realized.1. 5. 1

Nanodimensional

Reactions

A

nanodimensional reactionis defined

as a reactionthatoccursin

a spacewhereat

least

onedimension

is less

than1

um.When

a reactionis

confinedto

avery

smallspace, the

molecules areforced

to

reactwitheach other wherethey

wouldnotordinarily

do

so.This

allowsfor different

productsin

the nanoscale thanwouldbe formed

in

the

macroscale.

In

this case,

areactionis

confinedwithin a carbon nanotube.10-50

nm

Figure

11.

Reaction

inside

acarbonnanotube.solution and

diffuse into

the

carbon nanotube through twoforces.

First,

the

solutionis

being

pulledinto

the tube

by

capillary

action.Secondly,

the

light-colored

spotslocated

on

the

inside

oftheCNTs

represent electrondensities

onthe

nanotube.Electron

densities

are present anywhere onthe

nanotube where akink

orstep

is

found,

or wherethe

nanotubebends for

any

reason.They

are chargesthatbuild

up

onthesurface or within

the

nanotube that occurduring

the synthesis ofthe nanotubes.These

electron

densities

arenegatively

charged andthey

help

to attract thepartially

positivecharges on

the

molecules andhold

themuntilthey

can reactwithother molecules present.Hertel,

et al. showedthat

carbon nanotubes canbe

manipulatedby

anAFM

tip,

that

is,

they

canbe bent

atthe

point wheretheelectrondensities

occurin

thenanotubes[28].

1.6

Purpose

ofthe

Thesis

The

purpose ofthis thesis

is

threefold.The

first is

to examinethe

catalytic natureofthe multiwalled carbon nanotubes

in

organic oxidative reactions wherethe reactants,

intermediates

and products are presentin

the confined tubulartopology

of carbonnanotubes

containing

flexible

electrondensities.

For

thispurpose,

the

chemicaloxidationsof

primary

andsecondary,

aromatic andaliphatic,

amineshave

been

chosen asthey

form

animportant

classfor producing conducting

polymers through a coloredintermediate

species.The monitoring

ofany

chemical reaction withinthe

nanotubedirectly

is

an uphill task exceptin

situations wherethe

productis deposited

as a solidmetal and can

be

analyzedby

Transmission

Electron

Microscopy

[24].

As

it is

impossible

to

determine

whether reactants are situatedinside

ananotube,

there

has

notnanotubes.

If

a reaction produces a colored productinside

the

carbonnanotube,

thenits

diffusion into

the

outer solution couldbe

monitoredby

optical absorption spectroscopy.As

this

is

generally

a slowprocess,

atime

dependent

absorptionprofileis

to

be

expectedin

the

above oxidative reactions.The

second aspect ofthis

study

is

to examine the synthetic schemesin

theoxidation of

amines,

suchas anilineand/?-toluidine,

when carbon nanotubesare present.The

third

aspectis

to

study

the

effect of a column configuration of carbonnanotubes on

the

product yieldin

the

aboveoxidations, and,

to compareits

performanceto carbon nanotubes suspended

in

the medium.When

thecarbon nanotubes are arrangedin

a columnconfiguration,

the

reactants arecontinuously

in

contact withthe

carbonnanotubes.

This

reducestheinterference

arising from

theoxidative reactionsoccurring in

thesuspended medium.

The

multiwalled nanotubes usedin

theoxidationoftheabove amines are purifiedand

functionalized using

a modified method ofGreen,

et al.[29].

They

are analyzed andcharacterized

by

FTIR,

SEM

TEM

andTGA.

The

products obtainedin

theoxidation ofamines are

analyzed,

characterized anddetermined

by

UV-VIS, GC/MS,

Fluorescence

and

FTIR.

Based

on the analyticaldata,

the reaction andkinetic

mechanisms aredetermined.

The

results pointto thefeasibility

ofconstructing

a carbon nanotube-based2.

Experimental

2.1

Chemicals

/?-Toluidine and methylamine

(41% in

water)

were purchasedfrom

Aldrich

andused as received.

Aniline

(Aldrich)

was purifiedby

distillation.

The

sample wascollected at

1

80C,

sealed andkept

underrefrigerationuntilfurther

use.Azobenzene

waspurchased solid

from

Aldrich

andkept

in

adessicator

until use.Hydrogen

peroxide(30%

vol/vol) (Baker Analytical grade)

waskept

under refrigeration and usedin

all oftheexperiments.

All

solvents wereBaker Reagent

orAnalytical

grade and used asreceived.Nitric

acid(69.0-70%)

(Baker Analyzed ACS

Reagent)

was usedin

thefunctionalization

of

the

nanotubes.Fisher

Scientific

Decolorizing

carbon(Norite)

was used as the activecarbon sample.

2.2 Instrumentation

2.2.1

UV-VIS Analysis of

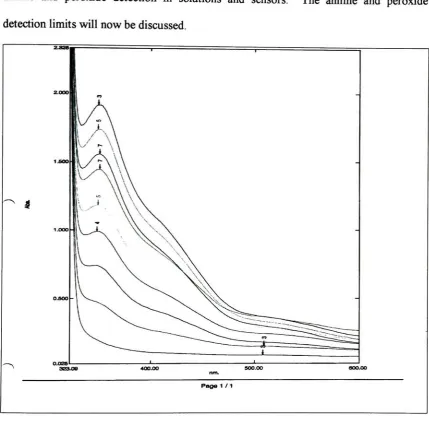

theReaction

All

reactions were monitoredusing

aShimadzu UV2000

series spectrometer.The

method parameters

for

theinstrument

were asfollows:

wavelength=200-800

nm

scan,

slit width =

0.5

mm,

scan speed =medium.

A

quartz cuvette was usedfor

allexperiments.

All

experiments were performedusing

thesolvent astheblank.

2.2.2

GC/MS

Characterization of

theProducts

with

HP 5973

mass selectivedetector

andfitted

with anAgilent (19091

S-396)

column).The

GC

column used prior toJanuary

2002

was an HP-IMS

(100%

dimethylpolysiloxane)

whichhad capillary

measurements of60

m x250

um x0.25

urnnominal.

The

column used afterJanuary

2002

was anHP SPB-5 (5%

Phenyl,

95%

Polysiloxane)

whichhad capillary

measurements of15.0

mx200

pmx0.20

umnominal.A

standard method was used withthis

column whendetermining

theformation

ofdifferent

azo groups.The

injection

temperature

was set at280

C

andhelium

gasflowed

at a rate of

1

mL/min withthe

flow

rate ofthe column set at2.2

mL/min.The

columntemperature

was set at80 C for

1 minute,

thenincreased

to220

C

at a rate of20

C/min

and then

increased

to280 C

at a rate of4

C/min.

The

injection

ofthe sample rangedfrom

1

to5

uL.2.2.3 FTIR of

Carbon

Nanotubes

andtheProducts

Infrared

spectraweredetermined using

aBio-Rad FTIR

spectrometer(Excalibur

Series).

Solid

samples were analyzedusing

adiffuse

reflectance attachment.Multiwalled

carbon nanotubes were groundin KBr

andkept

in

the

powderform

during

analysis.

Liquid

samples wereplacedbetween

twoKBr

salt plates and placeddirectly

in

thepathofthe

infrared beam.

2.2.4 TGA

of

Carbon Nanotubes

The

carbon nanotube samples were analyzedfor

theirthermal

degradation

temperatures

using

aUniversal TA TGA Instrument (model

V2.6D).

Samples

were2.2.5

Fluorescence Spectra

ofAzobenzene

andtheProducts

A

Perkin-Elmer

Luminescence

Spectrometer LS50B

was used todetermine

the

fluorescent

properties ofazobenzene, aniline,

acetonitrile andacetone.2.2.6 Atomic Absorption of

Carbon

Nanotubes

The

carbon nanotubes were sonicatedin

a nitric acid solution and analyzedfor

Cu

and

Fe

contentusing

aPerkin-Elmer AAnalyst

100

atomic absorption spectrometer.2.2.

7pH of

theCarbon

Nanotubes

The

carbon nanotubes were sonicatedin

water and analyzedusing

aVWE

pHmeter

Model

#8005

withAccumet

glassand reference electrodes.2.3 Procedures

2.3.1 Functionalization of Carbon Nanotubes

Multiwalled

carbon nanotube core material was purchasedfrom

DEAL

International,

Nanotechnology

Division.

To

functionalize,

open andpurify

the carbonnanotubes,

2 g

carbon nanotube core material were suspendedin

43

mL concentratednitric acid and refluxed

for

12-24

hrs.

at atemperature of140

C.

The

nanotubes werethenwashed several timeswith

distilled

water and thenrefluxedin

distilled

waterat100

C for

approximately 5-10 hrs.

The

nanotubeswerethenfiltered

anddried

overnightin

aPolytechnic Institute

andfunctionalized in

the

above manner.2.4

Oxidation

ofAniline.

Aniline

andhydrogen

peroxide were reacted togetherin

acetonitrile,

acetone,

hexane

or methanolin

the

presence offunctionalized

CNT,

nonfunctionalizedCNT,

activated charcoal and graphite

in

ahoneycomb

sheet receivedfrom

Prof. D. D. L.

Chung

at

the

University

ofBuffalo.

The

reactions were performed at room temperature and at40

C for

comparison.Various

amounts ofCNT

were addedtothe

solutionfor kinetic

studies.

Upon

formation

ofthe simulatednanomachine,

a solution ofaniline,

hydrogen

peroxide and solvent was mixed and added

dropwise

tothe

CNT

column.The

productswereanalyzed

by

GC/MS

andUV-VIS

in

all cases andby

Fluorescence spectroscopy in

some.

2.5 Oxidation

of/J-Toluidine./?-Toluidine and

hydrogen

peroxide were reacted togetherin

acetone oracetonitrile

in

the presence offunctionalized

carbon nanotubes andvarying

amounts ofnonfunctionalized

CNT.

A

control solution was madethat

containedonly

thetwo

reactantsand solvent

for

comparison.All

reactions were performed at roomtemperature

unless otherwise noted.

Upon

completion ofthe

simulatednanomachine, the

solutionwas prepared and then

introduced

into

the

CNT

columndropwise.

The

productsin

all2.6

Oxidation

ofMethylamine.

A

1:1

ratio of methylamineto

hydrogen

peroxide solution was preparedin

acetone and acetonitrile

in

the

presence offunctionalized

CNT.

A

control solution wasalso made

for

comparisonthat

contained noCNT.

Upon

preparation ofthe

simulatednanomachine,

the

solution was preparedin

atest tube

and thenintroduced into

the

CNT

column

dropwise.

The

productsin both

cases were analyzedby

GC/MS

andUV-VIS.

2.7

Oxidation

ofDiphenylamine.

A

1:1

solution ofdiphenylamine

to

hydrogen

peroxidein

acetonitrile wasprepared.

This

solutionwasthen addeddropwise

to

thefunctionalized

CNT

column andthe

product obtained was analyzedby

GC/MS

andUV-VIS

spectroscopy.3. Results

andDiscussion

3.1 Characterization

ofCarbon Nanotubes.

3.1.1

Fourier Transform

Spectroscopic Studies

Multiwalled

carbon nanotubeswere analyzedusing

the

FTIR

spectrometerbefore

and after

functionalization

to

determine

whether thereis

a changein functional

groupsduring

the

process.Figure

12

shows theIR

spectrumbefore

the

tubes

were47"

impurecnt.bsp(2)

46

5-<D O

C

oq 46

0-c C

45

5-45

0-44

5-J{

44

0-t ,i,l.,,,l,, r 1 t i i i i i i i . i . . ti iiit i > i i i 1400

2800 2600 2400 2200 2000 1800 1600

Wavenumber

Figure 12.

FTIR

spectrum of carbon nanotubes priorto

functionalization.

It

canbe

notedthat

no carbonyl peak(1600-1800

cm"1)

canbe

observedin

this

spectrum.The

peaks are rather weakin

this

spectrumdue

to the

reflection ofthe

light

scattering

offof

the

nanotubes.However,

whencomparing

this

spectrum withthe

Figure

13,

there is

asignificantpeak

difference

afterfunctionalization.

Figure 13. FTIR

spectrumof carbon nanotubes afterfunctionalization.

A

peakis

presentat1880

cm"1

after

functionalizing

the

carbon nanotubes whichindicates

nanotubes,

but

it

oxidizes some ofthe

end groups anddefect

centersto

carbonylgroups.3.1.2

Thermogravimetric Studies

The

nanotubesbefore

and afterfunctionalized

were analyzedby

thermogravimetric

analysisto

determine

whetherthe

degradation

temperature

andcharacteristics change

during

functionalization.

Figure 14

showsthe

TGA

graph ofthe

core ground material as received.

The

materialbegins

to

degrade in

the range of560

to

720 C.

100%

ofthestarting

material(3.865 g

corematerial)

wasdegraded

under airflow.

Sample: Unpurified CNT Size: 3.3550mg Method:Ramp

Commentatmosphere-air

TGA

File:unpurrfiedcarbon nanolu...

Operatorrajrv

RunDate:9-Apr-02 i 1:06

,-I

100J

80-\

\

\

\

\

20-\

\

\

0-

V

^(J 200 400 60C BOO 1CK

Temperature

(CC)

UnwersalVZ.6D TA InstrunienteFigure 14. TGA

graphofCNT

priorto

functionalization.

shows a phase

transition

atapproximately

the

sametemperature,

580

C,

but does

notfinish

degrading

until almost900

C,

adifference

of almost200

C.

There

is

no residueleft in

this

experiment.This

difference

couldbe due

to the

carbonyl end groupsthathave

been

acquiredduring

functionalization.

It

wouldbe harder

to

oxidizethe

carbonylgroupsthan

to

oxidize purecarbon, causing

thebreakdown

ofthe

carbon nanotubesto

take alonger time,

providing

alonger

range ofdegradation in

theTGA data.

The

spectraclearly

show adifference between

the

two samples ofCNT.

Sample:pimSed earner nanotubes trar

Size: B.2390mg

Method: ftamc

TGA

File-C:_vunT*a

crt n ar Operatorrapv

Rut. Dale: 7-Apr-0220:18

120- -oo-

60-\

\\

a 3\

\

\

\

40-\

iZ>-\

\

\

D 20G 400 00

Temperature(=0)

?:: i

UrncnslVSGD

WO

TAntum-,1

Figure 15. TGA

spectrumofCNT

afterfunctionalization.

3.1.3

Scanning

Electron Microscopic Results

The

carbon nanotubes were takento

RPI

(Troy, NY)

to

be

analyzedby

SEM

anddetermine

whatthe

content ofthematerial was.Figure 16

showsthe

SEM

image

ofthe

carbonnanotubes after

functionalization.

The

image

showsmostly large

masses ofgray

nanotubes.

This

analysis showsthat the

carbon nanotubebundles

were present afterpurification.

The

samplesfrom

RPI

wererelatively

non-bundled and showed separatedtubes.

Figure 16. SEM image

offunctionalized

carbon nanotubes.3.1.4 Transmission Electron Microscopic Studies

The

carbon nanotubes were then analyzed under atransmission

electronmicroscope also at

RPI

todetermine

the characteristics ofthe nanotubes,

i.e.,

whetherthey

wereopened,

whetherdefect

centers werepresent,

and what changesmay

have

Figure 17. TEM

analysis of closedcarbon nanotube.Figure 18. TEM

analysis ofafunctionalized

carbon nanotube.Comparing

Figures 17

and18

providesimportant information regarding

the

change ofthe

CNTs

afterfunctionalization.

Before

functionalization,

the

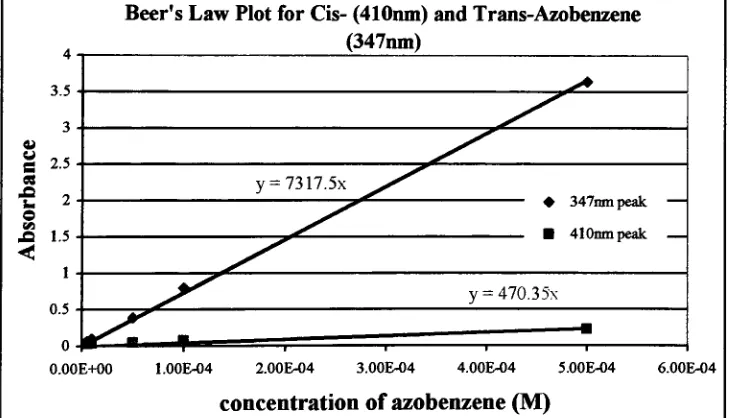

nanotubeshave

a closedend,

the

pointed end ofthe

nanotubein Figure 17.

In

both

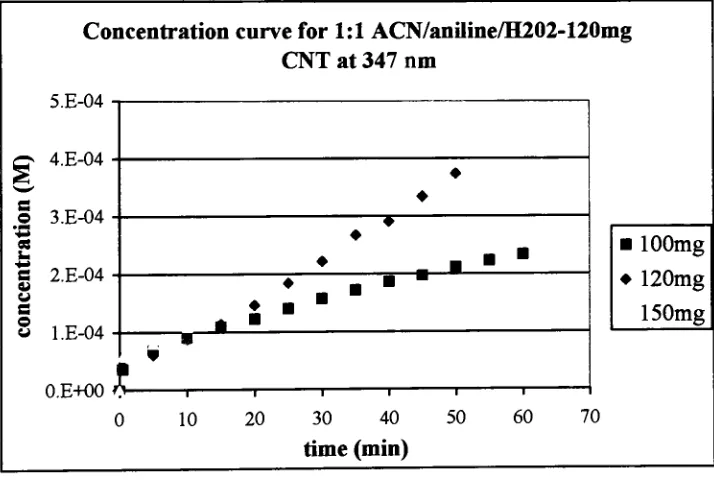

figures,

the

hollow

center ofthe

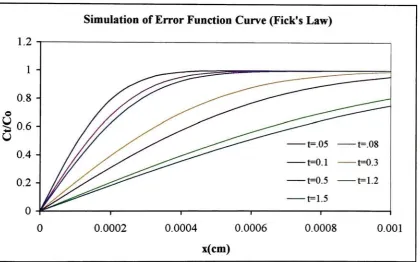

nanotube can

be

seen andthe

many

layers

ofthe

multiwallednanotube are visible.After

off.

The

nanotubeshave

alsobeen broken

in

some placesby

the

nitric acid.3.2

pHofCarbon Nanotubes

To

ensurethat

there

was no nitric acidleft

onthe

nanotubes,

60

mg

offunctionalized

CNT

were placedin distilled

water and sonicatedfor

1

hr before

being

analyzed

for

the

pH ofthe

water.It

is

assumed that after1

hour

ofsonication,

any

nitricacid

that

may

be

adsorbed ontothe

surface ormay

have diffused into

the

nanotubeswillbe

removedandleft in

the

watersolution.Table 1

givesthevaluesfrom

this

experiment.It

is

obviousfrom

these

results thatthere

is

no nitric acidleft

afterthewashing

processfrom functionalization

ofthe tubes.The

overall resultis

asolution thatis

slightly

morebasic

thandistilled

water.*

Table

1.pHofFunctionalized Carbon NanotubespH ofbuffer ,,. .... . pHof

CNTs

v

, . pH ofdistilled . , solution v , sonicated in

water

(7.00)

water1 7.03 7.14 7.51

2 7.03 7.18 7.59

3 7.02 7.15 7.63

4 7.03 7.13 7.57

5 7.03 7.14 7.56

average 7.028 7.148 7.572

Std.

Dev. 4.47E-03 1.92E-02 4.38E-023.3 Atomic

Absorption

ofFunctionalized

Carbon Nanotubes

3.4

Oxidation

ofPrimary

Amines

3.4.1

Aniline-Discovery

of

theEffect

of Carbon Nanotubes

The

initial

experiments were performed with1 M

aniline and1

M hydrogen

peroxide

in

25

mL of acetonitrile(control

solution)

in

a reflux at60

C for

3

hours.

After

the

first

hour,

the

solutionbegan

to

turnalight

yellow color and afterthe second,

adarker

yellow color.

At

this

point,

no carbon nanotubeshad been

added.The

solution wasanalyzed

by

GC/MS

andthe

major peaks seemed tobe

aniline,

acetonitrile and carbondioxide

although nitrobenzene and nitrosobenzene were alsoformed

after24

hours.

Carbon

nanotubes werethenaddedto

adifferent

1

M

aniline and1

M

hydrogen

peroxidesolution and refluxed

for

3

hours

at60

C. At

the

end ofthe three

hours,

the

solutionwasa

deep

redin

color(see Figure 19).

Due

tothe

color ofthe

solution with carbonnanotubes,

it

wasdecided

thatUV-VIS spectroscopy

shouldbe

performed.The

controlsolution wasthen analyzed.

The

peaksweresaturatedin

the

range of190-3

10

nmand nootherabsorptionpeaks were observed.

The

peaksin

thisrangearedue

to

theacetonitrileand aniline and are apparent

in

allUV-VIS

spectrathat contain aniline and acetonitrile.The

solutionwithCNT

alsocontainedthesepeaksalong

with apeakin

the

347

nmrange,

a peak

in

the

440

nm range and a peakin

the510

nm range.The

solutions werevery

.

ttl'

tic

fi Br'"'

i ^^^w

Control

Funct

Nanotubes

CNT

as

Received

Figure 19. Photograph

ofreactionin

cuvettes.3.4.2 Influence ofHydrogen Peroxide Concentration

The

nextstep

of experimentationincluded making

solutionsthat

contain1M

aniline and

2 M

hydrogen

peroxidein 25

mL of acetonitrile.One

solutioncontained100

mg CNT

and one control solution withoutCNT.

These

solutions were stirred at roomtemperature

for

three

hours.

The

solution withoutCNT

became

alight

yellowcolor andthe

solution withCNT

became

adark

red color at the end ofthe three

hours.

The

solutions were

then

analyzedby

GC/MS

andit

wasdetermined

thataniline, acetonitrile,

carbon

dioxide,

nitrobenzeneandnitrosobenzenewerepresentin both

samples;

however,

the

solutionwithCNT

producedboth

more nitrobenzene and more nitrosobenzenethan

the

solutionwithoutCNT

whencomparing

peakareas.Solutions containing 1 M

anilineand

3 M hydrogen

peroxide werethen

madein 25

mLacetonitrile,

onecontaining 100

mg

ofCNT

and onewithout.The

solution withoutCNT

againturned

alight

yellow colorFigure

Related documents

Product Name: PT Radiant Utama Interinsco Tbk Company Profile - Business Description, Strategies and SWOT Analysis. Web

It was previously reported that high milk yield (11,443 kg fat and protein-corrected milk in preceding 305 d lactation) and associated assumed large energy deficits ( − 82 MJ in

Quantification and localization of contrast agents using delta relaxation enhanced magnetic resonance at 1.5 T. Magn Reson Mater Physics, Biol

RABORAL V‑RG ® is an oral rabies vaccine bait that contains an attenuated (“modified‑live”) recombinant vaccinia virus vector vaccine expressing the rabies virus glycoprotein

Parameter identification based on lag synchronization via hybrid feedback control in uncertain drive response dynamical networks Liu et al Advances in Difference Equations (2017) 2017

The present work demonstrated an efficient strategy of exploiting wheat DDGS as raw material for polymer (poly-D-lactic acid, PDLA) production. The process

In Europe only the species belonging to the genus Rickettsia are responsible for Rickettsiosis, and typically fall into two general groups: the spotted fever group

APHL: Association of Public Health Laboratories; CDC: US Centers for Disease Control and Prevention; CRHRL: Central Public Health Reference Laboratory; DHMT: District Health