The rheology of butter : a thesis presented in partial fulfillment of the requirements for the degree of Doctor of Philosophy in food technology at Massey University

Full text

(2) T HE RHEOLOGY OF. A. BUT TER. thesis presented. in partial. fulfillment of. the. requi rements for the degree of. Doctor in. of. Food. Phi losophy. Technology at. Massey. Pniversity.. Michelle Harnett. 1989..

(3) ii. Abstract.. A p a r a l l e l p l at e vi s co e l a s t omet e r was b ui l t t o p e r f o rm creep c o mp l i ance t e s t s on b ut t e r and re l ated fat s . C reep movement w a s me a s ur e d with a l i near d i s p l acement t r ans d uc e r and r e c o rded by a data l ogger de s i gned and b ui l t f o r c reep c o mp l i ance e xpe r iment at i on . A t emperat ure o f 1 0 ° C was ma i n t a i ned b y p l a c i n g the par a l l e l p l at e v i s c o e l a s t ome t e r i n a re f r i ge r a t e d i n c ubat o r . A s e r i e s o f pre l im i n a r y expe r i ment s e s t ab l i shed t h e creep r e s p o n s e w a s l in e a r and that t he d i re ct i o n i n wh i ch s ome s amp l e s we r e sheared was cr i t i c a l . The d urat i on o f creep c o mp l i ance t e st ing was a l s o f o und to a f fe ct r e s ul t s . C r eep behavi o ur o f b ut t e r wa s a s s umed t o be v i s c o e l a st i c ( b a s e d o n p revi o us s t ud i e s ) g e n e ra l i z ed Ke l v i n mode l .. a n d was mode l l e d w i t h a. El a s t i c and v i s c o us p a r ame t e r s were. f i t t e d to the dat a by a Mar q ua dt non- l i n e a r l e a s t squares c urve a l g o r i t hm . Cont i n uo us r e t ardat i o n spect r a we re f o und by p l ot t ing L(�). aga i n s t l n t ime .. Data wh i ch had been both. s mo o t hed and di f fe rent i ated by the met ho ds of S av i t z ky and Golay. (1964). showed evidence o f the e xi s t en c e o f three o r f o u�. m a in g r o up s o f ret a rdat i on mechan i sms . O n remova l o f s t re s s a ft e r c r e ep comp l i ance t e s t i n g a part i a l r e c ove ry o f st r a i n w a s ob s e rv e d ,. howeve r ,. s amp l e s fai l ed t o. r ec ove r a s m uch a s p redi cted b y v i s co e l a s t i c t h e o r y . A s e cond c reep / recovery c y c l e re s ul t e d i n a r e s p o n s e s s im i l a r in m a gn i t ude to the f i r s t recove r y . All fat p r o du c t s t e s t e d s h owed the s ame pat t e rn o f r e s p o n s e o n repe a t e d c r e ep / recove ry c y c l ing . An e x p l anat i o n ,. ba s e d on the behavi o r o f p o l yme r s ,. was p ut. f o rward t o e xp l a i n t he ob s e rved pat t e rn o f r e s p on s e . The.

(4) i ii. c r y s t a l network was t h o ught t o a l i gn i n t h e d i r e ct i on in whi ch s t r e s s was app l i e d . The format i o n o f new ' bonds ' t h o ught to l o c k the network i n i t s ' A n umbe r o f s amp l e s w e r e rewo r ke d ,. w a s t hen. new p o s i t i on . The c re ep c urve s e e n o n. c r e e p / re c ove r y c y c l i n g o f rewo r k e d s amp l e s was s im i l a r in s hape to t h at s e en for t he o r i g i n a l s amp l e s . Howeve r ,. the. c urve s were t hree to f o ur t im e s great e r than tho s e s ee n f o r t he o r i g i n a l s amp l e s .. I n gen e ra l ,. creep r e spon s e wa s f o und t o. b e inve r s e l y p r op o rt i on a l t o h a rdne s s . The ret a rdat i on spect r a o f reworked s amp l e s di f fe r e d from t h o s e s e en for the o r i g i n a l s amp l e s in s eve r a l way s . The spect r a we r e s m o o t he r ,. the b ul k o f the spectra had moved t o. s h o rt e r t ime s and t he y were l a rg e r than t h o s e s e e n f o r the o r i g i n a l s amp l e s . A s urve y o f s e a s on a l b ut t e r s amp l e s was a l s o unde rt aken . C reep c omp l i ance paramet e r s were f o un d t o c o r r e l ate we l l w i t h s e ct i l i t y h a rdne s s a n d s o l i d . fat c ontent ..

(5) iv. Aim of. S tudy.. The a ims o f t h i s work a r e : a). T o s t udy t h e rhe o l og i ca l p r ope rt i e s o f b ut t e r a n d re l at e d. f a t p r o d uct s by a creep comp l i ance metho d . b) •. T o g a i n a c l earer unde r s t an d i n g o f the re l at i on s h i p between. rhe o l o g i c a l pr opert i e s ,. c omp o s i t i on and s t r uct ure o f b ut t e r. a n d r e l at e d p r o d uct s . c). T o us e t h i s knowledge t o improve the rhe o l o g i c a l prope r t i e s. o f b ut t e r ..

(6) V. Acknowledgments.. I am i ndebt ed t o my s up e rv i s o r s D r . M . W . T ay l o r , L e L i evre ,. D r . R . Lambert and D r . R . Norr i s ,. s upport wa s grat e fu l l y r e c e ived .. Dr .. J.. who s e adv i c e and. I am a l s o i ndebt ed to the New. Z e a l and D a i r y Re s e a r c h I n s t i t ute who funded t he pro j ect in the f o rm o f a r e s e a r ch c o n t r a c t . A l a s t a i r MacGibbon , Mi l k fat S e ct i on ,. In addi t i on I wou l d l i ke to thank. Trevor B i s s e l l and othe r membe rs o f the. New Z e a l and D a i r y Re s e arch I n s t i tute f o r. t he i r i de a s a n d d i s cu s s i on .. I nva l u ab l e t e chn i ca l a s s i s t ance. w a s rende red by t he t e c hn i c a l s t a f f of t he F o o d T e chn o l ogy D ep a rtment ,. Ma s s e y U n i ve r s i t y a n d by the Da i ry Pr odu c t s. D eve l opment Cent r e s t a f f , N e w Z e a l and D a i ry Re s e a rch I n s t i t ute . N o rt h .. F i na l l y ,. t h a n k s to TD f o r mov i n g to Pa lme rs to n.

(7) List. of. Contents.. AB S TRAC T .. ii. A IM .. iv. ACKNOWLEDGE MENT S .. v. C HAP TER ONE : AN INT RODUCT ION IN THREE PARTS .. 1. P a rt A : Rhe o l ogy .. 1. lA . l .. Int r oduct i o n .. 1. 1A . 2 .. S t re s s and s t r a i n .. 1. 1A . 3 .. S o l i ds ,. 2. l i qu i d s ,. plast i cs .. 1A . 4 . V i s c oe l a st i c s .. 7. 1A . 5 .. 7. Me chan i c a l mode l l i ng .. 1A . 6 . F undame nt a l t e st ing . 1A . 6 . 1 .. S t at i c t e st ing .. 1A . 6 . 2 . D y n am i c t e s t i n g : 1A . 7 . Emp i r i c a l t e s t ing . P a rt B :. 10 10 19 22. Me a s u rement o f the rhe o l og i c a l paramet e r s o f b ut t e r. and marg a r i n e .. 23. l B . l.. 23. Int roduct i on .. 1B . 2 . Fundame nt a l t e chn i que s .. 23. 1 B . 2 . 1 . Creep c omp l i ance .. 23. 1 B . 2 . 2 . Cont i nu o u s s he a r .. 34. 1 B . 2 . 3 . D y n am i c t e s t ing .. 37. 1 B . 3 . Emp i r i c a l and i m i t a t ive t e s t i ng . 1B . 3 . 1 .. S e ct i l i t y ha rdne s s .. 41 41. 1 B . 3 . 2 . E xt ru s i on .. 43. 1 B . 3 . 3 . Comp r e s s i o n .. 45. 1 B . 3 . 4 . P e ne t r omet r y .. 47. 1B . 3 . 5 .. 50. Spreadab i l i t y s i mu l at i on .. P a rt C : But t e r and margar i n e .. 51. lC . l .. 51. I n t roduct i on .. 1 C . 2 . Butter. 51.

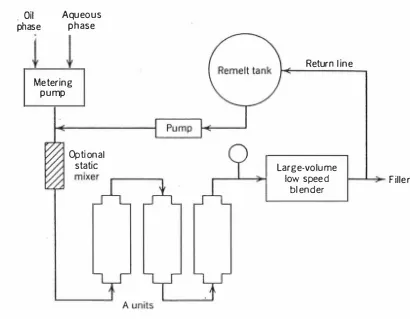

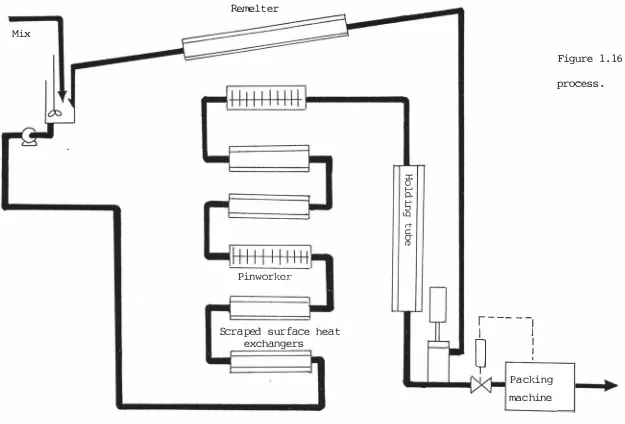

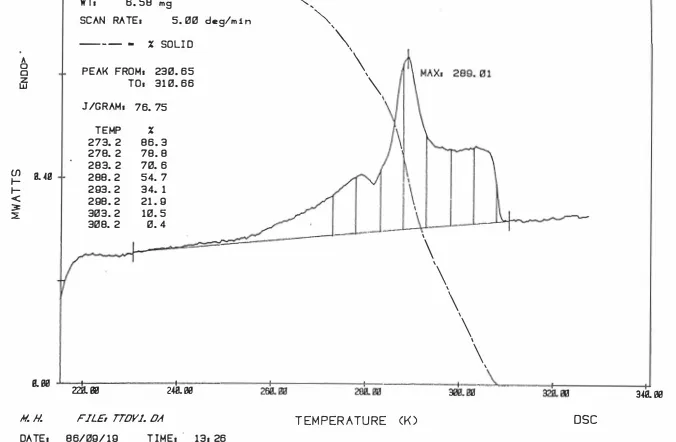

(8) 1C . 2 . 1 .. Manu f ac t u re .. 51. 1C . 2 . 2 .. S t rut u re .. 54. 1 C . 2 . 3 . F ac t o rs af fect ing rhe o l ogy . 1C . 3 .. 55 62. Marg ari ne 1C . 3 . 1 .. Man u f ac t u re .. 62. 1C . 3 . 2 .. S t ru t u re .. 66. 1 C . 3 . 3 . F act o rs af fect ing rhe o l ogy .. 67 72. 1 C . 4 . Ammi x but t e r . 1C . 4 . 1 .. Man u f ac t u re .. 73. 1C . 4 . 2 .. S t ru t u re .. 73. 1 C . 4 . 3 . F act o rs af fect ing rhe o l ogy .. 75. 1 C . 5 . A ft e rw ard .. 78. C HAP TER TWO :. 79. MAT ERIALS .. 2 . 1 . But t e r f rom comme rc i al dai ry fact o ri e s .. 79. C omme rc i al s amp l e i dent i f i c at i on .. 79. 2 . 2 . B ut t e r m ade u s ing di f fe rent c re am c o o l ing t e chn ique s .. 79. 2 . 3 . B u t t e r and anhydro u s p r o duct s made f rom the s ame f at .. 80. 2 . 4 . Rewo rk in g .. 83. 2.5.. 84. 2.1.1.. S t o rage .. C HAP T E R T HRE E : E S TABL I S HED ME T HOD S .. 85. 3 . 1 . E xt ract i o n o f mi l k f at .. 85. 3.2.. 85. S e ct i l i t y h ardn e s s .. 3 . 3 . F at t y ac i d c ompo s i t i o n .. 86. 3.4.. T ri g l y c e ri de comp o s i t i on .. 88. 3.5.. S o l i d f at content by nu c l e ar magnet i c re s o n an c e .. 88. 3.6.. S o l i d f at cont ent by di f fe re nt i al s c an n i n g c al o rimet ry . 8 9. 3 . 7 . C omp ari s on o f n u c l e ar magnet i c re s o n ance and d i f f e rent i al s c an n i ng c al o rimet ry .. 90. C HAP T E R FOUR :. 92. CREEP CO MP L I ANCE ME T HOD .. 4.1.. The i n s t rument .. 92. 4.2.. T e mp e rat u re ' cont ro l .. 94. 4.3.. The d at a c o l l e ct i on s y s t em .. 96. 4.4.. S amp l e p rep arat i on ,. 10 0. 4.5.. Re c ove ry and l o ad c yc l i ng .. 4 . 6 . D at a an al y s i s .. l o ad i n g and runn i ng .. 10 3 103.

(9) 4.7.. 4 . 6 . 1 . C reep c u rve s .. 10 3. 4 . 6 . 2 . Re cove r e y .. 114. 4 . 6 . 3 . P re s e nt a t i on o f re s u l t s .. 114. 4 . 6 . 4 . Re t a r dat i o n spect r a .. 117. P re l im i n a r y exper iment s .. 12 9. 4.7.1.. L in e a r i t y .. 12 9. 4.7.2.. O r i en t at i o n .. 12 3. 4 . 7 . 3 . Repe at ab i l i t y . C HAP T ER F IV E :. 141. LARG E D EFORMAT ION T EST I N G .. 149. 5.1 .. I nt roduct i on .. 149. 5.2.. Expe r ime nt a l me th od .. 15 2. 5.3.. Expe r i men t a l and r e s u l t s .. 15 3. 5.4.. D i s cu s s i on .. 16 3. 5.5.. Concl u s i o n .. 17 2. 5. 6.. Trad it i on a l s e ct i l i t y ha rdne s s t e s ti n g vs .. l a rge. de f o rmat i on t e s t i n g .. 17 2. C HAP T ER S I X : AN INTROD UCT I ON TO CREEP CO MP L IANC E EXP ER I MENTAT I ON .. 17 4. P a rt A. 17 ·4. 6A . 1 .. Exper ime nt a l .. 17 4. 6A . 2 . Re su l t s .. 17 4. 6A . 3 . D i s cu s s i o n .. 17 6. P a rt B : But t e r s manu f a c t u red u s i n g di f f e r ent c r e am c o o l i n g t e chn i qu e s .. 17 8. 6B . l .. 17 8. Expe r i me nt a l .. 6 B . 2 . Re s u l t s .. 17 8. 6B . 3 . D i s cu s s i on .. 17 9. C HAP T ER S EV EN : T HEORY .. 18 1. 7 . 1.. I n t roduct i o n .. 18 1. 7.2.. Load c y c l ing .. 18 1. 7.2.1.. 18 1. 7.3.. Expe rime nt a l .. 7 . 2 . 2 . Re s u l t s .. 18 1. 7 . 2 . 3 . D i s cu s s i on .. 19 1. Rework i n g .. 19 4.

(10) 7 . 3 . 1 . Expe r i me nt a l .. 1 94. 7 . 3 . 2 . Re s u l t s .. 1 94. 7 . 3 . 3 . D i s cu s s i on .. 204. 7 . 4 . Deve l opment o f a t h e o r y t o e xpl a i n ob s e rved behavi o u r . 2 0 6 7.4.1.. I nt r odu c t o r y c omment s .. 206. 7 . 4 . 2 . Theory A .. 206. 7.4.3.. 208. Theory B .. C h apt e r E i ght : But t e r and Anhydrous P r oduct s made from the S ame F at .. 213. 8.1.. I nt rodu ct i on .. 213. 8 . 2 . Expe r iment a l .. 213. 8 . 3 . Re s u l t s .. 214. 8.3.1.. S e ct i l i t y h a r dne s s and s o l id fat cont ent .. 8 . 3 . 2 . Creep comp l i an ce . 8 . 4 . D i s c u s s i on .. 214 229 235. 8 . 4 . 1 . Compo s i t i on. 235. 8 . 4 . 2 . Rewo r k i n g .. 242. C HAP TER N I NE :. SEAS ONAL TREND S I N FRI T Z AND AMM I X BUT TE R .. 245. P a r t A : E s t ab l i shed method s .. 2 45. 9A . 1 .. I nt roduct i on .. 245. 9A . 2 . E x p e r iment a l .. 245. 9A . 3 .. 2 46. Re s u l t s and d i s cu s s i on . 9A . 3 . 1 .. S e ct i l it y h a r dne s s .. 24 6. 9A . 3 . 2 .. S o l i d f a t c o n t e nt .. 2 46. 9A . 3 . 3 . Comp a r i s on between s e ct i l i t y ha rdne s s and s o l i d f a t c ont ent .. 251. 9A . 3 . 4 . D i f fe rent i a l s canning ca l o r imet r y .. 255. 9A . 3 . 5 . F a t t y a c i d c ompo s i t i on .. 256. 9A . 3 . 6 . T r i g l y c e r i de c ompo s i t i i on .. 261. 9A . 4 . C o n c lu s i on .. 2 64. P a r t B : C reep c omp l i an c e .. 2 65. Exp e r iment a l .. 2 65. 9B . 1 .. 9 B . 2 . Re s u l t s .. 2 65. 9 B . 3 . D i s cu s s i o n .. 271. 9 B . 4 . C on c l u s i on .. 272.

(11) C HAP TER TEN : GENERAL D I S CU S S ION .. 274. 1 0 . 1 . D eve l opement o f the c reep comp l i ance method .. 274. 1 0 . 1 . 1 . Equ i pment .. 274. 10 . 1 . 2 . D a t a C o l l e ct i on .. 274. 10 . 1 . 3 .. 275. Tempe r a t u re Contr o l .. 1 0 . 1 . 4 . Ac c u r a c y . 1 0 . 2 . D at a ana l y s i s .. 276. 10 . 2 . 1 . The V i s c oe l a s t i c Mode l .. 276. 10 . 2 . 2 Dat a Ana l y s i s .. 277. 10 . 2 . 3 . Ret a rdat i o n Spectra .. 278. 10 . 2 . 4 . App rop r i atene s s o f t he Mode l .. 278. 1 0 . 3 . P re l i m i n a r y E xper iment s .. 10 . 4 .. 275. 279. 10 . 3 . 1 . L i n e a r i t y .. 279. 1 0 . 3 . 2 . Durat i o n o f E xper iment .. 280. 10 . 3 . 3 . O r i e nt a t i on o f Samp l e .. 282. Load Cyc l i ng .. 284. 1 0 . 5 . P r oduct s made from t he s ame fat .. 289. 1 0 . 6 Rewo rked pr oduct s .. 2 90. 10 . 7 .. S e a s o n a l s u rvey .. 291. 10 . 8 .. Conc l u s i on and fut u r e work .. 2 93. AP P END I X 1 : Compu t e r P r ograms .. 296. AP P END I X 2 : Non- l i n e a r Le a s t Squ a re s Cu rve F i t t ing Re s u l t s . 3 13 APP END I X 3 : D i f fe rent i a l S c ann ing C a l o r ime t r y Me l t i ng The rmo grams , REFERENCE S .. 19 8 5 - 19 8 6 S e a s on .. 3 42 356.

(12) List Table 1 . 1 :. of. Tables. 26. Cr eep r e s u l t s report ed by var ious work er s .. Table 1 . 2 : Re s u l t s r epor t ed b y D a v i s met hods .. ( 1 9 73 ). us ing a var i e t y o f r heological 29. Table 1 . 3 : Compar i s on o f the r e s u l t s r epor t ed by S hama a nd S herman and Gup t a a nd D eMan ( 1 9 8 5 ) .. ( 1970 ) 31. Table 2 . 1 . Pr oduct i o n condi t i o n s used i n t he man u f a c t ur e o f but t er and anhydr ou s pr oduct s from the s an e milk f a t . 82 Table 2 . 2: Product temper a t ur e s r ecorded dur ing pr oduct ion of butter and a nhydr o u s pr oduc t s from the sam e milk fa t . 82 Table 3 . 1 : Compo s i t i on o f s t a ndard a� hydr ous mi lk fa t .. 87. Table 3 . 2: No rma l iz ing factor s f or fat t y a c id we ight per centage s , r e l a t ive 87 to c 16 : o· Table 4 . 1: The e f fect o f var y i�g the n umb er of ex ponent i a l terms used i n f i t t ing da t a to t he pr e f i ned mode l . (Samp le TUI A ugu s t ' 86 , 1 0° C . ) 110 Table 4 . 2 : P ar ame ter s f i tted t o cr eep c ompl iance dat a by two met hods , e xponen t i a l pee l ing a nd n o n - l inear c�rve f i tt ing .. 1 13. Table 4 . 3 : A compar i s on o f r e t ardat ion t ime s c a l c u l a t e d by a lea s t sq uar e s c ur ve f i t t ing pr ogr am ( NONLIN ) a n d tak e n from conti nuous r e t arda t ion s pe c tr a, F igur e s 4 . 2 0 a nd 4 . 2 2 . 128 Table 4 . 4: S tr a in r e sponses obser ved o n the app l i c a t i o n o f s tr e s s .. 13 1. Table 4 . 5 : Cr eep comp l iance par ame ter s f ound for one s amp le on t he app l i c a t ion o f dif fer ent s tr e s s e s .. 13 1. Table 4 . 6 : Cr eep comp l iance parameter s obt a ined fr om p a t ted Fr i tz but t er s 13 4 s he ar e d i n t he thr ee p o s s ible dir e c t i on s . Table 4 . 7 : Re cover y dat a f or the butter TUI Apr i l ' 8 7 .. 13 6. Table 4 . 8: Cr eep comp l i a nce par ameter s obt a ined from p a t t ed Fr itz but t er s 13 6 s h e ar e d i n two dir e c t ions . Table 4 . 9 : Cr eep comp l iance par ametr s obta ined from unpa t t ed Fr i tz but ter s 13 8 s h e ar e d i n two dir ec t i o n s . Table 4 . 1 0 : Cr eep comp l i a nce par ameter s f i t t ed t o cr eep curves obser v ed for 144 t he b u t t er TT Januar y , 1 9 8 6 . T a b l e 4 . 1 1: Cr eep c omp l iance par ameter s f it t ed t o cr eep c ur ve s obser ved for t he b u t t er TT A pr i l , 1 9 8 6 . 1 47 T a b l e 5 . 1 : P er cent age s o l id f a t determined by NMR and tr adit i o n a l sect i l ity h ar drie s s v a l u e s a t 1 0° C for but t er s used in large de f or ma t ion t e s t ing . 1 5 4.

(13) T a b l e 5 . 2 : An e xample o f da t a reco rded by the P e r k i n E lme r dat a s t a t io n 16 1 du r i ng la rge de fo rma t io n tes t ing . T a b l e 5 . 3 : Comp a r iso n o f s e c t i l i t y h a rdness tes t ing ( t radi t io n a l ) s he a r t es t ing . T a b l e 5 . 4: S e c t i l i t y hardness res u l ts. with. ( C R Ana l ys e r ) .. 16 4 16 4. T a b l e 5 . 5: The fit o f v a r io us mo dels to s he a r speed vs . fo rce data fo und at 5 , 1 0 a nd 1 5° C fo r fo u r s amples exp ress ed as co rre lat io n co e f f i c ients . 16 9 T a b l e 6 . 1 : Rheo lo gical pa rame t e rs fo und fo r c reep and reco v e r y expe r iments o f d i f fe ring length . 175 T a b l e 6 . 2 : S e c t i l i t y ha rdness v a lues a t 1 0° C fo und fo r but t e rs manu f a c t u red f ro m c ream s ub j ected to di f fe rent c re am coo l ing t e chniq u es . 180 Tab l e 6 . 3 : C reep compl iance pa ramet e rs f it t ed to t he c reep res po nse o f but t e rs manu f a c t u red f ro m c ream s ub j e c t ed to di f fe rent c re am coo l ing 180 t e c h n iq ues . T a b l e 7 . 1 : S e c t i l ity ha rdness es and so l id fat co n t ents o f s e le c t ed det e rmi ned at 1 0° C .. 1 83. T a b l e 7 . 2 : C reep compl iance pa rame t e rs fo r s amp les co l le c t ed t h ro ugho u t the yea r . 1 8 7 T a b l e 7 . 3 : Ov e r a l l c reep respo ns e d isp layed by s amples co l l ected thro ugho ut t he ye a r . 188 T a b l e 7 . 4 : Co r re lat io n co e f f ic ients fo und b etween v a r io us c reep comp l i a nce pa r a me t e rs and sect i l i t y ha rdness fo r s amp les o f but t e r co l lected t h ro ugho u t t he yea r . 189 T a b l e 7 . 5: Creep compli ance pa rame t e rs f itted to o ri g i n a l and rewo rked but t e r pa i rs . 195 Table 7 . 6: P e rcent age changes s een i n c reep res po ns e o n t he rewo rking o f but t e r s amp les . 197 Table 7 . 7 : P e cent age cha nge fo und i n s e lect ed pa ramet e rs o n compa ring f i rs t 1 97 and s e co nd c re e p respo ns es . T a b l e 7 . 8: Ret a rda t io n t imes found fo r o rigianl and rewo rked but t e rs . Table 8 . 1: S e c t i l i t y h a rdness res u l ts ,. 1 0° C .. Table 8 . 2 : So l id fat co n t ents as det e rmined by NMR .. 203 215 215. T a b l e 8 . 3 Creep comp l iance parame t e rs fo r o r igina l and rewo rked s amples o f but t e r , p l as t i c ized mi l k f a t and a mi l k f a t /o i l blend man u f a c t u red f rom t he 220 s ame f a t so u r c e . Table 8 . 4: Co r relat io n co e f f i c ients found between v a r io us c reep comp l iance ' pa r amet e rs and s e ct i l i t y h a rdness fo r o r igina l and rewo rked but t e rs ,.

(14) p l a st ic ized m i lk f at and m i lk fat/ o i l b l e nd m an u f a ct u red f rom th e s am e f at . 221 Table 8 . 5 : Pe rcent age ch a nges seen i n v a r ious p a r am et e r s go ing f rom 23 1 o r ig i n a l t o rewo rk ed . Table 8 . 6 : Comp a r i s o n o f s ec ond c reep respon s e w ith the f i r st c reep response .. 233. Table 9 . 1 : Th e sect i l it y h a rdne s s o f s amp les o f p atted butt e r det e rmined at 247 1 0° C . Table 9 . 2: Pe rcent age s o li d fat a s det e rmined b y NMR f o r s ampl e s o f m i lk f at ext r a cted f rom F r itz butt e r . 249 Table 9 . 3: P e rcent age s o l id fat a s det e rmined b y NMR f o r s amp l e s o f m i lk fat ext r a ct ed f rom �� ix butt e r . 250 Table 9 . 4 : Fatt y a c i d comp o s it ion o f F ritz b utt e r s col lect ed du r ing the 1 9 8 5 - 1 9 8 6 season . 2 57 Table 9 . 5 : Fatt y a c i d comp o s s iton o f Amm ix b utt e r s c o l lect ed du r i ng th e 1 9 8 5 - 1 9 8 6 season . 258 Tab le 9 . 6 : T r i gly ce r ide c om po s it ion o f F r itz b utt e r s c o l l e cted du r ing th e 1 9 8 5 - 1 9 8 6 season . 2 62 Table 9 . 7 : T r i glycer ide c ompo sit ion of Amm ix butt e rs c o l le ct e d du r i ng th e 1 9 8 5 - 1 9 8 6 season . 2 63 Table 9 . 8 : C reep c om pl iance paramet e r s f itted t o butt e r s .. 2 67. Table 9 . 9: Co r re l at ion coe f f ic ient s found between sect i l it y h a rdne s s a nd s o l id f at cont e nt a nd c reep compl i a n ce paramet e rs f o r a numbe r o f b utt e r s . 269 Table 9 . 1 0 : C reep c om p l iance par amet e r s f o r samp l e s c o l lect ed th rough out the ye a r . 270.

(15) List F igure 1 . 1: Rate o f sh ea r vs .. of Figures.. sh e a r f o r a Bingh am p l a st i c .. F i gu re 1 . 2: Stan da rd rh eolog i c a l m ode ls : a) da sh pot , c ) St Ven ant glide r .. 6. Hook e an s p r in g , b). F i gure 1 . 3: Rh eological m ode l s: a) B ingh am plast i c , b ) Kelvin un it an d d) , Burge r s m ode l .. Newt on ian 8. Max we l l un it , c) 9. F i gu re 1 . 4: Typi c a l c reep an d rec ove ry c u r ve f o r a p l a st i c f at .. 13. F igure 1 . 5 : A m ode l c reep cu rve .. 14. F igure 1 . 6: The gen e r a l ized Ke lvin m odel .. 16. F i gu re 1 . 7: St re s s re spon s e t o s in u so ida l st rain .. 21. F igure 1 . 8: Creep paramet e r s repo rted by G upt a an d D eMan again st force used .. ( 1985). p l otted 33. F igure 1 . 9: Th e m odif ied Bin gh am body . F i gu re 1 . 1 0: a) Th e Vis cous -Max we l l -Bin gh am mode l 1 9 86) , b) st uct u r a l app l i c at i on of the m ode l .. 36 (D e in e r an d He ldman, 39 53. F i gu re 1 . 1 1: Th e P a s i la c HCT 2 cont in uous butt e rm ak e r .. F igure 1 . 1 2: D i f f e rent i a l scann in g c a l o r im et ry m e lt in g th e rm og r am o f a F r itz butt e r . 57 F igure 1 . 1 3: D i agram of a sect i on th rough a sc raped s u r f a c e h e at exchange r . 64 F igure 1 . 1 4: Cont in uous s o ft m a rga r in e p roduct ion. ( E r i ks on,. 1 9 8 5) .. 65. F igure 1 . 1 5: D i f f e rent i a l s cann in g c a l o r im et ry m e lt in g th e rm og r am o f a t ab le m a rg a r ine . 69 74. F igure 1 . 16: Th e Amm ix proce s s .. F igure 1 . 1 7: D i f f e rent i a l s c ann in g c a l o r im et ry m e lt in g th e rm og r am of an 77 Amm ix b utt e r. F igure 2 . 1: P l ant c on f igurat i on used in the m an u f a ct u re o f butt e r an d anh ydrous product s f rom t he smae f at .. 81. F igure 4 . 1: The p a rallel p l at e v i s co e l a st omet e r .. 93. F igure 4 . 2 : D i f fe rent i a l s c ann in g c a l o r im et ry m e lt in g t h e rm og ram i l l u st rat in g th e c han ge s in s o l id fat c ontent with t em pe r at u r e at 1 0 an d 1 5oC . 95 F i gu re 4 . 3 : Fluct u at i on in t em pe rat ure obse rved ove r. �. f o rt y h o u r pe r i od . 97.

(16) F igure 4 . 4: D at a c o l lect ion syst em .. 98. F igure 4 . 5: Ch a rt recorde r t race seen on pe r f o rming a c reep comp l i a nce 99 e xpe r iment . F igure 4 . 6: P l an and s ide views o f th e s ample c utt e r .. 101. F igure 4 . 7: A c reep and recove ry cu rve .. 104. F igure 4 . 8 : A c reep comp l iance cu rve sh o wing ext rapo l at ion back t o 0 t ime . 1 06 F igu re 4 . 9: Ln Q p l ott ed aga inst t ime sh owing th e st r a i ght l ine port ion of th e graph ext rapo l ated to 0 . 108 F igure 4 . 1 0 : C reep and recove ry curve s sh owing inst a nt aneous comp l ianc e , th e s um o f comp l i ances recovered a n d th e un recovered st r a i n . 115 F igure 4 . 1 1: Re s u lt present at ion b y th e c u rve f itt ing p rogram NONLIN .. 1 16. F igure 4 . 1 2 : An ide a l cont inuous ret a rdat ion spect rum c a l c u l at ed for the s ample MAN May 1 9 8 7 . 119 F igure 4 . 13 : Ret a rdat i on spect rum found f o r th e samp l e MAN May 1 9 8 7 u s ing 120 raw dat a . F i gure 4 . 1 4 : Cont inuous reta rdat ion spect rum found f o r MAN May 1 9 8 7 a fter smooth ing raw dat a . 122 F igure 4 . 1 5 : Th e ide a l cont inuous ret a rdat ion spect r um f o u n d f o r MAN May 1 9 8 7 a ft e r smooth ing . 122 F igure 4 . 16: Th e cont i nuous ret a rdat ion spect rum found f o r MAN M a y 1 9 8 7 123 a ft e r d i f f e rent i at ing th e raw dat a . F igure 4 . 1 7: Th e ide a l cont inuous ret a rdat ion spect u rm f ound f o r MAN Ma y 1 9 8 7 a ft e r d i f f e rent iat ing a c c o rding t o th e meth od o f S az itz ky and Go lay ( 1 96 4) . 123 F igure 4 . 1 8: Th e ide a l cont inuous ret a rdat ion spect u rm f ound f o r MP� Ma y 124 1 9 8 7 a ft e r a 13 p o i nt cub i c d i f f e rent i at i on . F igure 4 . 1 9 : Th e i de a l cont inuous ret a rdat ion spect u rm f ound f o r MAN Ma y 124 1 9 8 7 a ft e r a 7 p o i nt qua rt i c d i f f e rent i at i on . F igure 4 . 2 0 : Th e cont inuous ret a rdat i o n spect u rm found f o r MAN May 1 9 8 7 a ft e r smooth ing and d i f f e rent iat ing a c c o rding t o the meth od o f S avitz ky and Golay ( 1 96 4) . 125 F igure 4 . 2 1 : Th e ide a l cont inuous ret a rdat ion spect u rm f o und f o r MAN May 1 9 8 7 a ft e r smooth ing and di f fe rent iat ing a c c o rding to th e meth od o f 125 S a v itz ky a nd G o l a y ( 1 96 4 ) . F igure 4 . 2 2 : Th e cont inuous ret a rdat i o n spect u rm found f o r MAN Ap r i l 1 9 8 7 a ft e r smooth ing and di f fe rent i at ing � c c o rding t o the meth od o f S avitz ky and 1 26 Golay ..

(17) F igure 4 . 2 3: The ideal cont in uous ret a rdat ion s pecturm f o un d f o r MAN Ap ril 1 9 8 7 a ft e r smoot h in g an d di f fe rent i at in g according to t he met hod of 126 S avitzk y an d Go lay ( 1 9 6 4) . F igure 4 . 2 4: Th ree dimen s ion a l axes imposed on a pat o f butt e r .. 133. F igure 4 . 2 5: Ope rat in g p r in c iples o f t he S ig FD 1 4 0 patt e r .. 139. F igure 4 . 2 6 : Creep comp l i an ce cu rve s foun d f o r t he samp le T T Jan ua ry ' 8 6 . 143 F igure 4 . 2 7: Creep comp l ian ce curve s foun d f o r the samp le T T Ap r i l ' 8 6 . 1 4 5 F igure 5 . 1 : Front an d s ide views o f t he apparat us att a c hed t o t he c R An a lyser used for shea r test ing .. 151. F igure 5 . 2: Force vs . shear speed f o r t he sam p l e TUI Februa ry 1 9 8 7 .. 155. F igure 5 . 3 : Force v s . s hea r speed f o r t he samp le MAN MAy 1 9 8 7 .. 1 56. F igure 5 . 4 :. Force vs . s he a r speed f o r t he sample TT Februa ry 1 9 8 7 .. F igure 5 . 5 : Force vs . s he a r speed f o r t he s amp l e TT M a rch 1 9 8 7 .. 1 57 158. F igure 5 . 6:. Shear fa i lu re st re s s p l otted aga in st t empe rat u re .. 16 0. F igure 5 . 7 :. St r e s s vs . dist an c e moved by the p robe .. 16 2. F igure 5 . 8 : Fo rce vs . s he a r speed f o r both s he a r te st in g an d sect i l it y 165 h a rdn e s s t e st ing, sample MAN May 1 9 8 7 . F igure 5 . 9: Fo rce vs . s he a r speed f o r bot h shea r test in g an d sect i l it y 166 ha rdn e s s t e st ing, samp le T T Ma rch 1 9 8 7 . F igure 7 . 1 : Typ i c a l c reep comp l i an ce c u rve s een on repeat edly applyin g an d 184 removin g st re s s . F igure 7 . 2: Cont in uous reta rdat ion spect ra foun d f o r t h e butt e r TUI Apr i l 185 1 9 8 7, a ) f i r st c reep respon se, b ) , s econ d c reep re spon s e . F igure 7 . 3: Cont in uous ret a rdat ion spect ra foun d for t he butt e r T T March 1 86 1 9 8 7, a ) f i r st c reep re s pon se, b ) , s e c on d c reep respon se . F igure 7 . 4: F i rst and s econ d c reep c u rve s obse r ved f o r t h e but e r TUI Ma rch 1987 . 192 F igu re 7 . 5: Cont in uous reta rdat i on s pect ra f o un d for t he butt e r TUI Ma rch 199 1 9 8 7, a ) f i r st c reep re spon se, b ) , s e c on d c reep respon s e . _ Cont in uous reta rdat ion spect ra f o un d for t he butt e r T T Feb . F igure 7 . 6: 200 1 9 8 7, a ) f i r st c reep respon se, b ) , s e con d c reep re spon s e . F igure 7 . 7: Cont in uous ret a rdat ion spect ra f o un d for t he rewo r ked butt e r T U I Ma rch 1 9 8 7, a ) f i r st c reep respon s e, b ) , s e c on d c reep respon se . 201.

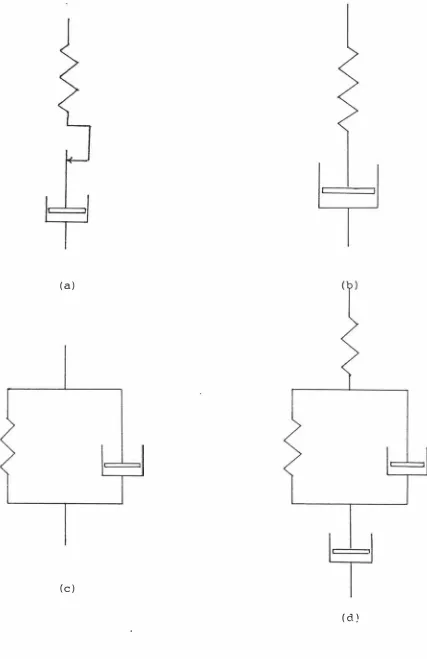

(18) F igure 7 . 8 : Cont i nuous ret a rdat i o n spect ra foun d f o r th e rewo rked butt e r T T Feb . 1 9 8 7, a) f i r st c reep respon se, b) , secon d c reep re spon s e . 202 F igure 8 . l a : D i f f e rent i a l s c a nn ing c a l o r im etr y m e lt in g th e rm ogram found for 2 16 o r i g in a l p l a st i c ized m i l k fat . F i gu re 8 . l a : D i f fe rent i a l s c a nn i ng c a l o r im etry m e lt ing therm ogram found for rewo rked p l a st ic ized m i l k f at . 2 17 F igu re 8 . 2 a : D i f ferent i a l s c a nn ing c a l o r im et ry m e lt ing th e rmogram found for 2 18 o r i g in a l m i lk fat/ o i l blend . F igure 8 . 2b : D i f ferent ia l s c ann ing c a l o r im et ry m elt i ng th e rm ogram found for 219 rewo rked m i lk f at/ o i l blend . F ig u re 8 . 3 : Cont in uous ret a rdat i on spect ra found f o r p l a st i c iz e d m i l k f at : 223 a) i n it i a l creep respon se, b) secon d c reep re spon se . Figu re 8 . 4 : Cont inuous ret a rdat i o n spect ra found for butt e r : c reep res pon se, b) s econ d c reep respon se .. a). in it i a l 224. Figure 8 . 5: Cont in uous ret a rdat i on spect ra found fo r m i lk f at/ o i l bl en d : a) i n it i a l creep re spon se, b) s e c ond c reep re spon s e . 2 25 F ig u re 8 . 6 : Cont in uous ret a rdat ion spect ra found f o r rewo rked p l a st i c ized 2 26 m i l k f at: a) i n it i a l c reep re spon s e, b) s e c ond creep respon s e . F igure 8 . 7 : Cont in uous ret a rdat i on spect ra found f o r reewo rked butt er: a) 227 in it i a l creep respon s e, b) sec ond c reep respon s e . F igure 8 . 8: Cont in uous ret a rdat i on s pect ra found f o r reworked m i lkf at/ o i l 228 blend : a) i n it i a l c reep re sponse, b) secon d creep r e s pon s e . F igure 9 . 1 : Th e variat ion o f sect i l it y h a rdness w ith s e a s o n .. 248. F igu re 9 . 2 : Th e variat ion o f pe rcent age s o l id fat with s e a s on .. 252. F igure 9 . 3 : S o l i d f at cont ent plott ed aga i n st sect i l it y h a rdne s s showing l in e s of best f it for a l l s am p l e s and F r itz and Amm ix butt e r s sepa rate ly . 253 F igure 9 . 4 : D i f fe rent i a l s can n ing c a l o r im et ry m e lt ing th e rm og ram s found for 255 Oct ob e r an d Decemb e r Amm ix butt e r s F igure 9 . 5 : We ight pe recent age s o f c 16: 0 and c 1 8 : l f o r F r itz an d Amm ix 259 butt e r s col lected ove r th e ' 8 5 - ' 86 s e a s o n . F igure 1 0 . 1 : A c reep a nd rec ove ry cu rve .. 281. F igure 1 0 . 2 : Typ i c a l c reep com p l i a nce cu rve seen on repeatedly applyin g and 285 rem o vin g st re s s . Figure 1 0 . 3 : P roposed rh e o l o g i c a l m ode l s t o represent th e c reep com p l iance beh av i o u r of butt e r . 288.

(19) 1. CHAPTER ONE. AN. PART. A:. 1A . 1 .. INTRODUCT I ON. IN. THREE PART S. RHEOLOGY. I NTRODUCT I ON. Rhe o l ogy i s the s c ience o f d e f o rmat i on and f l ow o f mat e r i a l s . The s t udy o f rhe o l ogy encomp a s s e s m a n y f i e lds ,. f r om ge o l ogy t o. medi c i ne . Even l im i t i ng t h e s cope o f t h i s i n t r oduct i on t o f o o d s p r e s ent s a f o rmi dab l e cha l l en g e .. Man y good b o o k s have. been wr i t ten on the rhe o l ogy o f f o o d s ,. for ex amp l e ,. ' I ndu s t r i a l Rhe o l o gy ' ,. by P .. T e xt u re i n Food Qu a l i t y ' , ( 1 97 6 ) , Rizvi. She rman. ( 1 97 0 ) ,. by de Man , Voi s e y ,. ' Enginee r i ng P rope rt i e s o f F o o ds ' ,. ( 1 98 6 ) ,. etc .. ' Rh e o l ogy and Ra sper and S t an l e y. e d i t e d b y R a o and. The s e b o o k s out l i n e t he f o u r m a i n r e a s on s. f o r t he st udy o f rhe o l o g i c a l . prop e r t i e s o f foods ; t o g a i n a � i n s i ght int o t he s t ructure o f t h e m a t e r i a l ,. t o impr ove qua l i t y. c ont r o l and predi ct the behavi our o f new pr odu ct s ,. to. c o r r e l at e consume r accept ance o f a p r oduct w i t h s ome me a s u r ab l e rhe o l o g i ca l prope rty and t o de s i gn machi n e s for h a nd l i ng foods . I n P a rt A it i s p ropo s e d t o su rve y t h o s e a spect s o f rhe o l ogy n e c e s s a ry to prov i de a ba ckground t o the t op i c s c ove r e d , n ame l y a b r i e f i n t r oduct i on t o s o l i d s ,. l i qu i d s a n d p l a s t i c s ,. a n o u t l ine o f rhe o l og i c a l mode l s a n d rhe o l og y o f v i s c o e l as t i c mat e r i a l s .. 1A. 2 .. S T RE S S AND STRAIN. For a de format i on to occur a f o r ce has t o a c t o n a body . S t re s s. ( cr ). i s t he i n t e n s i t y fact o r o f t he fo r c e , e xpr e s s ed a s f o r c e p e r u n i t a re a ( Nm - 2 , P a ) . T h e v a r i o u s t yp e s o f s t res s ,.

(20) 2. c at eg o r i z e d by the w ay i n whi ch t h e y ac s are c ompr e s s i ve s t re s s ,. t en s i l e s t r e s s and she ar s t re s s .. Comp re s s i ve s t r e s s act s at r i ght ang l e s and t ow ards t he p l ane i n wh i ch it is act ing . Ten s i l e s t re s s c ompone nt s al s o act at r i ght ang l e s , eg .. t he y act ,. but are di r e ct ed aw ay from t he p l ane i n wh i ch s t re t ch i n g ,. wh i l e she ar s t re s s e s act. t angent i al l y t o the p l ane . C onve r s e l y ,. when a body i s s t re s s e d and i t s d i me n s i on s ch ange ,. a de format i o n h as o c c u r red . D e f o rm at i on c an b e e xpre s s ed as s t r ai n . F o r e x amp l e , stress. when a body o f l engt h L i s s ub j e ct e d t o a. ( t en s i l e o r c omp re s s ive ) ,. c an be e xp r e s s ed as �L / L , W i t h l i qu i d s , de format i o n with t ime .. 1A . 3 .. o r s t r ai n. ( y,. �L ,. unit l e s s ) .. i t i s more app ropr i at e t o spe ak o f the r at e o f. (y),. S OL I D S ,. the l in e ar de f o rmat i o n ,. whe re. L I QU I D S ,. y. =. d y/ dt. ( s - 1 ) , t he ch ange i n s t r ain. P LAS T I CS. Two ext reme s o f behav i o u r ,. s o l i d and l i qu i d ,. m ay re s u l t when a. f o r ce i s app l i e d t o a mat e r i al . The s e e x t r eme s are the b as i s f o r two b r o ad c at e g o r i e s i n t o whi c h foods c an b e divided, s o l i d f o o d s and l i qu i d or f l u i d foods . Gene r al l y , r e t ai n t he i r s h ape unde r g r av i t y ,. s o l i d foods. whe r e as f l u i d foods f l ow. under g r av i t y and do not r e t ai n the i r s h ape . Mo s t s o l i d foods howeve r ,. c an e xh ib i t l i qu i d p rope rt i e s unde r s ome condit i on s .. F r om a rhe o l o g i c al v i ewpo i nt t he beh av i o u r o f an i de al s o l i d i s de s cr i b e d as pu r e l y e l as t i c and t h at o f an i de al l iqu i d as p u r e l y v i s c ou s . 1A . 3 . 1 .. S o l ids. P u re e l as t i c beh av i o u r i s de f ined s u ch t h at when a f o r c e i s app l i ed t o a m at e r i al i t w i l l i n s t ant l y and f i n i t e l y de f o rm , and when t he f o r ce i s re l e as e d i t w i l l i ns t an t l y r e t u r n t o i t s.

(21) 3. o r i g i n a l f o rm . s o l id .. S u ch a mat e r i a l i s re f e r r e d to a s a H o o k e an. The amount o f de format i on i s p ropo r t i on a l t o the. magn i t ude o f the force . A mate r i a l o f t h i s nat ure has a rhe o l o g i c a l p a r amet e r t e rmed t he e l a s t i c modu l u s. (E) ,. the. s t re s s / s t r a i n rat i o o f t he mat e r i a l . Three t ype s o f modu l i e x i s t f o r Hookean s o l ids , modu l u s ,. E. The e l a s t i c. ( t he force perpend i cu l a r t o the area de f ined by. s t re s s ) ; t he s he a r modu l us , de f i ned b y s t r e s s ). G. ( t he force p a ra l l e l t o the a re a. a n d the bu l k modu lu s ,. K , where f o rce i s. app l i e d from a l l d i re ct i on s . A fourth p a r ameter i s t he P o i s s on s r at i o . On comp re s s i o n o r s t ret ch i ng the rat i o o f l at e ra l s t r a i n t o l on g i t ud i n a l s t r a i n i s t he P o i s s on s r at i o . At sma l l s t r a i n s. ( l e s s than 1 % ). many b i o l o g i c a l mate r i a l s act. as H o o k e an s o l i d s . 1A . 3 . 2 .. L i qu i ds. F o r a pure v i s co u s mat e ria l ,. f l ow beg i n s o n the app l i c at i on o f. the s l i ght e s t force and the rate o f f l ow i s proport i o n a l t o t h e magn i t ude o f the app l i e d· force .. The l i qu i d f l ows unt i l the. f o r c e i s removed and i t has n o ab i l i t y t o re cove r i t s o r i g i n a l s t at e . The magn i t ude o f de format i on depends on the t ime f o r wh i ch the f o r c e was app l i ed . A mate r i a l w i t h the s e c h a r a ct e r i s t i c s i s ca l l ed a Newt on i an l i qu id . Newt on i a n l i qu i ds are charact e r i z e d by a rheo l og i c a l p a r amet e r ,. t he c oe f f i c i ent o f vi s co s i t y. ( � ) , t he rat i o o f t he. s h e a r s t re s s t o t he r e s u l t ing s t r a i n r a t e . (1 . 1). The un i t s o f vi s co s i t y a re P a . s . Vi s co s i t y can be thought o f a s t he i n t e r n a l f r i ct i on o f a l i qu i d . The v i s co s i t i e s o f Newt on i a n f l u i ds a r e i n fluenced o n l y by t e mpe r a t u r e and compo s i t i on ,. whe r e a s the f l ow p r op e rt i e s o f. '{.

(22) 4. n o n - Newt on i an f l ui d s are i n fluenced by c h an g e s i n t h e r ate o f s h e ar .. Mo s t foods e x h i b i t non-Newt on i an b e h av i o u r .. Non - Newt on i an behav i o u r c an be e i t h e r t ime - i ndependent or t ime - depe n de nt . The f l ow p rope rt i e s of t h e f o rmer depend on l y o n t he s he ar r at e ,. wh i l e the f l ow p r opert i e s o f t h e l at e r al s o. depend o n t he dur at i on o f the s he ar . A l arge numb e r o f t ime -i n dependent n on-Newt on i an f o o d s e xhib i t she ar t h i n n ing o r p s e u do -p l as t i c behaviou r ,. w i t h v i s c o s i ty. de c r e as ing as the she ar r at e i n c re as e s . F o ods who s e v i s c o s i t i e s i n c r e as e w i t h s he ar r at e , t h i c ke n i ng foods , An. are r ar e ,. di l at ant o r s he ar. but h ave been rep o r t e d .. i mp o rt ant s ub group o f n on-Newt on i an f o o ds w i t h t ime. depende nt p ropert i e s i s t h at o f t h i xotrop i c foods . At a fixed she ar r at e the v i s c o s i t y of such foods de c r e as e s with t i me , unt i l an e qu i l ib r i um i s re ached . T h i s e f fe ct b r ought ab out by m e c h an i c al act i on bre ak i ng down s t ructure . F o o d s wh i ch unde r g o t ime - dependent s he ar t h i c k e n in g ,. rhe ope ct i c foods ,. are. u n c ommo n . Many att empt s h ave been m ade t o mode l the b e h av i o u r o f non Newt on i an f l u i d foods . P e rh aps the most r e l evant to t h i s wo r k i s t h e p ower l aw mode l t ime - i ndepende nt. ( Equ at i o n 1 . 2 ). fo r foods e x h i b i t ing. f l ow p r ope rt i e s . The power l aw mode l h as. b e e n v e r y w i de l y u s e d t o de s c r ibe f l ow b e h av i o u r . (1 .2) whe r e n i s t he f l ow behav i o u r i ndex and K i s a c on s t ant , s omet i m e s c al l e d t he c on s i s t en c y inde x . n i s a me as u r e o f the deg r e e o f n on-Newt on i an b e h av i ou r ,. the l ow e r t he v al u e of n ,. t h e m o r e a m at e r i il ' s propert i e s devi ate f r om n o n-Newt on i an b e h av i o u r . n i s dimen s i on l e s s . When n 1 A . 2 . 3 . P l as t i cs. =. 1,. K. =. viscos ity ..

(23) 5. I n rhe o l og i c a l t e rm s a p l a s t i c mat e r i a l f l ows when a s t re s s g r e a t e r than a l im i t ing va l u e act s o n it . i s t e rme d the y i e l d s t re s s. (00) .. The l imit ing s t r e s s. A p e r fect l y p l a st i c mat e r i a l. doe s n o t st art t o de f o rm unt i l a s t re s s e x ceeding the y i e l d s t r e s s i s app l i ed ,. and wou l d cont inue t o de f o rm unt i l t he. s t r e s s i s removed . De f o rmat i on i s pe rmanent . A pract i c a l de f i n i t i on o f a p l a s t i c o ft en u s ed i s a mat e r i a l whi ch w i l l n o t f l ow under gravity a l one . Ve ry fe w bodi e s a r e p e r f e ct l y p l a s t i c . A more c ommon t ype i s the B i n gham o r p l a s t o -vi s c o e l a s t i c body . Whe n a s t re s s be l ow the y i e l d s t re s s i s app l i e d ,. the B i ngham p l a s t i c behave s i n an. e l a s t i c fashion . Once the y i e l d s t re s s i s exceede d , de f o rmat ion con s i s t ing o f b o t h p l a s t i c and v i s cous component s o c cu r s .. Upon the remova l o f s t re s s ,. st rain ,. e l a s t i c component de cre a s e s i n s t ant l y .. repre sent i ng t he. The v i s c o u s and p l a s t i c. de fo rmat i on i s pe rmanent . A B i ngham p l a s t i c obe y s t h e equat i o n :. ( 1. 3). whe r e. o0. equ a l s t he y i e l d s t r e s s ,. and �. ,. the p l a s t i c. vi scos ity . Many f o ods approx i mate t o B i ngham behavi o u r . O ften i n p r a ct i ce a c l e a r y i e l d p o i nt may n o t be s e e n . Thi s i s �l l u st ra t e d i n F i gu r e 1 . 1 . The y i e l d s t re s s can be t aken at t hree di f fe rent p o i nt s :. the l ower y i e l d v a l ue. f r om t he s t re s s a x i s ,. (1). whe re the cu rve dev i at e s. the upper y i e l d v a l u e. t h e cu rve becomes s t r a i ght ,. (2). t aken whe re. and the B i ngham y i e l d va l u e which. i s found by e xt r apo l at ing t he s t r a i ght l i ne p o rt i on o f the cu rve b ack to t he s t r e s s a x i s ..

(24) 6. stress. 2 3. 1. rate of shear. Figure 1 . 1 :. Rate of shear vs . shear for a Bingham plast ic ..

(25) 7. 1 A . 4 . VI SCOELAS T I CS S ome foods have rhe o l o g i c a l prope rt i e s a s s o c i at e d with both t h e e l a s t i c s o l i d and t he Newt on i an f l u i d .. The se foods are. r e f e r red t o as v i s coe l a s t i c foods . Vi s c oe l a s t i c mat e r i a l s can e x h i b i t both s o l i d and v i s cous component s s imu lt a n e ou s l y du r i n g shear i f s u f f i c i ent t ime i s a l l owed and t he s t r e s s app l i e d i s l a rge enough t o p revent the s amp l e showi ng pure e l a s t i c i t y . The mate r i a l s tend to behave l i ke s o l i d s i n i t i a l l y and t hen exhi b i t f l ow . comp l e t e l y c o n s e rved. Thus the work o f de f o rmat i on i s not. ( a s in s o l i d s ). or di s s ipated. ( a s in. fluids ) .. 1A . 5 .. MECHAN I CAL MOD E L L I NG. H o o k e an s o l ids and Newt o n i an fl ow can be rep r e s e n t e d me chan i c a l l y . Hookean s o l i d e l emen t s are u s u a l l y rep r e s ented b y a s p r i ng da s hpot. ( F ig .. (Fig .. 1 . 2a). and Newt o n i an f l u i d e l ement s by a. 1 . 2b ) . P l a s t i c behav i o u r i s o ften rep r e s ent ed by. a f r i ct i on e l ement known a s the S t . Ve nant s l ide r. (Fig .. 1 . 2c). Vi s c o e l a st i c foods are u s u al ly repres ented by at l e a s t one s p r i ng. ( a s an e l a s t i c c omponent ). and one d a s hpot. ( a s the. v i s c o u s component ) . An a c cu r a t e model can be u s e d t o predi ct change s i n a mat e r i a l due to va r i ou s s t re s s - s t r a i n c ondit i o n s , eg . ,. harve s t i ng ,. handl i ng ,. etc .. The e l ement a r y mode l s o f spr ing s , bu i l d more comp l e x mode l s ,. da shpot s and s l i de r s can. the B i ngham mode l. ( sp r i n g ,. a n d da s hpot i n s e r i e s ,. F ig .. 1 . 3a ) ,. the Ma xwe l l mode l. and d a s hpot i n s e r i e s ,. Fig .. 1 . 3b ) ,. the K e l v i n mode l. and da s hpot i n p a r a l l e l ,. Fig .. 1 . 3c ). s l i de r ( sp r i ng. ( sp r i ng. and t h e Burge r mode l. ( Ma x we l l u n i t and K e l v i n u n i t i n s e r i e s ,. Fig .. 1 . 3d ) .. The B i ngham mode l i � c ommon l y u s e d t o repr e s ent p l a s t o v i s c o e l a s t i c behavi o u r . App l y ing s t re s s t o t he B i ngham mode l , F i gu r e 1 . 3 a ,. i n i t i a l l y c a u s e s t h e spring t o s t re t ch . On. r e a c h i n g fu l l exten s i o n t he St . Venant s l i de r ,. rep r e sent ing.

(26) 8. (a ). ( b). (c). Figure 1 . 2 : Standard rheological mcx:iels; a ) Hookean spring , b ) Newtonian. dashfx:>t and c ) , St. Venant. slider ..

(27) 9. (a). (c) (d). Figure 1 . 3 : Rheological m:xiels: a ) Bingharn plastic c ) Kelvin unit arrl d). I. Burgers mcxiel .. I. b ) Maxrhell unit. I.

(28) 10. y i e l d s t re s s ,. and the dashpot ,. repre s e n t ing v i s co s i t y ,. move. t ogether unt i l fu l l y ext ende d or s t r e s s i s remove d . The othe r t hr e e comp l e x mode l s ment i oned above c a n repre sent t he respon s e o f v i s coe l a s t i c mat e r i a l s with t im e . Vi s co e l a s t i c mode l s can cont a i n d i f fe rent comb in a t i o n s o f s p r i ng s and d a s hpot s to repre sen t t he comp l e x behav i o u r s s h o wn by d i f fe rent f o o ds . I n t he Maxwe l l mode l. (Fig .. 1. 3 b ). t he app l i e d s t r e s s i n i t i a l l y. s t ret che s t he s p r i ng . A s the s p r i n g r e a che s fu l l e xt e n s i on a l l t he s t r e s s goe s into caus i ng f l ow i n the d a s hpot . The K e lvin mode l. (Fig .. 1. 3 c ). r e a ct s t o s t r e s s w i t h b o t h the. s p r i ng and d a s hpot moving to gethe r at a c o n s t an t r at e . The Burge r s mode l i s made up o f a Maxwe l l and a K e l v i n body in series. (Fig .. 1 . 3 d ) . When a force is appl i e d spr i ng 1 de f o rms. i n s t ant l y . On re aching fu l l exten s i o n t he s p r i n g and t he d a s hpot o f the K e l v i n u n i t move t ogethe r unt i l t he y a r e ful l y e x t ended . A t the s ame t ime dashpot 1 f l o w s . The f o u r e l ement B u r g e r s body i s one o f the be s t kn own rhe o l og i c a l mode l s and h a s been u s e d t o predi ct the behav i o u r i n a numb e r o f m at e r i a l s. 1A . 6 . F UNDAME NTAL T E S T ING F undament a l rhe o l og i c a l t e s t s me a s u re we l l de f i n e d p r ope rt� e s i n he rent t o a mate r i a l . Re s u l t s d o n o t depend o n s amp l e g e omet r y ,. t e s t c ondi t i ons o r t he app a r at u s u s ed .. F undament a l rhe o l o g i c a l t e s t i n g u s u a l l y i nvo lve s o n l y s ma l l de f o rmat i on s whe r e . the di s t an c e between the s t r u ct u r a l u n i t s i n the mat e r i a l b e i n g t e s t ed d o e s n o t change s i g n i f i c a nt l y , ie .. s t ra i n i s ve r y s m a l l .. When s t r a i n i s l arge e nough t o give. r i s e t o f i n i t e de fo rmat i on s , cope .. e x i st i ng the o r y can n o l onge r.

(29) 11. Fundament al te chn i que s c an be d i v i de d i n t o two group s , c o nducted unde r condi t i ons of. those. ( qu as i ) s t at i c l o ad i n g and those. c o ndu ct ed under dyn am i c condi t i on s .. St at i c tests are r e al l y. qu as i st at i c as the o re t i c al l y no t e s t c an be t ru l y s t at i c . The m o s t u s e fu l t e s t s for eval u at i ng v i s c oe l as t i c f o o d s are c reep ,. s t r e s s re l ax at i on and dyn am i c t e s t ing . Creep t e st s l o ok. at s t r ai n as. a. funct i on of t ime unde r c o n s t ant s t re s s .. S t re s s. r e l ax at i on e x am i n e s s t re s s as a fun ct i on o f t ime unde r c o n s t ant s t r ai n . Creep and s t re s s re l ax at i on ope r at e i n the t ime domai n . D y n am i c t e s t ing ope r at e s i n the frequ e n c y dom ai n an d e x am i n e s dyn am i c modu l i as a funct i o n o f the frequency o f a s i nu s o i d al s t r ai n . F o r l i n e ar v i s c oe l as t i c mat e r i al s the modu l i and coe f f i c i e nt s o f v i s c o s i t y from the three t ypes o f t e s t s shou l d be i n t e r c onve rt ab l e mathemat i c al l y and i ndependent o f the m agn i t ude o f the imp o s ed force or s t r ai n . 1A . 6 . 1 .. S t at i c T e s t i n g. 1 A . 6 . 1 . 1 . C reep C reep ,. the i ncre as e o f de f o rmat i o n as a funct i on o f t ime ,. is. b r ought about b y c o n s t ant she ar o r dyn ami c f o r c e s p ar al l e l t o t he l on g i t u d i n al ax i s o f the spe c i me n . When t h e f o r c e i s app l i ed r apid de fo rmat i on o c c u r s ,. ( st re s s ). imp o s ing a s t r ai n on the. m at e r i al . The s t r ai n t hen i n c re as e s at a decre as i ng r at e with t ime . The st r e s s impo s ed mu st not be s o l arge as to c au s e l arge s amp l e de format i ons and a n o n - l i ne ar v i s c c�las t i c r e spon s e .. I f t h i s h appens the u s e o f rhe o l o g i c al :�o de l s t o. repre sent a m at e r i al i s n o longer v al i d . C reep h as been s t u di e d u s ing a v ar i e t y o f t e chn i qu e s . E x amp l e s i n c l ude compre s s i on u s ing a c on s t an t s t re s s , t h e u s e o f c o n s t ant s h e ar and c o - ax i al c y l i n d e r v i s c omet ry ..

(30) 12. C reep r e c ove r y i s an a l t e rnat ive c r e e p t e s t whe re the const ant s t re s s i s r e l e a s e d a l l ow i ng t he s t r a i n to d e c re a s e ,. depending. o n s amp l e propert i e s . 1 A . 6 . 1 . 1 . 1 . The C reep Comp l i an c e Cu rve A p l ot o f s t r a i n as a funct i on o f t ime i s k n own a s a c reep cu rve . F i gure 1 . 4 i l l u s t r a t e s a t yp i ca l c r e ep and r e c overy cu rve for a p l a s t i c fat . C reep cu rve s may b e u s e d to s t udy a mat e r i a l ' s phy s i ca l propert i e s . F i gu re 1 . 5 s hows a t y p i c a l c r e e p comp l i an ce / t ime cu rve ,. whe r e c reep comp l i an c e i s t he. rat i o o f t he s t r a i n to the c o n s t ant shear s t re s s at any t ime (t ) .. The c re ep and recove r y cu rve can be div i ded i n t o f ive. p r i n c i p l e reg i o n s . (1) ,. a r e g i on o f i n s t ant aneous c omp l i ance ,. e l a s t i c de f o rmat i on ,. J0 ,. occu r s .. ( A- B ) ,. i n wh i ch. I t i s be l i eved bonds between. s t ru ct u r a l e l emen t s a re b e i ng s t ret ched e l a s t i c a l l y .. I f s t re s s. i s removed t h e s amp l e shou l d c omp l e t e l y recover i t s o r i g i n a l s t ru c t u re . ( 1 . 4) whe re E o i s the i n s t antaneous e l a s t i c modu lu s . (2) ,. a t i me dependent ret a rded e l a s t i c reg i o n ,. comp l i an ce ,. Jr ,. whe re it i s s ugge s t ed ' bonds '. (B-C) ,. with a. may be b r e a k i ng. and r e f o rming at d i f fe rent rat e s . T h i s regi o n may be r ep r e s e n t e d by the equat i on ( 1 . 5) (3). A l in e a r r e g i o n ,. (C-D ) ,. o f N e wt on i an comp l i an c e ,. JN ,. whe re. f l ow i s o c c u r r ing . ( 1 . 6).

(31) 13. strain. tirre. Figure 1 . 4 : Typical creep and recovery curve for a plastic fat ..

(32) 14. canpliance J( t). D. J 0. I. F. �------t-'--. 1 I. I. I. J N. I I I. I I I I I I I I I I I. I I. ----- - -----------. J N. J. ----------- --'------ J _R. J A. 0. tirre ( t). Figure 1 . 5 : Mcxiel creep curve ..

(33) 15. (4). O n the removal o f s t r e s s r e g i o n. (D-E ). repre s en t s. i n s t an t an e o u s r e cove ry o f e l ast i c s t r ai n e qu al t o t h e i n i t i al i n s t an t an e o u s s t r ain . (5). A r eg i on o f t ime dependent de c ay o f s t r ai n ,. t o t h e r e t arded e l ast i c r e g i on .. (F-G) ,. equ al. S t r ain doe s not de c ay t o z e r o. as p e rmanent de format i on h as o c c u rred in t he C -D r eg i on . The who l e c reep compl i an c e - t ime p l ot i s de f i ned i n det ai l by the sum o f the p art s . (1 .7) 1A . 6 . 1 . 1 . 2 . The Mode l The B u rge rs mode l can be u s ed t o. represent the c r e ep. beh av i o u r o f a v i s c oe l as t i c mat e r i al . Thi s c an w r i t t en mat he m at i c al l y as (1 . 8) ( Mo h s en i n ,. 1 98 6 ) .. I f a comp l i ance funct i o n J ( t ). i s de f i ned as. the r at i o o f s t r ain t o s t re s s the above e qu at i on c an be expre s s ed in t e rms of c omp l i ance . (1 . 9) Expe r imen t al re s u l t s f o r s ome v i s c oe l as t i c m at e r i al s h ave shown mo r e t h an one ret ar d at i on me chan i sm . F o r t h e s e mat e r i al s ,. the comp l e t e behav i o u r c annot b e rep r e s en t e d by a. s i n g l e Maxwe l l o r Ke lvin mode l ,. o r by the B u rge r s mode l . To. p r e s ent t he v i s coe l as t i c beh av i o u r more r e al i st i c al l y a ch ain of Ke l v i n mode l s , as sume d .. e ach wi t h its own ret ar d at i on t ime i s. The gene r ali z ed K e l v i n mode l ,. as i t i s known ,. c o n s i s t s o f n Ke lvin e l ement s c o nn e ct e d i n s e r i e s w i t h an i n i t i al s p r ing and a f i n al v i s co u s e l ement de s c r ibed by t h e gen e r al i z e d equ at i on. ( F ig .. 1 . 6).

(34) 16. .. . .. Figure 1 . 6 : � generalized Kelvin model ..

(35) 17. ( 1. 7 ) T h i s equ at i on i s the s ame as t hat de s c r ib i ng the creep comp l i ance - t ime curve . 1A . 6 . 1 . 1 . 3 . Re t a rdat i on Spect r a A n a l t e rn a t i ve app r o a ch t o creep cu rve s i s the u s e o f r e t a rdat i on spect r a . One o f the fu n dament a l rhe o l o g i c a l p a r amet e r s o f a s i mp l e v i s c o e l a s t i c s o l i d i s the re �a rdat i on t ime . Ret a rdat i on t ime c an be de f i ned a s t he rat i o o f vi s c o s i t y t o e l a s t i c i t y in the s amp l e .. In a comp l e x vi s c oe l a s t i c s o l i d more than one. r e t a rdat i on t ime wou l d be pres ent . E xper iment a l c reep c omp l i ance data can be an a l y s e d t o give e i the r a cont i n u o u s spect r um o f ret a rdat i on t ime s o r a l i ne s pect rum . Warbu r t o n and B a rry. ( 1 968 ). s t at e that the re s o l ut i o n. o f individual ret a r dat ion t i me s become s i mpo s s ib l e i f the number i s great e r t h an t e n and the sma l l e s t spa c i ng between any two r e t a rdat i on t ime s is l e s s than five t ime s the v a l ue o f t he sma l l e r ret a rdat i on t ime . The numbe r o f ret a r dat i on t ime s p r e s ent depends o n a ) , s i z e o f t he mo l e cu l e s or part i c l e s i nvo l ve d , b ) , and c ) ,. the. t he i r s hape. the numb e r o f mo l e c u l e s pre s en t . H igh mo l e cu l a r we ight. m o l e cu l e s ,. made up o f component s o f w i de l y d i f f e r i ng mo l e cu l a r. we i ght s w i l l g ive r i s e t o a comp l i ca t e d spect rum o f ret a r da t i on t ime s comp l e x s y st ems ,. ( Wa rbu r t on a n d B a r r y , s u ch a s foods t u f f s ,. 1 9 6 8 ) . F o r most. a cont i n u o u s spect rum o f. r e t a rdat i o n t ime s e xi st s . The a na l y s i s o f c r e ep curve s u s ing E qu at i on. (1 .7). a s s ume s a. f i n i t e number o f r e t a rdat i o n t ime s . On int r o du c ing t he p a rame t e r s obt a in e d back int o E quat i on (1 .7). a theore t i c a l c reep cu rve can be gene rat e d .. I f E qu a t i on.

(36) 18. (1.7). r ep r e s e nt s the c reep behavi our adequa t e l y ,. the. t he o ret i c a l curve shou l d approx imat e the expe r i ment a l c reep c u rve . The de r ived c omp l i ance p a r amet e r s and retarda t i o n t ime s can be u s e d t o c a l cu l at e a l in e s pe ct rum o f ret ardat i on t ime s . Th i s c a n b e u s e d a s a check t o s e e i f the numbe r o f e xponent i a l t e rm s o r ret a rdat i on t i mes u s ed t o mode l a c r e ep cu rve i s approp r i at e .. I f the mode l i s app r opr i ate ,. the l i ne spect rum. s h ou l d app r o x i ma t e t he cont i nuous spect rum ,. wh i ch i s found a s. de s c r ib e d be l o w . I n the c a l cu l at i o n o f the cont i n u o u s spect rum o f reta rdat i on t ime s ,. E qu at i on. J {t ). = d/d l nt. whe re L ( 't) ( 19 6 8 ). (1.7). j. i s first. wr i t ten in i n t egra l form. L ( 't) [ 1- exp ( -':./ 't) ]. dlnt. +. t / Tl N. ( 1. 1 0 ). i s t he re t a rdat i on spe ct rum . Shama and S he rman. u s e S chwa r z a l ' s f i r s t orde r approx imat i on o f L ( 't). to. c a l cu l at e r e t a rdat i o n spect ra for margarine . L ( 't ). ( 1 . 11). S h ama and She rman. ( 1 97 0 ). u s e S chwa r z a l ' s s e cond o rde r. appr o x i mat i on t o c a l cu l at e the r e t ardat ion spe c t r a o f but t e r a n d marga r ine . T h e s e c ond o rde r app r o x i mat i o n h a s t he a dv a n t age that the v i s co u s f l ow t e rm , 11 , doe s n o t " have t o be s ub t r a c t e d f r om J {t ). be f o r e making the c a l cu l at i o n and. t he re f o r e doe s not have to be known a c curate l y . L ( 't). = dJ ( t ) / d lnt - d 2 J ( t ) / d ( l nt ) 2. t = 2 't. or L ( 't ). =. ( d / d l nt ) [J ( t ). -dJ ( t ) / d l nt ]. t = 2 't. ( 1 . 12 ).

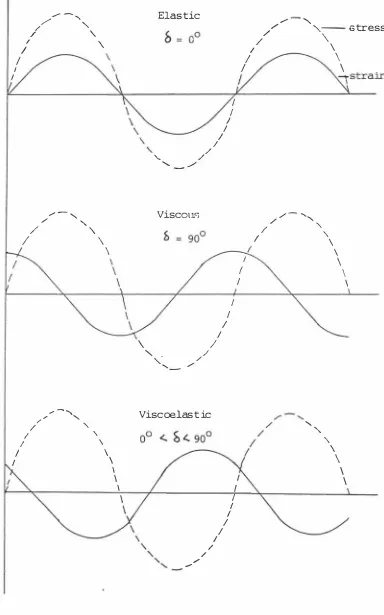

(37) 19. 1A . 6 . 1 . 2 .. St r e s s Re l ax a t i on. St r e s s r e l a x at i on t e st i n g i s frequ en t l y u s e d to det e rm ine mode l component s o f a m a t e r i a l .. St r e s s re l a x a t i o n is b e s t. de s c r ibed a s the ab i l i t y o f a mat e r i a l t o a l leviate a n imposed s t r e s s under condi t i on s o f a const ant s t r a i n .. St re s s. r e l a x a t i o n i s u s ua l l y mode l led u s i n g a gene r a l i z ed Ma xwe l l mode l comp r i s e d o f a. ( f i n i te ). numb e r o f Maxwe l l un i t s i n. p ar a l l e l w i t h e ach othe r . St r e s s re l axat i o n t e st i n g can be c a r r i ed out in a numb e r o f d i f fe rent ways , p r odu ct s ,. f o r e xamp l e ,. c omp re s s i on o f agr i cu l t u r a l. s t re t ch i n g mat e r i a l s such a s whe a t dough and mu s c l e. f i b r e and cone- and-p l at e and co- a x i a l c y l inder vi s come t r y fo r s em i - s o l ids and l i qu i ds .. 1 A . 6 . 2 . D y n ami c T e s t i ng D y n a m i c t e s t ing o f f e r s a very rap i d t e chn i qu e caus ing m i n i m a l change s i n chemi c a l and phy s i c a l propert i e s . Dynam i c t e s t ing methods vary s t r e s s or s t rai n with t ime ,. usually in a. s i n u s o i da l manne r . Ba s i c i n s t rument at i on f o r dyn am i c s t re s s - s t r a in t e s t ing requ i r e s a s in u s o i d a l f o rce provided by a n e l ect rodynamic v i b r a t o r . The spec imen i s he l d between t he vibr a t o r and a dynam i c force t r an s duce r . C o - a x i a l c y l i nde r and cone and p l at e c o n f i gurat i o n s such a s t he F e r r ant i - Sh i r l e y and We i s s e nberg Rhe o g o n i omet e r s have b e e n used f o r semi - s o l i d mat e r i a l s . The e xt reme l y sma l l s t r a i ns imp o s e d. ( l e s s t han 1 % ). a lmost. a s s u r e l i ne a r s t re s s / st ra i n behavi o u r . Whe n a H o o k e an s o l i d i s sub j e c t e d t o a s i nu s o ida l l y vary i ng s t r e s s the s t r a i n a l s o v a r i e s pe r i od i c a l l y i n pha s e w i t h the s t re s s . Sub j e ct i ng a Newt o n i an f l u i d to a p e r i odi c a l l y v a r y i n g s t r e s s r e su l t s i n a s t r a in 90° out o f phas e . A v i s c o e l as t i c mat e r i a l , behaving i n a l in e a r f a s h i o n ,. wh i ch i s sub j e ct e d t o.

(38) 20. a s in u s o i da l l y va rying s t r e s s e x h ib i t s a s t r a i n r e spon s e l e s s t h a n 90° o u t o f pha s e. (Fig .. 1 . 7) .. I f the s t re s s i s such that. cr. = cr 0 s i n rot t he s t r a i n wi l l v a r y w i t h the s ame frequency but l ag by an ang l e e, the phas e ang l e , i e , y = y0 s i n ( rot - 8) . T h i s b e h av i our re s u l t s i n a comp l e x frequency dependent m o du l u s ,. E* ,. wh i ch can be s e p a r a t ed int o a re a l ,. in-phase. c omponent a s s o c i ated with the st o rage of energy and an i m a g i n a ry ,. out - o f-pha s e c omponent a s s oc i at e d w i t h the l o s s o f. e n e r g y such t hat E* = E' + iE'. (1 . 13). I. The r a t i o o f s t r e s s t o the amp l i t ude of s t r a i n g i ve s t he va lue o f t he comp l e x modu l u s . (1 . 14 ) T he r e f o r e t he st orage modu l u s c a n be wr i t t e n a s E' = E* cos 8. (1 . 15). a n d t he l o s s modu lus a s E' ' S ub s t i t u t i ng Equat i on s. = E* sin 8 ( 1 . 15). and. (1 . 16) ( 1 . 16). int o t he e q at i on fo r. s t r a in cr� = y0[E ' i s obt a i ne d . E quat i o n i n t o t w o c omponent s ,. s i n rot + E ' ' ( 1 . 17 ). c o s rot ]. ( 1 . 17 ). s hows t he de c ompo s it i on o f stre s s. o n e i n pha s e and one 90° o ut o f phase .. At v e r y h i gh f r e quen c i e s the s t o r age modu l u s E '. h a s a constant. m a x i mum v a l u e and mat e r i a l s e x h i b i t an e l a s t i c ,. s o l i d- l i ke. b e h a vi ou r . At l ow frequ e nc i e s mat e r i a l s e xh i b i t a v i s c o u s t ype o f b e h a v i o u r as the s t o r age modu l u s decrea s e s ..

(39) 21. /. /. I. I I. I. /. ...-' - "'. ". Elastic ". I. I. \_. /. "". I I. I. '-. / I. //- ....... ........ '-_/. /. /. I. ". \. _.r _. \. I I. \. " · ". ,_. I I. //. /. ,..�,. ........ "\.. /. /. /. I. I. I I. I. I. /. /. /-,. \. '. \ \ \ \ \. -. /. /. /. I. "". "\.. \. \ \. \ \. I. Viscoelastic '. ".-- 6tress \ \ \ \ . stram ". I I I I I. Viscous. I I. I I. /. /. /. I I I I I I I. Figure 1 . 7 : Stress response to sinusoidal strain.. "". '-... ". \. \. \ \.

(40) 22. The t angent o f t he pha s e ang l e. ( t he l o s s t angent ). i s s omet ime s. c a l l e d t he coe f f i c ient o f i n t e r n a l f r i ct i o n . I n a ddi t i on t o the comp l ex s he a r modu l u s , m at e r i a l s a l s o h ave a comp l e x v i s co s i t y �* whe r e � '. =. �'. viscoelastic �*· (1 . 18). - �' '. i s the rat i o o f s t r e s s in pha se w i t h the rate o f. s t r a i n t o s t ra in and � ' '. i s t he rat i o o f s t re s s out o f pha s e. w i t h the r a t e o f s t r a i n t o s t ra i n. ( Sherman ,. 1 9 8 6 ) . The rate o f. s t r a i n i n s i nu s o i d a l de f ormat i o n s i s d y/ dt. =. i w exp. ( i wt ). (1 . 19). t h e r e f o re � * = E * / i w and t he two c omponent s o f the comp l e x v i s co s i t y a re s im i l a r l y re l ated t o t h e component s o f the c o mp l e x she a r modu l u s : � ' =E ' / W. (1 . 20). and � ' ' =E ' ' / W At l ow freque n c i e s. �'. (1 .21). s hou l d approach. va l u e s � 0 . A t h i gh frequenc i e s G ' v a l u e s f r om creep .. s t e ady s t ate vi s co s i t y. va l u e s s h o u l d app roach G 0. 1 A . 7 . E MPI R I CAL T E S T I NG Emp i r i ca l o r s em i - q ua l i t at ive t e s t s me a s u re p a r amet e r s t hat a r e n o t c l e a r l y de f i n e d . Emp i r i ca l t e s t s a l l t end to have spe c i f i c app l i cat i on s i n that t h e y a r e u s ua l l y i n i t i a l l y deve l op e d f o r one p r o du c t ..

(41) 23. The ma j o r i t y o f e mp i r i c a l t e s t s i nvo l ve l a rge de f o rmat i on s . Wh i l e s u ch t e s t s do not give a n y fundament a l dat a ,. t h e y may be. more app rop r i at e i n that they mimi c more c l o s e l y a c t u a l condi t i o n s o f u s age ,. and o ft e n c o r r e l ate we l l w i t h s e n s o r y. eva l u at i on s . T e s t condi t i ons and app a ratu s a l s o det e rm i n e the magn i t u de o f the parame t e r e s t imat e d . Often me ch a n i c a l t e s t s a re devi s ed t o repl ace human s e n s o r y eva luat i on a s a t o o l t o app ra i s e food t e xture . Emp i r i c a l t e s t s do n o t p r o v i de fundame n t a l dat a .. PART B : MEASUREMENT OF THE RHEOLOGICAL PARAMETERS OF BUT TER AND MARGARINE. lB . l .. I NT RODUC T I ON. As men t i oned above , the eva l uat i on o f the rhe o l o g i c a l prope rt i e s o f f o o ds may be divide d i n t o two b r o a d c a t e go r i e s , fundame nt a l t e st i ng and emp i r i c a l t e s t ing . Fundame nt a l t e s t ing me a s u r e s we l l de f ined propert i e s wh i ch ,. i t is hope d ,. the s t r u c t u re o f the samp le be i ng i nve s t i gated .. re l at e to. Emp i r i c a l. t e s t i n g i s u s e d t o study text u r a l pr opert i e s wh i ch a r e n ot c l e a r l y de f i ne d . Many such t e chn i qu e s have been deve l op e d to s t udy butt e r and other fat s y s t ems . T e chn i que s to st udy both fundamen t a l and t extural prope r t i e s o f fat s w i l l be out l ined be l ow .. 1B . 2 .. F UNDAMENTAL TECHN I QUE S. A l t hough a numb e r o f techniques e x i s t for eva l u at ing fundament a l rhe o l og i c a l p a r ame t e r s v e r y l it t l e w o r k has been done on fat p r o d u ct s . O f the t h ree general methods o f i nve s t i gat ing fundament a l p a r amete r s , and d y n a m i c t e s t i ng ,. s t re s s r e l axat i on. creep and dynam i c t e s t ing have p r oved the. mo re popu l a r . 1B . 2 . 1. creep ,. Creep C omp l i ance.

(42) 24. S hama and S he rman. ( 1 968). u s e d a n aut omat ed par a l l e l p l at e. v i s c o - e l a s t omet e r t o e x amine t h e c r e e p c omp l i an c e behav i o u r o f m a rg a r ine .. S h ama a n d She rman ana l y s e d the c reep comp l i ance. c u rv e s g r aphi c a l l y u s i n g the met hod o ut l i ned by S h e rman ( Chapt e r 4 ,. ( 1 966). S e c t i o n 6 . 1 . 1 ) . On t he b a s i s o f the i r re s u l t s they. m o de l led t he rhe o l o g i c a l behavi our of marga r in e u s i n g a g e n e ra l i z e d K e l v i n comp r i s ing o f a Maxwe l l u n i t i n s e r i e s with f o u r Ke l v i n u n i t s . S h ama and S h e rman fo l l owed the harde n i ng o f marg a r i n e w i t h age ,. ob s e rv i n g change s i n t he rhe o l og i c a l p a rame t e r s . A s. m a r g a r i n e aged,. v i s c o s i L y t e rm i n c re a s e d ,. i ndi c a t i ng t he. m a r g a r i ne wa s growing more vi s c ou s . At the s ame t i me ,. the. c o nt r ibut i on of both t he i n s t ant an e o u s and r e t a rded e l a s t i c c o mponent s de c r e a s e d . O n c a l cu l at i n g t he ret a �dat i o n s p e c t r a ,. L ( � ) , whe re L ( � ). i s an. app r o x imat i o n o f the i nve rse Lap l ace t r a n s form o f the creep funct i o n. ( S e ct i on A . 6 . 1 . 1 . 3 ) ,. f o r m a rgar i n e s of va r i o u s a g e s. t h e y c l a imed e v i de n c e f o r the n umber o f ret ardat i on mechan i s ms s e en . Later ,. Shama and S h e rman. ( 1 970 ). u s e d t he s ame equ ipmen t t o. f o l l ow change s i n v i s c o e l a s t i c behav i our w i t h t i me a ft e r w o r k s o f t e n ing marga r i ne and but t e r . p ap e r. (1968). I n c o n t r a s t with t he p revi ous. whe r e t he c reep comp l i an c e r e s p o n s e was obse rved. f o r f ive hou r s ,. the creep comp l i ance re spon s e o f marga r i ne. a ft e r wo r k s o ft en i ng wa s ob s e rved f o r 1 0 m i nut e s o n l y , t h e r ap i d r a t e marga r i ne recovered i t s st ructure. due t o. ( s et up ). a ft e r wo r k s o ft e n i ng . The behav i o u r o f the marga r i ne was mode l e d u s ing a genera l i z ed K e l v i n un i t comp r i s i ng a Maxwe l l un i t i n s e r i e s w i t h two K e l v i n u n i t s compared w i th four K e l v i n un i t s u s e d f o r the l o nger t ime e xpe r iment s de s c r ibed i n t he 1 9 6 8 pape r . Al s o ,. due. t o t he s h o r t e n e d o b s e rvat ion t ime t he v i s c o u s t e rm obt a i n e d i s.

(43) 25. n o t t he t rue Newt o n i an v i s co s i t y , but more appropr i a t e l y c a l l e d the appa rent v i s c o s i t y . C a l cu l ated rhe o l o g i c a l p a rame t e r s f o r marga r i ne are l i s t e d i n b o t h papers , s ame o rde r. a n d , whi l e n o t direct l y comp a r ab l e ,. ( T ab l e 1 . 1 ) .. are o f t he. The v i s c o s i t y t e rm repo rted i n t h e. 1 9 6 8 pape r i s t e n t ime s l arge r t han t he v i s c o s i t y t e rm rep o rt ed in 1 9 7 0 . Thi s i s probab l y due t o t h e di f f e r i n g du rat i on s o f t h e two exp e rime nt s . Apparent v i s c o s i t y i n c r e a s e as the lengt h o f t he e xp e r iment incre a s e s a n d the vi s co s i t y t e rm approache s i t s t ru e value . The apparent vi s c o s i t y t e rm a l t e =ed ve r y l i t t l e w i t h rewo r k i ng and r e cove red sub s t ant i a l l y a ft e r rewo r k i n g .. Shama and She rman. fe l t t he apparent v i s co s i t y best cha ract e r i s ed t he c on s i s t en c y o f margarine a ft e r work i n g . The r e s u l t s o f ob s e rv i n g the vi s c oe la s t i c behavi our o f but t e r ove r e i ght hour p e r i ods. �r�. a l s o report e d i n t he 1 9 7 0 pape r .. The s ame number o f parameters were u s e d t o charact e r i s e butter behav i our a s were u s e d f o r marga r i ne a ft e r a t e n minute expe r iment . As a re s u l t t he v i s cous f l o w t e rm wi l l be c l o s e r t o t he t rue Newt on i an f l ow t e rm but the p a r amet e r s f o r b u t t e r be f o r e and a ft e r w o r k i n g wi l l not be comp a r able t o the marga r ine re s u l t s . On w o r k i ng the · e l a s t i c modu l i de c r e a s e d l e s s than the vi s cous t e rm and ,. on aging , but t e r con s i s t e n c y w a s f e l t to be. c h a r a ct e r i s e d to a great e r extent by t he e l a s t i c t e rm s . The que s t i on a r i s e s ,. i s i t va l i d t o comp a r e the behav i ou r o f. but t e r and marga r i n e , b o t h be f o r e and a ft e r rewo rk i ng o n t he b a s i s o f the s e experime nt s . The w i de l y di f fe r ing t ime l e ngths of t he expe r iment s make t hem ve r y di f fe r en t .. Sho rt t ime c reep. expe r iments l e a d to a l a rger apparent v i s c o u s t e rm and a c o r r e spondin g l y decre a s e d ret a rded e l a s t i c c ont r ibut i o n , l onge r durat i on exp e r i me n t s give t he e x a ct oppo s i t e ,. whi l e. a s ma l l e r.

(44) Table. 1 . 1 :. Re f e re n ce. C reep. resul t s. I n s t rume n t. repo rted. S a mp l e. by. Mod e l. and. Parallel. S h e rma n ,. plate. S h ama. Parallel. 1 9 68 .. and. S h e rma n , 1 97 0 .. wo rke r s .. LE. Eo Pa. (a) S h ama. va r i ou s. ll N. Pa . s. Pa. 5. 7. 4. e xp. 9 . 2xl0. Ma r g a r i n e. 2. e xp. 3 . 8x106. 1 . 6x 1 0. Bu t t e r. 2. e xp. 4 . 5x l 0 6. 6 6 . 5x l 0. Lard. 3. e xp. 5 . 9x10. Ma rg a r i n e (35. l . Ox l 0. plate. 4. 2 . 7x 1 0. 7. 15. 4hr .. 1 . 9x10. 9 . 3x10. 9. 10. 1 0 mi n. 10. 10. 8h r .. 8 . 7xl0 6. 25. 1 5m i n. 5. 3 . 4x106. 25. 1 0 - 2 0m. 20. 2 - 3 0 0m. 20. 2 - 3 0 0m. 10. 1 0min. 10. 1 0min. ". ". Shorten ing. 3. e xp. 2 . 1x10. ". S ph e r i c a l. La r d. 3. exp. 3 . 5x 1 0. ". ". S h o r t e n i ng. 3. exp. l . Oxl0. G u p t a a nd. C omp re s s i o n Ma rg a r i n e. 1. e xp. 3 . 7xl0 6. 4 . 0x 1 0 6. But t e r. 1. exp. 5 . 2x106. 4 . 3x10. c y l i nde r. i nd e n t o r. DeMa n , 198 5 .. (a). c. 5. Concen t r ic. ". 0. T i me. days ). Davis , 1 97 3 .. 1 . 5xlo1. T o. ". T h e numbe r o f e x p o n e n t i a l s ,. r e f e r r i ng. to. 4 4. 4. 1 . 4x10. 8. -. 1 . 2x10. -. l . 6x 1 0 8. t h e n u mb e r o f. 4. 7 . 4xl0 1 . 2x10. 8 8. r e t a rd a t i o n me c h a n i sms. f i t ted .. N 0\.

(45) 27. v i s cous t e rm w i t h ret a rded e l as i i c c omponent s p l ay in g a n i n c re a s ed part . The i n s t antaneous e l a s t i c re spon s e i s un a f fe c t e d by exper iment lengt h . T h i s t re n d can be s e e n i n Shama and Sherman ' s r e s u lt s . Ret ardat i on spe c t r a were c a l c u l a t e d ,. u s i n g a s e c ond o rder. approx imat i o n o f t he Lapl ace t ra n s f o rm wh i ch avo i ds the n e ce s s i t y o f knowing � N pre c i s e l y. ( S e ct i on 1A . 6 . 1 . 1 . 3 ) . The. r e t a rdat i on cu rve s pre sented do n o t g i ve any i n d i c at i on of the number o f retardat i on mechan i sms i nvo l ve d a s t h e y d i d previou s l y i n the 1 9 6 8. pco.p e..��" .. On the b a s i s of the i r creep c omp l i an c e r e s u l t s S hama and S he rman conc lude but t e r cont a i n s a s ma l l e r prop o rt i o n o f i r reve r s ib l y b r e a k ab l e bonds a s i t r e c ove r s mu c h o f i t s o r i g i n a l i n s t ant ane o u s e l a s t i c component a fter r ewo rk i ng . contrast ,. In. margar ine l o s e s mo s t o f i t s i n s t antan e o u s e l a st i c. re spon s e o n rewo rk ing and doe s not recove r it , far l a rge r p ropo rt i o n o f st rong ,. i nd i cat ing a. i r reve r s ib l e bonds .. Thi s. c on c l u s i on i s una f fe cted by the l ength o f the e x p e r iment a s t he i n s t ant aneous e l a s t i c r e s p o n s e i s n o t t ime dependent . D av i s. ( 1 97 3 ). report s the v i s c oe l a s t i c p r opert i e s o f. pharmaceut i ca l p repa rat i o n s have b e e n w i de l y s t u d i e d u s ing c reep t e chn i que s . He goe s on to c omment on the fact few s emi s o l i d foods t u f f s have been s ub j e ct e d t o det a i l e d fundament a l t e s t ing .. I n a n att empt t o a s s e s s ava i l ab l e met h o d s D av i s. c a r r i e d out concent r i c c y l inde r and sphe r i ca l i n d i cat o r creep t e s t s o n l a rd and s h o rt e n i n g . C on cent r i c c y l i nder t e s t s we re pe r fo rmed u s i ng a mod i f i e d We i s s enbe r g Rheo g o n i ome t e r de s c r ibed b y Warburt o n and B a r r y ( 1 968) .. A s t re s s � a s sudde n l y app l i e d t o t he s amp l e and. m a i n t a ined for a pe r i od of up to t h i r t y mi nut e s .. The t ime. dependent s t r a i n re sponse w a s me a s u re d . P r i o r t o t e s t ing a check f o r l i n e a r v i s c oe l a s t i c behav i o u r w a s made ..

(46) 28. D avi s o b s e rved the creep r e s p o n s e for both l a rd and s h o r t ening at 2 5 ° c .. ( T ab l e s 1 . 1 and 1 . 2 ). The curve s obt a i n e d we r e. i nt e rp re t e d i n the s ame way a s S hama and S he rman , 1 97 0 ,. i e � as c l a s s i c vi s co - e l a s t i c curve s ,. i n s t ant a n e o u s e l a s t i c re spon s e ,. 1 9 6 8 and. having an. a n umbe r o f ret a rded r e spon s e s. and eventu a l l y a region o f v i s c o u s f l ow . T h e curve s we r e a na l y s ed b y t he procedu re de s c r ibed b y Warbu r t o n and B a rry ( 1 96 8 ) .. Thi s p r o cedure is ba s i c a l l y the s ame as t he met hod. u s ed by She rman 4,. (1966). S e c t i on 6 . 1 . 1 .. and i s de s c r ibed mo r e fu l l y i n Chapt e r. Three r e t a rded e l a s t i c me chan i sms we r e. t hough t t o be pres ent . D avi s a l s o exper imented w i t h creep by sphe r i c a l i n d i c a t o r , where a sphe re part i a l l y pene t r at e s a s emi - i n f i n i t e s e a o f mat e r i a l. ( B a r ry and Warburt o n ,. 1 9 6 8 ) . Data i n t h e form o f. penet r at i on dept hs were cu rve f i t t e d and an a l y s e d t o g i ve a c ont i n u o u s c reep funct i on .. ( T ab l e 1 . 2 ). •. I. .. The t ime s c a l e o f the i ndent at i on experiment s w a s t e n t i mes a s great a s t h a t emp l o yed for c o ncent r i c cyl i n d e r t e s t i ng .. The. i n d ent a t i on t e s t s were a l s o done at a lower t empe r a t u re ( 2 0 ° C ) . The s ame s amp l e s o f l ard and s hort en i ng previou s l y u s e d we re emp l oyed i n t h i s t e s t . Vi s co s i t y v a l u e s obt a i ned by i n dent a t i on were mu ch l a rge r a s a c o n s equen c e o f b o t h t he change i n t empe rature and l ength o f expe r ime n t ,. whe r e a s. i n s t a n t a n e o u s response v a l u e s f o r t he t w o met hods were o f the s ame m a gn i tude. ( s ee T ab l e s 1 . 1 and 1 . 2 ) . The cu rve s l o o k e d. qu ite d i f fe rent , po s s ib l y a s a r e s u l t o f di f f e r e n c e s i n t empe r at u re and s amp l e d i s t u rbance p r i o r t o t e st i ng . A d i s advan t age o f c oncent r i c c y l i nde r t e st i ng i s t he n e e d t o d i s tu rb s amp l e s dur i ng l o ading , sphe r i ca l i nd i c a t o r ,. i n c o n t r a s t w i t h c r e ep b y. whe re s amp l e d i s tu rbance i s m i n i ma l .. B o t h c on c e n t r i c c y l i nde r and sphe r i c a l indi c a t o r t e s t s s h o u l d g i ve app r o x i ma t e l y the s ame re s u l t s . The di f fe re n ce between t h e two s et s of re s u l t s empha s i z e s t he need t o p e r f o rm t e s t s a t t he s ame t empe r a t u re ,. f o r t h e s ame l ength o f t ime a n d t he. - I.

(47) 29. T ab l e t 2 : Re s u l t s report ed b y Davi s. ( 1 97 3 ). u s i n g a va r i e t y o f. rhe o l og i ca l methods .. S amp l e. Me thod L a rd. S h o rten i ng. S t at i c y i e l d value ( P a . ). 1 . 4x103. 7 . 0x10 3. F e rrant i - Shi r l e y c o n e and plate Shear r a t e 1 5 6 0 / s 2 5 °c. Dynamic y i e l d value ( P a . ). 1 . 7x102. 1 . 4x102. P l ast i c v i s co s it y. 0 . 31. 0 . 27. C o n cent r i c c y l i nde r creep . We i s s enbe rg Rhe ogoni omet e r . 2 5 °C .. Go. ( pa . ). 5 . 9x1 0 4. 2 . 1x104. ll o. (Pa . s ). 8 . 7 x1 06. 4 . 3x107. Go. (Pal. 3 . 5x1 0 4. 1 . 0x104. ll. (Pa . s) mi n. 1 . 2x108. 1 . 6x 1 0 8. ll. ( pa . s ) mi n. 3 . 0x107. 5 . 1x107. 6 . 0x1 0 4. 1 . 6x 1 0 4. 3 . 2x 1 04. 1 . 9x 1 0 4. C reep by s phe r i c a l i nd i c at o r . 2 0°c .. (Pa . s ). 2g0-300. 2 g-30. D yn ami c v i s co e l a s t i c t e st i ng . P a r a l l e l p l ate c o n f i gu r a t ion , We i s s enbe rg Rhe ogon i omet e r . 2 5°C .. G ' ( P a·) 1 0 Hz (Pa . s ) 2 . 5 X E- 3 Hz. Tl '.

Figure

Related documents

Interventions less clearly linked to patient harm or poor health outcomes and with combina- tions of messages, such as those to reduce use of multiple inhaler devices, and improve

The mammalian reporter vector pUG-CAT containing natural promoter also showed transcriptional consistency in its expression profile but transcribed higher expression of CAT

In this study, the reasons for teeth cleaning were to make the teeth clean, prevent mouth odour, make teeth stronger, prevent pain and dental diseases.. This indicates that

The aim of this study is to explore and compare the subjective perception of fairness and standard of care in the German health care system among students of medicine, law,

Here we describe production of ESCs from blastocysts obtained from a standard mouse strain in the absence of feeder cells or sera, with an emphasis on a laser-based ICM

A larger panel of allogeneic HLA-matched and - unmatched melanoma, glioma, breast and colorectal car- cinoma cells were used as targets in cytotoxicity assays. Four of the

The study compares the number of sickness absence days during the last 12 months and the impact of employment status, psychosocial work stress, self-rated health and demographics

Background: CEA, CYFRA21-1 and NSE are tumor markers used for monitoring the response to chemotherapy in advanced adenocarcinoma, squamous cell carcinoma and small-cell lung