Performance Evaluation Of Coordinate Measuring Machines

Full text

Figure

Related documents

Recently, studies had been made on analyzing and comparing the 3D scanner and the CMM machine on Comparison of Different Method of Measurement Geometry using CMM,

4.2 Measurement errors for each experiment run 50 4.3 Measurement errors at different stylus length 51 4.4 Measurement errors at different ball diameter 52 4.5

According to the frame key size table obtained by the finite element analysis of the previous chapter, the dimension of the frame need to be determined includes: the size of

During measurements, the spherical probe tip touches the object ’s surface to be measured, and an image from the infrared light sources on the hand tool is captured with the camera

• Calibrated sphere is measured three times at the same location, in approximately the middle of the reach of the arm. • During this test, the articulation of the AACMM should

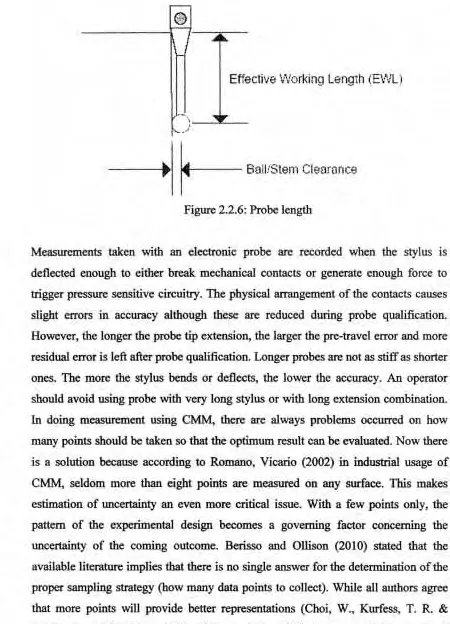

Measurements taken by this contact method were often unreliable as machines were moved by hand and each machine operator applied different amounts of pressure on the probe or

Leaving nothing to chance in your measuring tasks, Mitutoyo offers an extremely wide range of contact and non-contact probe systems, each component carefully coordinated with

In addition to simplifying measurement of contoured parts like blades, dies, molds and models, PC-DMIS CAD++ has a complete suite of thin-walled (sheet metal) functions.. With