A

(

AUSTRALIA)

1922

-

19620Tm;SIS

LTD.

,

Presented for the Degree of Master of Economics in the School of General Studies,

Australian National University,

by

1\Y01\O

SHERIDAN

0DECLARAT I ON

This is to

certify

that

I have

acknowledged all the sources of

this thesis

and that the thesis

is

my own composition

.

P

REFACE

ABBREVIATIONS

CHAPTER I

FOffiqING THE FIRM

,

19

13-

192

6

.

.

..•

1CHAPTER II

HAl UFACTURIN

G EXPERIE

N

CE, I,

24

19

26-

1945

• • • • 0.

. .

.

.

.~!

CHAPTE

R

III

MAN

UFACTURIN

G EXPERIE

N

CE

,

II,

57

1945

-

19

62

...

• • • • 0C

HAPTER IV

TRADING PRACTICES

...

95

C

HAPTER V

FINAN

CIAL STRUCTURE

...

142

CHliPTER VI

THE R

OLE OF JVIAN

AGEMEN

T

17

4

APPENDIX I

STATISTICS

PREFACE

The study of the firm is one of the important

fields in which until now little work has been undertaken in Australia, yet to understand how this important unit operates in the Australian context i t is necessary to examine local institutional business activity as well as the basic economic forms of a firm I s behaviour.

In the following study of the business activity of Lincoln Mills (Aust , ) Ltd, I aimed not only to write a straightforward history of the firm but also, as far as I could, to add to the knowledge of the characteristics of business in Australia. Because the firm conducted its business as a woollen and worsted yarn spinner and wool knitting manufacturer practically from the inception of the industry in Australia, its history sheds a great deal of light on the changing features of the Australian

woollen textile industry. Although this study is confined to one particular firm in a single industry a

relatively large part of its experience has common features vIi th those of other Australian rr.anufacturing enterprises in the years between 1920 and 1962.

In order to stress the economic importance of the various business experiences of the firm, and partly due to my personal preference, I adopted a thematic approach examining various aspects of the firm' s business practice in turn rather than relying merely on chronological

description. With the exception of the opening chapter which is devoted to a general analysis of the early history of the firm, the study is therefore divided into chapters dealing wi th manufacturing, trading, financial and

on whom the maj_n burden of supervision fell; to Professor

N.

G

.

Butlin and Dr. Alan Barnard for theircontinued interest in my work; and to Mr Bruce Shields and his assistants in the Australian National University Business Archives for their invaluable help in handling

ABBREVIATIONS

CP

P

BPT

'

Prospectus

t'

Minu

t

e Books

'

'

Hinutes

(

Spinning

Mill)

'

't1inu

tes

(Knitting

Mill)

'

Commonwealth Parliamentary Papers,

Australia

.

British Preferential Ta

r

iff

.

'

Lincoln

Hills

(Aust

.

)

Ltd

:

Prospectus

of the issue of 400

,

000

Fixed

Cumulative

9%

Preference

Shares at £1

'.

'

Lincoln

Mills

(Aust

.

)

Ltd

:

Minutes

Books of Directors

VMeeting

'.

'

Lincoln Spinning

Mills Pty Ltd

:

Minutes of General and Directors

'

Meetj.ngs

' .

'

Lincoln

Knitting Mills Pty Ltd

:

Minutes of General and Directors

'

JvJeetings

' .

1

Balance

Sheets

... "

Lincoln

Mills (Aust

.

) Ltd

:

Balance

Sheets and Statements of Acc

o

unts

'.

'

Balance

Sheets

..• ' '

Lincoln

Spinning Mills Pty Ltd

:

(

Spinning

Mill)

Balance Sheets and Statements of

Account s

' .

'

Balance Sheets

... ' '

Lincoln

Knitting Mills Pty Ltd

:

(Knitting

Mill)

Balance Sheets and Statements of

Accounts

' .

Numbers such as

(71/8), (71/123),

etc. indicate

t

he

A

.

N

.

U

.

Business

Archives series numbers of the

relevant

company

records

.

.

;0"CHAPTER I

1a

I

.

Lincoln Mills to 1922Lincoln Hills was born in humble surrou~dings in the backyard of a house in Lygon street, Carlton, in Melbourne. In 1913 Mrs Thomas Neville Rowlands, the wife of the

founder , began working on two flat knitting machines in her home with two or three women to help her. Her husband was then a wood cartage contractor to the El Dorado gold mine in the Bendigo area. The Australian wool textile industry goes back to the 1860s and 1870s. As the gold rush boom faded, consumer industries grew, and in Victoria the government introduced tariffs which stimulated the foundation of textile mills. But the growth of the industry in terms both of its production and its variety of products was slow. Thus, before the first world war the domestic mills contributed only a negligible part to the total supply of wool textil es consumed in Aus tralia, and Ivlrs Rowlands' workshop came at the beginning of a new wave of expansion.

'With the onset of the first world war output

expanded rapidly, aided by the growing needs of the armed forces. 1 As his wife's knitting business developed,

although it remained small-scale, Rowlands became interested in it. In 1915, 30 to 35 girls were working in the

workshop. By the end of 1915 shipping difficulties became se rious. This was reflected firstly in the

difficul ty and uncert&.inty of obtaining imports - materials (particularly yarns) as well as finished goods - and in the subsequent price increases of imported goods produced from them. The average retail cost of clothing was 70 per cent higher in the first half of 1919 than it had been in

1

1914, mainly as a result of abnormal increases in labour and material costs, shipping charges, freight cost and insurance charges. 1 Secondly

tne

shipping problem created difficulties in the import of machinery. All the Australian mills were working at full capacity. The lack of shipping acted as a check upon imports andas the probability of a lengthy war developed into certainty, manufacturers began to wish to extend their

scal e of operati ons.

At the end of 1916 Rowlands sent a friend to the

U.S.

A.

t o purchase some knitting machines. In themeantime he moved part of the machinery to Brunswick and bought the property at Coburg on which Lincoln Mills was afterwards built. The old home was turned into the Lincoln Hat Factory. His employees from the wood

cartage business gradually moved into the mills and began operating knitting machines although the work was completely

foreign to them. The brand name 1 Eldoradol was adopted for some of the first products such as stockings.

Early in 1918 Rowlands set up a knit ting mill with a spinning section in Coburg (then called Ivlorelands) , which became the core of Lincoln Hills. 2 The t·1ill had a

spinning section, but the spinning capaci ty vlaS originally not big enough to meet all the yarn requirements from the

kni tting mill. Nevertheless it contributed substantially tovmrds the development of Lincoln Mills, because there was an extremely serious shortage of yarn, particularly knitting yarn, in that period. Encouraged by the

1

lInter-State Commission of Australia - Price

Investigation, No.ll Report, Clothing', Commonwealth Parliamentary Papers, (hereafter CPP) vol. V, 1917-19, pp.401-47.

2

3

favourable trading conditions the number and output of Australian knitting mills increased greatly during the war, but the supply of yarn could not keep pace with

expanding yarn requirements. In 1918 the sole suppliers of imported manufacturing and knitting yarn, John Paton and Son Ltd and J.J . Baldwin and Partners Ltd said:

I • • 0 we have not a thread of wo 01 on hand •. 0 we have had no stocks since November 1917. At the present time we have not a skein in stock •. o o ,1 Domestic yarn

production remained negligible. Only one knitting manufacturer was providing a significant proportion of

its own hosiery yarns for knitting. All others were wholly dependent upon supplies of yarns from the United Kingdom. Thus, when the press reported the possibility

of the establishment by an English firm of a large-scale wool scouring, combing and spinning works in Helbourne, i t was hailed as a step likely to accelerate the progress of the knitting industry. 2

In the knitting industry the shortage of yarn became more serious year by year until approximately 1920. Thus

a number of knitting mills which were fortunate in laying in comparatively large stocks of yarn during the earlier period of the war shovled a striking expansion, though

their scal e of operation was still quit e small. Lincoln Hills seems to have been one of these lucky firms, but the

overall shortage of yarn made Rowlands realize the

necessity and profitability of a large scale spinning mill for the further growth of the knitting side of his

business. Late in 1918, he went to the

U

.

S

.

A.

and the U.K. to acquire the necessary spinning machinery. He1

' Inter-State Commission of Australia' ,

Ope

cit., p. 10. 2purchased secondhand

machinery

from

newly modernized

British factories

.

He was thus

able

to import

sufficient

machinery

to spin yarn to

meet

the

demand

from

his

knitting mill

.

The

machines

were

still

operated

ma

i

nly

by his inexperienced cartage workmen who were the

cause of cons

t

ant breakdowns

and accidents

.

Nevertheless

orders poured in

from

defence

and

civilian

sources

.

1

Employment

grew

t

o between 1

,

000

and

1

,

200 hands

towards

the end of the first world war

.

For a further

and more

rapid

expansion of

the firms

,

financial assistance frofl outside the

mills

'

accumula

t

ed

in

t

ernal

fund was wanted

.

I

t

seems that it was

in

19

1

9

t

ha

t R

owlands succeeded in obtaining

a

close connection

wi

t

h

W. C.Gaunt

,

a woollen

mill

owner

in Bradford

,

who

became a large supplier of capital funds

.

Immediat ely

af

t

er the war large scale investment was

made

in

both

the

spinning and

knitting mills

.

The

mills

attracted

a

great deal of public

attention because

of their

exceptionally up

-

to

-

date installations

and their

well

planned site which

allowed for

future

expansion

.

Amongst

t

heir novel features were

up

-

to

-

date

water

and sewerage

facilities

and

the large

and

lofty buildings including

a

s

t

oreroom and a motor

garage

which

had

been

planned

with

careful consideration for

efficient

receipt

and dispatch

of

goods

.

O

f particular note was

a special

installati on

which maintained a suitable

humidity

in the

factories

,

for

1

T

he expansion of the firm in this

period

was

alleged

to

have been largely

t

he result of its success in

obtaining

a share in war orders

.

Rowlands was

said

to

have

had

close connections

with

one of Prime

Minister

W.t1.Hughes

'

sons

w

ho later became

sales manager

of

i ts Sydney branch

.

S

miths

Weekl~,1

4 June

,

1924

.

2

.. f

"., ..

:.-. ,

.

.

):

..

5

at this

date

it was

still

widely

believed

th

a

t

wool and

cotton

manufacturing could only be satisfactorily

conducted in European

countries

where the

atmosphere

contained

the

necessary degree of humidity

.

1

Following the

establishment of the Coburg mill

Rowlands in

early

1920

planned

to open

a factory at

Kyneton

in

Victoria in

order to produce additional

hosiery

.

The

president of the Kyneton Shire Council

was

very eager

to

see

Lincoln

Knitting Mills move

into

his

area and guaranteed

th

a

t

suitable female workers would be

available

.

The

Kyneton factory was opened

in

December

1921

,

15

months after

the

scheduled date because of a delay

in the

arrival of some parts of

the

machinery

.

Initially,

twenty

-

seven

girls

were

employed but several more women were

2soon

taken

on

.

At

about

the

same

time,

however,

the

firm began to

experience

financial difficulties because of its high

operation costs

.

Inexpert

operation of

machine

ry

meant

that

machines

were

often run at wrong speeds, and the

high proportion of faulty

work

emerged as a serious

drawback

once

the

abnormally favourable

trading

conditions

gradually

reve rt

ed back

towards

no rmali

ty

.

vlhen

the firm

ceased to

enjoy

the benefits

of

the

sellers

'

market of

the war

and

immediate

post war years

,

it was

forced

to

cut

down

its operations

and employment declined to 500

in 1920

.

In July 1920

,

the

company had

to

borrow heavily and

it was re

-

organized and incorporated as Lincoln Spinning

1

Industrial Australian

and Mining Standard,

cp

.

cit

.,

pp

.

296

-

9

.

2

The Kyneton Guardian

,

15

January

,

12

and

17 February

,

17 June

,

4

and

30

September, 1920

,

8 January

,

13

December,

1

9

21

and 2

1

January

,

1

9 22

.

'

.

.

-. ( .~+

~ .. -'." ,

.

· , :-"1

-.

-,

:

..\:

·

' o· .. ,!.'

·

Mills Pty L

t

d

and Lincoln Knitting Mills

Pty Ltd

.

The two

firms

were

controlled by four shareholders

-Rowlands

,

Gaunt

,

J

.

W

.

Robertson and

G

.

A

.

Manton II

.

II

.

Its

establishment

-

1929

.

Lincoln

Mills Australia Ltd was formed in

1922 with

£2

,

000,000 nominal

capital to acquire the whole of the

assets of

Lincoln

Spinning Mills Pty Ltd and

Lincoln

Knitting

Mills Pty Ltd

.

In

the first issue

£802

,

631 was

subscribed and fully

-

paid up

:

402,631 ordinary shares of

£1

each and

400,000

£1

fixed cumulative

9 per cent

preference shares

were

issued

.

The

whole of the ordinary

shares were allotted

to

the four former share-hold

e

rs of

th

e

t

wo

proprle ary companles

.

t

.

.

1

The

new firm

was

a holding co

m

pany which conducted

the

affairs of

the

former proprietary companies as its

subsidiaries

.

Although they

were

built into a vertically

integrated

process

the two

subsidiary co

m

panies were

operated

as financially independent units

.

Supply of

materials flowing

from the

spinning to the knitting mill

was charged

on a current market price basis or slightly

lower

,

annual business accounts were calculated

independently

and dividends were paid to the holding

company

.

The

products of both subsidiary com

p

anies were

distributed mainly

through

its own sales branches which

were

attached to the knitting mill

.

They

acted as a

wholesaler

directly

to

outside

k

nitting manufacturers in

the

case of yarns

,

to retailers for knitted goods,

hand

-

knitting yarn and other consumer products, and

to

exporters for

tops

and knitted goods

.

1

'

Lincoln

Mills

:

May

,

1

922

( 71

!

1

)

Minute Books of Directors' Meeting

'

,

(hereafter

Minute Books)

.

~. " .. ~.

. ,

'\-...

'.

7

The

main motive

behind the

establishment of the new

firm

as a public company is

to be found in its ambition

to

exploit fully

the

currently prosperous conditions in

the industry

.

1

The

continuing dislocati on of world

shipping

kept

textile imports

at a low level until

1919

.

The Australian textile

manufacturers, realising

that

the

wartime

sellers

'

market could not

last

forever, had

been

urging the Government to raise the

level of protection for

domestic

products

because they

fe

Itthat

it was

necessary

t

hat

they

should meet

the

demand by

themselves

and so

develop the wool textile industry

in

the country

of

the

'

golden

fleece

'.

Already in 1915 they

criticized

the

Federal

Government

'

s policy

of

encouraging the export of

combed tops

.

They claimed that

it seemed

to

be

economically unsound

and antagonistic

to the recognised

methods

of expanding production of

local in

d

ustry

,

and

that its direct

effect

vJaSto

encourage

the establishment

of

new

woollen

spinning and

weaving

mills in Japan

,

China

and India, countries which would

be formidable

competitors

to Australia

.

2

Their

pressure

was

partially successful

and

the 19

14 tariff

rates were revised upwards by

about

5per cent in

March

1920

.

On imports

of United Kingdom

origin

,

which represented the

greater part of

the total,

the

tariff rates imposed were 10

per cent

on woollen

yarn,

1

The

company's reasons

for establishing

the

new

firm

w

e

re

explained

in

'Linc

oln Mills

:

Prospectus of the

issue of

400

,0

00 fixed cumulative

9per cent preference

shares

at

£1 '(71/9) (hereafter Prospectus),

-

particularly

in the

section

on

'

Trade prospects'

and

'

products of

Lincoln

Mills'

.

2Inter-St

ate

Commission of

Australia,

OPecit.,

p.11."

.

~" .-

.:-, ,

...

"

,

.

'0'

25 per cent on blankets and rugs, 30 per cent on

woollen piece goods, 30 per cent on socks and stockings

and 40 per cent on general knitting apparel such as outer and underwear, cardigans, pullovers and jumpers. 1

Yet even in the favourable period of late 1920 and

1921, the firm was borrowing heavily under the pressure

of growi ng total sales and higher rates of growth because

it was short of working capital. Short-term credit needs

exceeded the bank overdrafts available and Gaunt had to

make good the difference by personal advances. The

shortage of working capital nevertheless became more serious year by year. Even after the seasonal peak of stockpiling and extensions of trade credit were cleared in mid winter, capit al was short. The bank overdraft for

example , reached its maximum ceiling of £200,000 in June 1921 and even increased up to £287,000 by the end of the year. Gaunt' s personal advance account , on which 7 per

cent interest per annum was charged, was also increased

from the June figure of £103,214 to £122,024 in December.2 In order to continue to expand its business the firm again,

just as in 1919, needed out side capital. The Company

succeeded in raising £400,000 by issuing preference shares. It also obtained an overdraft accommodation up to £150,000

1

Tariff Board Reports on ' Woollen Yarns', 1925 in

C££,

1925III, pp.2079-86, on iWoollen Piece Goods!, 1925 in ~,1925 II, pp. 2071-8, on 'Knitt ed Piece Goods', 1927 in CP:P, 1926 on

28 IV, pp.2127- 36, and on 'Socks and Stockings', 1925 in C:PP, 1925 II, pp. 2011-6.

2

'Lincoln Mills: Balance Sheets and statements of Account ' (71/11) (hereafter, Balance Sheets ..• ), February, June and

December 1921, 'Lincoln Knitting Mills Pty Ltd: Minutes of

General and Directors' Meeting' (71/2) (hereafter, Minutes

(Knitting Mill) ), June 1920 to June 1922, and 'Lincoln Spinning Mills Pty Ltd: Minutes of General and Directors ' Meetings' (71/3) (hereafter, Minutes (Spinning Mill)) , June 1920 to June 1922.

, i

.. '

-

'

.

"

9

from the National Bank of Australasia and, by mortgagiLg

its properties, a long-term loan from Gibbs Bright

& Co

of £200,000.1 The overdraft limit was too small tofinance the Company's enlarged business activity, and as a

result of Chairman Rowland's tactful negotiation with the

bank the overdraft was extended to £200,000 in April , 1922.

Gaunt' s direct and indirect assistance from England

was important to the firm. He sent Lincoln Mills a number of experienced managers , expert mechanics and skilled

workmen from his own or related mills in Bradford. This

influx of experienced personnel certainly constituted a

great advantage for the firm over its competitors during

this early stage of the enterprise. The expenditure on

salaries and accommodation for these immigrants amounted to

a fairly big sum. The expenditure on accommodation, mainly the purchase of houses , and salaries paid for the

staff and workmen from England was on various occasions

reported by the company. For example it advanced between £7, 000 and £8,000 to purchase houses for 12 people in 1922. Salaries paid for managing staff from England seemed to be

relatively high. J. ~. Whitehurst , a Director, was paid £1 ,250 a year, J.A. Floyd, J.Vlanagement Supervisor, was paid

£1,000 and F. Hede of the Managing Staff was paid £780 in

2

the year 1922. These amounts should, however, have been well offset by the assistance the new men gave to overcoming

the difficulties associated with the firms' growth.

Between 1918 and 1922 many mills of varied size sprang up,

' . ~

.

.

.,'; ..

-.

;:1:

but only a limi ted number of them survived and expanded as ~:' competition from imports returned again after 1923.

1

1 Balance She et s •.• , June 1922. 2

In the 1920s the lack of adequate managing staff and

skilled or even semi- skilled workers was, above all , the most important factor determining the success or failure

of an enterprise in the wool textile industry. Where i t _J 1

was not available chaos and bankruptcy usually followed. Gaunt's assistance in purchasing capital equipment in

England meant relatively quick delivery and choice backed

by experience, but Lincoln was only one of several mills which were provided with modern equipment in this way.

On the face of i t the prospects for woollen textiles

in the land of vlool seemed good. Local production would eliminate transport costs to England and back again, and

save any stock holding. The tariff and successive

increases were an addi tional incentive.

Owing to the imposition of tariff protection in 1920,

several British woollen textile manufacturers and exporters

had shown considerable interest in establishing mills or

investing in Australian mills in order to maintain or

extend their share of the Australian market. The manufacture of knitting yarn hosiery and other knitted

goods I/Jere particularly favourably protected compared with

th e remainder of the wo 01 t exti 1 e indust ry be tween 1921

and 1925. During this period, the Australian wool spinning and weaving industries were protected by tariff duties of

10 per cent on woollen yarn and 30 per cent on woollen piece goods by the ad valorem British Preference Tariff

(BPT) . On the other hand, the knitting and hosiery industries were protected, generally speru(ing, by

relatively higher duties because of the Tariff Board' s

1

Colin Forster, Industrial Development in Australia 1920-30, A.N.V., 1964, pp.86-7.

.

J

' .. ' ..

I,

..

,11

appreciation of these industries

'

achievements in

replacing imports

.

1

For example

,

ad valorem BPT duty

on cotton

or sj.lk socks

and

st ockings was 30

per

cent

and

th

a

t

on

\,-Joollen

socks and stockings was 35 per cent

.

On general knitted

apparels

(

such as

jumpers

,

cardigans

,

shirts

,

coats)

,

the

duties were set both

as

fixed duties

(shilling

per article) depending on the type of clothing,

and ad valorem

rates

of 40

per

cent (BPT) whichever was

the

higher

.

Although

the

same duties

w

ere

imposed

on

woollen

and

worsted

yarns for weaving

and knitting purposes

,

yarns used for

the

manufacture of underwear

and hosiery

were

protected more advantageously so that it was cheaper

for

knitters

to

buy from Australian

spin

n

ers

than

to

use

imported

yarns

.

2

T

his explains

why

British investment

came

into

this

par

t

of

the

industry one

s

t

ep

in advance

of the

other sections

;

t

he effect of foreign

inves

t

men

t

became important

in sections such

as

woollen

and

worsted

weaving only

aft

er

the revision,

in 1925

,

of the

1

92

0

t

ariffs

.

In

order

to

retain

marke

t

shares for English

manufacturers already by

1925

six wool

t

extile

companies

had

been established with

the

help of

En

gl

ish

capital

.

Four of these, Lincoln

Mills

,

Australian Knitting

~ills

Ltd

,

3

1

Bec

a

use

of

the

pauci ty

of

statistics

,

it is

no

t

possible

to reliably

ascertain

the

extent

to

which local

mills me

t

the total

Aus

tr

alian

requ

iremen

t

s

of

knitted and

hosiery

goods

,

but the

subs

t

antial

import replacement is roughly

measu

re

d as 35 per

cent

of

the tot

al

market in

1

9

19-

20

and

1

92

0-1.

The Austr

a

lian

produc

tion

of woollen

and

worsted

cloth (piece

g

oods

)

was

estimated, on

the

other hand

,

as

being only

equal

to

a

quar

ter

of

the

total consumption in

th

e period

.

C.

Forster

,

Industrial

Development in

Australia 1920-

30

,

op

.

cit

.,

pp

.

8

0

and 98

,

and Tariff

Board

Report on

"v

oollen

Piece Goods

'

, CPP 1925,

II, pp

.

2071

-

8

.

2Tariff

Board Report

on

'

Woollen Yarns

',

1925,

ibid.

3

Th

e origin

of

Australian Knitting Mills

Ltd

goes back to

the beginning of the century

,

but the

substantial inflow

of English capital took

place only

af

ter

its re

-

construction

in 1921

.

'

Australian

Knitting Mills

Ltd

:

Re

por

t

of

the

Dir

ectors

¥,

1921

and

1922

.

-

~ j- . .,

. i

, l'

'

.

' .

.

. -.-•. r

.

.

.

"~ .. ,

-,

Yarra Falls Ltd

1

and Patons

and Baldwins

Ltd

were

in

the

knitting field in Victoria

.

2

The

first

two

companies

manufactured knitted goods and

the

latter

two

were

knitting yarn spinners

.

These

companies were the

largest

wool textile

producers

,

and played an

important

part

in the

expansion of

the

Aust ralian

vlO 01t

exti le

industry

by

introducing

new

techniques

and new products

from England

.

3

--Linc

oln

ills

'

manufacturing activities by

the

early

-19

2

0s

covered

t

he following products

:

1 .

Wool tops

.

In

1922 the topmaking

section of

the

firm handled

ah

o

u

t

12

,

000

bales of greasy

wool

,

or

1,7

50

,

000 lbs

.

of

wool tops

.

pproximately 800

,

000 to

900

,

000 lbs

.

supplied

the

entire demand of the firms

'

spinning mill so

th

a

t

sales were

also made

to

outside mills and some tops

w

ere exported

.

2

.

Worst

ed and Nul e

-

spun Yarns

.

Th

e yarn production capacity of the spinning mill

wa

s

estimated

at

5

,

000 lbs

.

per week

.

The capacity

was

big

enough

to

meet all

the

yarn requirements of the

knitting

mill

in

addition to a substantial amount of sales

to outside

knitting manufacturers

.

3

.

Wooll ens

.

1

Yarra Falls Ltd was

estbblished initially to spin yarn

for the

Australian Knitting

Iills

Ltd, in 1917

.

Support

by British capital

became substantial when

the

firm

re

-i

ncorporated

as a public company in

1924

.

Yarra Falls

Lt

d

in Sydney Stock Exchange

Research and Statistical

Bureau, Investment Service

.

2

The

r

emaining

two

companies were

Kelsall and Kemp

(T

asmania)

Ltd

manufacturing mainly flannels

,

and Valley

Mills Pty Ltd the

products of which were not known

,

bu

t

it is said that

W

.

C

.

Gaunt

was one of its proprie

t

ors

.

F

o

rster,

Industrial

Development

in Australia

1

920

-

30,

op

.

cit

.,

pp

.8

2

-

4

.

3

Ibid,

p

.

82

.

- : ...

:-. (

'.

.

.

4. ' . ".

.

, ... : ....13

The

production of woollens could to a large

extent

absorb other by-

products of worsted yarn

.

These

products were used for manufacturing rugs

,

blankets

and some flannels

o

4

.

Hosiery

.

This

section was the major part of the firm

,

producing socks and stockings in pure wool

,

silk

,

artificial silk

,

cashmere

,

and other materials for men

,

women

and children

.

The

annual

capacity

was estimated

at about 350

,

000 dozen

.

5

.

General

£nitted goods

.

This

section produced a great range of knitted

goods

including

men

'

s, women

'

s and chi

l

dren

'

s wool

underwear

,

golf

coats

,

jumpers

,

sweaters

,

coats

,

scarves,

capes

and khaki

jerseys

for the forces and some other

minor products

.

6.

Silk throwing

and

weaving

.

Lincoln

was the only one Australian mill which

possessed a silk

throwing

and 1,oleaving plan t

,

so

that

this business

',.,as a local monopoly

.

The

firm proviced

about 130

,

000 lbs

.

of silk yarns from imported raw silk

for

the

manufacture of silk stockings in the knitting

mill

.

A part of

the

spun yarn was sold to outside

customers

.

From

a

technical

point of view neither the

'

vertically

integrated

'

nor

'

multi product

'

structure

in

the worsted

industry contributed to economy of

.

.-

-..

.

".

.

~ .-.

.

.

' ".

.

,....

:. '! '

production costs to any

~;ubst8Xltial

extent

.

1

Lincoln

Iiills was not

,

hOi/ever, the only example in the worsted

industry of a

l

vertically

integr~ted'firm nor was iLs

at tempt top roduce a Hide variety o· Co

CXls uni que

.

Australian Kni tting

l'i lIs Ltd had a similar structure

.

In the

1920s

when the industry was in the early stages

of

its devcloT)Iilent

'

verticaL integration

'

and

'

multi

product

'

structure Has certDinly a c.,reat advant8ge over

knitting

coopetitors

Hho had to purche<.se yarn from

outside miJls and who produced a narrOH range of products

.

This

advantage

W2,Smainly due to the follovring factors

which Here, however,

particul~rlyimport

0nt only in this

period

:-1

In the

United Kingdom vertical integration was much

less p

r

evalent in worsted production than in woollen

production

.

This

is

tlinly due to the following

characteristics

of the worsted

indu~try:-(a)

It is diffictilt for a worsted manufucturer

to

maintain a precise balance bet\'leen llis combing,

spinning

,

Knitting Gnd weaving capacities

.

The

problem of reconciling ontima is not so great in

woollen

proQuction because there Gre fevler proc esses

and economies of scale are not so important

.

(b)

\'10rs

ted combing an d spinning Lwch inery is

less flexible than woollen spinninb uachinery

.

A

worsted

spinner finds

consider[~leeconomy in

concentrating

on a narrow range of counts and

qualities whereas the spinning plant of a vertically

integrated

mill Hill probably have to make sL1811

lots

of a variety of yarns to meet Lle

require~entof its

knitting or weaving department

.

(c)

Hand knitting yarn is one of the iLlportant

sections of vlorsted industry in terms of production

value

.

This yarn is sold directly to the public

without passinb througn integrated production

process

.

Sumnarized

from

1Great Bri tg,in, 11/orkine;

Party

Report

'

which is quoted in M

.

DedDen

'

s article

'

Integration in the Australian wool textile industry

'.

Eeonoraic

Record

,

June

,

1940

.

~,

.~

.

. ~ {;;

. ~.

.: :., .' . .

..

'I -.

....

,/'

"

_." . I."

..... .

... 'I"" ~ . -," .'

.,

\ '

15

(i) For yarns drawn from overseas sources,

purchasing firms had to bear all the expenses

connected with shipping, but protective

tariffs were even more important after 1920.

It was estimated in 1922 by Lincoln Mills

tha t the company was ab 1 e to sp in yarn for

its knitting mills requirements at 10- 15 pef

cent less than yarn' s current market price.

(ii) In times of difficulty iL obtaining yarn from

abroad , having one' s mm spinning mill gave

the advantage of operational stability.

Imported yarns \vere often in short supply,

there were delays in delivery and wide

short-term price fluctuations. 2 Yarns therefore

had a ready market so long as their prices

were reasonable as compared with imports.

(iii) A further and continuing advantage associated

with having allied mills was that mills did

not have to carry large volumes of raw yarn.

This was particularly important for this

industry which carried relatively large

amounts of stocks - in raw as well as

manufactured and semi-manufactured states

because of its particular trading pattern.

(iv) Apart from Ivertical integrationl a Imulti

product I structure gave the mill greater

stability in the face of changing demand

patterns and supplies of different types of

wool. From 1923 to 1925 a number of knitting

mills, usually ones operating on a very small

scale, which had concentrated on one or two

varieties of product went out of business 3

owing to fluctuations and changes in demand.

In order to make use of these advantages , many mills

established in the 1920s and 1930s adopted a vertically

integrated as well as 'multi product ' structure. The

consequent shortsge of specialised large-scale knitting

1

Tariff Board Report on ' Woollen Yarns' , 1925, Ope cit.,

and 'Prospectus I.

2

For example, Wangaratta Woollen Mills Ltd, which

specialised in a relatively small range of products,

converting wool tops into worsted yarn, is reported in

this period to have found difficulties in maintaining

its supply of wool tops from outside sources. Forster,

Industrial Develo,Pfgent in Australia 1920-30, Ope cit., p. 90,

and Industrial Australian and Mining Standard, ~cit. ,

15 May 1926, p.722, and September 1923, p.362.

3

It is reported that 36 small knitting mills in Victoria

were forced to close down in 1923-24 largely because of

narrowness of their production ranges which made it

extremely difficult for them to adapt to changes in

market requirements. Forster, ibid, p.95.

"

.

;'. , i

. ~. ,'.

.. ". ~.

-.

. ... . '.

.....

' . .

~ . I'

~,' . ,.: ..... \ "

~

.

.. . -.... .

~

mills,however, acted as an obstacle to the establishment

of specialised large-scal e spinning manufacturers because

of the necessari ly restricted size of the potenti8~ market

for their yarn. The establishment of specialised

large- scale knitting mills, in turn, was hindered.

-

.

However, in later years, as the industry developed and "

.

the market expanded the tendency to est~blish new ~'

-specialised mills grew, hand in hand with a trend towards

converting existing mills to the production of a narrow

range of products.

~ . "l' f

III. Lincoln Mills, 1922 to 1926 =

After its several years of manufacturing and trading

experience, albei t on a small scale, Lincoln Mills and it s ., -. managemen t might have been expected to have a fair grasp

-.

of the problems arising in the course of running a business

in the wool textile industry. But as soon as the new firm

embarked on large scale operations, much confusion, . ',"

unexpected mistakes and miscalculations occurred in the

business. The firm seemed to be growing too fast , too

soon, and its managing staff was not capable of handling

a large scale enterprise.

When the firm was reorganized in 1) 22, Gaunt sent

" two business associates from England. One of these was

J .W. Whitehurst and he became a director of the firm.

But already by June 1922 the market price for the ,. ...

firm' s products had been falling for six months and the

val ue of sales was decreasing. This problem was about

to become more serious. Production was not curtailed in " "

response to the market conditions and consequently - ! •

I, ;'" "

manufactured stocks increased, first in the knitting mill .: '.~ .... ' I

and then in the spinning mill. To economize, the

top-making section temporarily discontinued its operation

.,

)

17

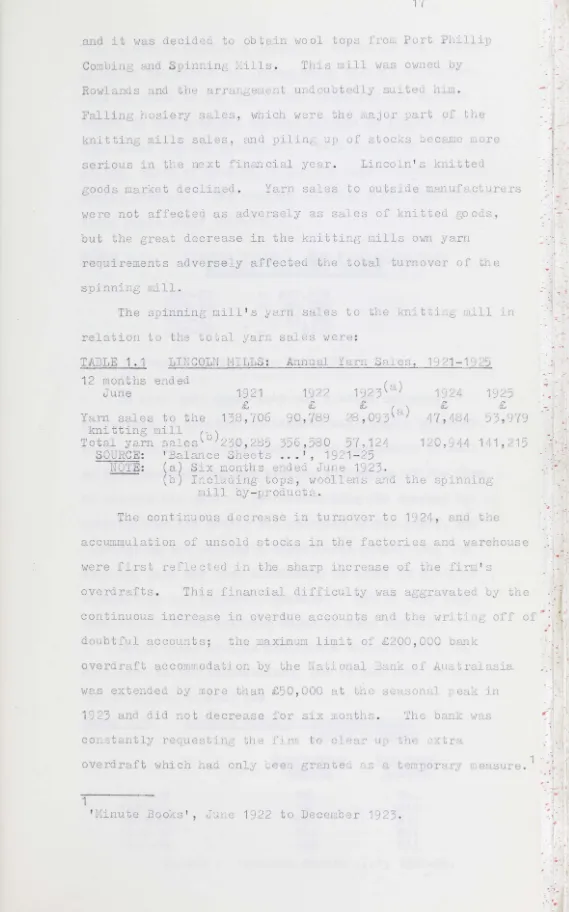

and it was decided to ob tc: in \-1001 tops froIL. Port Philli.p

Combing and SpinninG l'Jills. This mill was owned by

ROvl1ands and the arranc:e:.nent undoubtedly sui ted him.

Falling hosiery sales, which were the major part of the

knitting mills sales, and pilinE, up of StOCAS became more

serious in the next financial year. Lincoln' s knitted

goods market declined. Yarn sales to outside mru1ufacturers

Here not affected as adversely as sales of knitted Goods,

but the great decrease in the knitting mills ovm yarn

requirements adversely affected the total turnover of the

spinning mill.

The spinninG millIs yarn sales to the knitting mill in

relation to the total yarn sales were:

TABLE 1. 1 LIKCOLN HILLS: Annual Yarn Sales, 1921-1925

12 months ended

June 1921

£,

1922

£,

90,789

1923(0.)

£

28,093 (a) Yarn sales to the 138,706

knitting mill (b)

Total yarn sales 230,285 356 ,580 57,124 SOURCE: 'Balance Jheet s .•. ', 19=-1- 25

10TE: (a) Six months ended Lme 1923.

1924

£,

4

7

,t.841925

£,

53,979

120,<)44 1~1 , 215

(b) IncluQing tops , woollen~ and the spinning

mill by-products.

The continuous decrease in turnover to 1924, and the

accumrnulation of unsold stocks in the factories &nd \'Jarehouse

were first r9~lJctcd in the sharp increase of the firm' s

ove rdrctfts. This financial difficulty was aggravated by the

".: .. - .

:

[image:24.600.25.594.14.926.2]0' .

...

,,-"' . . .

L,

o ·

': ... i

.

.

-...

..

.continuous increase in overdue accounts and the wrj t Lng off of "': ','

doubtful accounts; the uaximLLrn limit of £200,000 bank

overdraft accommodati on by the :~ a ti onal ..Jank 0 f' Au..:; t ra1 asia

was extended by more than "",50,000 at the se'3...,ona1 D eak in

1923 and did no t decrease for six months. The bank was

cOl1.stantly requesting the ~'-inn to clear UD the extra

overdraft 1,lhich had only been granted as a tempor ry measure. 1

1

II''linute Books', June 1922 to December 1923.

.

•

~.

.,

I

The

directors adopted a policy of unloading the knitted

goods on

the

market at prices below current production

cost

~norder to

get

rid

of

the

heavy stocks, without

regard to the

possible adverse effects on future orders

from their

regular customers

.

As a result of this sales

policy, sales of both mills did not bear even the wholesale

profi

t

margins

.

The company

recorded a net loss in

the

three

years after

1922

-

23

.

TABLE

1.

2

.

LINCOLN

MILLS

:

Net

Profit

and

Loss

Account

,

192~-1925/6

1922

-

23

+

£17

,

634

1923-

24

.£1,383

1924-

25

£ 1 ,169

1925-

26

£934

Source

Appendix Table 12

.

In late 1923

Gaunt sent out a

third

emissary,

R

.

Feather

,

a Bradford auctioneer and textile engineer,

to re

-

examine the

efficiency of

the

management as well

as

the

manufacturing and

trading

operations of the firm

.

He

started his

\-fOrk

of re

-

constructing

the company by

cutting

dO\-Jn

the

number and salaries of the staff, and

liquidating the

company

'

s

superfluous properties

,

for

example

,

land

and some machinery, in order to minimize

expenditure

and

improve

liquidity

.

Bu t :.. t took some

time before these

measures began

to

t8~eaffect

.

Under these

adverse

conditions the

firm paid few

dividends to

the

shareholders, and at one time in

1924

the £1

shares

touched 10s

.

TABLE

1.

3

.

LINCOLN

MILLS

Dividend

-

Paid,

1921/2

-

1925/6

192

1-

22

1922-

23

1923-

24

1

924

-

25

1925

-

26

Source

Preference

Shares

9%

9%

Nil

Nil

4~·%1

Bal ance

Sheets

Ordinary

Shares

Nil

Nil

Nil

Nil

Nil

I

.

.

.

,

1921-25

.

.

.

..

. . • 0 "

~ ,

.0:.... •

# . . . •

. :

.

.

'\.~ ".

-

" .. -, .

, .

.

.

' [image:25.603.24.594.54.922.2]1

9

R

e-

construction,

particularly

changing

some of

the

managine staff

,

was

planned and

J.Kellett

came

from England to be

a director

in

July

1924

.

The

relation between Gaun

t

and 1hitehurst

was

unilaterally

discontinued by Gaunt without

any

official

notice

.

The

company consequently required the resignation

of Whitehurst

in early

1

925

,

and

there

seems

to

have been some personal

rancor on the

occasion

.

1The business

of

the

fi

nnwas

conducted largely under the

guidance of

Gaunt

'

s

emissaries,

R

.

Feather

and

J.Kellett

(

spinning mill manager)

.

O

n

20 July 1925

,

fire

destroyed a large part of

the

knitting mill and a part of the spinning mill

together

with the warehouse

.

But most

of the

assets were covered

by insurance

and

the

firm lost

little in cash

terms

,

and

it did not

appear

,

so far only as

its

short

-

term effects

were concerned

,

to h"ve caused the

firm any real harm

.

The firm was

said

to

have

received

about

£782,000

in

compensati on from the Law Union

and

Rock Insurance Company

,

for the buildings

,

machinery and stocks

.

2

The

amount of

compensation

seems

to

have been enough

to

mitigate

the

firm

'

s

finan cial

st

rain

at

the time

.

The fire was one of the

biggest in Australia and

the

cause of the outbreak was

a mystery

.

Various factors

give

rise to the

suspicion

that the

cause was not purely

accidental;

(a)

the

fire affected mainly the relatively

obsolescent

part of

the firm

'

s plant which went back to

the beginning of the

firm

while the part

newly developed

after

1920

escaped

.

Also

a

huge

amount of unsold stocks

1

'

Minute

Books

',

February

,

1925

.

2Press cutting from Coburg Courier

,

? October 1952(?)

.

In

t

erview

with

Mr

R

.

G

.

Dixon

,

the

secretary of

Lincoln

Mills on

6 December

,

1965

.

. -. • I

..'

, ....

" . " .

- ! .

were destroyed

;

(b)

Feather who worked

efficiently

in the post

-

fire re

-

organization of

the factories

had

been

sent out

from England

before

the

fire

.

This

suspi cion

viaSso serious

that

no insurance

compClny,

inside and

outside

Australia

,

would accommodcte insurance

on Lincoln

'

s assets

for

approximately three months

in

spite of

all

the

efforts

1

of

Gaunt and

the

directors.

By an

interesting coincidence

the underwear factory

of Australian

Knitting

Mills Ltd

was also destroyed by

fire in January 1924

and the disaster was

turned to

advantage by

the

installation of modern plant

.

Insurance

compensation

seems

to

have financed modernisation

to

a

2

great extent

.

Officially, Lincoln

gave

the

severe

competition

with imports from England

as the main reason for its

continuous

decline

of turnover,

financial strain

,

and

inability to

pay dividends during

1923

-

24 and

1925

-

26

.

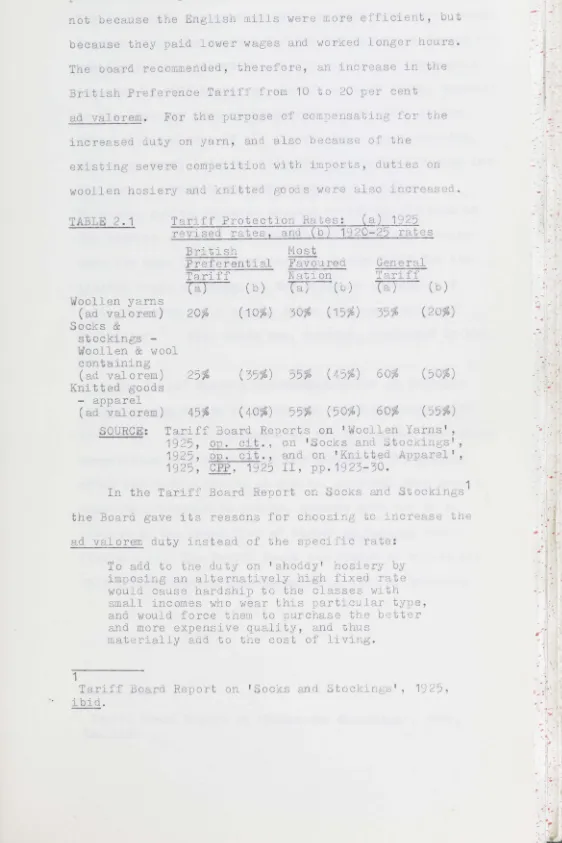

This

adverse market

condition

seriously affected many

newly established

mills

in

the period and led

the Tariff

Board to recommend

an

increase in

the

tariff

in

1925

.

•• ' 0 . ~.

..

.

:', •...

,

. . .

.'

...-.

But competition

with

imports

was not

the

only

reason

.

Ibehind the firm

'

s failure

.

Thi

s was largely due

to

inexpert

management

,

a clumsily organized sales

br~chessystem

and

lofty

ambi

tions to

produce a

large

variety

of

products

.

The

post

-

war

boom

in the wool textile industry

did

not really fade

out until

the

middle of

1923

.

Not only

Lincoln but

many mills

in the industry

were enjoying

prosperous conditions till 1922

-

23

.

Then

the

market

1

'

Minute Books

',

July 1925 to

December

1926

.

2

Australian

Knitting Hills

Ltd,

'

Report and statement

of Accounts

',

1924

-

25

.

. . '

:.;.'~

21

condition changed suddenly in the second half of 1923

when imports from the United Kingdom came surging into

the local ~arket . In the twelve months between July

1922 and June 1923 imports of Bri tish vJOollen piece

goods and hosiery goods (including socks and stockings)

had risen from £3. 1m. to £4.7m. , and from £1 .6m. to

.co2

7

t· 1 1~ . m. respec lve y. This import avalanche from the

United Kingdom was partly the result of economising the

long-standing shipping shortage dating back to the war

years. But more importantly i t was the effect of the

contemporary currency depreciations taking place in Europe

vlhich enabled Uni ted Kingdom manufacturers to import yarn

and other raw materials and semi-finished goods from these

continental countries at prices considerably below the cost

of manufacture in the United Kingdom as well as in Australia.

This situation was aggravateu by the fact that the final

articles which had only been partly produced in the United

Kingdom were brought into Australia under the British

Preferential Tariff. This was not a problem facing only

the wool textile industry - i t also drove various other

Australian industries into serious difficulty during the

period. Adopting the complaints made by Australian

manufacturers, the Tariff Board in 1924 recommended the

alteration of the definition of imports to which the benefit

2

of British Preferential Tariff, should be granted.

1

Commonwealth Bureau of Census and Statistics, Oversea

Trade Bulletin, 1923 and 1924.

2

Under these new recommendations, preference was now limited,

on and after the 1 April 1925 to the following goods:

' (1) Goods which are wholly produced or wholly manufactured

in the United Kingdom. Manufactured goods will only be

considered ' wholly manufactured in the United Kingdom' if in

the raw material used, and also in the finished goods, no

manufacturing process has been performed outside the United

Kingdom which is being commercially perforned in the Uni ted

Kingdom.

(2) Goods not It/holly produced or wholly manufactured in the

United Kingdom provided they contain at least 75 oer cent of

United Kingdom labour and/or material in their factory or

Works cost.' Customs Act 1925, Third Annual Report of the

Tariff Board, p.18.

--,

-~.

'

.

.

... \' ..

.

.

"... -.

..,~.

-

......... .

.'

~:,

,