Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

1990

Simulation and analysis of a digital scanning system

Eugene A. Rogalski

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

Recommended Citation

Simulation and Analysis of a Digital Scanning System

by

Eugene A. Rogalski, Jr.

A Thesis Submitted

in Partial Fulfillment

of the

Requirements for the Degree of

MASTER OF SCIENCE

in Mechanical Engineering

Approved by:

Prof.

Joseph S. Torok

(Thesis advisor)

Prof.

Prof.

P Venkatar

Prof.

Wayne W. Walter

Mr.

Thaddeus Kciuk

Prof.

B.

Karlekar

(Department Head)

Department of Mechanical Engineering

College of Engineering

Rochester Institute of Technology

Rochester, New York

Simulation

and

Analysis

of

a

Digital

Scanning

System

I,

Eugene

A.

Rogalski,

Jr.

hereby

grantpermissionto the

Wallace

Memorial

Library,

ofthe

Rochester Institute

ofTechnology

to

reproducemy

thesis

in

wholeorpart.

Any

reproduction willnotbe for

commercial use or profit.Acknowledgment

This

work could nothave

been

possible withoutthe

supportandguidance ofseveral

individuals.

Its

success

is due

largely

to their

encouragementandsuggestions

andI

extendmy

deepest

appreciation:To Xerox

Corporation

for

the

useofcomputing

facilities.

To

Dr. Wayne

Walter,

Dr.

P.

Venkataraman,

andDr.

Hany

Ghoneim for

taking

time

outoftheir

busy

schedulesto

read and critiquemy

work.To Michael Boyack

whodesigned

the

control system which was usedin

this

analysis

and who providedthe

controlshardware

and software.His

enthusiasm

for

the

design

and analysisof controlsystems wasaninspiration.

To

Thaddeus

Kciuk

who providednumerous suggestions and guidance.To Dr. Joseph

Torok,

Rochester

Institute

ofTechnology,

Department

ofMechanical

Engineering

for

his

very

functional

guidance andencouragement.And

lastly,

though

notatalllast,

to

my

wifeMarlene

whosuppliedAbstract

The

analysis

and simulation ofthe

motion of adigitally-controlled digital

imaging

systemis

presented.The

dynamic

system consists ofascanning

carriage,

powertransmission

elements,

a primemover,

andacontrolsubsystem.

The

prime moveris

apermanent magnetDC

motorthat

is

positionedby

adirect

digital

control system.The

scan carriage motionis

mathematically

modeledand simulatedusing ACSL

andDADS

simulationsoftware.

T

he

simulationresultsare comparedto

empiricaldata.

It is

shownthat

the

dynamic

response ofthe

actualscan system canbe

predicted quitewell

using

suchsimulations.Furthermore,

these

simulations can aidin

the

Table

of

Contents

Page

List

ofTables

viList

ofFigures

viiList

ofSymbols

ix

I

Introduction

1

II

Control System

Preliminaries

11

III

Description

ofthe

Physical

System

24

IV

Mathematical

Modeling

28

V

Simulations

42

VI

Results

44

VII

Conclusions

55

VIII

References

58

List

of

Tables

Page

1.

Full Model

Step

Response

Comparison

47

2.

Physical Constants

69-70

List

of

Figures

Page

1.

Building

Blocksof

aDigital

Scanning

Device

2

2.

Imaging

Definitions

3

3.

Contrast

Sensitivity

ofthe

Human Eye

to

Square Wave Gratings

5

4.

Perceptibility

Threshold

ofEdge

Raggedness

6

5.

Motion Error

Detectability

-ThresholdDesign Goal

8

6.

Velocity

Error Design Goal

9

7

Basic Components

of aClosed

Loop

Control System

11

8.

Nonlinear

Element

12

9.

Linearity

Improvement

13

10.

Block Diagram

Transfer Function

15

11.

Block Diagram

Reduction

17

12.

Digital

Control

System

19

13.

Uniform

Sampler

19

14.

Sampler

withZero Order Hold

20

15.

Physical

System

24

16.

Control

System

/Mechanical

Block

Diagram

25

List

of

Figures

(continued)

Page

18.

Controls

Block Diagram

29

19.

Motor

Circuit

31

20.

Simple Mechanical

Model

Block Diagram

35

21.

Lumped Parameter

Mathematical Model (Translational

DOF)

38

22.

Linearized Lumped

Parameter Model

(all

DOF)

39

23.

Eigenvalues,

Eigenvectors

andMode

shapesfor

3 DOF

model41

24.

Simple

Model Motor

Step

Response

ACSL Simulation

45

25.

Simple

Model Motor

Step

Response

DADS Simulation

45

26.

Full Model Motor

Step

Response

ACSL Simulation

46

27.

Motor

Step

Response

Experimental Result

46

28.

Motor/ Carriage

Ramp

Response

-ACSLSimulation

48-49

29.

Motor/ Carriage

Ramp

Response

Experimental Result

50

30.

Motor

Ramp

Response Increased

Sampling

Period

52

-ACSLSimulation

31.

Motor

Ramp

Response Increased

Sampling

Period

52

-Experimental

Result

32.

Mechanical

Frequency

Response

53

List

of

Symbols

a;

Linear

acceleration, ith

elementB

Viscous

damping

coefficient

c

Command

positionCj

Viscous

damping

coefficientek

discrete

errorkth

sample

f

Position

feedback

Ffj

Linear

friction

G

Plant Transfer Function

H

Feedback Transfer Function

ia

Armature

currentli

Inertia

lm

System

inertia

Kd

Derivative

gain constantKe

Generated

back

EMF

constantK,

Spring

constant,

ith

elementKp

Proportional

gain constantKj

Motor

torque

constantLa

Motor

armatureinductance

Mj

Mass,

ith

elementNenc

Encoder

line

density

R

Result-Ouput

Ri

Radius

ofthe

ith

elementRc

Capstan

radiusRm

Motor

armature resistances

Laplace Variable

Tfj

Torsional

friction

TmotorTorque

producedby

motorTres

Resultant

Torque

Ts

Sampling

time

List

of

Symbols

(continued)

Va

Applied

motor voltagevi

Linear velocity

Vb

Generated

back

EMF

voltageVm

Motor

armature

voltagexj

Linear

positionz

Z Transform Variable

9i

Angular

positionai

Angular

acceleration8(t)

Unit Impulse Function

Qi

Angular

velocity

$

Magnetic

field

flux

I

INTRODUCTION

Digital

scanners

are

taking

on an ever-increasing

role asinput

devices

to

computer-based

systems.

As

typical

opticaldisk

storage

capacitiesexceed

1

Gigabyte

and

desktop

publishing

equipment

rivals printshop quality,

digital

scanners are

becoming

a popularcomputing accessory for

data

storage,

andimage

manipulation

purposes.

Acting

as

alink between

the

paper andelectronic

worlds, the

input

scannercreates

an electronicimage

ofthe

paperoriginal which

is

then

processed

according

to

the

user's requirements.Downstream

processing

may include intelligent

character recognitionfor

text

input

and subsequent

wordprocessing

applications,

enhancementfor image

input,

orfile

compression

for

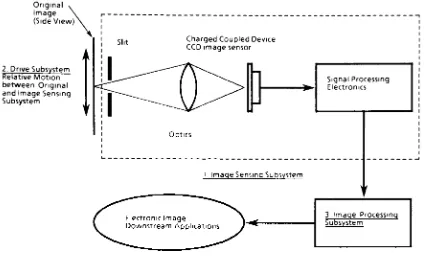

archival storage purposes.The

operation ofany digital scanning

device

requiresthree

basic

building

blocks

as

shownin

Figure

1

.The

first

and

mostimportant block

containsthe

image

sensor and optical system.Together

these

elements convertthe

light

anddark

portionsofthe

originalimage into

individual picture elementsor pixels.Charged

coupled semiconductordevices

(CCD's)

are

typically

usedas

image

sensorsin

many

scanners onthe

markettoday.

The

second

building

block

assures

that

the image

sensorphysically

scansthe

input

to

create atwo

dimensional

map

ofthe

original.This

motion canbe

achieved

by

moving

the

image

sensororthe

input document

relativeto the

otherusing

avariety

ofdrive

transmission

schemes.The

last step is

then to

processthe

two

dimensional

pixelbitmap

into

usefuldata.

Depending

uponthe

downstream

Original Image

(Side

View)"2 Drive Subsystem Relative Motion between Original

andImage

Sensing

SubsystemChargedCoupled Device CCDimage sensor

Signal

Processing

Electronics

Optics

1 Image

Sensing

Subsystem3 Image

Processing

[image:13.523.53.477.116.374.2]Subsystem

FIGURE 1

:Building

Blocks

ofa

Digital

Scanning

Device

The

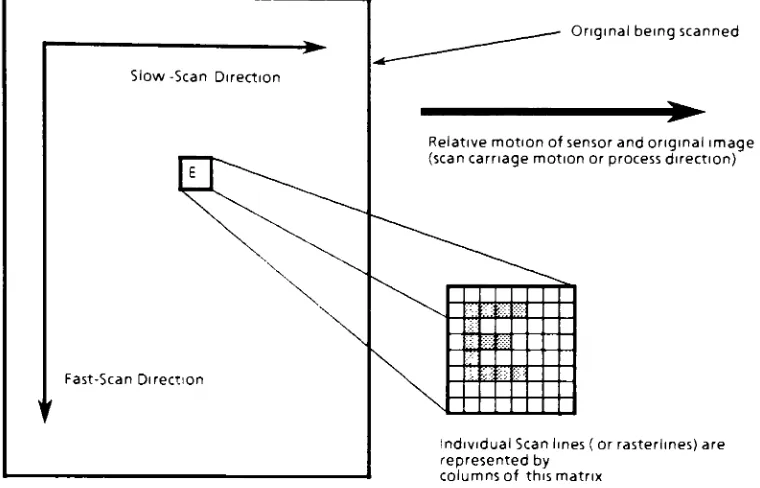

two

dimensional

map

ofpixels

formed

by

scanning

the

image

may

be

conveniently

thought

ofas

agroup

ofparallelbut

separate

scanlines

eachcontaining

a

line

of pixelsimaged

at aninstant

in

time.

The

lines

oriented

parallel

to

a scanline

are

saidto

lie

in

the

fast-scan

direction,

because

in this

direction

the

pixels

areimaged

more

rapidly.This is

the

direction

perpendicular

to

the

motion ofthe

imaging

carriage

or paper processdirection.

The

slow-scandirection is

defined

as

that

whichis

perpendicular

to

the

fast-scan direction

and

is

in the

direction

of motion ofthe

carriage.In

the

scanning

lines

ofa cathode

ray

tube.

The

above

definitions

are

illustrated

in

Figure

2

and are

further described

in

HI.

>?

Slow-Scan Direction

Fast-Scan Direction

Original

being

scannedRelativemotion of sensor and original image scan carriage motion or process

direction)

!*"rrr. m

^

individualScan lines

(

orrasterlines)are representedby

columnsof thismatrix

FIGURE

2:

Imaging

Definitions

Image distortion

can occurwhen eitherthe

fast

or slow-scan ratesare

not constant.Perturbations

ofscanrates

in

eitherdirection

cause pixelsto

be

imaged

incorrectly

and

as a result createlocal

variationsin

the

reflectance

ofthe image.

Random

fluctuations

in

onedirection

cause

onedimensional

disturbances in

the

recordedimage. This

phenomenonis

termed

"banding"and

typically

refersto

image

distortion

causedby

disturbances

which occurin

the

processdirection.

Banding

in

scannedimages

refers

to

the

fluctuations

[image:14.523.72.452.144.388.2]output

image.

Thus,

to

faithfully

reproduce

aninput

and

keep

customerperceptions

ofscanning devices

favorable,

vibrationsin

the

slow-scandirection

must

be kept below

perceptible

limits

[2-3]

.To

avoid such errors

in the

image,

the

main objective of scan mechanismdesign

must

be

to

provide a

smooth, i.e.

constant,

slow-scan velocity.However,

friction,

systemdynamics

and

otherdisturbances

causevelocity

fluctuations

and

vibrationswhichmust

be

attenuatedif

image distortions

are

to

be

minimized.

The

useoffeedback

to

control slow-scan motionis

usually

anecessity,

but

evenwiththe

added

robustnessofa controlsystem,

vibrationand

image

motion problems can stillbe

present.Additionally,

downstream

processing

andimage

outputdevices

can eithermagnify

or attenuatethese

errors and

like

consideration mustbe

givento these

additionaldevices.

Thus

some

questionsremain, namely,

how

to

determine

the

perceptiblelevel

ofslow-scan motion error

and

whatis

an acceptablelevel

of vibration?Much

ofthe

published workrelating to perceptibility

and motionrequirements

is

concerned withprinting

oroutputdevices,

specifically

xerographic

laser

printersMl.

However,

the

psycophysical experiments usedto

determine

human

visionsensitivity to image

defects

are

still applicableto

input

scanning devices.

Visual

perceptual phenomenaare

highly

dependent

upon avariety

offactors.

Variations

in

exposureduration,

illumination,

viewing

distance,

image

significantly

shift

perceptibility

thresholds.

A

full

discussion

ofthese

parameters,

the

eye's

structure,

andthe

psychology

of perceptionis beyond

the

scope

ofthis

work.

The

reader

is

directed

to the

appropriate references[4-71

for

more

detailed information

onthese

subjects.

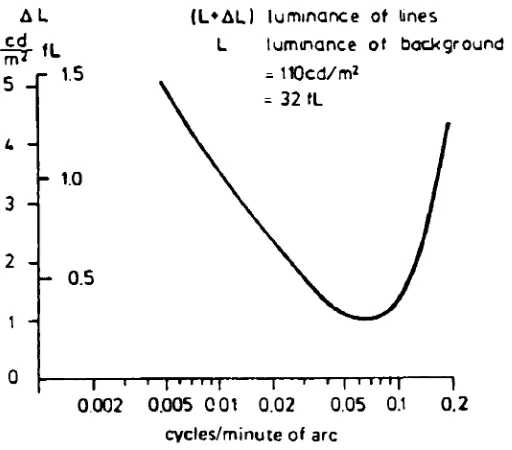

When

imaging

aspecific

pattern, if

groups

ofscanlines are

imaged

more

closely

together

orfarther

apart, the

average

reflectance ofthat

regionincreases

ordecreases,

respectively.

As

demonstrated

by

Hilzfs],

the

resulting

AL

cd

5

4

IL

r

1.5

(.

--

1.0

3

-2

-(L*ALl

luminance

of linesL

luminance

ofbackground

- HOcd/m*

-

32

tL

0.5

I 1

|

''"I

I r"'

I ""I

1

0002

0.005 0 01

0.02

0.05

0.1

0.2

cycles/minuteofarc

FIGURE

3: Contrast

Sensitivity

ofthe Human

Eye

to

Square Wave Gratings

8

periodicone-dimensional

brightness

fluctuations

and contrast

sensitivity

ofthe

human

vision system relatedto

local

frequency

is

depicted

in Figure

3.

Hilz's

work presentsthe

eye as most sensitive

(with

respect

to

background

[image:16.523.130.386.276.501.2]1

.2cyc/mm

(assuming

a300mm viewing

distance).

Bestenreiner

et

alIU

reinforce

the

supposition

that the

detectability

ofline

lattice

interference

structures

in

recorded

images

relies

uponthe

contrast

ofthe

lattice,

the

luminosity

ofthe

background

and

the

spatialfrequency

ofthe

lattice.

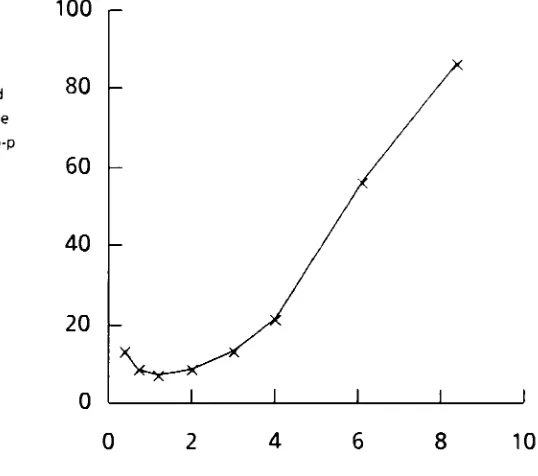

The

work ofHamerly

and

SpringerOl

(see

Figure

4),

in

regardsto

edge

100

r-Threshold

Amplitude

micronsp-p

80

-60

-40

20

-0

8

10

Spatial

Freguency

(cycles/mm)

FIGURE

4:

Perceptibility

Threshold

of

Edge Raggedness

8

detection

anddegree

ofraggedness,

alsosupports

the

presence

offrequency

select channels

in

the

eye

which mightbe

appropriate

for

describing

the

detectability

andthresholds

ofedge

raggedness.Figure

4

depicts

the

[image:17.523.120.389.215.453.2]frequency

based

upon a

viewing distance

of400mm. This

result

reinforcesHilz'

findings

and

describes

the

eye as most sensitive

to

errors

ofspatialfrequencies

in

the

0.5

-1

.2

cyc/mm

range.The

previous

findingsM-9]

and

Figures

3

and4

reinforce

the

inclination

to

develop

a

steady-state

motion specificationfor input scanning

devices

withthe

spatial

ortemporal

frequency

ofthe

motionas

the

independent

variableand

the threshold

amplitude

in

units ofdisplacement

asthe

dependent

variable.

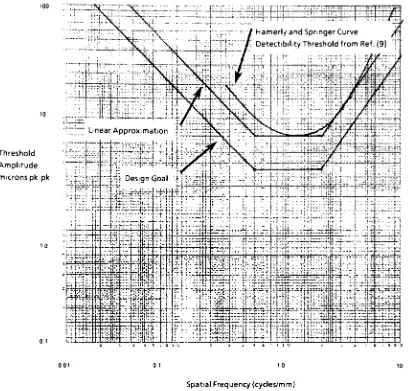

Replotting

Figure

4

on alog-log

scale

(see

Figure

5),

severalregions can

be

identified

and a

linear

approximation canbe

usedto

delineate

the

threshold

values ofperceptible

error.Furthermore,

since

the

curveindicates

threshold

values(i.e.

errorswithamplitudes above

the

curveare

noticible

to

anobserver)

,

dividing

the threshold

by

asafety factor

of2

yieldsaspecification which

may

be

anappropriate

design

goal.Realizing

that the

measurement

of motionis

aninevitable

task,

it

is

appropriate

to

expressthe

perceptibility

threshold

in terms

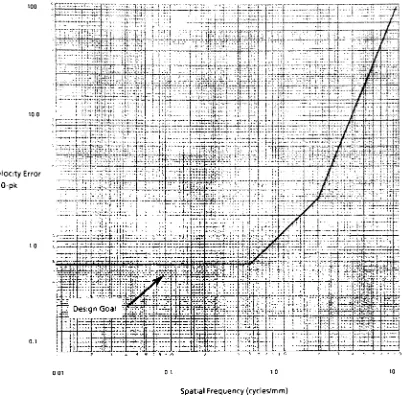

ofvelocity

error(as

shownin Figure

6)

to

accountfor

different

sensortypes.

Refer

to

Appendix

A

for

the

conversionfrom

adisplacement-based perceptibility

threshold

to

a velocity-basedperceptibility

threshold.

The

motion requirementsandthresholds

for

many

commercialscanning

devices

reflectthe

scanning

resolutionand

oftentake

into

consideration

the

anticipated outputor

hardcopy

devices.

For example,

a

xerographiclaser

Threshold Amplitude microns pk-pk

^ 3 1

001 0.1

Spatial

Frequency

(cycles/mm)

FIGURE

5: Motion Error

Detectability

-Threshold

Design Goal

requirements

are

typically

very

stringent

to

allowfor

this

uncertainty.It

should

be

notedhere

that

the

derivation

ofthe

specification curves

is

[image:19.523.63.474.75.466.2]100

Velocity

Error%0-pk

y||I

Sfe^^^^fM^^fg^

Jig

g|Mfi

,4lferfft|FtrHt:-'-nT3:-n^l1i:>r

;

r

Mist

*A~h:l\i\:

>!:

;. ;Design Goal '-.!2^Ip.

-t

4t-&j*

w-i'it 2D" TTTT XXt#tSE!;CI

13x1CAiErfejtSitip

lit * Jtjt."fci~ f'

;

"

-ty---rt.{.-jrtiS;'*.f;''* r.

Silt rH'~T

-i-r-n--'-tl-'"- t^^ffi^-rr-?

7* ::':^:::i ;:4...:_.:-..ai-;i4-;-. . --pif-p Si}:!a::::r r+f7'Trj '

0.1 10

Spatial

Frequency

(cycles/mm)

FIGURE

6:

Velocity

Error Design Goal

In

light

ofthe

abovediscussion,

the

characterization ofthe

scanning

systemand measurementof motion

are

the

maingoals

in

an

analysis anddesign

ofa

scanning

system.The

motion goalsdefined

in

Figures 5

and6

are

the

specifications.

Mathematical

modeling

and simulationtools

canbe

usedto

predict

the behavoirof

a

systembefore

any

hardware

is

constructed.These

[image:20.523.67.469.64.459.2]analysis.

Experimental

verification

ofany

simulationis

prudentand

oftena

necessity.

The

goal ofthis

workthen

is

to

discuss

the

basic

operation ofaparticular

scanning

system,

performthe

analysis and

simulationsto

predictthe

characteristics

ofthat

systemand

finally,

to verify

these

predictions withII

CONTROL

SYSTEM

PRELIMINARIES

It is

appropriate

to

engage

in

a generaldiscussion

ofthe

mathematicsand

basic

principles

ofcontrol systems

that

willbe

requiredin the

simulationprocess.

Control

systems are

usedin

a widevariety

ofapplications

to

enablea

desired

performance

of adynamic

system underchanging

conditionsand are

generally lumped

into

two

categories-open and closed

loop

systems.Open

loop

(nonfeedback)

systems are

less

robustand areeasily

affectedby

externaldisturbances.

A

closed

loop

system,

onthe

otherhand,

usesfeedback

to

monitor

the

output and

is

able

to

compensatefor

externaldisturbances.

Feedback

can alsobe

usedto

improve

the

linearity

ofasystem and enablesit

to

be

more

robustin

rejecting

externaldisturbances.

Figure

7

shows

the

basic

componentsofa closedloop

control system.The

CONTnni sic;mai <;

PLANT

ACTUAL OUTPUT

COMPENSATION

UNIT

REQUIRED

'

'

OUTPUT

FEEDBACK

SENS ORS

Figure 7:Basic Components

of aClosed

Loop

Control System

plant

defines

the

processor system whichis

to

be

controlledand

may

containany

number ofcontrollable variables.To

obtain optimalperformance

from

adjusted accordingly.

Feedback

is

provided

by

sensors

which monitorthe

variables

that

affect

the

performance

ofthe

plant.The

compensation unitmakes

acomparison

between

the

required output and

feedback from

the

plant,

determines

if

the

error

between

them

is

withinacceptable

limits

and

then

adjusts

the

control signals

to

the

plant

to

achieve

the

actual output.To

examine

how

closed

loop

controlsystems

canimprove

the

linearity

of asystemtiO],

consider

the

configurations

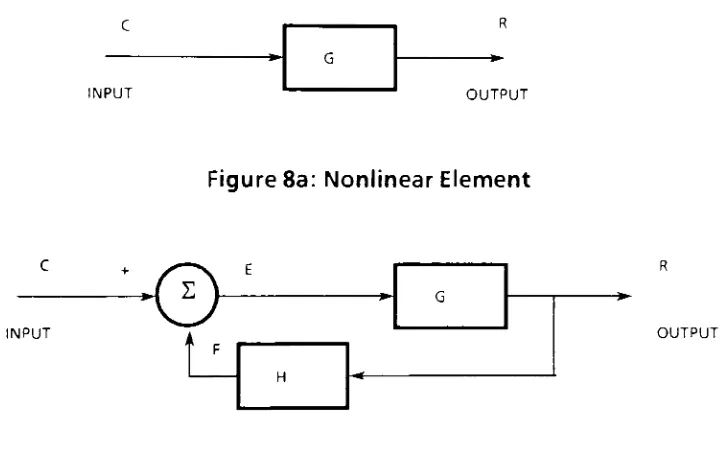

shown inFigure 8.

The input-output

c

G

R

NPUT OUTP

Figure

8a: Nonlinear Element

INPUT i

o

fc

G

J

' f

H

OUTPUT

Figure 8b: Nonlinear Element

withFeedback

relationship

for

nonlinear elementG

in

Figure 8a

is

R

= C2Figure

8b

shows

the

same nonlinear element with aunity

gainfeedback

loop

element

H

(H

=1).

The

equationfor

the

outputR,

in

terms

ofthe

input

C

for

the

closedloop

system ofFigure

8b

canbe developed

by

expressing

E

and

F

in

terms

ofC

[image:23.523.67.431.262.488.2]E

=C-F

E

=R/G

F

=HR

(2.1)

(2.2)

(2.3)

Substituting

2.2

and

2.3

for

E

and

F

in

equation

2.1

and

rearranging

yields:R

=CG

(2.4)

(1

+GH)

Figure

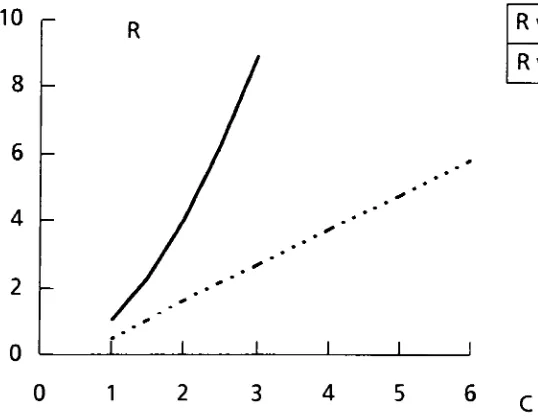

9

plots

both

the

open

loop

and closedloop

outputs versesthe

input

C.

The

output

R

ofthe

closed

loop

caseis

more

linear

and

follows

the

input

C

more

closely

due

to

the

feedback

loop.

10

6

4

2

0

R

w/ofeedback

R

w/feedback

Figure

9:Linearity

Improvement

Another

feature

ofusing

closedloop

controlis

that

if

designed

properly, the

system

may be

less

sensitiveto

plant variations.If the term GH

in

the

denominator

of equation2.4

is

madeto

be

suchthat GH>

>1,

then the

[image:24.523.66.335.286.495.2]R~

CG_

(2.5)

GH

and

further:

R

~C_

(2.6)

H

If

GH>>1,then

variations

in

G

willhave

little

or no affect onthe

ability

ofthe

control system

to

effectively

controlthe

processG

as shownby

2.6.

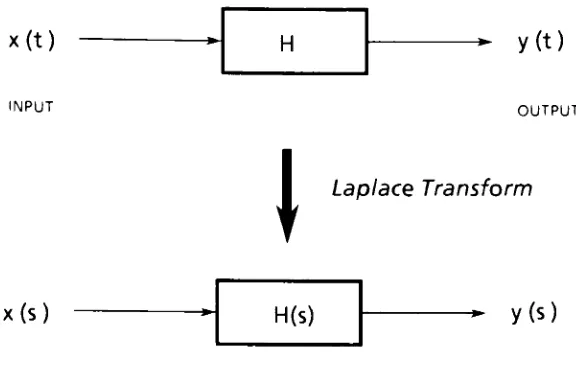

The

Laplace

Transform

and

Transfer

Functions

Another

tool

that

is

used whenanalyzing

and

modeling linear

control systemsis

the

Laplace

transform.

This

is the

main mathematicaltool

ofthe

controlsystem

designer

because

it

simplifies

the

manipulation oftransfer

functions.

The Laplace

transform

relates afunction

oftime

f(t)

to

afunction

F(s)

wherethe

variable,

s,

is

in

general a complex quantity.The

transform

is

defined

by

the

definite

integral

F(s)

=/.

{

f

(t)

>

= 0/-f(t)e-stdt(2.7)

The

mainadvantage

ofthe

transform

is that

differentiation

andintegration

operations

are

changedinto

simple

algebraic operations.Consider

the

block

diagram

in

the

top

portion ofFigure

10.

The

generic

function

H

can representany

mathemathicalrelationship

between

the

input

and

output.The

function

H

couldbe

a

constant valueindicating

a

linear

relationship,

a

first-order

pole ora

complexnonlinearfunction.

Applying

the Laplace

transform

to the

relationsdepicted

by

this

block diagram

wex(t)

H

y(t)

INPUT OUTPUT

\

Laplace Transform

x(s)

TRANSFORMED EXCITATION

H(s)

-y(s)

SYSTEM TRANSFER FUNCTION rRANSFORMED RESPONSE

Figure

10: Block Diagram

-Transfer Function

y(s)

=H(s)x(s)

(2.8)

Once

the

transfer

function

is

manipulated

to

the

properform

in

the

sdomain,

the

response

y(t)

ofthe

systemto

an excitationx(t)

may

be

recovered

by

the

inverse

Laplace Transformation

ofy(s)

represented

by:

y(t)

=Z.-1

{y(s)}

=M

{

H(s)

x(s)

}

(2.9)

Equation

2.9

canbe

usedto

derive

the

response

ofany linear

time-invariant

system subjected

to

anarbitrary

excitation.The Laplace

transform

ofthe

unit

impulse, 8(t),

is

8(s)

=J-8(t)e-stdt

=

e-st|t

=00/-8(t)dt=

1

(2.10)

[image:26.523.114.402.76.260.2]where

the

mean-value

theorem

has been

used.Inserting

x(s)

=8(s)

=1and

y(t)

=h(t)

into

2.10,

we obtain

h(t)

=M

{H(s)}

(2.12)

Thus

the

impulse

response

function, h(t),

of a constant coefficientlinear

system

is

equal

to the

inverse

Laplace

transformation

ofthe

transfer

function.

Furthermore,

the

unitimpulse

andtransfer

function

representaLaplace

transform

pair.Tables

oftransform

pairs,

applicablefundamentals,

andtheorems

ofLaplace

transform

theory

canbe

found

in References 10-1 3

and

will

not

be

covered

here.

Block Diagram

Reduction

-CDH

G,G2"3

1 + G,G,H2u3n2

Minor

Loop

reducedtosingleblockFigure 11b: Block Diagram Reduction

Block

diagrams

are

very

useful whenmodeling linear

systems,

however

the

analysis can getcumbersome

for

a

system withmany blocks.

The

reduction

ofa

large

systemis

accomplishedusing

equation2.4.

The

minorfeedback

loop

c +

a

-y~*Gi

\^J^G*

-*G'

-i

1

H2

*K

-1

H,

-* -1

Figure

11a: Minor

Loop

Feedback

shown

in

Figure

11b.

Further

reduction

ofthe

remaining

loop

in Figure 11b

is

represented

by:

R

=Gi G2G3

1

+G2G3H2

+G1G2G3H1

(2.13)

Control Laws

The

controllogic

elements

incorporated into

the

compensation unitare

designed

to

act uponthe

errorsignalto

produce

the

control orcompensation

signal.

The

algorithmthat

carries outthe

production ofthe

control signalis

the

controllaw

or compensation action.The

main controlobjectives are

to

minimize

steady

state

error,

minimizesettling

time

andachieve

othertransient

specifications such asminimizing

the

maximumovershoot.

Two

control

laws

that

form

the

basis

ofmany

control systemsare

two-position

and

proportional control.

As

the

nameimplies,

two-position

controlis

either

fully

on or

fully

off,

depending

uponthe

magnitude ofthe

error.

Proportional

control

implements

a

control signal proportionalto the

errorsignal

to

correct

Other

control

law

features

are possible

by

further

mathematical manipulationof

the

error signal.

By

using

the

derivative

and/orintegration

ofthe

errorsignal

in

conjunction

withproportional

control,

many

othertypes

of controlare possible.

The

transfer

function

X(s)

for

aproportional-integral-derivative

(PID)

controller

is

given

by

X(s)

=M(sl

=KP

+Ki

+KDs

(2.14)

E(s)

swhere

Kp, K|,

and

Kq

are

the

proportional,integral,

and

derivative

constants

respectively.

The

constants

Kp,

K|,

andKD

mustbe

chosencarefully

to

avoidinstability

and

to

yield an optimal response.References

10

and12

explainthe

advantages

ofusing

varioustypes

of controlfor

first

and

second ordersystems.

DIGITAL

CONTROL SYSTEMS

Digital

controlsystems are

fundamentally

different

from

continuoussystems

in

that

adigital

computeris

usedto

performthe

controllogic

operationsthat

are

requiredto

act

uponthe

error signal.Thus sampling

of acontinuous

variable

and

the

generation ofa

digital

compensation signalrepresent a

fundamental

departure

from

the

continuous systemanalysis

discussed

so

far.

The

respectiveeffects

upon systemdynamics

require

carefulattention.

The

sampling

period and

type

of control mustbe

selectedproperly

to

prevent

aliasing

ofthe

variablesand

possibleinstability.

The

control systemdiagram

changesslightly

withthe

introduction

ofthe

change

may

take

place.

Consider

the

digital

control system shownin Figure

Interface

Input +

Interface

<;

Output

^V

A/D Computer D/A PlantJ^

>

Sensor

Figure

12: Digital Control System

12.

The interface

atthe

input

ofthe

computeris

an analog-to-digital(A/D)

converter,

and

is

required

to

convertthe

continuous error signalto

aform

that

is

readable

by

the

computer.At

the

outputend

is

adigital-to-analog

(D/A)

converterthat

convertsthe

digital

compensation signalinto

aform

necessary

to

drive

the

plant.The

maindifference

from

a continuous systemis

that

some

portion ofthe

loop,

namely

the

controllogic,

is implemented

digitally.

Discrete

Time

Systems

Sampling

a continuoussignal canbe

representedby

the

closing

and

opening

ofa switch

as

shownin Figure 13. The

continuous signaly

(t)

is

sampled

uniformly

every T

secondsto

yieldthe

discrete

time

representation y*(t).The

sampled sequence

y*(t)

may

be

representedby

atrain

of unitimpulse

functions

occuring

atsampling

time

kT,

eachhaving

a

strength equalto the

o

o^Y

o

oContinuous

signal

y(t)

Discrete

signal y*(t)

Figure

13:

Uniform Sampler

withPeriod T

y*(t)

=y(0)8(t)

+y(T)8(t

T)

+y(2T)8(t-2T)

+=

E

y

(iT)

8(t

-iT)

fori

=0,1,

.,

N

(2.15)

The

sampler represented

in

Figure

1

3

does

notexist

in

real controlsystems

because

the

impulse

funtion

existsonly for

abrief instant

ofthe

sampling

interval

T. For

the

remainderofthe

sampling

interval

the

value ofthe

discrete

signal

y*(t)

is

equalto

zero.In

realsystems,

adata

hold

is

usedto

make

anO

^ CYT

Zero-Order

Hold

Continuous

Discrete

signaly*(t)

Digital

signaly(t)

Representation

Y(t)

y(t)

I

y*(t)f

Y(t)

|

.,

tin,

-"-t

0

T

2T

3T

0

T

2T

3T

Figure 14: Sampler

withZero

Order Hold

iT

<

t

<

(i

+1)T.

A

zero-order

hold

is

the

most

common althoughfirst

andfractional-order

data holds

are also

used.A

samplerand

zero-orderhold

andthe

associated

outputs are shown

in

Figure

14.

The

Z

Transform

The Z

transform

is

usedin the

analysis

ofdiscrete

time

systemsfor

the

analogous reasons

that

the

Laplace

transform

is

usedin linear

continuoussystems

-itmakes

the

analysis

easier.By

taking

the

Lapace

transform

ofthe

impulse

representation

of asampled

signalas

givenby

equation2.1

5

wearrive

at:Y*(s)

=y(0)

+ y(T)e-Ts + y(2T)e-2Ts +(2.16)

In

equation2.16,

the

shifting property

ofthe

Laplace

transform

has

been

used.

Using

the

definition

z = eTs

(2.17)

Y*(s)

may

be

rewritten as afunction

ofz:Y*(z)

=y(0)

+y(T)

1

+y(2T)

1

+. . .(2.18)

z z2

and

Y*(z)

is

the Z

transform

ofthe

function

y*(t).As

shownin

equation

2.18,

1/z

is

a

delay

operatorand

represents atime

delay

ofT. Thus the

powerseries

Y*(z)

=2 +3+6

2

+7 +...(2.19)

corresponds

to

sampled values

y(t)

=2, 3, 6,

-2,

7.

. .at

t

=0,

T, 2T, 3T,

4T.

.Tables

of

ztransform

pairs and

further discussion

ofthis

discrete

transform

can

be found

in

references

10,13

and

14.

Difference

Equations

The

control algorithms

ofadigital

control system areimplemented

by

discrete

time

approximations

oftheir

continuous

counterparts.This is

achieved

by

using

difference

equationapproximations

for

the

derivative

and

integral

parts

ofthe

controllaw.

First

difference

approximations are

often usedto

represent

the

slope

(derivative)

ofthe

error signale(t)

at

t

=kT:

forward

difference

backward

difference

(2.20)

central

difference

2T

Similarily

the

secondderivative

ofthe

error signale(t)

may

be

approximated

by

using

seconddifference

equations(see

Reference 14).

To

approximatethe

integral

term

/e

dt,

the

last

approximation ofthe integral

up to time

(k-1)T,

given asvk-i

is

used.The

approximationvk

up to

some

time

kT

may

be

written as:Vk

_Vk

_} +jek1

forward

rectangle rule

Vk

_Vk

^

+jek

backward

rectangle rule(2.21)

vk

=vu

+T(ek-i

+ ek)/2trapezoidal

ruleek

11

-ekT

ek

ik-1

T

Any

difference

equation control algorithm

is essentially acting

as a

digital

filter.

It

is

quite

different

from

an

analog

filter,

since

it is

implemented using

a

set

ofdigital

computer

instructions

ratherthan

a

physical circuit.As

anexample, the ouput,

Uk,

ofa

PD

(proportional-derivative)

digital filter

using

backward

difference

is

givenby

Uk

=KPek

+Kn(ek

ek-i)

(2.22)

T

For

further

information

on controlsystems

anddigital

control consultIll

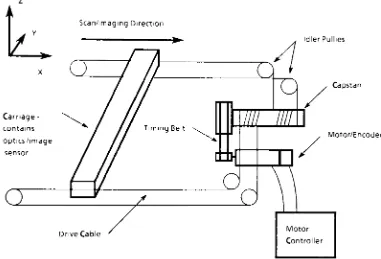

DESCRIPTION

OF

THE PHYSICAL

SYSTEM

The

physical system under

investigation

is

shownschematically

in

Figure

1

5.

An

original

is

placed

onthe

platen glass positioned at a

fixed height

in

the

z-direction

above

the

carriage.

The

carriage provides

the

relative

scanning

motion

in

the

xy

plane

between

the

originaland

the

image

sensor.The

motion

is

achieved

by

asingle-capstan

dual-cable

system(Figure

15).

The

Drive Cable

IdlerPulhes

Capstan

Motor/Encoder

FIGURE

15: Physical System

carriage

rides

ontwo

precision-ground carbon steelshafts

whichare

fixed

to

the

machine

base.

Five

bearing

surfaces supportthe

carriage

onthe

shafts.

This

configuration prevents rotation ofthe

carriageabout

the y

and

xaxes.

[image:35.523.74.455.214.473.2]from

the

drive

motor

(4:

1

drive

ratio).

The

feedback device

is

a

1000

lines/rev

incremental encoder.

Two

encoder

outputs,

90

degrees

out

ofphase,

yield aquadrature

output

ofposition

and an effective resolution

of4000

lines/rev.

A

4-pole

permanent-magnet

DC

motor

is

the

prime mover.

Specifications

for

the

drive

components

and

manufacturer's

literature

onthe

motor/encoder

package are given

in Appendix

B.

Figure

16

shows a

block diagram

ofthe

control andmechanical

systeminteractions.

The

control system produces

the

torque,

Tmot0r,

whichsets

the

mechanical system

in

motion.

The

dynamics

ofthe

mechanical system affect

the

motor position

whichis

the

primary feedback

variable.The

controlMicroprocessor

Position Xcarriage

Vcarriage

Acarriage Position Error

Command

^^-^ Digital

i PWM

Filter/ i amplifier/

DtoA

j

Motor Converter iCircuit

'motor

Motor/Capstan

Carriage Dynamics

+s

-. _ _ _ J

^motor

Sack EMF

Feedback

Position

^motor

Encoder

[image:36.523.66.475.345.581.2]hardware

is

based

onthe

Intel

80286

microprocessor

which residesin

a

personal

computer.

A

prototype expansion

board handles

decoding

ofthe

encoder

output,

digital

to

analog

conversion,

control

loop

timing,

andassigns

communication addresses.

Initialization

ofvariables and

generation ofthe

position and error commands are encoded

in

software

(C

language). Since

the

position and error commands reside

in software,

aninherent

flexibility

in

customizing

and

optimizing

these

portions

ofthe

control systemis

allowed.An

external pulse-width modulated amplifier

circuit,

based

uponthe

L298

integrated

circuit,

amplifies

the

errorcommand

to the

motor.Operationally,

the

motoris

commanded

to

ramp up

as shownin

Figure

17,

Velocity

(m/s)

Velocity

requiredfor 50% magnificationNominal

Velocity

Velocity

requiredfor 200%magnificationImagesensor

activated

[image:37.523.50.473.329.587.2]Time

(seconds)

and must

then

settle

to

anacceptable

constantvelocity

before

the

image

sensor

is

activated.

The

nominal

velocity

ofthe

carriage

depends

uponthe

speed and resolutionof

the

imaging

sensor.The

nominal

slow-scanvelocity

forthe

scanning

device

is 208

mm/s.This

correspondsto

a motorvelocity

of51

rad/s.To

provide

for 50

-200%image

magnification, the

carriage mustbe

ableto

scanone-

half

and

twice

the

nominalvelocity

(104

and

416

mm/s respectively).The

motion requirements

during

the

steady-stateorimaging

portion ofthe

IV

MATHEMATICAL

MODELING

For

the

scanning

system

underconsideration, two

distinct

subsystemscanbe

identified.

The

mechanical

subsystem

includes

several elements - scancarriage, cables,

drive belt

and motor.

The

dynamics

ofthese

lumped

elements are

readily

described

by

the

usuallaws

of classical mechanicsandthe

subsequent system

ofdifferential

equations.The

control subsystemelements,

however,

are considered

individually

due

to the

nonlinearbehavior

ofsome elements.

Each

function

ofthe

control subsystemis

represented

by

ablock.

By

using

the

appropriateassumptions,

arelationship

between

the

input

and

ouput variables ofthat

block

canbe

determined.

The

reduction of

the

control systemto

a mathematical modeldemands

that

eachelement and

its

behaviour be

thoroughly

understood.This

sectiondiscusses

in

detail

how

the

control and mechanicalsubsytems are modelled.Controls

Model

The

initial step in mathematically

modeling

the

control nucleus ofthe

scanning

systemis

a

more specificdefinition

ofits individual

controlelementsMO-14].

Figure 18

elaborates onthe

single-block representation ofthe

control systeminitially

givenin Figure 16.

Each

block

representsa

mathematical

relationship

between input

and

outputvariables.All

variablesdepicted

are time-varying.

This

systemhas direct digital

control ofthe

motorposition,

01,

and providesthe

forcing

function

torque

necessary

for

input

to

the

system ofdifferential

equationsthat

describe

the

dynamics

ofthe

mechanical system.

In

turn,

the

dynamics

ofthe

mechanical systemaffect

the

the

secondary

loop

variable

ofmotor shaft

velocity,G)i

.The

control systemPC

based

Microprocessor1 Position 1 Command ^ e

C>

i i i i up U PD Control LawKd

kp

v3

vm

Motor Circuit 1. 1 ,

-h

DAC PWM-(!)

+

\

*

'

Ts

1

+"

vb

BackEMF!

f KaCO,

|

Position ! Feedback Encoder ' from motorUi6

s4Nenc

e,

[image:40.523.52.475.108.350.2]\

inFigure 18:Controls

Block Diagram

consists of

a

digital

section and ananalog

section.The

microprocessorsamples

the

motorencoderevery

Ts

seconds(nominally

600psec)

to

obtainthe

positionfeedback,

f,

and comparesit

to

a positioncommand,

c.The

resulting

discrete

error,

e,

givenby

e =

f-c

(4.1)

isthen

digitally

filtered

using

a proportional/derivative

(PD)

controllaw.

The

discrete

corrected or compensatederror, up,

whichis

outputto the

Digital to

Analog

Converter,

(DAC),

canbe

expressed

using

the

present

valueThe

result

is

expressed

as

up

=Kpek

+_Kd_[ek-ek-i]

(4.2)

Ts

where

Kp

is

the

proportional

gainconstant and

Kd

is

the

derivative

gainconstant.

This

portion

ofthe

control system

is

encodedin

software, thus

the

derivative

and proportional

gainconstants

canbe

adjustedto

optimize systemperformance.

The

discrete

compensated

error,

up,

computed

by

the

microprocessorevery

Ts

seconds

is

then

converted

to

ananalog

signal, u,

by

the

D

to

A

converter,

DAC.

The

modelled

DAC

has

aneight-bit

resolutionand

maximum output voltageof

3.3

volts.Since

it is

adiscrete

device,

the

DAC

canonly

recognize

alimited

range of

digital input

valuesbeyond

whichits

outputbecomes

saturated.

Thus

the

range ofdiscrete

compensated error enabledby

the

DAC is

28/2

or128

encoder counts.A

valueabove

128or

below-128

willsaturatethe

DAC

and

limit

the

output voltageto

the

amplifier.Since

the

D to A

converter

must calculate an

analog

voltage,

a

computationaldelay

of10

microseconds

was

also

included in

the

representation ofthis

control element.Amplification

ofthe

analog

errorsignal, u,

is

accomplished

by

aPulse Width

Modulated

amplifier(PWM)

witha

switching

frequency

of20khz.

This

type

of

amplifier,

as

the

namesuggests,

modulatesthe

width ofthe

pulse sent

to

the

motordepending

uponthe

level

of errorbetween

the

command and

the

feedback.

Appendix

C

explainsthe

operation ofthis

elementin

more

detail.

The

resulting

ouput,

Va,

is

the

amplified command signalapplied

to the

motor

The

modelling

ofthe

permanent

magnet

DC

motorrequires some

simplifying

assumptionsti

1.15-19];

1

.Magnetic

fieldflux,cb,

created

by

the

permanent magnets

is

constant.

2.

The

torque

developed

is

proportional

to the

magnetic

field

flux,

cb,

and armature

current,

ia,

givenexplicitly

asTmotor

=Ky

dp

ia

(4.3)

3.

Nonlinear

affects,

suchas

torque

rippledue

to

the

commutationdiscrete

poles are

ignored.

4.

Induced

electromotive

force (Back

EMF)

is

proportional

to

motorshaft

velocity,

an

:+

a

j>

vm

o--\AAA

Motor

Figure

19: Motor

Circuit

Vb

=KeG0i

(4.4)

The

voltagewhich acts onthe

motorarmature,

Vm,

is

equalto the

amplified

command

voltage,

Va,

reducedby

the

back EMF

voltage,

Vb,

generated

in

the

motor armature.

Thus

The

motor

armature

may be

modelled

as an

R-L

circuit as represented

in

Figure

19

with adriving

voltage

ofVm.

The instantaneous

potentialdifference

across

the

inductor

is

La

dia

/dt

and

that

acrossthe

resistoris

givenby

Rm

'a-The

sum

ofthese

potentials equals

the

applied

voltageto the

circuitindicated

by

Ladja

+Rmia

=Vm

(4.6)

dt

Assuming

initial

conditions equal

to zero, the

Laplace

transform

ofequation4.6

results

in:

(LaS

+Rm)ia(s)

=Vm

(s)

(4.7)

or rearranging:

LsM.

=1

(4.8)

Vm

(S)

(La

S +Rm )

Thus

the

transfer

function

ofthe

armature

circuitis

described

by

afirst

orderpole and

canbe

writtenas

ia(s)

=1

(4.9)

Vm

(s)

Rm

(

xes +1

)

where

xe

is

the

electricaltime

constant ofthe

motor circuit.Consequently,

the

motor

does

notimmediately

respondto

aninput

voltagedue

to

armature

lag.

Multiplying

equation4.9

by

the torque constant,

Kj

, wearrive at

anexpression

for

the

generatedtorque:

Tmntnr(s)

=_J<I

(4.10)

Vm(s)

Rm(xes+

D

The

effective

motorvoltageis

the

applied voltageVa

less

the

voltageVm(s)

=Va(s)

Vb(s)

(4.11)

where

the

back

EMF

voltage can

be

writtenas

Vb(s)

=KeCOi(s)

(4.12)

Thus

generated motor

torque, Tmotor,

in

terms

ofthe

applied voltage androtational speed

ofthe

motor

is

Tmotor(s)

=(Va(s)-KpCOi(s))

Kt

(4.13)

Rm(xeS+

1)

Equation

4. 1 3

shows

the

dependence

of motortorque,

Tmotor,

uponthe

input

voltage,

Va,

and rotational speed

ofthe

motor,

coi,

as

well as alag

in

responsedue

to

the

inductance

ofthe

armature

windings.The

driving

torque,

Tmotor,

is

used asthe

forcing

function

in

the

system ofdifferential

equationsthat

describe

the

mechanical subsystem.The

last

controlelement

to

be discussed

is

the

encoder.Although

this

element

discretizes

motorposition,

it

wastreated

as

aconstant

-gain amplifierelement.

At

steady

state, the

lowest

velocity

ofthe

motoris

~4rev/sec.Th

is

corresponds

to

asample

rate ofthe

motor position at1

6.4

khz.

The

nominalsampling

rate ofthe

control systemis

1

.67khz. This

10:1

ratio

is

high

enoughto

preventaliasing

ofthe

motorposition.The

physical constantsand

specifications ofthe

scanning

systemare

givenin

Simple

Mechanical

Model

Assuming

sufficiently

high

belt

and cable stiffness and

neglecting

carriage

and capstan

dynamics,

the

mechanical

subsystem

may be

represented

by

alumped

inertia

at

the

motor shaftHBJ

.

Viscous

and coloumb

friction

arethe

resistive

forces

present.

Denoting

lm,

B,Tf

and

Tmotor

respectively

as

the

system-reflected

inertia,

damping

coefficient,

frictional

torque

and generated

motor

torque,

the

differential

equation

ofthis

simple mechanical model

reduces

to

lmdco

= -BwTf

+Tmotor

(4.14)

dt

where

a)

is

the

rotational

velocity

ofthe

motor.

Combining

the

frictional

and

driving

torque terms in

asingle

term,

TreS/

and

taking

the

Laplace

transform

yields

(lms

+B)co(s)

=Tres(s)

(4.15)

from

whichand as a result

co(s)

=1/(lms

+B)

(4.16)

Tres(s)

H(s)

=coisi

(4.17)

Tres(s)

Thus

the

transfer

function,

H

(s),

ofthe

simple mechanical model

is

also

afirst

order

pole

and

canbe

modelled as such.

The

block diagram

ofFigure 20

shows

the

motorand simple

mechanicalmodel.

Motor

position

canbe

obtained

by

simply

integrating

the

velocity

term.

This

simple model provides

MS>-

'Tiotor(s' V^(S)CO,(s>

T(s)

Back EMF

K

CO,

Motor

Position

To Microprocessor

Mechanical

Model

The primary

concern

ofthis

investigation

is

the

oscillatory

response

ofthe

scanner

in

the

process

direction,

and as

such, the

following

degrees

offreedom

which are

kinematically

responsible

for

this

motionare

taken

into

consideration:

1

.)Translation

ofthe

carriage

in the

xdirection;

2.)

Rotation

ofthe

motor about

the

xaxis;

3.)

Rotation

ofthe

capstan about

the

xaxis;

4)Rotation

ofthe

carriage about

the

zaxis.idlerPulhes

Motor/Encoder

Drive Cable Motor

Controller

FIGURE

15: Physical

System

Rotation

ofthe

carriage aboutthe

x ory

axis and

linear

movement

in

the

z ory directions is

prohibitedby

a

low-profile

carriage,

proper placement

ofthe

[image:47.523.74.452.282.567.2]to the

guide shafts.

Figure

1 5

is

reproduced

so

the

readermay

visualizethese

degrees

offreedom.

In the transition

from

the

physical mechanical

systemto the

mathematicalmodel,

several

simplifying

assumption are

made:1.

Natural

frequencies

ofthe

idler

pulleys are

high (>

500

hz).

Previous

workincluding

these DOF

in

the

model verifiedthis

assumption.

2. Idler

pulley

masses

arelumped

with other significant masses:2

lumped

with capstan mass/ 4

lumped

with carriagemass

3.

Rigid

mountings

i.e.

pulley

supports/

brackets

no structuraldeformation.

4.

Only

drive-side

springs are

included

5. Capstan /motor

is

constrained

to

rotate about

the

x axis.6.

Cable

acts as

linear

spring,

regardless ofcarriage

position(

k

measured

at

3

locations

within5%).

7 Rayleigh

proportionaldamping

is

assumed

@

5%,

consistantthroughout the

model(translational

DOF)

8. Friction

coefficientsare constant9. The

systemis

alumped

parametermodel,

withsufficient stiffness

in

the

carriageto

avoidfinite

element analysis.The lumped

parameter,

mathematical modelfor

the

translational

DOF

Timing

BeltCable Motor

Carriage

Figure

21

:Lumped Parameter Mathematical Model

(Translational

DOF)

From the

modeldepicted

in Figure

21,

the

equations of motionforthe

translational

DOF

canreadily

be

obtained[20-22]:Motor:

MQi

=Tmotor

-Ri[Ci(RiCO,-R2CO2)

+Ki(Ri9i

R202 )

]

Tfi

(4.18)

Capstan:

l2d2

=R2(Ci

(Rico,

R2a)2)

+K1(Ri0i-R202)l

-Rc[C2(RcO)2-V3) +

K2(RC02-X3)]

Tf2

(4.19)

Carriage

Translation:

M3

a3

=C2 (Rc"2

-V3) +K2

(Rc02

-X3 )

[image:49.523.70.478.93.328.2]Capstan

Assembly M2

c 12Motor M

Carriage

Figure

22:

Linearized Lumped

Parameter Model

(all

DOF)

Figure

<