Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

11-1-1999

Quantitation of yohimbine utilizing capillary

electrophoresis. Method development through

statistical design.

Jonathan Cooper

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion in Theses by an authorized administrator of RIT Scholar Works. For more information, please contactritscholarworks@rit.edu.

Recommended Citation

Quantitation

of Yohimbine

Utilizing Capillary Electrophoresis.

Method Development through Statistical Design.

Jonathan W. Cooper

Novembe~,

1999

Thesis

SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE

DEGREE OF MASTER OF SCIENCE

APPROVED:

Paul A. Craig

Project Advisor

G. A.

Takacs

Department Head

Rochester Institute of Technology

Rochester, New York 14623

Copyright Release Fonn

QUANTITATION OF YOHIMBINE UTILIZING CAPILLARY ELECTROPHORESIS.

METHOD DEVELOPMENT THROUGH STATISTICAL DESIGN.

I, Jonathan William Cooper, hereby grant pennission to the Wallace Library of the

Rochester Institute of Technology to reproduce my thesis in whole or in part. Any

reproduction will not be for commercial use or profit.

Date:

Iz/1/9~

I

ACKNOWLEDGEMENTS.

Iwould

like

to thank myadvisor, Dr. PaulCraig,

withoutwhomthis researchwould nothave been

possible. His continuing support and suggestion were essential towardsdriving

this project to completion, andhis faith in

my abilities allowed me to begin todiscoverand

develop

myownprofessionalinterests.

Many

thanks toDr. Carol Marchettifor

her

contributions to the statistical aspects of this study. Her enthusiasm andmotivation

helped

to turn a seeminglyimposing

statistical tool into aninteresting

andbeneficial

challenge, onethatIhopeothers willfollow my footstepstoward. Iwould alsolike

to extend my gratitude to JamesWesley

forhelping

direct the path of thisinvestigation,

and Dr. T. C. Morrill for his guidanceduring

my graduate career. I thankthe Rochester Institute of

Technology

Department ofChemistry

for

giving me theopportunity to earn this

degree,

as well as providing me with a solid educationalfoundation fromwhichIcanexpand.

I thankmy

family

for

theirunconditional love and understanding. These pastfew

yearshave

been challengingfor

all of usin

ways otherthan academic,but

somehow wehave

been able to maintain and even

develop

our unique relationships. As I complete thisproject and

look

toward thefuture,

there are alarge

number of uncertainties that I willACKNOWLEDGEMENTS.

I would

like

to thankmy advisor, Dr. PaulCraig,

without whomthis research would nothave been

possible. His continuing support and suggestion were essential towardsdriving

this project to completion, andhis faith

in my abilities allowed me to begin todiscover

anddevelop

myown professionalinterests.Many

thankstoDr. Carol Marchettifor

her contributions to the statistical aspects of this study. Her enthusiasm andmotivation

helped

to turn a seeminglyimposing

statistical toolinto

aninteresting

andbeneficialchallenge,onethatI hopeotherswillfollow my

footsteps

toward. Iwould alsolike

to extend my gratitude to JamesWesley

forhelping

direct the path of thisinvestigation,

andDr. T. C. Morrill for his guidanceduring

my graduate career. I thankthe Rochester Institute of

Technology

Department ofChemistry

for giving me theopportunity to earn this

degree,

as well as providing me with a solid educationalfoundation fromwhichI canexpand.

Ithank my

family

fortheir unconditional love and understanding. These pastfew yearshave

been challengingfor

all of us inways otherthan academic,but

somehow wehave

been able to maintain and even

develop

our unique relationships. As I complete thisproject and

look

towardthefuture,

there are a large number of uncertainties that I willTABLE

OF CONTENTS.

ABSTRACT

iINTRODUCTION

1Yohimbine

Background 1History

ofCapillary

Electrophoresis 4Theory

ofCapillary

Electrophoresis

7Modesof

Capillary

Electrophoresis 10Factorial Experimental Design 13

Summary

19Definitions 20

MATERIALS AND METHODS 23

Reagents 23

Instrumentation 24

Commercially

AvailableProducts 25Methods 27

ExperimentalDesign

27

PreparationofBuffers

for

Capillary

Electrophoresis

32Methodsof

Extraction

35Optimized Extraction

ofCommercial Samples

40Instrumental Methods

41RESULTS 44

Factorial Design

One

(Fractional)

44Factorial Design Two

(Full)

50Optimized Experimental Conditions 54

Commercially

Available Products 55DISCUSSION 59

Factorial Design One

(Fractional)

59FactorialDesign Two

(Full)

69Optimized Experimental Conditions 71

Commercially

Available Products 72Summary

72Future Work 73

REFERENCES 74

FIGURES.

Figure

1.Molecular

structure of yohimbine 2Figure 2. CE Schematic 7

Figure 3.

Capillary

wallinteractions

9Figure 4. Reverse

laminar

flowdiagram

10Figure 5. 'Plug-like'

flow diagram

10Figure 6. Designgeneratorsfor factorial designone 28

Figure 7. Run 13andRun 16

factorial design

one 46Figure 8. Run 2andRun 14factorial designone 47

Figure 9. Maineffects plot

Area(2)

48Figure 1 0. Run 1 5 andRun 1 6 factorial designone

49

Figure 1 1. Run 2 andRun 34

factorial design

one 50Figure 12. Run 5 andRun 7 factorialdesigntwo 52

Figure 13. Run 5 andRun 6 factorial designtwo 53

Figure 14. Run 1 andRun 5 factorial designtwo 54

Figure 15. Yohimbinecalibrationcurve 56

TABLES.

Table 1. 23

factorialexperimental design 14

Table 2. 25 factorialexperimental

design

16Table3. y4 fractionof

25

Table 4. Factor levels

chosenfor factorial design

one 28Table 5. Designmatrix

for factorial

design one 29Table 6. Factor

levels

chosenfor factorial design

two 31Table 7.

Design

matrixfor factorial design

two 31Table 8. Methods

for factorial

designone 42Table

9.Methods for factorial

designtwo 42Table 10. Method forcommercial analysis 43

Table 1 1. Descriptive statistics

for

factorial designone 44Table 12. pvalues of

factorial

designone 45Table 13. Descriptivestatisticsfor factorial designtwo 51

Table 1 4. pvaluesoffactorial designtwo 51

Table 15.

Commercially

availableproducts 55Table 16. Tenextraction conditions 56

ABSTRACT.

In an effort to combat the rising cost of

health

carein

the United Statesby

encouraging preventative and self-care, the

federal

government passed theDietary

Supplement

HealthEducation

Act of1994. This act essentiallyderegulated

the naturalproduct market allowing

herbs,

including

yohimbine, tobe

sold overthe counter withoutundergoing the same strict evaluation as a traditional synthetic

drug

candidate. As thefull

potential ofthesenaturalproductsis

realized,including

possibleharmfulside effects,a need arises

for

theidentification

and quantitation of the active components fromcommercial preparations.

Commercial samples were qualitatively and quantitatively analyzed for

yohimbine utilizing a capillary electrophoretic method optimized through statistical

design.

Calibration curves produced with this method routinely achievedR2

> 0.998.

Method reproducibility (n =

10)

and extraction efficiency (99.8% recovery) weredeterminedtobe sufficient. Itwas shownthata statistical designcould

limit

the amountof experimental runs while providing a significant amount of

information

aboutINTRODUCTION.

Yohimbine Background.

The West African tree

Yohimbe is located

in thelow

altitude,jungle

forestsenveloping southwestern Nigeria.

Growing

from 20 to 50feet

high,

this tall evergreenforest

treehas

glabrous,leathery

leaves

three tofive inches in

length with upcurvinglateral nervesthat

fade

out at the margins. Whiteflowers,

containing winged seeds, arearranged

in

umbel-like clusters attheends oftheshoots(1,

2). Itis

thecompoundsfound

inthe

bark

ofthis tree thathave

historically

drawnattentiontowards theYohimbe.Documentation of the

Bantu-speaking

peopledescribes

yohimbe as anaphrodisiac andstimulant

traditionally

usedduring

mating ritualsthat last upto 15 days.There are several methods ofpreparing yohimbe bark for use (2). A tea

is

preparedby

boiling

yohimbe bark shavings in waterforless

than fourminutes. Heatis

then turneddown,

allowing the brew to simmerfor

an additional 20 minutes. The shavings arestrained,andtheteaissipped onehour beforethedesiredeffects aretoberealized.

A method that leads to the effects in a shorter time after

ingestion involves

extractionofthebarkpowder witha

drinkable

alcohol. Aftera period ofeighthours,

thealcohol

is

strained and evaporated,leaving

a residue that canbe

snuffed or takensubcutaneously. Effects through this method are more pronounced, occurring within

twenty

minutes (2).The bark is reported to contain up to 6% yohimbine

(Figure

1),

along with anumber of similar indole alkaloids

including

yohimbenine,isoyohimbine

H,COOC

QH

[image:14.537.190.348.35.147.2]Yohimbine

Figure 1. Molecularstructure ofYohimbine.

the

form

of thehydrochloride is

also known as quebrachine,isolated

from the SouthAmerican evergreenQuebracho tree

(2, 3)

as well asfrom

Rauwolfia viridisleaves

(4),

Rauwolfia caffra root bark and seeds

(5),

Rauwolfia serpentina root(6),

Rauwolfiaoreogiton root

(7),

Rauwolfia volkensii root(7),

Rauwolfia vomitoria root(8),

andRauwolfiayunnanensis(9).

Yohimbine is the most

interesting

alkaloidfrom

these sources,having

gainednotoriety in a number of circles as an alternative medicine treatment. Suggested for

humanuse in

bodybuilding

as an alternative to anabolic steroids(1, 10),

yohimbinehas

been employed in veterinary medicine as an antagonist for anesthesia and sedation of

animals, as well as

for

the treatment of impotent stallions(11,

12). Classified as analpha-2-adrenergic

blocker,

this sympathomimeticindole-type

alkaloid alsodisplays

serotonin

inhibiting

properties(1,2). Inboth

humansand animals,yohimbine produces acomplex patternofresponsesthat includeanti-diuresis and central excitation, comprising

elevation ofblood pressure and

heart

rate, increased motor activity andirritability

(13).

Recent focus

has

beenconcerned withtheaphrodisiacproperties and use of yohimbine asThe marketing of yohimbine

falls

under theDietary

Supplemental HealthEducation

Act(DSHEA)

of1994,

a governmental efforttolimit

the skyrocketing cost ofUnited

States health

care thathas

essentiallyderegulated

the natural product market.Natural

products are not strictly evaluated pre-market as a synthesizeddrug

candidatewould

be,

and tend todraw

scrutiny only when adverse effects are noted as a result ofconsumer use.

Regulatory

action toward another natural product with central nervoussystem stimulant properties, ephedrine, arose only after toxic

levels

were witnessedclinically

(36,

37). These complications may be due to the inherent properties of thesources

from

which these natural products areharvested,

namely vegetation. Alkaloidquantitiesfromtwo

distinct

plantsmay be different from differentregions,quantitiesmaybe different betweentwodistinctplantsinthesameregion, orquantitiesmay

be

differentbetween

two leavesonthesametree. Apreparation of naturalproductsmayin

turnhavevarying concentrations between

batches,

betweenbottles,

and even between pills in thesame

bottle for

this reason. Thisis animportantconsiderationforacompoundthathas

asmall range between a therapeutic dose and toxic

dose,

when product variance couldmeanthedifference between lifeanddeath.

Asthe drawbacksoftheDSHEAareeventuallyrealized and attention

focuses

ondose

reproducibility, qualitative and quantitative characterization of many naturalproducts,

including

yohimbine,will gainimportance. Efforts have thusfar been

reportedtoward the identification and quantification of yohimbine

in

commercial products andbiological fluids utilizing fluorescence

(6),

ultra-violetspectroscopy(UV) (5-8),

infrared

spectroscopy

(IR) (7, 8),

nuclear magneticresonance spectroscopy(NMR)

(8),

thin-layermass spectroscopy

(GC/MS)

(8, 13),

gas-liquid chromatography(GLC)

(5),

liquid

chromatography

(LC)

(40),

andhigh-performance

liquid

chromatography(HPLC)

(6, 13,

39-44). There

have been

no reportedinvestigations

of yohimbine utilizing capillaryelectrophoresis, a technique that

is

swiftly gaining prominence in the analyticallaboratory.

History

ofCapillary

Electrophoresis.Inthe 1930's Arne Tiselius developed the first moving

boundary

electrophoresismethodutilizinganopenU-shapedquartzcolumn. Proteinmixtures in freesolution were

partially resolved as abutting bands detected

by

ultraviolet absorbance (45).However,

this pioneering technique had

drawbacks

that included large sample volumes, and anincomplete separationoftheproteins.

Investigation ofimproved anticonvective media in subsequent

decades directed

the

focus

toward zone electrophoresis. Polyacrylamide gels,developed in

thelate

1960's,

contain stacking and resolving buffer systems that yield native protein andsodium dodecyl sulfate

(SDS)

boundprotein separations (46). Knownas polyacrylamidegel electrophoresis

(PAGE)

andSDS-PAGE,

these techniques continue to givehigh-resolution separationsasimportanttoolsin biochemical characterization.

Around the time PAGE was designed to separate proteins on the

basis

of chargeor size, an investigation was underway to

develop

a separationbased

on proteinisoelectric points. Isoelectric

focusing (IEF)

employs a gel containing animmobilized

deprotonated

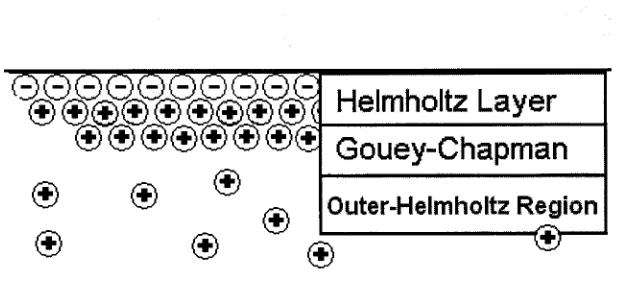

(50). Hydratedbuffer

cations coordinateto the anions atthe capillary wallto

form

the rigidHelmholtz

layer,

and the mobile Gouey-Chapmanlayer

to completeelectroneutrality

(Figure

3). Adrop

in

negative potential, describedby

the zetapotential,characterizes the Gouey-Chapman

layer:

the magnitude of wall negative charge isdirectly

proportionaltolayer

thickness. Whilethisregion extendsonlyafewnanometersbeyond

the Helmholtzlayer,

itis

the mobile cations contained within that generatebulkelectroosmotic

flow.

Mobile hydratedcationsoutnumbermobileanionsinthis area,Helmholtz Layer

|

Gouey-Chapman

Outer-Helmholtz

Region

Figure3. Interactionsatthecapillarywallthatfuelelectroosmotic

flow. Notshown:hydratedanionsinthediffuse layer (Outer-Helmholtzregion).

resulting in a net

flow

toward the cathode under an applied voltage.Immediately

uponthe application of voltage, cations in this layer will have a greater velocity then the

remainderofthe capillary cross section. The resultantflow profile may

have

a paraboliccharacter asthe electrophoretic mobility ofcations inthe

diffuse

portion ofthe capillaryare partially shielded

by

coordinated mobile anions with an opposite pe.This

phenomenon would appear similartoalaminar

flow

profiletowards the anode,but in fact

[image:17.537.105.415.262.405.2]'plug-}

Figure 4. Reverse laminar flowdiagram

like'

flow is

obtained at any cross sectional areabeyond

the Helmholtz plane, as thispulling force

is

uniformforthelengthofthecapillary. Cationflow

nearthecapillarywallinside

the rigid Helmholtz layer approaches zero, resulting in the accepted depiction ofelectrically driven flow (Figure 5).

r

]

p.

+|

>

h

T_

, ,:- *

Figure 5.'Plug-like'electroosmoticflow

Modesof

Capillary

Electrophoresis.The term capillary electrophoresis describes the

family

of separation techniquesbased

onthe mobility differences of charged species under an applied voltage.Mention

shouldbe givento the variations onthis empirical analytical technique that

have

gained [image:18.537.113.424.402.476.2]popularity toward specialized analysis. A summary of the notable techniques and

applications

follows.

Capillary

ZoneElectrophoresis

(CZE).Capillary

zone electrophoresisis

theelectrophoretic separation ofions

inabuffer

solution under an applied voltage.

Micellar Kinetic

Capillary Chromatography

(MEKC).Upon the addition of anionic surfactant molecules above a critical micelle

concentration

(CMC),

hydrophobic

tails ofthese molecules coordinate, exposing theirhydrophilic heads and assuming a spherical shape characteristic of a micelle. These

micelles

have

a ue toward the anode. Analytes inthiselectrophoretic system are furtherresolved on the basis of

hydrophobicity

asinteraction

with the micellesdelays

theobservedmigration.

Capillary

Gel Electrophoresis (CGE).The capillary

is

loadedwith agel, such as polyacrylamide, commonly employedin

PAGE. Analytes are then separated based on charge to size ratio under an appliedvoltage. This technique

has

a high resolving powerfor

proteins, peptides, and aminoacids.

Capillary

IsoelectricFocusing

(CIEF).

An electrolyte

containing

a mixture of ampholytes and sampleis

loaded onto thecolumn.

When

voltageis

applied, the ampholytes migrate to form a continuous pHgradient

in

thecapillary.Analytes

migrateto thelocationoncapillarythatcorrespondstotheir pi. Thevoltageisremoved, and capillarycontentsare elutedpastthedetectorunder

an applied pressure.

Capillary

Isotachophoresis (CITP).This

is

a movingboundary

electrophoretic technique. The sample plugis

introduced after a

leading

electrolyte with mobility faster than the fastest analyte, andbefore a

terminating

electrolyte of slowermobility than the slowest analyte. Compoundsare resolved withinthe sampleplugasitmigratestowardthedetectionwindow.

Capillary

Electrochromatography

(CEC).CEC is acapillaryelectrophoretic techniqueutilizing acapillary packed with one

ofanynumber ofstationaryphases used in HPLC. This technique can employpressure,

voltage, oracombinationofthe two asthe

driving

separationforce. This isuseful intheseparation ofcharged analytes that differ

in hydrophobicity.

Theinvestigation

ofthistechnique has aided

in

the advancement ofmicro-HPLC systems, as pumptechnology

advances.

Factorial Experimental Design.

Recently,

statistical experimentaldesigns have been

increasingly

employed as auseful option

in

analytical methoddevelopment.

A factorial designis

equipped toaddress several major experimental concerns

for

which the traditional One Factor at aTime

(OFAAT)

trialand errordevelopment

techniqueis

not suited(52).Jointeffects or

interactions

aretheeffectthat the simultaneous variationoftwo ormore experimental parameters will

have

on response. These effects can only beidentified and studied

by

the correlative change ofthe selectedfactors.

The OFAATmethod

involves

systematically optimizing one experimental variable, whileholding

allother variables constant. The method is then optimized for a second variable, again

keeping

all other variables constant. Subsequent variables are investigated in the samemanner. To evaluatejointeffects withthis

design,

it is necessary to reevaluate variableoneupon optimizationofvariable

two,

then thereevaluation of variabletwowithchangesin variable one, eventually moving through all variables

in

this systematic approach.Clearly,

the number of experimental runs would quicklybecome

exhausting as thenumber ofinvestigatedvariablesincreased.

A factorial experimental design allows for the systematic

investigation

ofjoint

effects

by

enablingastatisticalanalysistointerpretthesignificanceoffactor

levels,

whilelimiting

the number ofexperimental runs needed. Thisdesign

is useful when expense,quantityofmaterialortimeare

limited,

as experimentnumbers aresignificantlyreduced.There are several software programs that are capable of

handling

the complexcalculations to analyze data from a factorial

design,

but it is useful to understandhow

thesevaluesarecomputedtoemploythis technique.

development

ofthe methodfor synthesizing

ampholyte mixturesfor

high-resolution IEFin

1969,

still a separationtechniquefound

inthemodernbiochemistry laboratory

(47).O'Farrell

combinedIEFwithSDS-PAGE in

the1970's,

creatingtwo-dimensionalelectrophoresis, a technique capable of resolving more than 50 components in each

direction.

Utilizing

anisoelectric

point separation followedby

an electrophoreticseparation

in

the perpendiculardirection,

several thousand compounds canbe

isolatedwiththis approach(48).

During

thelate

1970's,

thefamily

of gel electrophoretic techniques gainedacceptancein

biochemistry

laboratories,

openingdoors

for investigationofprotein-basedbiopharmaceuticals.

Meanwhile,

high performanceliquid

chromatography(HPLC)

wasgaining notoriety as an analytical tool in pharmaceutical and chemical laboratories.

Along

withhighresolution, HPLC offeredease ofautomation,andexcellent quantitativeprecision for the determination of low molecular weight compounds and

industrial

polymers (49). As gel techniques were applied in an industrial setting, their detection

limitations and inherent

lengthy,

involved

preparation proceduresdid

not comparefavorably

to the swift and reliable chromatographic techniques employed at the time.This prompted pharmaceutical and bioanalytical chemists in these

fields

to turn theirattentionto HPLC for biomolecule characterization as protein, peptide, and nucleic acid

chromatographic mediabecame available

during

theearly1980's,

(50).

A strong environmental awareness movement occurred in the

1980's

as thebiotechnology

field broadened. Thisinvolved

a chain of events effectivelyincreasing

waste disposalcosts. Amain analyticaltoolatthis

time,

HPLC,

routinelygenerateslarge

Consider

the case of afull

factorial

2k= 23

design:

variation ofthree

factors (k

=3)

at twolevels.

For example; the effect oftemperature (factor A:25,

37),

pressure(factor B: 1 atm, 3 atm), and wavelength(factor C: 300 nm, 500 nm) on photosynthesis

by

a newlydiscovered

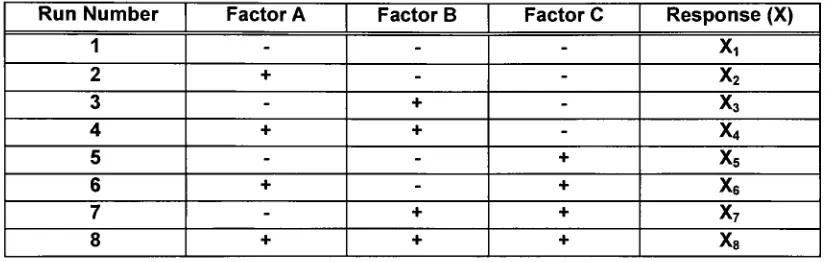

algae. An experimental run chart is assembled and completed, [image:23.537.55.470.228.359.2]recording theresponse (Table 1). Therearefoursets ofexperimentalruns where factor

Table 1. 23

Factorialexperimentaldesign. Threefactors

(A,B,C)

attwolevels: low(-)

andhigh (+).Run Number Factor A Factor B FactorC Response

(X)

1 - -

-X,

2 + -

-x2

3 - +

-x3

4 + +

-x4

5 - - +

x5

6 + - +

x6

7 - + +

x7

8 + + +

x8

A

is

varied asfactors

B andC remained constant. Runs 1 and2,

where Achanges whileB andC areboth negative:Runs 3 and

4,

where Bis

positive, and C isnegative: Runs 5and

6,

where B is negative and C is positive: Runs 7 and8,

where B and C are bothpositive.

Therefore,

theeffect offactor Acanbe describedthroughEquation 2.Effect A=

((X2-XQ

+(X4-X3)

+(X6-X5)

+(Xg-X?))

4Thenumber generateddescribestheeffectofmoving froma

low

toahigh level

inA,

regardlessofthe levels ofB andC. Thiscalculationcanbe

completedfor

each ofthefactors

employedinafactorial designtodeterminetheireffect(52).

Joint

effects arehandled in

a similar manner. Forthis analysis, thedesign has

twopairs of

data

points with a variation ofA;

one atthehigh

level ofB,

the other at the lowlevel,

while C remains constant. Halfofthedifference

ofthese two pairs isthevalue oftheAB

interaction (Equation

3).Effect Aat positiveB=

((X

-X7)

+(Xfi

-Xs))

2Effect AatnegativeB=

((X*

-X,)

+(X,

-X^)

2Effect AB=((Effect A

atpositive

B)

-(Effect Aat negative

B))

32

Scheme 1.

This calculation can be completed for each factor of interest to

determine

themagnitude of joint effects.

Utilizing

computer software in thehandling

of theseequations

dramatically

lowersanalysistimefor

thisas well asalarger

model.Dueto the number offactorsthataffect a separation in

Capillary

Electrophoresis,

a factorial design presents an

interesting

choicefor

athoroughly

systematic methoddevelopment. Separation voltage,

temperature,

buffertype,

buffer pH,buffer ionic

strength, column

length,

organic modifier concentration,injection

type,

andinjection

setpoints are nine relevant factors. To investigate the main and

interaction

effects ofthese ninefactorswitha

full

factorialdesign,

k=9,

and29

or 512 runs would

be

needed.It

is

possibletolowerthis number, utilizingafractionalfactorial design

(55,

56).Fractional

Factorial Design.

There are several advantages to utilizing a fractional factorial design when the

numbers of experimental variables

in

afactorial

investigation are large. There islittle

loss

ofinformation

whilesignificantly

lowering

the length of experimentation(52,

53).Considerthe

design

of a2s

[image:25.537.72.469.223.690.2]factorial

experiment(Table 2). This investigationwouldTable 2. 2 Factorialdesign.(Fivefactorsattwolevels,centerpoints excluded).

Run Factor A Factor B Factor C Factor D FactorE Response

(X)

1 - - -

-^

2 + - - -

-x2

3 - + - -

-x3

4 + + - -

-X4

5 - - + -

-x5

6 + - + -

-Xe

7 - + + -

-x7

8 + + + -

-X8

9 - - - +

-x9

10 + - - +

-X10

11 - + - +

-X11

12 + + - +

-X12

13 - - + +

-X13

14 + - + +

-X14

15 - + + +

-X15

16 + + + +

-X16

17 - - - - +

X17

18 + - - - +

X-I8

19 - + - - +

X19

20 + + - - +

X20

21 - - + - +

X21

22 + - + - +

X22

23 - + + - +

X23

24 + + + - +

X24

25 - - - + +

X25

26 + - - + +

X26

27 - + - + +

X27

28 + + - + +

X28

29 - - + + +

X29

30 + - + + +

X30

31 - + + + +

X31

32 + + + + +

X32

requirethe collection of

32 data

points.Generating

afractional

factorialdesign

of a%

fraction

ofthis tablewould requireonly8

experimental runs(Scheme2),

witha2(k-s)=2(5-2)=23 =

8

Where

k

-number of

factors

and sis

derived fromtheequation1/4=(l/2)s

Wherethe fraction=1/4.

Scheme 2. Generationof a%fractional factorial designoffive factorsattwolevels(k=

5,s= 2).

minimum ofinformation

loss

duetoconfounding.Any

3(k-s)

factors

are setup inafull

factorial

experiment. It isfirst

necessary to determine design generators (53). Designgenerators represent the products ofmultiplying together a combination ofthe + and

values from these first three columns. It is necessary to utilize s number of unique

generators

for

a fractional factorialdesign;

these generators must not be theproducts ofanyother generator combination(Scheme 3). Thevalues

for

thefourth factor

column areproduced

D =

AC,

E=ABAC * AB=AACB=

CB

Scheme3. Designgeneratorsforfactors DandE. Theimplicit designgeneratorisCB,theunique product ofDE.

by

multiplying the + or - incolumns A andC,

corresponding to the

design

generatorfor

variable D and resulting in a + or . The values

for

thefifth factor

column are thenproduced

by

multiplying

the + or-in

columns A andB,

corresponding todesign

generatorE. Theresult

is

a V*fraction

of a25

[image:27.537.72.466.147.280.2]factorial design

(Table 3).Table 3. Vafractionof a

2s

factorial design.Generators D=

AC,E=AB.

Run Factor A Factor B Factor C Factor D FactorE Response

(X)

1 - - - + +

Xi

2 + - - -

-x2

3 - + - +

-x3

4 + + - - +

x4

5 - - + +

-x5

6 + - + +

-x6

7 - + + - +

x7

8 + + + + +

x8

Therearethree additional quartersthatcanberepresented

by

thedesigngenerators D =-AC andE=

-AB,D =AC and E=-AB, orD

=

-AC andE =AB. The quarter chosento

be

utilizedisarbitrary.It

is

importanttounderstandandaccountfor confoundingfactors.

Ifseveralmeasurementsaremade whentwofactorsare atthelower

level,

and alsowhenthe twofactors

areat ahighlevel,

butnot whenthefactors

are atdifferent

levels,

the effectduetothe individual

factors

cannotbeestimated.Any

information lost inafractional design

canbeattributedto these confounding factors.

Resolutionof afractional factorial

design is determined

as the minimum numberof variables employedinthe design generators, a number thatrelates to the

confounding

offactor interactions. Intheexampleabovefora%

fraction

of a25

design,

theresolution(R)

is

calculated as R= 2. Effectshaving

an orderless

than 2 are not confounded withany othereffect with order

less

thant =Rof

4,

main effects(e

=1)

are not confounded with any othermain effect (t=1)

ortwo-factor

interaction (t = 2).Two-factor interactions (e

=2)

are not confounded with maineffects

but

maybe

confounded with othertwofactor interactions

(53).When approaching a complex analytical technique such as capillary

electrophoresis,

it

may bebeneficial

toutilize afractional factorial designtowardmethoddevelopment,

ruling out a large number ofinfluential factors with a limited amount ofexperiments.

Summary.

At this

time,

there have been no reported studies concerning the usefulness ofcapillary electrophoresis in the qualitative and quantitative analysis ofyohimbine from

eithercommerciallyavailable productsorbiologicalfluids. This paper willdeal withthe

investigation of capillary electrophoresis as an analytical tool for the qualitative and

quantitative analysis of yohimbine in commercially available products. In addition, the

use of a factorial experimental design will be evaluated to

investigate

nine importantfactorsthatinfluencecapillary electrophoresis methoddevelopment.

DEFINITIONS IN CAPILLARY

ELECTROPHORESIS.Area.

Thearea under a peak on an output electropherogram.

Capillary

Effective Length (I).Lengthofthecapillary employedfrom inletto detectorwindow.

Capillary

TotalLength (L).Lengthofthecapillaryemployedfrom inlettooutlet.

Electrophoretic

Mobility

(pe).pe =

q/(6Tcr)r)

Where: q=ion

charge

r\ =

solutionviscosity

r=ionic radius

Electrophoretic

Velocity

(vep).Thisvalue

is

calculatedby dividing

theeffective capillary lengthby

themigrationtime

Joule Heating.

Theresultant

heating

of aconductive mediumupon application of a currentflow.

Field Strength (E).

V L

Where:

V=applied voltage

L =

totalcapillary

length

Migration Time.

Migrationtime

is described

as the amount oftimefor

a compound to travelfrom

the point of

injection

to the point ofdetection in capillary electrophoresis. This value isanalogous to a retention time in liquid chromatography (LC).

However,

separations ofcompounds in CE are a

function

of individual compound mobilities under an appliedvoltage, where LC separations are afunction ofindividual compound

interactions

with astationaryphase.

Resolution(Rs).

Resolution is described as the separationbetween two peaks, andrepresented

by

the equation:

Rs

=0.18Ape(EI)1/2Pern

Symmetry.

Symmetry

is

ameasureof peak shapedeviation

from

aGaussian

curve.Theoretical Plates (N).

Theoreticalplatesarethechromatographicdeterminationofseparation efficiency.

N= iteEI

2D

Where:pe =

Electrophoretic mobility D=Diffusion

coefficient ofthesolute inthebuffersystem

E =Electric Field

I =Column

effectivelength

Zeta Potential (Q.

The zeta potential is a measurement ofthe potential difference between

thecapillarywallandthebuffersolution within.

thiswaste removal.

Renewed

interest

surfaced atthis timefor

thedevelopmentofmicro-bore

columnchromatography in

an effort to reduce solvent waste. The development ofthis technique

theoretically

lowers

experimental costs while maintainingresolution (50).A combination of the positive aspects ofthese techniques are employed in capillary

electrophoresis, which utilizes a charge

based

separationin

a microbore column.Hjerten

described

thefirst

capillary electrophoresis design in 1967 while at theUniversity

ofUppsalain

Sweden (51).Utilizing

1- to 3-mm internal diameter quartzcapillaries coated with methylcellulose, separations ofinorganic

ions,

proteins, nucleicacids, and microorganisms were demonstrated

by

free

zone electrophoresis andlater,

isoelectric

focusing.

Capillary

technology

appearedto be detrimentalto the evolution ofthis

technique,

as variations in optical pathway andlarge

columndiameters

were thelimiting

factors

of performance (50). Gel techniques remained superior for theseapplicationsduetotheavailabilityofthenecessary

technology

atthe time.During

the latterpart ofthe1980's,

theinvestigation ofcapillary electrophoresisadvanced

due

to the useful advantages ofsmall amount of solvent employed and thequalitative precision obtained

in

analysis ofbiopharmaceuticals.

This evolution wasaided

by

thetechnology

found in gas chromatography, in the form of smallinternal

diameter fused silicacapillaries, andfrom advancesin

HPLC,

namelyimproved detector

and autosampler capabilities. CE has since emerged as a technique complimentary to

HPLC that offers reliable, efficient separations

for

several unique applicationsin

thebiotechnology

and biopharmaceuticalfields.

The separation of structural proteins(49,

50),

restrictiondigests

(49, 50),

andPCR products(50)

are only afew

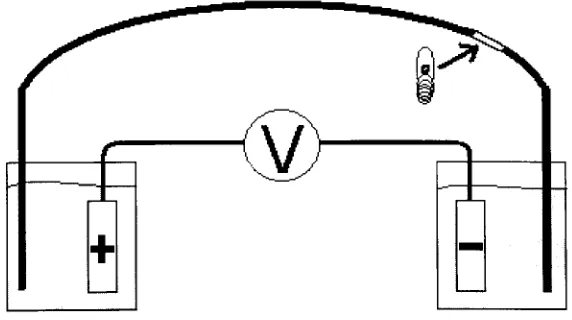

ofthe examplesTheory

ofCapillary

Electrophoresis.

Capillary

electrophoresis(CE)

is

thefamily

ofseparationtechniquesbased

onthemobility

differences

of charged species infree

solution under an applied voltage.Typically,

afused

silica capillary with an internal diameter between 25 and 100 um isplaced

between

twobuffer

reservoirs. The capillary is filled withbuffer,

then a highvoltage

is

applied to the electrodes in each buffer reservoir, creating an electricfield

across the length of the capillary (Figure 2). It is within this electric field that a

separation

based

on charge to size ratiosis

afforded. Detection of resolved analytes isachieved on-column througha window on the capillary from whichthe external coating

has been

removed.v;

[image:33.537.117.403.374.534.2]Electrophoretic Mobility.

Electrophoretic

mobility(pe)

is described

asthevelocity that anion

demonstratesunder an applied voltage.

Magnitude

ofmobilityis

afunction

ofseparation buffer pHeffect on analyte charge.

Theoretically,

anions have pe towards the anode, cationshave

Pe toward the cathode, and neutral analytes will

demonstrate

no pe-However,

in thecapillary electrophoretic separation of a mixture of cations, anions, and neutrals, at a

neutral or alkaline pH,peaks characteristic foreach species will

be

seen on theresultantelectropherogram. This result

infers

that regardless ofcharge, each ion will have a netmobility toward the cathode. Thephenomenon that contributes to thispeculiar effect is

called electroosmoticflow (EOF).

GenerationofElectroosmotic Flow.

Electroosmoticflow

(electroosmosis)

(Equation1)

isdescribed

as abulkflow

of= sE

Atu\

Where: s=dielectric constant ofthe

buffer

r| =

viscosityofthe

buffer

,

=zeta potential measuredatthecapillarywall

buffer solution under an applied voltage. This

flow is directed

toward the cathode in abare fused

silicacapillarywhenbufferpHis

abovethree.As buffer pH

is

increased betweenthree and eight, the walls ofthefused

silicacapillary are proportionally

deprotonated,

inferring

a negative charge on oxygen at theMATERIALS AND

METHODS.

Reagents.

Standards.

Standard

Company

CAS# EEC#Yohimbine hydrochloride Sigma 65-19-0 200-600-4

Reserpine Sigma 50-55-5 200-047-9

Eserine

(Physostigmine)

hemisulfatesaltSigma 64-47-1 200-585-4

BufferComponents.

BufferComponent

Company

CAS#o-PhosphoricAcid 85% FisherScientific 7664-38-2

Sodiumphosphate,

monobasic, monohydrate

J.T. Baker 10049-21-5

Sodium phosphate,

dibasic,

anhydrousJ.T. Baker 7758-11-4

Citricacid,anhydrous J.T. Baker 77-92-9

Sodiumdihydrogencitrate anhydrous

Fluka Chemica 18996-35-5

Sodium hydrogencitrate sesquihydrate

Aldrich Chemical 6132-05-4

Methanol J.T. Baker 67-56-1

Capillary

Electrophoresis Reagents.CE Reagent

Company

Part#1.0 N Sodium Hydroxide Solution for HPCE

Hewlett Packard 5062-8576

0.1 N Sodium Hydroxide Solutionfor HPCE

Hewlett Packard 5062-8575

Waterfor HPCE Hewlett Packard 5062-8578

Instrumentation

.Capillary

Electrophoresis

Hewlett

Packard

HP3D-CE,

Model#

G1602A,

Serial#

3546G00733Computer:

Hewlett

Packard Vectra

XMseries3 5/90.Control

Program:Hewlett Packard HP

3D-CE Chemstation.

Revision A.05.04[273]

Labline Environmental Orbital

Shaker.

Rotary

Evaporator:Labconco

Centrivap

Concentrator.Catalog

#

78 1 00-00Labconco Cold Trap.

Catalog

# 781 10-00Fisher Scientific Vacuum Pump. Maxima C Plus. Model M4C.

pHMeter:

VWR Scientific. Model8005

Beckman Combination Electrode 39846.Lot 59098

Experimental Supplies.

Capillary:

Polymicro Technologies. 25pm Internal Diameter Fused

Silica

capillary,360 pm Outer Diameter Polyimidecoating. Part

#:

200001 1Syringes:

Becton DickinsonandCompany: 10cc syringe,2.5 cc syringe

Filter discs:

Acrodisc,

sterile syringefilter. Pore

size:0.2pm,

Diameter: 25mm. HT Tuffrynmembrane.

Product

#4142

Commercially

Available Products:.

Action

Labs, Farmingdale,

NY.Yohimbe Powermax2000- 50 capsules

Pure

Yohimbe

Bark Extract. Maximum Potency. Fast Acting.Yohimbine

Bark Extract Complex: 2000mg/2CapsulesYohimbe Powermax2000-2

fluid

ouncesPure Yohimbe Bark Extract. Maximum Potency. Fast Acting. ExtractofYohimbe Bark: 2000mg/2ml

General Nutrition

Corporation, Pittsburgh,

PA.Men's Yohimbe 451-60 Capsules

Standardized Herbal Support Preparation.

Yohimbe Bark Extract(Pausinystaliayohimba):451 mg/Capsule

(2% Yohimbine Alkaloid=

9 mg)

Great American

Nutrition,

Salt LakeCity,

UTMen'sPerformance-20 Tablets

Herbal Formula.

Intimacy

Formulafor Men. MaximumPotency.

Yohimbe (Pausinystalia yohimbe) (bark): 250mg/Tablet

Irwin

Naturals,

CulverCity,

CA.Yohimbe-Plus-30 Extra Large Tablets

Five High

Potency

Herbs for Male DriveandStamina

2000 mg

Daily Supply

ofYohimbe. GuaranteedPotency.

Yohimbe Bark Powder: 2000mg/3 Tablets

Natrol,

Chatsworth,

CA.

Yohimbe

Bark.

Whole HerbPowder-90Capsules

Yohimbe,

powdered(bark):

500mg/CapsuleOnly

Natural,

IslandPark,

NY.Yohimbe

1 000plus- 10tablet trail packFor Men

Only

Booster. 100% Pure African Yohimbe Bark.Yohimbe

Bark. (100%

PureAfrican Bark):

1000mg/2 TabletsPower

Force, Hauppauge,

NY.Male Formula. PerformanceEnhancer-30Capsules 100% Pharmaceutical Grade.

Yohimbe Bark Extract: 800mg/3 Capsules

Smart Health

USA,

Beverly

Hills,

CA.V Herbal Ultra-30tablets

Ultra Pleasure

Delivery

System. The All Natural Alternative.Yohimbe Extract 2%: 250mg/2 Tablets

Saint Rose

Heights, Norwalk,

CT.SobeEnergy-20

fl

oz.Energy

drinkGuarana, Yohimbe,

ArginineTwinlab,

Ronkonkoma,

NY.Yohimbe Fuel- 50capsules

Guaranteed

Potency

Yohimbe Bark Extract.Standardized for Yohimbine.

Yohimbine: 8 mg/ capsule

MaleFuel-60capsules

Male Formula. With Yohimbe Bark Extract.

Standardized

for

Yohimbine.Yohimbe Bark Extract: 800mg/

6 Capsules

Powerman Yohimbe

Power-100 Capsules

The

AllNight

Long

Pill. Pure

Yohimbe Bark Extract.Yohimbe

BarkExtract:

225mg/CapsuleStandardized for 4.5

mg yohimbine alkaloidsPowerman

Yohimbe

Stack-30Tablets

The All Night

Long

Pill. PureYohimbe

Bark Extract. Yohimbe BarkExtract:

225 mg/TabletStandardized for

4.5 mgyohimbine alkaloidsFactorialandFractional Factorial Design.

Statistical Design Software.

Minitab 12 for Windows. Release 12.21. Minitab Inc. 1998

Methods.

Experimental Design.

Run voltage,

temperature,

buffer composition, buffer pH, buffer ionic strength,injection

type,

injection setpoint, organic modifier concentration, and effective columnlengthcomprisedthe

factors

chosenfor fractionalfactorial design

one (Table 4).A

two-level,

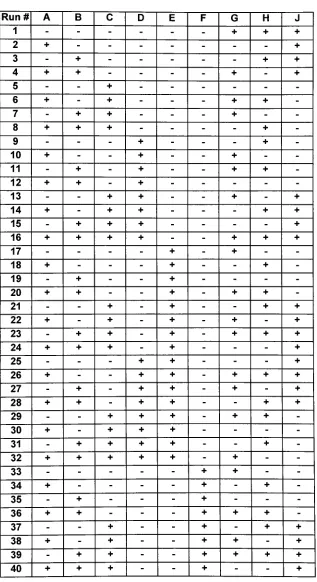

one-quarterfractional factorialexperimentaldesignatresolutionfourwas compiledusing designgeneratorsprovided

by

Minitab(Figure 6). FourcenterpointsTable4. FactorlevelschosenforFFD1. Low levelrepresented

by

-,high levelrepresentedby

+,centerpoints represented

by

0. FactorsDandFbasedonfactorsCandE,respectively(i.e.whenCis-,correspondingtocitrate

buffer,

D+is 6. WhenCis +,D+correspondstophosphatebufferat pH8).Factor

>

A B C D(C-) D(C+) E F(E-) F(E+) G H J

Level T kV Buffer Citrate PH

Phosphate

PH

Injection

Electro-kinetic Inj(kV)

Pressure Inj(mbar)

Column Length

Methano (%)

Ionic Strength

25 10 Citrate 3 3

Electro-kinetic

5 20 25 0 0.01

+ 35 20 Phosphate 6 8 Pressure 15 50 75 10 0.1

0 30 15 X 4.5 6.5 X 10 35 50 1 0.05

G=ABCD H=ACEF J=CDEF

Figure6. Designgeneratorsfor factorialdesignone. Generated

by

Minitab Statistical Software.were added to complete the

design,

resulting in 68 experimental runs performedin

duplicate (Table 5).

[image:40.537.47.489.100.313.2]Table 5. DesignMatrix forthefactorial designone. Designgenerators

G=ABCD,

H=ACEF,andJ=CDEF.The leveloffactor G foranyrunis determined

by

thelevelsoffactorsA, B,C,

andDforthatrun.(example:runthree.A=-,

B=+, C=-, D=-, E=-,

F=- Thereforetheleveloffactor G=ABCD=(-)(+)(-)(-)

=-,leveloffactorH=ACEF=

(-)(-)(-)(-)

=+)

Run# A B C D E F G H J

1 - - - + + +

2 + - - - +

3 - + - - - + +

4 + + - - - - + - +

5 - - + - - -

-6 + - + - - - + +

-7 - + + - - - + -

-8 + + + - - - - +

-9 - - - + - - - +

-10 + - - + - - + -

-11 - + - + - - + +

-12 + + - + - - - -

-13 - - + + - - + - +

14 + - + + - - - + +

15 - + + + - - - - +

16 + + + + - - + + +

17 - - - - + - + -

-18 + - - - + - - +

-19 - + - - + - - -

-20 + + - - + - + +

-21 - - + - + - - + +

22 + - + - + - + - +

23 - + + - + - + + +

24 + + + - + - - - +

25 - - - + + - - - +

26 + - - + + - + + +

27 - + - + + - + - +

28 + + - + + - - + +

29 - - + + + - + +

-30 + - + + + - - -

-31 - + + + + - - +

-32 + + + + + - + -

-33 - - - + + -

-34 + - - - - + - +

-35 - + - - - + - -

-36 + + - - - + + +

-37 - - + - - + - + +

38 + - + - - + + - +

39 - + + - - + + + +

40 + + + - - + - - +

41 - - - + - + - - +

42 + - - + - + + + +

43 - + - + - + + - +

44 + + - + - + - + +

45 - - + + - + + +

-46 + - + + - + - -

-47 - + + +

- + - +

-48 + + + + - + + -

-49 - - - - + + + + +

50 + - - - + + - - +

51 - + - - + + - + +

52 + + - - + + + - +

53 - - + - + + - -

-54 + - + - + + + +

-55 - + + - + + + -

-56 + + + - + + - +

-57 - - - + + + - +

-58 + - - + + + + -

-59 - + - + + + + +

-60 + + - + + + - -

-61 - - + + + + + - +

62 + - + + + + - + +

63 - + + + + + - - +

64 + + + + + + + + +

65 0 0 0 0 0 0 0 0 0

66 0 0 0 0 0 0 0 0 0

67 0 0 0 0 0 0 0 0 0

68 0 0 0 0 0 0 0 0 0

The secondary investigation focusedonthree

factors

attwolevels,

buffer

pH,buffer

ionicstrength,andrunvoltage(Table 6).A full factorial designof

23

experimentalruns and an additionaltwocenterpoint

runswerecompleted,

totaling

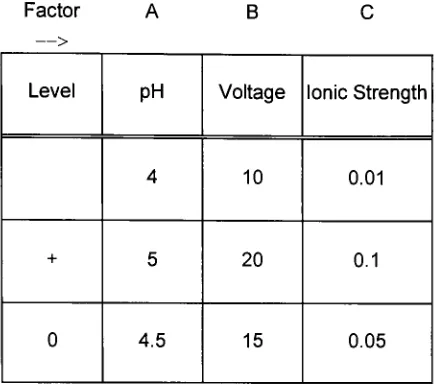

tenrunsin duplicate (Table 7).Table6.Factorlevelschosenfor factorial designtwo.(Low levelrepresented

by

high levelrepresented

by

+,centerpointsrepresentedby

0)

Factor A B

Level PH Voltage Ionic Strength

4 10 0.01

+ 5 20 0.1

[image:43.537.161.379.81.273.2]0 4.5 15 0.05

Table 7. Designmatrixforfactorialdesigntwo.

Run# Level A Level B Level C

1 - -

-2 + -

-3 - +

-4 + +

-5 - - +

6 + - +

7 - + +

8 + + +

9 0 0 0

10 0 0 0

[image:43.537.165.369.343.503.2]Preparation ofBuffers for

Capillary

Electrophoresis.

Citrate and Phosphate

buffers

employedin

this investigation were preparedutilizing the

Henderson-Hasselbach

(Equation

4)

and ionic strength (Equation5)

equationstowarda

known

pH andionic

strength(Scheme

4).pH=

pKa+

log

[conjugatebase]

[conjugate acid]

I=0.5Z

(cjZj2)

Buffers that

did

not measure to the calculated pH were recalculated with acorrection

factor

equalto thatofthedeviation (i.e. abufferwith a measured pH of5.2 hasa deviation of 0.2 pH units. 0.2 is the correction

factor.

The buffer is recalculatedtowardsapH of

4.8.)

All buffersolutions were

filtered

througha0.2 pmAcrodisc syringeCitratebuffer: pH=5

.00,1

=0. 1

0,

pKa2citrate=4.76[H2A]

=C6H707"

[HA-]

=C6H607+

0.10=0.5

(([H2A"](12)

+([Na,+](12))

+([HA=](22)

+2[Na2+](l2)))

Setting [H2A]

=[Naf]

=xand

[HA=]

=[Na2+]

=y

0.10=0.5

(((x)

+(x))

+((4y)

+(2y)))

Solving

forxx=

0.10-3y

6The Henderson-Hasselbachequationfortheseconditionsis

5.00=4.76+

log (y/x)

Solving

fory/x yields10-24

=

(y/x)

Substituting

Equation6 forx1.738=y/(0.10

-3y)

Solving

for yyieldsy=0.028 M=

[HA=]

Substituting

y into Equation 6x=0.016 M=

[H2A']

Scheme 4: BuffercalculationsforcitratebufferpH5.00,1= 0.10.

Preparation

ofStandards

forCapillary

Electrophoresis.

Yohimbineand

Eserine Standard (Factorial

Design One).A measured amount of yohimbine was quantitatively transferred to a 10 mL

volumetric

flask.

Buffercorresponding

to the proper pH and ionic strengthfor

theexperimental run was addedtovolume and mixedtoyield a2000ppm standard.

A measured amount of eserine was quantitatively transferred to a 10 ml

volumetric

flask.

Buffer corresponding to the proper pH and ionic strength for theexperimentalrunwas addedtovolume andmixedtoyielda2000ppm standard.

Equal parts 2000 ppm yohimbine standard and 2000 ppm eserine standard were

added to a 10 ml conical plastic graduated centrifuge tube and vortexed to yield a

standard of 1000 ppm in both yohimbine and eserine. The standard solution was then

filteredthrougha0.2pmAcrodisc syringefilter

disc.

Yohimbineand EserineStandard (Factorial Design Two).

Deionized ultra filtrated water was employed to utilize the stacking effects that

occur when a buffer oflower ionic strength than the separation

buffer is

present in theinjectionvial (50). Ameasured amountof yohimbine was quantitatively transferred to a

10 ml volumetricflask. Deionizedwater wasaddedtovolume and mixedtoyielda2000

ppm standard.

A measured amount of eserine was quantitatively transferred to a 10 ml

volumetricflask. Deionizedwaterwas addedtovolume and mixedto yield a

2000

ppmstandard.

Equal parts 2000 ppm yohimbine standard and 2000 ppm eserine standard were

added to a 10 mL conical plastic graduated centrifuge tube and vortexed to yield a

standard of 1000 ppm

in both

yohimbine and eserine. The standard solution was thenfiltered

througha0.2 pmAcrodisc

syringefilter disc.

MethodsofExtraction.

ExtractionofYohimbine from Liquid Products.

Portions of 1 ml of ethanol based

liquid

products were evaporated with acentrivap concentrator. The resulting solids were reconstitutedwithdeionized water and

filtered with a 0.2 pm Acrodisc syringe filter. An aliquot ofthe filtrate was combined

with an aliquotofinternalstandardandbufferand

injected

ontothecolumn.Waterbasedproducts werefilteredwith a0.2 mmAcrodisc syringe

filter,

and analiquot ofthe filtrate was combined with an aliquot of

internal

standard andbuffer

andinjectedontothecolumn.

ExtractionofYohimbine from Solid Products.

Capsules were broken open and the cellulose casing

discarded.

Portions

ofthepowdersremovedwereutilized

for

thisinvestigation. Tabletswere crushed with a mortarandpestle, andtheresultant powder utilized

for

thisinvestigation.

Extraction

MethodOne.

Portions of0.1 gram of

bark

powder(0.1 gram ofproduct) was wet and broughttovolume

in

a 10 ml volumetricflask

withdeionized

water. This slurry wasagitated for20 minutes at room temperature. The contents were then filtered through a 0.2pm

Acrodiscsyringe

filter,

and an aliquot ofthefiltrate

was injectedontothe columnwith analiquot of an

internal

standard andbuffer.

Extraction Method Two.

Portionsof0.05 gramof

bark

powder (0.5 gram ofproduct) was wet andbroughttovolume in a 10mlvolumetric flaskwithdeionizedwater. This slurry wasagitatedfor

20 minutes at room temperature. The contents were then filtered through a 0.2 mm

Acrodisc syringe

filter,

and an aliquot ofthe filtratewas injectedontothe columnwithanaliquotof aninternalstandard andbuffer.

Extraction Method Three.

Portions of0.1 gram ofbarkpowder (0.1 gram ofproduct) was wet and

brought

tovolume ina 100mlvolumetricflaskwithdeionizedwater. This slurrywastransferred

to a 1 L Erlenmeyer flask and agitated for 60 minutes at

60

C in a Labline

environmental orbital shaker. Thecontents were allowedto cool,andthe

liquid decanted

and filtered through a 0.2pm Acrodisc syringe

filter.

An aliquot of thefiltrate

wasinjectedontothecolumn withanaliquotof aninternalstandard and

buffer.

Extraction

Method

Four.Portions

of0.1 gram ofbark

powder (0.1 gram ofproduct) was wet and broughttovolumein a 100 ml volumetric

flask

withdeionized

water. This slurrywas transferredto a 250 ml

Erlenmeyer flask

and sonnicatedfor 15 minutesat room temperature. Thecontents were allowedto coolto room

temperature,

and the liquid decanted and filteredthrough a 0.2pm Acrodisc syringe

filter.

Analiquot ofthefiltrate

was injectedonto thecolumn with an aliquot ofan

internal

standard andbuffer.

Extraction Method Five.

Portions of0.1 gram ofbarkpowder(0.1 gram ofproduct) was wet andbrought

to volume in a 10 ml volumetric

flask

with 10 ml of 95% ethanol. This slurry wasagitated

for

20 minutes atroom temperature. The contents were thenfiltered

through a0.2 pm Acrodisc syringe filter. The ethanol was evaporated with a rotary evaporator

concentrator, andthe remaining powderreconstituted

into

3 ml ofdeionizedwater. Thesolution was thenfilteredthrough a0.2 pm Acrodisc syringe

filter,

andan aliquotofthefiltrate

wasinjectedontothecolumn withan aliquot ofaninternal

standard andbuffer.

Extraction Method Six.

Portions of0.1 gram ofbarkpowder (0.1 gram ofproduct) was wet and

brought

tovolume

in

a 10 mlvolumetricflask

withchloroformand added toa 125 mlseparatory

funnel.

It was equilibrated with 10 ml of deionized water, and the organiclayer

collected. The aqueous layer was washed with a portion of 10 ml chloroform. The

organic

layers

werecombined, andfiltered

through a0.2 pmAcrodisc

syringefilter.

Thechloroform was removed with a rotary evaporator, and the resultant solids reconstituted

into

3 ml ofdeionized

water.The

solution wasfiltered

through a 0.2 pm Acrodiscsyringe

filter,

and an aliquot wasinjected

onto the column with analiquot of aninternalstandard and

buffer.

Extraction Method Seven.

Solid

phase extraction was performed on an Alltech reverse phase 900 mgCis

solid phase extraction cartridge. The cartridge was first conditioned with 3 ml of

methanol, followed

by

3 ml ofdeionized water. 1 ml ofsample dissolved in deionizedwater (0.05 g/ 10 ml) was applied. A 5 ml portion of water was pushed through the

column, and collected as a fraction. 3 ml

fractions

of 10% methanol in water, 50%methanol in water, 75% methanol

in

water, and 100% methanol were collectedsuccessively. The methanol was removed from these fractions with a centrivap

concentrator. The resultant solids were reconstituted with 1 ml deionized water, and an

aliquot wasinjectedontothecolumn with an aliquotof aninternal standard andbufferto

determine

thetargetfraction.Extraction Method Eight.

Solid phase extraction was performed on an Alltech reverse phase 300 mg

Ci8

solid phase extraction cartridge. The cartridge was

first

conditioned with 3 ml ofmethanol, followed

by

3

ml ofdeionized water. 1 ml of sampledissolved in deionized

water (0.05 g/ 10 ml) was applied. A 3 ml portion of water was pushed through the

column, and collected as a fraction. 1 ml

fractions

of 10% methanol in water, 50%methanol

in

water, 75% methanolin

water, and 100% methanol were collectedsuccessively. The methanol was removed

from

thesefractions

with a centrivapconcentrator. The resultant solids were reconstituted with 1 ml

deionized

water, and analiquot was

injected

ontothecolumn with an aliquot of aninternal standardandbuffer

todetermine

the targetfraction.

Extraction Method Nine.

Solid phase extraction was performed on an Alltech reverse phase 900 mg

Cig

solid phase extraction cartridge. The cartridge was first conditioned with 3 ml of

isopropanol,

followed

by

3 ml ofdeionizedwater. 1 mlofsample dissolved indeionized

water (0.05 g/ 10 ml) was applied. A 5 ml portion ofwater was pushed through the

column, andcollected as a

fraction.

Two successive 3 mlfractions

of 100% isopropanolwere collected, followed

by

twosuccessive 3 mlfractionof2% ammoniumhydroxide

inisopropanol. The isopropanol was removed from 1 mlportions ofthese

fractions

with acentrivap concentrator. The resultant solids were reconstituted with 1 ml

deionized

water,and an aliquotwasinjectedontothecolumn with an aliquotofaninternal standard

andbuffertodeterminethe target

fraction.

Extraction Method Ten.

Solid phase extraction was performed on an Alltech reverse phase 300 mg

Cig

solid phase extraction cartridge. The cartridge was first conditioned with 3 ml of

isopropanol,

followedby

3 ml ofdeionizedwater. 1 ml of sampledissolved in

deionized

water (0.05 g/ 10 ml) was applied. A 3 ml portion of water was pushed through the

column, and collected as a

fraction.

Two successive 1 mlfractions

of100% isopropanolwerecollected,

followed

by

twosuccessive 1 mlfraction

of2% ammoniumhydroxidein

isopropanol.

The isopropanol

was removedfrom

thesefractions

with a centrivapconcentrator. The resultant solids were reconstituted with 1 ml deionized water, and an

aliquot was

injected

onto thecolumn with an aliquotof an internalstandardandbuffertodetermine

the targetfraction.

Optimized

ExtractionConditions

for Commercial Samples.Theprotocol of extraction

five

was expandedforcontinuedinvestigation. Samplemass andethanolvolumewere varied

between

highandlow levelstodetermine

the mostefficient extraction conditions. Thefinal conditions

for

real sample analysisinvolved

theuse of 0.05 g sample dissolved into 10 ml of95% ethanol in a volumetric

flask.

Theethanol was then decanted and filtered through a 0.2 mm Acrodisc syringe filter. 1 ml

aliquots ofthis slurry were evaporated with a Labconco rotary concentrator (60 C * 45

min). Theresultantsolids werereconstituted

into

1 ml ofwarmdeionized

water,filtered

througha0.2mm Acrodisc syringe

filter,

and an aliquotinjected

along with avolume ofeserinestandardandbuffer.

Instrumental.

Conditioning

oftheCapillary

Column.New capillary columns were preconditioned utilizing a standard method. A 45

minute

flush

with 1.0