Investigation Phenomena Of Flank Wear At Initial Stage During Cutting Process Of Stainless Stell 304

Full text

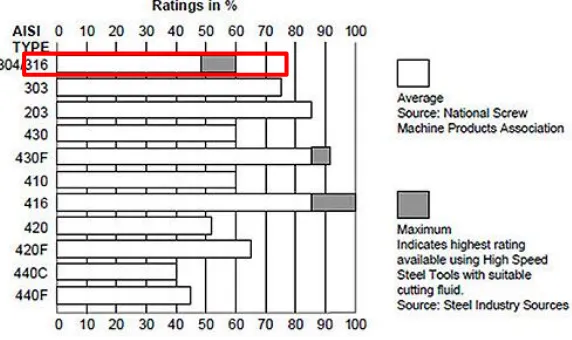

Figure

Related documents

[4], Investigated the influence of cutting parameters (cutting speed, feed rate and depth of cut) on tool temperature, tool wear, cutting forces and surface roughness

Figure 18 shows the graph of experimental and Palmai wear against time for high speed steel cutting tool on bright mild steel material at feed rate of 9mm/rev,

Lot of research papers are available wherein various machining parameters (Cutting Speed, Feed Rate and depth of cut ), tool nose radius and cutting conditions (Cryogenic, MQL

Mainly parameters like cutting speed, feed, and depth of cut have significance effect on surface roughness, cutting force, tool wear, tool life, material

The influences of the cutting speed, the feed per tooth and the depth of cut on surface roughness, tool wear and cutting forces in the face milling process have been examined in

This work aims to model and investigate the effect of cutting speed, feed rate, depth of cut and the workpiece temperature on surface roughness and flank wear (responses) of

This work aims to model and investigate the effect of cutting speed, feed rate, depth of cut and the workpiece temperature on surface roughness and flank wear (responses) of

Flank wear Rake face.. formation of built-up edge next to the main cutting edge than in the case of the wedge working at the cutting speed of 150 m/min. During the operation of