X-RAY LINE BROADENING AIm STORED ElffiRGY IN DEFORDffiD AI-ill ANlffiALED LH:ESTONES .

BY

K. A. GROSS .

A thesis submitted for the degree of Doctor of Philosophy in the Australian National University.

The work described in this thesis is entirely my own, apart from the assistance given by:

(1) Ur. J . Easton, who performed the chemical analyses given on pages 21 and 117.

(2) Mr. E. Pedersen, who prepared the sample cores by diamond drilling.

(3) The Photographic Section in the John Curtin

School of Medical Research, Australian National University, which helped with the reproduction of the various figures used in the text .

,

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CONTENTS .

INTRODUCTION 1.

The Deformed State in

Poly-crystalline Metals 38

The Effect of Annealing Deformed

Metals 4.

X-ray Line Broadening Studies of

Metals 7.

The Stored Energy of Deformation

of Metals 12.

Previous Work on Calcite Aggregates 15.

PREPARATION OF SPECIMENS Choice of Materials Deformation - Method

Some Results of Deformation Method of Annealing

19 . 19. 20. 23 . 28.

X-RAY DIFFRACTION OBSERVATIONS 32.

Methods 32 .

The Recording of X-ray Line Profiles 32. X-ray Diffraction Patterns 35 . Description of the X-ray Diffraction

Results 35.

The Effect of Deformation 35. The Effect of Annealing 40.

Other Observations 49 .

Interpretation of the X-ray

Diffraction Results

54

.

The Kinetics of the AnnealingProcesses

54

.

Analysis of the X-ray Line

Broadening 610

I

CHAPTER 40

CHAPTER 5.

CHAPTER 6.

u

CONTENTS.

Initial Line Broadening from

Limestones and Marbles 82.

STORED ElJERG Y T.ffiAS UREr.:ENTS . 91 0

Method 91.

The Results of Stored Energy

Measurements 103.

The Heat of Reaction of Solenhofen

Limestone after Annealing 110.

Cm.1PARISON OF STORED ENERGY

MEASURE:.LENTS WITH STRAIN ElJERGIES CALCULATED

r

ROM X-RAY LINEPROFILES . 120.

The Effect of Deformation 123. The Effect of Annealing 131.

DISCUSSION OF THE RESULTS 134. Comparisons with

r.

etals • 135. Recovery and Recrysta11isationKinetics 140.

A Possible Model for the Deformed

State in Calcite Aggregates 143. Comparison of the Annealing Data

with other Work on Calcite

CONTEN'rs .

Geological Implications

Summary

Bibliography Appendix 1 . Appendix 2.

Some Crystallographic Properties of Calcite

151.

156. 1590

iii.

End Piece.

-INTRODUCTION.

The phenomena accompanying the plastic

deformation and subseq~ent annealing of metals have been studied extensively for many years but, whilst our know -ledge is now considerable, there are many aspects which remain unexplained. It is still necessary to invent models which can best reconcile the results of the many diverse methods of examination that have been employed. Two of the methods which have been usef~ in the study of poly crystalline metals are measurements of x-ray line broadening and the stored energy of cold work. In the work now to be described these ~vo methods have been applied to the study of deformed and annealed limestones 0

In contrast to the field of metals very little effort has been devoted to the study of cold work and

2.

for this may be that elaborate equipment is required to

produce controlled deformations in such materials because

they are brittle in normal conditions of temperature and

pressure.

It seems to have been realised about the

beginning of this century (Adams and Nicolson, 1901) that

calcareous rocks become ductile and thus able to sustain

large deformations if they are enclosed in a high pressure

environment 0 Since then many investigations of the mechanical properties of rock forming minerals have been

madef both at room temperature and at elevated temperatures

and over a wide range of strain rates (Heard, 1963).

The structures produced by deformation in some

rocks have been extensively analysed by petrographic

methods which give information concerning the types of

slip or twinning system operating during plastic flowo

However, the processes which occur on a finer

scale have received little attention. Similarly, few

investigations have been made when deformation is followed

by annealing.

*

For an extensive bibliography see "Rock Deformation",Griggs and Handin, Editors, Geol. Soco America, Memoir

I~

I

Before reviewing earlier work on calcite aggregates it is desirable that we should attempt to summarise the present day state of knowledge of the behaviour of metals. A complete description of the various theories which have been advanced to explain the processes that occur during the plastic deformation and subsequent annealing of a metal is beyond the scope of this introduction. Attention must necessarily be con-fined to the current theories and to showing what contri-butions have been made by x-ray line broadening and stored

*

energy measurements.The Deformed S tate in Polycrystalline Metals 0

A currently held picture of the deformed state (Hirsch 1956, Warren 1959,) which reconciles the results of many diverse observations on polycrystalline metals,

*Many comprehensive reviews are available, e.g. Barrett (1952), Burke and Turnbull (1952), Greenough (1952),

is as

follows:-The individual grains are still extant, but

they have had developed within them, a mosaic of sub-grains.

Each sub-grain is slightly mis-oriented from its neighbour

and in the boundaries be~/een sub-grains there is a

broad region of intense deformation in which the density

of defects is very high. strain fields from the boundary

regions extend throughout the sub-grains which may also

contain some defects, but their concentration is much

lower than in the boundary regions.

The Effect of Annealing Deformed Metals.

When a deformed metal is annealed, there is

initially a reduction in the number and are-arrangement

of the defects in sub-grain boundary regions. One

consequence is that the strains in the sub-grains themselves

are reduced. This process is called recovery.

At high temperatures new grains appear and

consume old deformed material in the process of

recrystall-isation.

Relations giving the time and temperature

dependence of both the recovery and recrystallisation

Recovery.

There is evidence that there are a number of

processes occ~rring in the recovery stage of annealing

since different properties recover at different rates 5.

(Wilson and Thomassen, 1934). The most characteristic

feature of a recovery process is that the property

being measured changes very rapidly in the first few minutes of annealing to a value which is characteristic

of the temperature and thereafter subsequent changes

take place very slowly.

Some recovery processes have been found to

fit a rate equation of the form:

dx

- dt

=

C exp (.!) a.

.

.

.

. . . .

.

.

.

1.1 where x is the value of the property which is recoveringat time t, C is a temperature dependent constant and a is

a constant. The effect of temperature on recovery is

expressed by the usual Arrhenius equation for a thermally

activated process,

C

=

• • • • • • • • • • • 1.2where Q is an activation energy, R is the gas constant r

and T the temperature on the absolute scale, and Co is

LL

6.

Combining equations 101 and 1.2 gives

dx ( Q

r

-mx)

dt = Co exp - RT

where m

=

RT/aoThis equation can be integrated to give

x

=

Xo RmT . loge(1

+ t/t o ).0.

.

where Xo is the value of x in the deformed state and to

is defined by RT

-.

log (mc o to)e RT

=

mRecrystallisationo

In contrast to recovery, recrystallisation is characterised by an apparent incubation period at the end of which new grains appear and then grow by consuming the deformed matrix.- The length of the incubation period is determined by the severity of the initial deformation and

by the annealing temperature.

It has usually been considered that

recrystall-isation is a nucleation and growth process in which the rates of nucleation and growth can be described by

Arrhsnius type equations in which the activation energies are approximately equal. The isothermal rate of growth is independent of time. If the nucleation rate is also

Ii

70

growing grains then Johnson and Mehl (1939) and Avrami

(1940) show that the fraction X, which has recrystallised

at time t,is

X

=

1 - exp (- Btk) • • • • • • • • • 1.4where Band k are constants, the former being temperature

dependent 0 According to Avrami k should have a value

between 3 and 4 when recrystallisation proceeds three

dimensionally, 2 and 3 when it occurs two dimensionally

as in a thin sheet and between 1 and 2 when it occurs

linearly as in a wireo

If the activation energies for nucleation and

growth are equal then the rate of recrystallisation may

be expressed in terms of a single activation energy (Qc) o

That is

dX

dt

where A is a constanto

Qc )

RT • • 0 • 0 • • • 0

X-ray Line Broadening Studies of Metals .

1.5

The first observation that plastic deformation

caused x-ray diffraction lines to be broadened seems to

have been by Van Arkel

(1925).

It was found that asI

u

8.

eventually a limit was reached where increasing deformation

had no further effect (GoUgh and Wood 1936, Haworth 1937.)

Prior to 1950, the only parameter measured was

either the breadth of the line at half its peak height

or alternatively the integral breadth~, where

j I de

(B

=

:7i.e. the integrated intensity divided by the peak height.

It was recognised that broadening of x-ray lines could

result from a number of causes of which two could be

applicable to deformed metals.

(i) Deformation was causing the metal to be

broken up into very small fragments. A crystal particle

must have a certain minimum volume to give correlation of

the phases of the scattered radiation and therefore sharp

diffraction lines. If this critical volume exceeds the

volumes of the small fragments then broadening of the

lines will be observed. Scherrer (1918) showed that

the broadening in these circumstances was given by,

;B

=

~K_;\ _ _t cos

e

where t is the effective particle size, )\ is the wave

length of the x-radiation, K is a constant close to 1

but which depends on the particle shape.

metal, then the interplanar spacing would vary from

crystal to crystal.

represented by,

(0

-

2 € tane

where E is the strain.In this case the broadening is

Now unfortunately the behaviour of the sec 9.

and tan functions in the range of angles most amenable

to x-ray studies are very similar and as a result it

became difficult to decide whether one or the other cause

of broadening was the more important. Two schools of

thought emerged. The protagonists for small particle

size maintained that the limit in broadening was due to

a limiting particle size below which the metal could not

be broken. The strain supporters said that the elastic

strain could not exceed certain limits such as set by the

yield stress or the limit of applicability of Hookets law •.

In 1938, Brindley and Ridley obtained line breadths from filed rhodium which would have required a

very small, grain size of lO-6 cm if small particle size

broadening was the only cause. However, extinction was

observed and this could not be expected from such smalL

particles. Then in 1948, Paterson and Orowan found that

·

deformation in a similar way to the variation of the

yield stress.

10.

Experiments such as these suggested that

internal strains were the more important cause of the

line broadening effect.. Two mechanisms suggested

themselves as the source of the

strains:-(i) the strain fields associated with dislocations,

which had been invoked by Taylor (1934) to endeavour to

explain the phenomencnof work hardening,

(ii) by the presence of macro-stresses, which are

uniform over distances greater than the grain size~

Various suggestions have been postulated to account

for their occurrence (for a recent summary see Garrod

and Hawkes, 1963.) It is now believed that strains

introduced in this way do not make a substan~

con-tribution to the line broadening.

In 1948, Barrett suggested that stacking faults

could be introduced into a metal by deformation and

Paterson (1952) calculated the effect they would have on

the x-ray pattern of face-centred cubic metals.

Specifically some lines are broadened more than others

and some are shifted.

to other structures.

I-11.

Meanwhile, the development of Geiger counter

diffractometers made it possible to accurately and

conveniently determine the variation of intensity across

diffraction lines. Warren and Averbach (1950) developed

a method for analysing this complete line profileo Their procedure will be described in oome detail in

a subseQuent chapter; we need only say here that, in favourable circumstances, the effects of particle

size and strain broadening can be separated and a

distribution function for the strains determinedo If this last step cannot be made, it has

become customary to represent the strain distribution

by some assumed function. Once the strain distribution

has been determined or a satisfactory approximation made, the el astic strain energy can be calculated (Stibitz,

1937, Faulkner, 1960) and compared with the stored energy

of deformation measured by some direct method.

The x-ray line broadening method therefore can

provide the following information

:-(i) particle size - not necessarily implying

that the metal has been fragmented into discrete particles

12.

well~ ordered to coherently scatter x-rays,

(ii) the distribution of strains and hence the

strain energy,

(iii) the probability of the presence of stacking

faults.

However, the results cannot always be analysed

unequiv-ocally.

The Stored Energy of Deformation of Metals 0

The principles and methods involved in

measuring the stored energy of deformation have been

thoroughly discussed in a comprehensive review paper

by Titchener and Bever (1958). Only the more salient

features will be given here.

The energy stored in a body, which has

suffered plastic deformation can be expressed as

=

w

Q, • • • • • • • • 1.6where U is the stored energy, W is the work done on s

the body and Q is the heat energy liberated during

the deformation process. Measurements of Us may

therefore be based on one of two

principles:-(i) by direct measurement of Us and

defor-T

)

130

mation process.

Many of the early measurements of stored

energy employed this second principle, but since it

cannot be used for following the release of stored

energy during annealing it has tended to be displaced

by methods based on (i).

Methods for measuring Us directly falh into two distinct groups . In the first, the deformed

sample is annealed, usually by increasing the temperature

at a constant rate and measuring at the same time the power required to maintain the given rate of temperature

rise (e.g,. Clareborough, Hargreaves, Michelh and West, 1952.)

In the second method, the heats of reaction

of deformed and annealed samples with some suitable reagent are determined. The difference between the two

represents the stored energy. By also measuring the heat of reaction of partially annealed samples the

energy release pattern can be followed.

The results of stored energy measurements can

be summarised as

follows:-1. As deformation proceeds the stored energy

increases but the fraction of the work expended during

2 •. Stored energy is dependent on the particular

metal and its initial grain size.

3. Stored energy depends on the nature of the

deformation process.

14.

4. Stored energy depends on the temperature of

deformation, being higher for low temperatures, in

agreement with the behaviour of the mechanical properties.

5. The relative amo~ts of stored energy released

in recovery and recrystallisation are very variable.

The Mechanism of Energy Storage.

It is believed that significant energy is

stored by the elastic strain fields associated with

defects introduced by deformation. If this is so, then

there should be a correlation between stored energy

measurements and the strain energy deduced from x-ray

line broadening measurements. Unfortunately, there

have been very few investigations in which both quantities have been measured on the same set of samples, so that it

is difficult to draw any reliable conclusion. The

correlation of these two types of measurements will be

discussed in Chapter 5.

If the defect concentration can be found by

15.

calc~late the stored energy from a knowledge of the energy of dislocations and s~b-grain boundaries.

S~ch meas~res can be obtained from thin film electron

microscopy, b~t this reveals that defects are concentrated in s~b-grain boundary regions and unfortunately the

theoretical calc~lations of the energies of such bound-aries are difficult to make beca~se

,

so far,

no ade~uatetreatment of dislocation interactions has been developed. In some recent observations, the stored energy in deformed copper and silver has been satisfactorily predicted from meas~rements of dislocation densities and the energies of the dislocations calc~lated from the flow stress (Bailey and Hirsch 1960, Bailey 1963.)

Previo~s Work on Calcite Aggregates.

1. Mechanical Properties.

flow is usually smooth i.e. there is no sharp yield

point.

16.

Marble and limestones have been found to have

strengths comparable with those of the high strength

steels.

It has been found that if deformation of

Solenhofen limestone is carried out at elevated

temper-atures, the brittle to ductile transition occurs at

lower confining pressures and that the rate of work

hardening is decreased (Heard 1960.)

Heard (1963) has also investigated the effect

of varying the strain rate. In a series of experiments

with Yule marble he found that reduction of strain rate

lowered the rate of work hardeningo The effect was not

very great at room temperature but at temperatures of a

few hundred degrees centigrade it became very significant

and a region of steady state flow was entered.

It should be emphasised that the lowest strain

rates used in the laboratory are still many orders of

magnitude greater than those encountered in geological

conditions.

2.. X-ray Line Broadening.

17.

broadening in calcite aggregates. Rosenthal and Kaufman (1952) took advantage of the room pressure brittleness by crushing Yule Marble which had already been deformed. They reasoned that if the line

broaden-ing which they observed initially was due to internal

strains then, as the particles became finer, the internal

strains should be relieved whereas particle size broaden-ing would be unaffected or increased. They were able to

observe pronounced sharpening of the diffraction lines

when the particle size was reduced below 1 micron and

concluded that internal strains were the principle cause

of the original broadeningo

Paterson (1958a) examined Solenhofen limestone,

which had been compressed 15.5%. He measured broadening

for four different x-ray lines and concluded that

inter-nal strains were the most prominent source of broadening.

He also made various assumptions concerning the nature of

the strain distribution and calculated, for each, the

elastic strain energy stored in the material. He

-1

concluded that it could be as much as 5 cal gm ,which

is nearly two orders of magnitude higher than for similarly

deformed metals.

30 Annealing.

Griggs, Paterson, Heard and Turner (1960) found

18.

aggregates could be recrystallised by appropriate

annealing. Most of their experiments were with deformed

Yule marble and annealing was carried out in an atmos -phere of carbon di-oxide at 5 k bars pressure and the

results were assessed petrographically. Their results

were not extensive but they were able to conclude that

they fell into a pattern which was typical of the be-haviour of metals during recrystallisation.

Their experiments could not be expected to

reveal the existence of a recovery stage because of the

19.

C~P~R2.

PREPARATION OF SPECIMENS.

Choice of Materials.

A lithographic limestone, believed to be from

Solenhofen (Bavaria), was selected as a suitable material

for X-ray line profile measurements. There are a.number

of reasons for this choice which may be summarised as

follows:-(i) Solenhofen limestone is a fairly pure

calcite rock (96% CaC03).

(ii) Its grain size, about 10 microns, is suitable

for examination with an x-ray diffractometer.

(iii) The grains are randomly distributed in

orientation (Higgs, Friedman and Gebhart, 1960.)

(iv) Porosity is comparatively low.

20.

A coarser grained marble from Carrara (Italy) has also been ~sed. Its grain size, of abo~t

0.5

.

mms, makes it a s~itable material for text~ral studies.Chemical analyses of the two materials ~sed

in these experiments are given in table 2.1. A chemical analysis of Solenhofen limestone from the literat~re is also incl~ded in the table to show there are good gro~ds for thinking that the lithographic stone employed is, in fact, from Solenhofen. Miller (1952) gives a spectographic analysis of Solenhofen limestone, which agrees with these analyses and, in addition, shows

the presence of a small amo~t of stronti~ (between 0.1 and 1%.)

Deformation.

Method.

For deformation,specimens were prepared in the form of cylinders, 25 mm long by 10 mm diameter, by coring

210

TABLE 201

Chemical Analyses of Limestones.

Lithographic Solenhofen Carrara.

Limestone Limestone* Marble

A B A B

Water (H2O) 0.16 0.15 0.08 0005

Total Insolubles 1.61 1.47 0.03 0.06

Si02 (in insolub- 1017 1.15

les. )

CaO 53.80 53.82 54.74 55009

-CaC0

3 96.03 96.07 96.01 97.69 98.33

MgO 0.58 0.56 0.85 0.83

MgC0

3 1.21 1.17 1.18 1.78 1.74

Loss on ignition

43.41 43040 43075 43.81

- - -

(CO2)R203 0.34 0.30 0.45 0.07 0.05

Fe 203

~

0.14-

0.01-,

~i02 ) Nil

-

Nil-)

MnO

~

Nil-

Nil-Al 203 (by diff .) ) 0020 0.06

Total 99.89 99.50 99.52 99.89

Underlined values used in arriving at totals.

A and B are duplicate analyses.

[image:26.582.96.532.118.574.2]22.

thin walled latex rubber. The jackets overlapped the

ends of the specimens by about 1/8", and tool steel end

pieces of the same diameter and 1/4" thick were fitted

in the overlapping ends. The ends of the jackets were

sealed by additional rubber rings.

Deformation was carried out in compression in

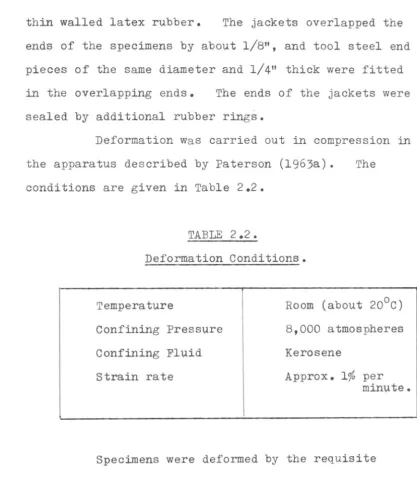

the apparatus described by Paterson (1963a). The conditions are given in Table 2.2.

TABLE 2.2.

Deformation Conditions.

Temperature

Confining Pressure

Confining Fluid

Strain rate

Room (about 200C)

8,000 atmospheres

Kerosene

Approx. 1% per minute.

Specimens were deformed by the requisite

nominal amount, usually 20%, measured under the confining

pressure. On release of the confining pressure deformed

specimens of limestone expand by several per cent (Paterson

[image:27.586.89.507.75.553.2]screw gauge, was used to calculate the plastic strain

suffered by the specimens.

It should be noted that the conditions during

deformation viz. 8,000 atmospheres, 20oC, lie in the

aragonite field of the calcium carbonate phase diagram

(Jamieson 1953, Macdonald 1956.) It seems that the

reaction is very sluggish under these conditions and that

it does not occur at all during the short time (about

20 minutes) that the specimens are in an environment

favouring conversion to aragonite.

Some Results of Deformation.

Some typical compression stress-strain curves

are shown in figure 2.1. These curves are qualitatively

similar to curves for Solenhofen limestone obtained by

Heard (1960) and for Carrara marble)Von K~r~n (1911).

They cannot be compared quantitatively because the earlier

measurements were made at different confining pressures.

None of the materials have given a sharp

yield point but the transition from an initial steep

slope in the elastic range to the lower one, which we

associate with work hardening, is more abrupt for Carrara

marble than for Solenhofen limestone. The rate of work

hardening is greater in the fine grained Solenhofen

1

2

.2

.1

'"

[image:29.699.17.684.46.603.2]~

FIGURE 2.1

SOLENHOFEN LIMESTONE AND CARRARA MARBLE .

Stress - Strain C~rveso

Solenhofen limestone.

Solenhofen limestone, heated to 860°C

for one ho~r befqre deforming.

Carrara marble •

Carrara marble, heated to 860°C for one

--After heating, Solenhofen limestone shows a residual length increase which may be attributed to

internal stresses arising from the anisotropy of the

thermal expansion coefficients of the constituent

25.

calcite grains. After heating to 860oC, this increase

is

3.4%

and since the diameter is not measurably affectedthe density must be correspondingly reduced, which

implies that the porosity has increased. Therefore

the initial low value of the slope of the stressrstrain curve of pre-heated Solenhofen limestone may correspond

to the closing up of pores.

For reasons which will .appear later, it seems

that heating causes a change in the nature of the

impur-ities in Solenhofen limestone, which might be the reason

for the greater rate of work hardening in preheated material. It is well known that the mechanical

proper-ties of metals are very sensitive to the presence of

impurities (McLean 1962.)

Preheated Carrara. marble gives a stress-strain

curve which is not very different from the unheated

material. The residual length change, after heating to

8600

c

(1.5%), is only about half that of Solenhofen andt~ere is no evidence of impurities being changed by

Some other results of deformation

are:-(i) Specimens become fragile, which appears to

be caused by a loss of inter-granular cohesion.

(ii) Cores of Carrara marble become slightly

elliptical, the difference be~~een major and minor

diameters being about 0.02 mm after 20% deformationo 26.

This indicates that there is some preferred orientation

of the grains in the block of marble used.

(iii) It has already been noted that after

deformation and during release of the confining pressure

there is an increase (6.1.) in the length of specimens

(Paterson 1963b.) The magnitude of this effect is

shown in table 2.3 for different strains. The values

quoted are averages for the numbers of specimens shown

in the second column. Where results are comparable,

the agreement with Pa'terson's values is satisfactory.

(The result is expressed as

~

where / is the lengthat 8,000 atmospheres after deformation.)

Also shown in table 2.·3 are values of the

work done during deformation (W), which were calculated

,)

27.

TABLE 203

Expansion on Release of Confining Pressure (

6

0

)

andWork done (W) during Deformation.

Material Solenhofen Preheated Solenhofen Carrara Preheated Carrara

No. of

Specimens 9 3 51 2 19 1 19 1

Average

fj

L

Plastic Strain(%) 1

at 8,000 atmos o 507 13.1 *20.0 25.8 20.0 6.5 20.0 20.7

at 1

atmos. (%)

3.9 1.9

9.6 400

16.0 5.0

2104 5.9

16.6 4.3

6.1 0.4

1606 403

18.1 3.3

W

(cal gm-l)

2.1 7.2 13.3 18.9 12.5 ll.9

F

28.

Method of Annealingo

It was necessary to prevent decomposition of

the sample during the heat treatment of deformed limestone

samples. When heated in air the reaction,

Cao + CO 2

can be detected at 7500Co In the course of some

prelim-inary experiments, it was found that temperatures higher

than this were likely to be req~ired. Therefore, all

heat treatments were made in a heavy walled stainless

steel vessel which co~d be connected directly to a

cylinder of carbon dioxide. The carbon dioxide pressl,lr' e

was therefore of the order of 50 atmospheres. Under

these conditions the dissociation temperat~re exceeds

11000C (Smythe and Adams 1923, Harker and T~ttle 1955.)

The vessel is shown in fig~re 2.2. A is the

specimen, inside a stainless steel caps~le 2. 3 is the

stainless steel wall of the vessel

in

thick 0 4 is thethermoco~ple (chromel-al~el), which fits into an

i

n

diameter hole drilled into the wall of the vessel.

5 and 6 are respectively a n~t and a cone seal. 7 is

the connection of flexible stainless steel tubing

leading away to the CO2 cylinder and 8 is a fire-brick

1

FIGURE 2.2.

The Eq~ipment Used for Annealing Limestone Specimens.

1 is the specimen enclosed in a small stainless

steel caps~le ~;

l

is the heavy walled stainless steel vessel;1

is the thermoco~ple used for temperat~re meas~rement;

2

is a n~t and 6 a cone seal and1

the flexible stainless steel t~be leading fromthe CO2 cylinder;

8 is the firebrick which fills the opening of

[image:35.650.10.596.9.679.2]•

5

6

I ·

1"--0 1"--0' , •

..

:....

'..

:.'.,~

:.!

:,

..

: ,'

.

• " • • to' "' • •

:

..

...

" ,.. : "...

.

:..

:.1° 00';'" 0'· • ••

~ •. 0'" • , •• :

.:

..

:' ,.

-,

.'

,..

.'.: "';

...

:

.

.

" ,.

: '.

..

:::' .:.

:

,:..

• • t • • :

3

u

cut to just fit the opening of a horizontal muffle

furnace 0

In use, the specimen in its capsule was

placed at point B, the system was flushed with CO2

300

and then the pressure appliedo The vessel was placed

in the muffle furnace and brought up to the required

temperature 0 The vessel was then qUickly removed from

the furnace and tipped, so that the specimen capsule

slid to point A, and then quickly replaced in the

furnace. At the end of the heating period, the vessel

was again removed from the furnace and tipped back to

allow the specimen to slide to the cool end (B).

This process was the best that could be

devised to define the heating period. In a typical run,

for example at 8500C, about half an hour was required for

the temperature of the vessel to come to equilibrium

after insertion in the muffle furnace. At this stage

the outside of the vessel near B, could still be touched

by hand, so that it seems unlikely that the specimen

reached a very high temperature during this period.

After heating for an hour point B reached a temperature

of approximately 2000C, so that cooling of the specimen

was quite slow.

The thermocouple (4) was connected to an

310

"Elliot" indicator with range 0-12000C. This system

was calibrated against a second chromel-alumel couple

connected to a "Cambridge" potentiometer. Standard

tables of E.M.F~ versus temperature calculated from

values given in the International Critical Tables (Vol.l,

p.59) were used and a check was made against the freezing

point of pure sodium chloride.

Temperature gradients in the equipment were

troublesome, and were measured by placing a thermocouple

in a hole drilled in a piece of limestone, which was

placed in position A. Comparison of readings obtained

from this couple with those from the main couple enabled the determination of a correction factor. However, this could only be done with a pressure of 1 atmosphere in the apparatus and, as a result, it is estimated that

+ 0 temperatures are known only to an accuracy of _ 5 C.

The temperature of the muffle furnace was

controlled by a "Foster" Electronic Indicating Controller

and a thermocouple placed against the walls of the

mUffle furnace. This instrument allowed fluctuations

of the order of + 50C in the temperature of the furnace

but the large heat capacity of the stainless steel vessel

I

32.

CHAPTER 30

X-RAY DIFFRACTION OBSERVATIONS.

Methods.

After heat treatment samples were sectioned

parallel to their axes and the faces formed were ground

on successively finer abrasive papers, finishing with

600 grade. Finally, the surfaces were etched with 10%

hydrochloric acid to remove any distortion which might

have resulted from the abrasion.

The Recording of X-ray Line Profileso

The flat surfaces formed were just large

enough for examination in a "Phillip's" PW 1010 stabilised

x-ray unit and a counter diffractometer. The

diffract-ometer was operated with a proportional counter and a pulse

height analyser, the output of which was fed to a

33.

This last item together with a step scanning device

enabled line profiles to be determined semi-automatically

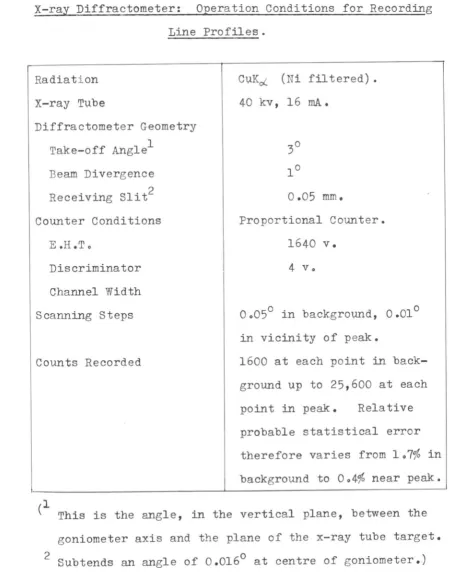

and with a known precision at each point. Full details of the operating conditions are set out in table 3.1 whilst the considerations which led to some of these

conditions are given in Appendix 1. Each diffraction line w:!a.s scanned over an angle of + 1.5 (028 ) from the

position of its main peak. Even from the most heavily deformed samples, this was ade~uate to ensure that the

intensity had fallen to the background level.

The geometrical properties of an x-ray

diff-ractometer modify the shape and position of x-ray

diffracti on lines, (Klug and Alexande~1954). To correct for this the usual practice is to compare the

broadened line with the same line from an annealed

sample of the same substance. A number of methods have

been proposed for obtaining the pure broadening from the

observed line profile and in this work, the method

described by Stokes (1948) has been employedo This

method makes use of certain relations found by Stokes, between the co-efficients of the Fourier series which

represent the three profiles involved, viz. the observed broadened profile, the observed instrumental profile

I

34. TABLE 301

X-ray Diffractometer: Operation Conditions for Recording

Line Profiles.

Radiation

X-ray Tube

Diffractometer Geometry

1

Take-off Angle

Beam Divergence

Receiving Sli t2

Counter Conditions

E.H.To

Discriminator

Channel Width

Scanning Steps

Counts Recorded

CUK~ (Ni filtered).

40 kv, 16 mAe

0.05 mm.

Proportional Counter.

1640 v.

4 vo

00050 in background, 0.010

in vicinity of peak.

1600 at each point in

back-ground up to 25,600 at each

point in peak. Relative

probable statistical error

therefore varies from 107% in

background to 004% near peak.

(l

This is the angle,in the vertical plane, between the

goniometer axis and the plane of the x-ray tube target.

[image:41.585.84.533.73.658.2]F

35.

A number of diffraction lines have been

corrected using an IBM 1620 Computer. (The programme

employed is given in detail in Fortran language in

Appendix 2.) The corrected line profiles covered a

wide range of line breadths and from them it was possible

to draw correction curves to give the integral breadths of the pure broadening from those of the observed curves. A sample, which was deformed 16 per cent and then

annealed for one hour at 8600C was used to provide data

to represent the instrumental broadening. This sample

was considered to be completely recrystallised and

therefore suitable for th~s purpose.

X-ray Diffraction Patterns.

X-ray diffraction photographs were made, usually by the "glancing angle" method, in a "Unicam' single crystal goniometer fitted with an 0.5 mm diameter collimator and a 6 cm diameter cylindrical film cassette.

The specimen was always stationary during the exposure.

Description of the X-ray Diffraction Results .

The Effect of Deformation.

The results of x-ray line broadening

36.

are given here to show the effect of deformatimn on

line broadening but a detailed discussion of the nature

of the deformed state will be left to a later chapter.

The results under the heading integral breadth are the

integral breadths of the pure broadening, corrected for

instrumental effects by the method described in the

last section.

A number of inferences may be made from this

table.

1. It is noted that prior to deformation this block

of Solenhofen limestone gives an appreciable amount of

line broadening.

2. There is the expected result that increasing

deformation leads to greater broadening. However, it

may be noted that there is a relatively larger increase

of line broadening in the early stages of deformation

(less than 10% strain) than in subsequent stages.

30 Deformation does not broaden all diffraction lines

equally nor do the breadths of the various lines follow

any simple relation to the Bragg angle,

e.

4. The integral breadth of the (1014) reflection depends

on the plastic strain and is independent of whether the

stress was compressive or tensile, despite the

'

-37. TABLE 3.2.

solenhofen Limestone: Effect of Deformation on the

Broadening of X-ray Diffraction Lines.

Residual Strain Integral Breadth (028 )

Plastic at 8,000 Sense

Strain atmos 0 (1014) (1120) (1123) (2022'

(%)

(%)

3.9 5.7 compo 0.180 0.227 0.244 0.224

9 .7 1301

"

0.24216.0 20.0

"

0.264 0.386 00441 0035021'.1 25.8

"

0.295...

5.5 ext • 0.180(1)- ""12

"

0...236(2)16 06 20.0 compo 00295 0.436 0.502 0.387

(3) 0.16

-

0.116Initial Condition 0.080 0.081 0.106 0.111

(1) Strain approximate because specimen was beginning

to neck.

(2) Preheated at 8600C for 1 houro

(3) Exposed to hydrostatic pressure of 8,000 atmospheres

[image:44.588.80.536.82.597.2])

5. Expos~re of a specimen to a hydrostatic pressure

of 8,000 atmospheres, i.e. a pressure equal to the

confining press~re in deformation experiments, has led

to a shortening of the specimen and a measurable increase

in line breadtho This can be attributed to the collapse

of pores, which is consistent with Paterson's (1963b)

observation of a small increase of density in similar

circ1,.UJlstances.

6. Preheating of Solenhofen limestone to 8600C for one

hour leads to greater broadening for a similar strain.

Perhaps this is a consequence of the larger rate of

work hardening in this material.

TIiffraction patterns of Carrara marble before

and after deformation (fig~res 3.1, 302, 3.3) show that

what were originally q~ite sharp spots are elongated into arcs lying on TIebye-Scherrer rings and asterism

streaks appear at low diffraction angles. These effects

can be attrib~ted to the development of a sub-grain

'"'

str~ct~re (Hirsch and Kellar, 1952), in whi ch there are

---small misorientations (of the order of one degree)

between individ~al s~b-grains. The lengths of the arcs,

which are broadened radially, are proportional to the

FIGURE 3.1

Carrara Marble Initial Condition.

,

(

FIGURE 3.2

Carrara Marble - Deformed 6%.

FIGURE 3.3

i

,

"

.

/

400

The Effect of Annealing.

The effect of annealing on the broadening of (1014) diffraction lines of Solenhofen limestone is

illustrated in figures 304 and 3.5. The former,figure presents values of the integral breadths of the broaden-ing of (1014) reflections from samples which were heated at constant temperatures for various times o All

specimens had been deformed to a final plastic strain of 16 per cent. Figure 3.4 suggests that two distinct processes are involved in the reduction of btoadening.

In the first stage, reduction of broadening to a value determined by the annealing temperature occurs

in the first few minutes of heating. Thereafter,

further reduction is very slow and appears to be proport

-ional to the logarithm of the heating time. If the temperature is high enough (order of 700oC) the

broadening is qUickly reduced to a constant value and prolonged heating for times up to 10 hours brings no further change. At still higher temperatures, the second process becomes important. The broadening

drops to the same constant value, remains there for a period dependent on the temperature and then falls

again until, if heating is prolonged sufficiently, it

[image:48.592.108.511.98.666.2]<::

~

FIGURE

3.

4

Solenhofen Limestone, deformed 16%.

Variation,of the Broadening of

(1014)

reflections,FIGURE 3.5

Solenhofen Limestone.

Variation of the Broadening of (10I4) Reflections with

Annealing Temperature. Heating time one ho~r.

1. Deformed 16%.

2. Heated at 8600C for one hour then deformed

3. Deformed 309%.

with

ur.

0·1, 0/5o

2 ... ""- "'-~ ~ ~ •-

-

-

/

3

--V ...

'" 1

-(/

-I ~\

\

\,

" " -j \ . ,

.-

-.~ " '\Z I "-'\\ _. '.

" I ~_ \

~-. - ._ . .s::fl

\" '\

•

•42.

(

4-

i

~

.

-... -. -.-.

--

--

...

--

..

-

-

-.

.

.

-.-

.

.

..

:-:-=--

----.

...

.

--

.. -.-.-

---.-

--~. ~·-·-t··-Xt'\\

\

\.

I \

\

\ .\

\

\-\\

W\ \

\

1>7*

O~

--~--~

J Z--~--~--~--~--=---~\I--~--

J • 5 6 7 81 943 co

The form of the curves in the first and

second stages is typical of the behaviour to be

expected from recovery and recrystallisation,

respect-ively 0 These processes were defined in Chapter 1.

Further evidence that the second stage

corresponds to recrystallisation is provided by x-ray

diffraction photographs which are reproduced in figures

In the first, which is from

the sample heated at 7750C for one hour, continuous

diffraction rings are obtained and the pattern is

v.irtually unchanged from that of an unannealed deformed

sample. As the heating time is prolonged, a progressive

splitting up of the rings into assemblages of spots

occurs, showing clearly that the material is

recrystall-ising in the second stageo

The same tendency for two stages in the

reduction of line broadening can be seen in figure

3.5

where data is presented showing the effect of heating

for periods of one hour at different temperatures on

samples with various histories.

Comparison of the temperatures at which

recrystallisation can be first detected, from the line

broadening measurements, shows that they are lower for

I ~

/ .

,

FIGURE 306

Solenhofen Limestone, deformed 16% and annealed

775

0C for one hour.FIGURE

3

.

7

Solenhofen Limestone, deformed 16~~ and anneal ed

775

0c

for two hours .The rings are starting to become spotty.

FIGURE 3.8

Solenhgfen Limestone, deformed 16% and anneal ed

775

C for 11 hours .FIGURE

3

.

9

Solenhgfen Limestone, deformed 16% and annealed 960 C for one hour .

Fully recrystallised. Note the greatly improved

(

• l :

.

,

:I

FIGURE 3..l0

Solenhofen Limestone - Initial Condition .

FIGURE 3011

Solenhofen Limestone - Heated to g600C f01' one hour .

(The different appearance at the right hand side of the

photographs is not significant. The sample used to obtain

tain

iably

o

FIGURE 3.12 .

Carrara Marble, deformed 16% and annealed at 500°C for one

hour . Compared with figure 3.3 the arcs are of similar

length but appear to be much sharper.

FIGURE 3 .. 13.

Carrara Marble, deformed 16% and annealed at 725°C for one

hour. Some sharp spots are beginning to appear.

FIGURE 3.14.

Carrara I.Iarble, deformed 16% and annealed at 890°C for one

houro The pattern is predominantly one of sharp

/

48.

not been observed and this suggests that polygonisation,

described by Guinier and Tennevin (1950), either does

not occur or is on a very fine scale.

An accurate measure of line broadening cannot

be obtained unless a sufficient number of the grains are

so oriented that they contribute to the diffraction line

being studied. Failure to meet this requirement can

be detected from the value of the integrated intensity

of the line, which will be higher than the correct value

if a few large grains are oriented to contribute to the

reflection or lower if too few grains are contributing.

For this reason, because of the large grain

size of Carrara marble, the radial broadening of the

arcs cannot be satisfactorily measured with the

diff-ractometer for the (1014) reflection. However, the

larger multiplicity factor of the (1123) reflection

made some approximate measurements possible. Integral

breadths for this reflection are given in table 3.3

together with the integrated intensities. It can be

seen that these latter values are very scattered so that

no great accuracy can be claimed for the integral breadth

measurements but they tend to confirm the visual impression

490

by anneal ing •

TABLE 3.3

Carrara Marble Integral Breadths of (1123) Reflections.

(B

Integrated Conditions (°28) Intensity (ArbitraryUnits)

Initial 0.04 383

Deformed 16.6% 0.32 281

Deformed 16.6% Annealed 5000C/l hour 0.25 281

"

"

"

695°C"

"

0.11 250\I

"

\I 730°C"

"

0.07 226"

"

"

775°C " \I 0.02 410"

"

"

860°C ""

0.09 245Other Observations.

1. Background. The background measurements made in

the course of line profile determinations are subject to

a relative probable statistical counting error of nearly

500

level between f~lly deformed and fully recrysta11ised

specimens.

To check this further, a number of measurements

over extended t imes were made at several points in the

background. The results are given in table 3.4.

TABLE 3.4

Measurements of Counting Rate in Backgroundo

Sample Angle Total Counting Counting

(029 ) Counts Time Rate

(mins.) (C/S)

IC 27.5 21,039 120 2092

DEF \I 19,946 113 2094

REC II 11,420 65 2.93

IC 33.8 23,382 134 2.91

DEF II 10,199 60 2083

IC 37.6 17,010 112 2.53

DEF II 19,660 120 2.73

REC II 8,788 51 2.87

IC

=

Solenhofen Limestone - initial conditionDEF ::: II II - deformed 16%

REC=

9600 for one hour.

16% and annealed

51.

They suggest that there is no significant

difference among the three sampleso The scatter amongst

the individual results probably arises from variations

in the natural background rate,that is the counting

rate observed when the x- ray tube window is shut.

This natural counting rate was quite appreciable and

probably averaged about

0

.

24

counts per second.2. Integrated Intensities of X- ray Diffraction Lines.

The integrated intensities of all the

x-ray diffraction lines are substantially constant

for most of the samples examined irrespective of their

history, except after recrystallisation has commenced.

The mean deviation from the mean integrated intensity

for

41

measurements on(1014)

reflections from Solen-hofen limestone is only

3

.

2

%

.

For Solenhofen limestone deformed 16% and

annealed at temperatures above 7500C the integrated

intensity increases by as much as 40%. This increase

is due, at least in part, to the development of a weak

preferred orientation of the recrystallised grains which

has been confirmed with x-ray diffraction photographs,

figure 3.15. The texture has not been observed in tbe

52.

prior to deformation. The reason for this difference

in behaviour is not knOWDo

The constancy of the integrated intensities

of all the diffraction lines suggests that extinction

does not occur even in the fully annealed specimens.

Peak Positions. It was found that the angular

displacement between the centroids of the various peaks

remained constant, within the limits of the accuracy

of the measurementso

40

Blue Colouration. When calcite crystals whichhave been deformed by slip are irradiated with x-rays

or gamma rays, they develop a bluish purple colouration

(Przibram 1927, Handin, Higgs, Lewis and Weyl, 1957,

Paterson 1958b.) Handin et ale also observed that

when discoloured samples were heated to 2900C the

colour disappearedo

The same effect has been observed in this

investigation in both Solenhofen limestone and Carrara

marble. It is found that immediately after i~radiation

the colour is purple but after a few days it decays to

blue, which is very persistent. After heating to 200oC,

irradiation causes the development of the blue colour

only and with a reduced saturationo After standing for

FIGURE 3015.

Solenhofen limestone, deformed 16% and annealed

at g600C for one hour, showing the weak maxima on the

(1014)

reflection which develops during recrystallisation.This photograph was obtained by transmission through

a platelet c~t so that its plane contained the long axis

of the specimen. The axial direction is indicated by

arrows"

To ens~re that a representative photograph was

obtained, the specimen was moved several times in its

ed

tiono

54.

disappears, only to reappear on further irradiationo The effect is still noted in samples heated at 200°C for 12 hours but disappears after 32 hours at this temperatureo It is still observed in a sample

heated to 260°C for one hour but has disappeared in

a sample heated to 340°C for the same time. This

temperature dependence agrees with Handin et alls observation.

It is to be noted that the effect has

disappeared before there has been any great change in

the x-ray line breadths.

Interpretation of the X-ray Diffraction Results .

The Kinetics of the Annealing Processes.

The data illustrated in f igure 3.4 can be used in a quantitative discussion of the kinetics of

the recovery and recrystallisation processes and this

will now be attempted.

Recovery. Since we are concerned with the recovery of line broadening, we may substitute.;8 for x in the equation 1.3 and obtain

where IcJ £)

0

RT

m log

55.

( mc o to)

e RT

The expression of the equation 3.1 gives a form of

dependence which is qualitatively similar to the results of the first stage of figure 3.4, but insufficient data has been accumulated to enable so many constants to be determined" The shapes of the curves of figure 3.4 do not agree with the hyperbolic time law proposed by Betteridge (1953-40)

A similar substitution of

f1

for x in equation 1,,21

tr

leads to the relation,

= Co exp _ (: ;) • • • • • • 3.2

where tr is the time to produce a given fraction, r ,

of the total recovery and T is the absolute temperature 0 The activation energy for recovery Qr is of interest because it is often found to be equal to the activ

-ation energies for self-diffusion and for steady- state creep.

Unfortunately, insufficient data has been obtained to test whether equation 302 is strictly

its val~e, which can be found from the gradient of

the straight lines obtained by plotting log JL

e tr

1

against I f 0 The limits found are Q

r (minim~)

56.

=

20 k cal mole-l and Qr (maxim~)=

35-k cal mole-loThese val~es were determined at a point where the

integral breadth of the broadening eq~alled 0.225028

which corresponds to approximately

30%

of recoveryhaving occ~rred.

These res~ts will be disc~ssed in Chapter 6.

Recrystallisationo

The c~rves for annealing temperatures of

7560C and higher in fig~re

3.4

appear to be approximatelyof the sigmoidal type generally found to be associated

with recrystallisation. Such curves us~ally obey an

eq~ation of the form,

X

=

1 - exp (_Btk) o • • 0 • • • 3.3 where X is the fraction of recrystallised material attime t; Band k are constants, the former being

temper-at~re dependento If this equation is applicable,

plots of loge log ( 1 ) vers~s loge t sho~d be straight

e ( I-X)

lines with slope k. A plot of this type has been made

1

"FIGURE 3.16.

Solenhofen Limestone Deformed 16% and annealed.

Values of log log

r

1 ]I

(It)

58.

With one exception, the experimental

points are seen to lie reasonably well on a set of

parallel straight lines, from which k is found to be

1.3

~

0.3. It has been assumed that X=

1 -~T'

where ~ is the integral breadth from material annealed

o

at 690 C, ioe. fully recoveredo

This assumption is equivalent to saying that

all the material is fully recovered before

recrystall-isation commences and that no further reduction of line

broadening occurs in the recovered material until it lli

consumed by new recrystallised grains . Whether this

assumption is justified could only be tested by

determining X by some independent method.

The temperature dependence of

recrystall-isation can usually be expressed in terms of a single

activation energy, Qc' by the equation

1

tx

=

0 0 0 • • • 0where ~ is the time at which a fraction X of the

material has recrystallised at the absolute temperature

T. R is the gas constant and A a constant. The

only assumption that is necessary when applying this

-I-590

represent constant values of X, irrespective of the

annealing treatment which has produced them.

Figure 3.17 shows the results of plotting loge (~) against 1 for several values of Xo

~

T

The

straight lines which are obtained are compatible with equation (3.4) and from their slope Qc is found to be

108 k cal mole-l + 15%.

The uncertainty in the value of Q

c

(±

15%)h~s been arrived at by considering the effects of the

uncertainty in temperature measurement and the

deter-mination of the broadeningo

A discussion of the results of this section

FIGURE 3.17

Solenhofen Limestone, Deformed 16% and Annealed.

1--t

-l--3

of

fJ·

0-071, / , ,

60.