Temperatured-Controlled Device For Medical Application Using Peltier Effect

Full text

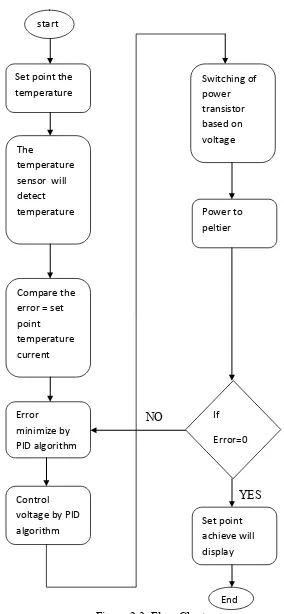

Figure

Related documents

The purpose of the I Comprehensive Mental Health Plan for Andalusia (2003-2007) (10) is to meet the mental health needs of people living in the region by reorientating existing

Factors such as (i) general economic conditions and competitive factors, particularly in key markets; (ii) the risk of a global economic downturn, in the financial services

ﺎﻫ ﺵﻭﺭ ﻱﻭﺭ ﺮﺑ ﻲﻠﻴﻠﺤﺗ ﻲﻔﻴﺻﻮﺗ ﻪﻌﻟﺎﻄﻣ 75 ﻡﺮﺗ ﻥﺎﻳﻮﺠﺸﻧﺍﺩ ﺯﺍ ﺮﻔﻧ ﻱﺭﺎﺘﺳﺮﭘ ﻩﺪﻜﺸﻧﺍﺩ ﻱﺭﺎﺘﺳﺮﭘ ﻲﺳﺎﻨﺷﺭﺎﻛ (ﺖﺸﻫ ﻡﺮﺗ) ﺮﺧﺁ ﻪﺻﺮﻋ ﺭﺩ ﻱﺯﻮﻣﺁﺭﺎﻛ ﺱﻭﺭﺩ ﺯﺍ ﻲﻤﻴﻧ ﻞﻗﺍﺪﺣ ﻪﻛ ﻥﺎﻬﻔﺻﺍ

Should this application be accepted by the Company, coverage will apply to claims first made against the insured during the policy period.. No coverage will apply for claims first

The study presents developed models of the geometrical parameters of an empty flanged diffuser that suitable for a scaled-down (1-6.5) horizontal axis wind turbine, the

As a response to troubling doubts about the success of Web-delivered courses that include problem solving and critical thinking skills, the authors gathered data from two

REALTOR® - is a registered mark which identifies a professional in Real Estate who subscribes to a strict Code of Ethics as Members of the NATIONAL ASSOCIATION OF REALTORS®. Page 4