Press Presse Press Presse

Industry

Sector

Drive Technologies Division

Nuremberg/Germany, March 14, 2012

Hannover Messe 2012 / Hall 9, Booth A72

Background Paper

Energy-efficient ship propulsion systems from Siemens

Increasing costs, greater competitive pressure and stricter environmental regulations call for developments in shipping and marine engineering that contribute to environmental protection and energy efficiency. For more than one hundred and thirty years, Siemens has been specializing in the planning, manufacture and assembly of electrical equipment for all types of merchant and naval vessels, as well as submarines. This covers turnkey projects and conversions throughout a ship's life cycle. The Siemens "Marine & Shipbuilding" Division offers shipyards and shipping lines solutions which sustainably increase the environmental compatibility and commercial efficiency of the entire shipping operation. Kay Tigges, the expert for "Green Ship" technology at Siemens and the "Siemens Inventor of the Year 2009", commented: "Efficiency and environmental sustainability are not opposites in the shipping industry; on the contrary, together they form a competitive factor." Two systems from Siemens are described here in detail.

Exhaust gas heat conversion on board ship to supply the on-board power network and to boost the propulsion with hybrid drives (Waste Heat Recovery System – WHRS)

Fuel consumption is one of the major cost items in ship operation. Highly efficient propulsion solutions and intelligent energy management are crucial to remaining competitive in the long term. At the same time, technologies that are more environmentally compatible are required to meet the ever stricter worldwide environmental protection regulations. The Waste Heat Recovery System (WHRS) helps to meet both of these demands optimally.

2 / 5

Reference number: IDT201203.BI10

Media Relations: Franz-Ferdinand Friese

Phone: +49 911 895-7946 E-Mail: franz.friese@siemens.com Siemens AG

Industry Sector – Drive Technologies Division Gleiwitzerstr. 555, 90475 Nuremberg, Germany

Clean, efficient, flexible

The WHRS uses exhaust gases from the diesel propulsion engine to produce additional electrical power from the ship's fuel in a clean and efficient manner. The system offers decisive competitive advantages by cutting energy costs by up to 12 percent, reducing CO2 and NOX emissions, and significantly lowering maintenance costs. The user also gains more flexibility in the ship design. Smaller fuel tanks give greater scope in the design of the ship's lines and its interior, and the main propulsion system can have a lower rated power. Reliable, internationally available standard components and well-established spare parts logistics make maintenance easier and ensure maximum safeguarding against failure.

Versatile, powerful, safe

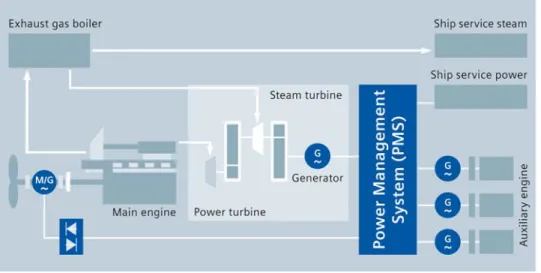

In two-stroke direct propulsion systems, the WHRS uses hot exhaust gases to generate

superheated steam, which drives a two-stage steam turbine. An exhaust gas turbine can be fed with excess exhaust gas that is not needed for turbocharging. Together with the steam turbine, it drives the electricity generator (waste heat conversion principle), which generally supplies the entire on-board power network. Surplus electric power can be used to boost the propulsion system by means of an electric drive that acts directly on the propeller shaft. At a low machine load, the waste heat recovery system can be run in parallel with a diesel generator set. Parallel operation with a shaft generator, also known as power take-off operation, is easily implemented, because this electric machine is in any case installed to feed in excess energy. This is a slow-running electric machine mounted directly on the propeller shaft without gears, which can work both as a generator and as a motor. All the functionalities of the WHRS are controlled by a power

management system that ensures optimal use of the available energy, and automatically adjusts the shaft generator operation to match respective requirements. This utilizes reserve power, reduces the wear on the main propulsion system, and increases the reliability of the on-board power supply.

Diagram of the WHRS from Siemens

Optimization of ship operation with the EcoMain communication platform

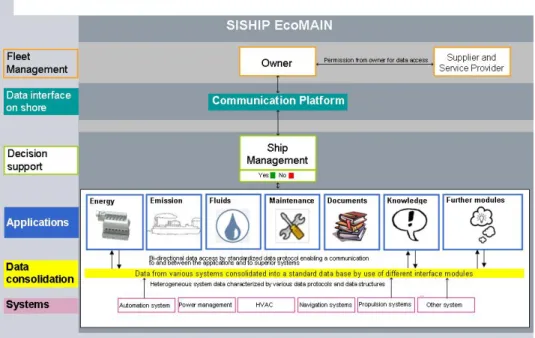

The many on-board technical installations and systems supply informative data about their status, performance and efficiency. The EcoMain communications platform helps to utilize the commercial potential of the ship by optimizing its operation. Through a wide range of on-board interfaces, EcoMain collects data from as many technical systems as possible, prepares it in a standardized format, and makes it available on a common data platform. Energy consumption, emissions, bunkering with liquids, maintenance schedules, document and knowledge management and a great deal more can be evaluated and subsequently optimized. The greatest potential for

improvement lies in energy consumption, environmental compatibility and maintenance intervals.

Targeted decision support for green fleet management

The system assists the ship management by providing specific information for optimization: Lower-level modules below EcoMain, such as the power management system, help in the making of decisions to improve the performance of a ship or an entire fleet. As a result, EcoMain enables significant cost savings to be made with "green" fleet management, which safeguard the investment and the future of the fleet. These are crucial competitive advantages.

Diagram of the EcoMain communication platform from Siemens

Kay Tigges, Experte für „Green Ship“-Technolgie bei Siemens und Siemens-Erfinder des Jahres 2009

4 / 5

Reference number: IDT201203.BI10

Media Relations: Franz-Ferdinand Friese

Phone: +49 911 895-7946 E-Mail: franz.friese@siemens.com Siemens AG

Industry Sector – Drive Technologies Division Gleiwitzerstr. 555, 90475 Nuremberg, Germany

The Siemens Industry Sector (Erlangen, Germany) is the world’s leading supplier of innovative and environmentally friendly products and solutions for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the Sector enhances its customers’ productivity, efficiency, and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the

5 / 5

Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit www.siemens.com/industry

The SiemensDrive Technologies Division (Nuremberg, Germany) is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive

Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the Division fulfills the key requirements of its customers for productivity, energy efficiency, and reliability. For more information, visit www.siemens.com/drives