University of Pennsylvania

ScholarlyCommons

Publicly Accessible Penn Dissertations

1-1-2015

Catalytic and Thermodynamic Studies of

Supported Core-Shell Catalysts

Chen Chen

University of Pennsylvania, chenc052@gmail.com

Follow this and additional works at:http://repository.upenn.edu/edissertations

Part of theChemical Engineering Commons

This paper is posted at ScholarlyCommons.http://repository.upenn.edu/edissertations/1646 For more information, please contactlibraryrepository@pobox.upenn.edu.

Recommended Citation

Chen, Chen, "Catalytic and Thermodynamic Studies of Supported Core-Shell Catalysts" (2015).Publicly Accessible Penn Dissertations. 1646.

Catalytic and Thermodynamic Studies of Supported Core-Shell Catalysts

Abstract

Interactions between metal catalysts and oxide supports have been known to be important in modifying the catalyst properties for many years, and catalysts with core-shell nanostructures are promising for optimizing these metal-oxide interactions. In this dissertation, core-shell nanoparticles that consist of a metal core and a metal-oxide shell were synthesized and deposited onto an alumina support. These core-shell catalysts exhibit unique catalytic and thermodynamic properties, and were investigated with different core-shell compositions as part of this thesis.

The first part of this dissertation focuses on a Pd@CeO2/Si-Al2O3 catalyst that has been developed and examined for methane-oxidation previously. To better understand this material, I investigated the catalytic, adsorption, and redox properties as they are related to the methane-steam-reforming. I also looked at the effect of calcination temperature on the catalytic properties since the catalysts were strongly influenced by the calcination temperatures, in a manner that is very different from that observed with conventional Pd/CeO2 catalysts. It was found that calcination to higher temperatures improved the performance of the Pd@CeO2 catalyst by modifying the redox properties of the ceria shell.

In the second part of this dissertation, the synthesis and investigation of core-shell catalysts was extended to other precious-metal cores and metal-oxide shells. To determine the effect of shell material, a Pd@ZrO2/Si-Al2O3 catalyst was investigated. The ZrO2 in contact with Pd was found to be reducible and to enhance the methane-oxidation.

A Au@TiO2/Si-Al2O3 catalyst was also synthesized and examined for CO oxidation. It was found that the strong interaction between Au and TiO2 not only enhanced the oxidation activity of Au but also effectively prevented Au sintering up to 873 K.

Additionally, catalysts with Pd or Pt cores and ZnO shells were prepared. The formation of Pt-Zn alloy was suggested by in-situ TEM and coulometric titration results and by catalytic properties for methanol-steam-reforming.

Finally, metal-oxide interactions were compared for Pd@CeO2 and Pt@CeO2. A very strong interaction between Pd and CeO2 helped to stabilize the core-shell structure at higher calcination temperatures and affected the CO accessibility of the core for catalyst calcined at lower temperatures, but these were not observed with Pt.

Degree Type Dissertation

Degree Name

Doctor of Philosophy (PhD)

Graduate Group

Chemical and Biomolecular Engineering

First Advisor Raymond J. Gorte

Keywords

Catalyst, Metal-oxide interaction, Nanoparticles

Subject Categories Chemical Engineering

CATALYTIC AND THERMODYNAMIC STUDIES OF SUPPORTED CORE-SHELL CATALYSTS

Chen Chen

A DISSERTATION

in

Chemical and Biomolecular Engineering

Presented to the Faculties of the University of Pennsylvania

In Partial Fulfillment of the Requirements for the

Degree of Doctor of Philosophy

2015

Supervisor of Dissertation

_______________________

Raymond J. Gorte, Professor of Chemical and Biomolecular Engineering

Graduate Group Chairperson

_______________________

Raymond J. Gorte, Professor of Chemical and Biomolecular Engineering

Dissertation Committee

John M. Vohs, Professor of Chemical and Biomolecular Engineering

Talid R. Sinno, Professor of Chemical and Biomolecular Engineering

ii

ACKNOWLEDGMENT

First, I would like to wholeheartedly thank my advisor, Professor Raymond J.

Gorte, for his continuous guidance and support. He has been a wonderful mentor to me

and I really appreciate him for giving me the opportunity to be his PhD student. Catalysis

is a fascinating research field, I have gained great insights and understanding of this

subject under his guidance and I will always be grateful for the experience working with

him.

Next, I wish to express my deep gratitude to Professor Paolo Fornasiero and

Professor John M. Vohs for their valuable suggestions and advice during the past five

years. I would like to thank professors Russell Composto and Talid Sinno for taking the

time to serve on my thesis committee and providing valuable comments. I would also like

to acknowledge Professor Christopher B. Murray for letting me use his lab facilities.

I would like to extend my sincerest thanks and appreciation to all the post doctors

and students I have been working with, particularly, Dr. Matteo Cargnello. Working with

them has made my time in graduate school enjoyable.

Finally, I would like to dedicate my dissertation of my family for their

iii

ABSTRACT

CATALYTIC AND THERMODYNAMIC STUDIES OF SUPPORTED CORE-SHELL

CATALYSTS

Chen Chen

Raymond J. Gorte

Interactions between metal catalysts and oxide supports have been known to be

important in modifying the catalyst properties for many years, and catalysts with

core-shell nanostructures are promising for optimizing these metal-oxide interactions. In this

dissertation, core-shell nanoparticles that consist of a metal core and a metal-oxide shell

were synthesized and deposited onto an alumina support. These core-shell catalysts

exhibit unique catalytic and thermodynamic properties, and were investigated with

different core-shell compositions as part of this thesis.

The first part of this dissertation focuses on a Pd@CeO2/Si-Al2O3 catalyst that has

been developed and examined for methane-oxidation previously. To better understand

this material, I investigated the catalytic, adsorption, and redox properties as they are

related to the methane-steam-reforming. I also looked at the effect of calcination

temperature on the catalytic properties since the catalysts were strongly influenced by the

calcination temperatures, in a manner that is very different from that observed with

iv

improved the performance of the Pd@CeO2 catalyst by modifying the redox properties of

the ceria shell.

In the second part of this dissertation, the synthesis and investigation of core-shell

catalysts was extended to other precious-metal cores and metal-oxide shells. To

determine the effect of shell material, a Pd@ZrO2/Si-Al2O3 catalyst was investigated. The

ZrO2 in contact with Pd was found to be reducible and to enhance the methane-oxidation.

A Au@TiO2/Si-Al2O3 catalyst was also synthesized and examined for CO

oxidation. It was found that the strong interaction between Au and TiO2 not only

enhanced the oxidation activity of Au but also effectively prevented Au sintering up to

873 K.

Additionally, catalysts with Pd or Pt cores and ZnO shells were prepared. The

formation of Pt-Zn alloy was suggested by in-situ TEM and coulometric titration results

and by catalytic properties for methanol-steam-reforming.

Finally, metal-oxide interactions were compared for Pd@CeO2 and Pt@CeO2. A

very strong interaction between Pd and CeO2 helped to stabilize the core-shell structure at

higher calcination temperatures and affected the CO accessibility of the core for catalyst

v

TABLE OF CONTENTS

ACKNOWLEDGMENT ... ii

ABSTRACT ... iii

LIST OF TABLES ... ix

LIST OF FIGURES ... x

Chapter 1. Introduction ... 1

1.1 Background ... 1

1.2 Evidence for Metal-Oxide Interactions ... 2

1.2.1 Bi-Functional Catalysts ... 2

1.2.2 Strong Metal-Support Interaction (SMSI) ... 3

1.2.3 Oxygen Storage Capacitance (OSC) ... 4

1.2.4 Alloy Formation ... 5

1.3 Mechanisms of Metal-Oxide Interactions ... 5

1.3.1 Schwab Effect ... 5

1.3.2 Bonding Interaction ... 6

1.3.3 Oxygen Transfer ... 9

1.4 Approaches to Improve Metal-Oxide Interaction ... 13

1.5 Scope of the Thesis ... 17

Chapter 2. Experimental Techniques ... 19

2.1 Catalyst Synthesis ... 19

vi

2.1.2 Supported Catalysts ... 20

2.2 Equilibrium Measurements ... 21

2.2.1 Coulometric Titration... 21

2.2.2 Transient-Pulse Measurement ... 23

2.3 Other Characterization Techniques... 24

2.3.1 TEM ... 24

2.3.2 XRD ... 25

2.3.3 Chemisorption ... 25

2.3.4 FTIR ... 26

2.3.5 TPO ... 26

2.4 Catalytic Studies ... 27

2.4.1 Steady State Rates Measurements ... 27

2.4.2 Light-Off Measurements ... 28

Chapter 3. High Temperature Calcination Improves the Catalytic Properties of Alumina-Supported Pd@Ceria Prepared by Self Assembly ... 29

3.1 Introduction ... 29

3.2 Experimental Methods ... 32

3.3 Results ... 37

3.3.1 Materials ... 37

3.3.2 Reactor Measurements ... 40

3.3.3 CO Adsorption ... 44

3.3.4 Transient-Pulse Studies ... 47

3.4 Discussion ... 52

vii

Chapter 4. Methane Oxidation on Pd@ZrO2/Si-Al2O3 is Enhanced by Surface

Reduction of ZrO2 ... 56

4.1 Introduction ... 56

4.2 Experimental Methods ... 58

4.3 Results ... 62

4.4 Discussion ... 76

4.5 Summary ... 79

Chapter 5. Au@TiO2 Core-Shell Nanostructures with High Thermal Stability ... 80

5.1 Introduction ... 80

5.2 Experimental Methods ... 82

5.2.1 Synthesis of MUA-Au Nanoparticles ... 82

5.2.2 Preparation of Au@TiO2 Core-Shell Structures ... 83

5.2.3 Preparation of Conventional Au/TiO2 ... 83

5.2.4 Characterization ... 84

5.3 Results and Discussion ... 85

5.4 Summary ... 94

Chapter 6. Supported Platinum-Zinc Oxide Core-Shell Nanoparticle Catalysts for Methanol Steam Reforming ... 95

6.1 Introduction ... 95

6.2 Experimental Methods ... 98

6.2.1 Materials ... 98

6.2.2 Synthesis of the Catalysts ... 98

6.2.3 Characterization ... 101

viii

6.4 Summary ... 115

Chapter 7. A Comparison of Hierarchical Pt@CeO2/Si-Al2O3 and Pd@CeO2 /Si-Al2O3 ... 116

7.1 Introduction ... 116

7.2 Experimental Methods ... 117

7.2.1 Synthesis of the Catalysts ... 117

7.2.2 Characterization ... 118

7.3 Results and Discussion ... 120

7.3.1 Catalyst Characterization ... 120

7.3.2 WGS activity ... 122

7.4 Summary ... 130

Chapter 8. Conclusion ... 131

ix

LIST OF TABLES

Table 2.1: Reactant gas-phase composition ... 27

Table 3.1: Pd dispersions, in percent, based on CO uptakes at room temperature for different H2 reduction temperatures. ... 45

Table 4.1: Pd dispersions based on CO uptakes at room temperature. ... 66

Table 4.2: Results of O2 titration and pulse study on different Pd based samples that used

in this chaper. ... 72

Table 6.1: Metal apparent dispersions (%) based on CO uptake at room temperature for the calcined samples after different pre-treatment conditions. .... 110

Table 6.2: Methanol steam reforming activity and CO2 selectivity of the catalysts at 573

K. ... 113

x

LIST OF FIGURES

Figure 1.1: Schematic representation of the procedure to obtain dispersible Pd@CeO2

core-shell nanostructures [60]. ... 15

Figure 1.2: Schematic representation of the agglomeration of Pd@CeO2 structures when

using the pristine alumina (A) and their deposition as single units after treatment of the same support with triethoxy(octyl)silane (TEOOS) [63]... 16

Figure 2.1: Schematic diagram of coulometric titration setup [64] ... 22

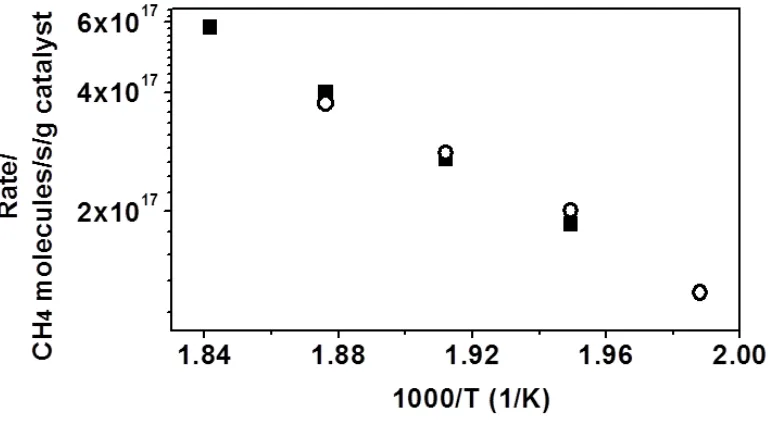

Figure 3.1: Methane-oxidation rates in 0.5% CH4 and 5% O2 over Pd@CeO2

/Si-Al2O3(1073) with total flow rate of 120ml min-1 (■), 80ml min-1 (

○

). ... 34Figure 3.2: Rates for MSR reaction over Pd@CeO2/Si-Al2O3(1073) with total flow rate

of 120ml min-1 (■), 60ml min-1 (

○

). The concentration of CH4 and H2O were held at 35torr and 70 torr respectively. ... 34

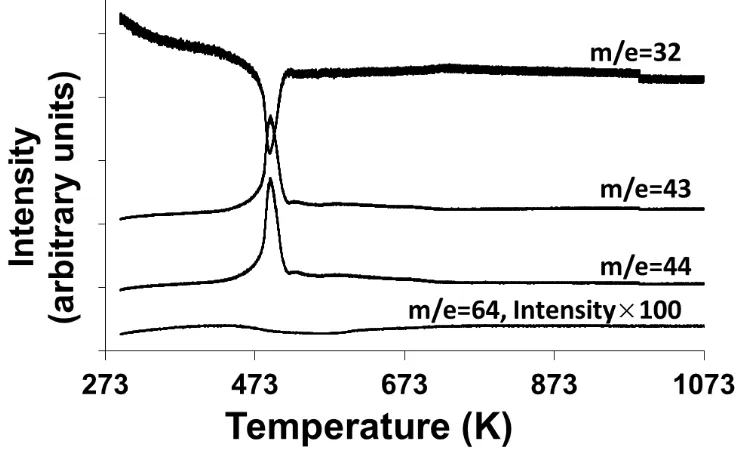

Figure 3.3: TPO results for uncalcined samples of Pd@CeO2/Si-Al2O3 in 10% O2. The

data were obtained monitoring O2 (m/e = 32), various hydrocarbons (m/e = 43), CO2 (m/e

= 44), and SO2 (m/e = 64). The data for O2, hydrocarbons, and CO2 were obtained using

0.1 g of sample, while data for SO2 were obtained using 1.0 g of catalyst for enhanced

sensitivity. ... 38

Figure 3.4: XRD powder patterns of Al2O3, Pd@CeO2/Si-Al2O3(773), and Pd@CeO2

/Si-Al2O3(1073) (Top). Bottom part: reference powder diffraction patterns of bulk Pd and

CeO2 phases labeled with Miller indices. ... 39

Figure 3.5: Methane-oxidation rates in 0.5% CH4 and 5% O2 for Pd@CeO2

/Si-Al2O3(773) (■), Pd@CeO2/Si-Al2O3(1073) (●), and Pd@CeO2/Si-Al2O3(1123) (▲). Data

were taken with 3.8 torr CH4 and 38 torr O2... 40

Figure 3.6a): CH4 conversion as a function of time during the MSR reaction at 693 K

over Pd@CeO2/Si-Al2O3(1073). Data were taken with 35 torr CH4 and 70 torr H2O. .... 42

Figure 3.6b): CH4 conversion as a function of time during the MSR reaction at 693 K

over Pd@CeO2/Si-Al2O3(773). The sample was exposed to oxidizing and reducing

xi

Figure 3.7: Rates for the MSR reaction over Pd/CeO2 (■), Pd@CeO2/Si-Al2O3(1073)

after oxidizing in O2 (

○

), and Pd@CeO2/Si-Al2O3(1073) after reducing in H2(Δ). Datawere taken with 35 torr CH4 and 70 torr H2O. ... 43

Figure 3.8: Diffuse reflectance FTIR spectra obtained in flowing He after exposure to CO at room temperature for the following samples: a) Pd@CeO2/Si-Al2O3(773) after

reduction at 423 K; b) Pd@CeO2/Si-Al2O3(773) after reduction at 673 K; c)

Pd@CeO2/Si-Al2O3(1073) after reduction at 423 K; and d) Pd@CeO2/Si-Al2O3(1073)

after reduction at 673 K. ... 46

Figure 3.9: Results from the pulse measurement performed at 673 K on Pd@CeO2

/Si-Al2O3(773). The data were obtained monitoring CO2 (m/e = 44), O2 (m/e = 32), and CO

(m/e = 28). ... 48

Figure 3.10: A plot of the amount of CO2 produced in a set of CO-O2 pulses, measured

as a function of temperature, using the Pd/Al2O3(■), Pd@CeO2/Si-Al2O3(773) (○), and

Pd@CeO2/Si-Al2O3(1073) (Δ) samples. ... 49

Figure 3.11a): A plot of selected peaks from the mass spectra of the effluent from the pulse reactor using Pd@CeO2/Si-Al2O3(773) at 673 K. The peaks that were monitored

were CO2 (m/e = 44 and 28), O2 (m/e = 32 and 16), CO (m/e = 28), and CH4 (m/e = 16).

The inlet to the reactor is shown at the top. ... 50

Figure 3.11b): A plot of selected peaks from the mass spectra of the effluent from the pulse reactor using Pd@CeO2/Si-Al2O3(1073) at 673 K. The peaks that were monitored

were CO2 (m/e = 44 and 28), O2 (m/e = 32 and 16), CO (m/e = 28), and CH4 (m/e = 16).

The inlet to the reactor is shown at the top. ... 51

Figure 4.1: TEM images of Pd@ZrO2/Si-Al2O3 catalysts. Parts A and B correspond to

the 500 °C sample, while part C to the 800 °C calcined sample. In parts D and E, a lattice profile analysis of a single particle is presented. ... 63

Figure 4.2: Powder XRD patterns of Pd/Si-Al2O3(1), and Pd@ZrO2/Si-Al2O3 that

calcined at different temperature and with different Pd:ZrO2 ratio(2-6). 500 °C 1:6 (2),

500 °C 1:9 (3), 500 °C 1:12 (4), 800 °C 1:6 (5), 800 °C 1:9 (6). Reference powder diffraction pattern of tetragonal zirconia is shown at bottom. Al2O3 phase was marked by

closed squares, ZrO2 phase was marked with open squares. ... 65

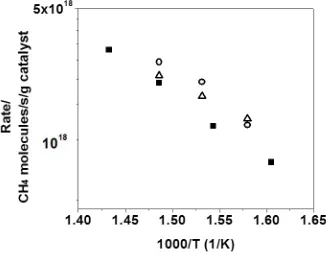

Figure 4.3: Rates for methane-oxidation reaction over 1-wt%Pd/Al2O3 calcined at 500 °C

(■),1-wt%Pd@9-wt%CeO2/Si-Al2O3 calcined at 500 °C (△),1-wt%Pd@9-wt%ZrO2

xii

and 1-wt%Pd@9-wt%ZrO2/Si-Al2O3 calcined at 800 °C (●).Data were taken with 0.5%

CH4 and 5% O2. ... 67

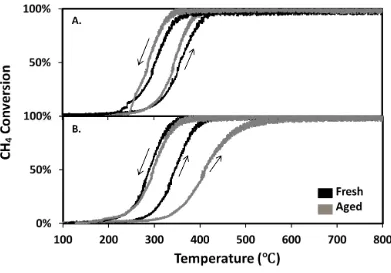

Figure 4.4: Effect of high temperature water poisoning over 1-wt%Pd@9-wt%ZrO2

/Si-Al2O3 (A), and 1-wt%Pd@9-wt%CeO2/Si-Al2O3 (B). Both catalysts were calcined at

800 °C. The aged samples were kept under wet reaction conditions for 4 hours at 600 °C, then cooled to room temperature under He, followed by light-off test. Data were taken with 1% CH4 and 5% O2. The heating and cooling rates are 10 °C min-1. ... 68

Figure 4.5: Effect of water on methane light-off curves over 1-wt%Pd@9-wt%ZrO2

/Si-Al2O3 (A), and 1-wt%Pd@9-wt%CeO2/Si-Al2O3 (B). Both catalysts were calcined at

800 °C. Data were taken with 1% CH4, 5% O2 and 10% H2O (if present). The heating and

cooling rates are 10 °C min-1. ... 70

Figure 4.6: Redox isotherms for Pd/Al2O3 (A) with 1-wt% Pd (□) and 5-wt% Pd (◆),

1-wt% Pd/ZrO2 (B), and 1-wt% Pd@9-wt%ZrO2/Si-Al2O3 (C). ◆ symbols were obtained

starting from the oxidized state. ◇ symbols were measured while re-oxidizing the sample. All measurements were conducted at 600 ºC. ... 74

Figure 5.1: Representative TEM images of MUA-Au nanoparticles (A, B, C) and histogram of particle size distribution with fit for a Gaussian distribution (D). ... 86

Figure 5.2: Representative TEM images of as-synthesized Au@TiO2 core-shell

structures. ... 87

Figure 5.3: Representative TEM images of Au@TiO2/Si-Al2O3 (A, B) and Au/TiO2 P25

(C, D) calcined to 400 °C. Arrows point at Au particles in the two samples. ... 89

Figure 5.4: CO oxidation rates for Au@TiO2/Si-Al2O3 (■), and Au/TiO2 (◇). Both

samples were calcined at 400 °C. Data were taken with 25 torr CO and 12.5 torr O2. .. 90

Figure 5.5: Light-off curves of CO conversion against temperature for Au@TiO2

/Si-Al2O3(A), and Au/TiO2 (B) that calcined at different temperatures. Data were taken with

7.6 torr CO and 152 torr O2. ... 92

Figure 5.6: Representative TEM images of Au@TiO2/Si-Al2O3 (A, B) and Au/TiO2 P25

(C, D) catalysts calcined to 600 °C. Arrows point at Au particles in the two samples. ... 93

xiii

Figure 6.2: Representative low (A, B) and high (C-F) resolution transmission electron microscopy (TEM) images of Pt@ZnO/Si-Al2O3 sample calcined at 773 K

in air. Yellow arrows point to core-shell structures where the higher contrast is attributed to Pt cores surrounded by a lighter, ZnO shell. ... 105

Figure 6.3: TEM images taken at 20 s interval (from A to D) of two Pt@ZnO core-shell structures (A) that progressively transform into Pt-Zn alloyed particles under the electron beam irradiation. The images were taken at 200 kV. ... 106

Figure 6.4: Representative TEM image of Pd@ZnO/Si-Al2O3 sample calcined at 773 K

in air. Yellow arrows point to core-shell structures where the higher contrast is attributed to Pd cores surrounded by a lighter, ZnO shell. ... 107

Figure 6.5: X-ray diffraction (XRD) patterns of (A) Si-Al2O3, (B) Pt/Al2O3, (C) ZnO,

(D) Pt/ZnO, and (E) Pt@ZnO/Si-Al2O3. Inset in (D) show magnification of the platinum

(111) region. ... 108

Figure 6.6: X-ray diffraction (XRD) patterns of (A) Si-Al2O3, (B) Pd/Al2O3, (C) ZnO,

(D) Pd/ZnO, and (E) Pd@ZnO/Si-Al2O3 calcined at 773 K. ... 108

Figure 6.7: Redox isotherms for Pt@ZnO/Si-Al2O3 at 873 K. Closed symbols

were obtained starting from the oxidized state. Open symbols were measured while re-oxidizing the sample. ... 111

Figure 6.8: (A) Methanol steam reforming (MSR) catalytic activity and (B) CO2

selectivity over the Pt@ZnO/Si-Al2O3 core-shell (triangle symbol), and

conventional Pt/Al2O3 (circle symbol) and Pt/ZnO (diamond symbol) calcined at

773 K. The catalysts were pretreated in a reducing (5% H2/He) atmosphere at 523

K for 30 minutes. All catalysts with 1 wt% of Pt. ... 112

Figure 6.9: (A) Methanol steam reforming (MSR) catalytic activity and (B) CO2

selectivity over the Pd@ZnO/Si-Al2O3 core-shell (triangle symbol), and conventional

Pd/Al2O3 (circle symbol) and Pd/ZnO (diamond symbol) calcined at 773 K. The catalysts

were pretreated in a reducing (5% H2/He) atmosphere at 523 K for 30 minutes. All

catalysts with 1 wt% of Pd. ... 114

Figure 7.1: Representative transmission electron microscopy (TEM) images of Pt@CeO2/Si-Al2O3 samples calcined at (A) 773 K and (B) 1073 K in air. Arrows indicate

Pt particles. ... 121

/Si-xiv

Al2O3-1073K. The samples were pretreated by oxidation in 20% O2-He mixture at 573 K

for 30 min prior to rate measurements. The reactant partial pressures were fixed at 25 torr CO and 25 torr H2O. ... 123

Figure 7.3: CO conversion in the WGS reaction as a function of time at 623 K over the Pt@CeO2/Si-Al2O3-773 K (■) and Pd@CeO2/Si-Al2O3-773 K (○) catalysts. The reactant

partial pressures were fixed at 25 torr CO and 25 torr H2O. ... 124

Figure 7.4: Redox isotherms for (A) 1-wt% Pt/Al2O3 (■) and 1-wt% Pd/Al2O3 (◇), and

(B) 1-wt% Pd/CeO2 (◆). The samples were initially calcined in air at 773 K.

Measurements were conducted at 873 K, starting from the oxidized state. ... 126

Figure 7.5: Redox isotherms for 1-wt%Pt@CeO2/Si-Al2O3 (■) and 1-wt%Pd@CeO2

/Si-Al2O3 (◇)calcined at (A) 773 K and (B) 1073 K. The samples were initially calcined in

1

Chapter 1. Introduction

1.1 Background

Metal catalysts play very important roles in many industries, including petroleum

refining, and chemicals production, as well as auto catalyst emissions control and other

environmental applications. For many reactions, the catalytic activity and selectivity

depend upon metal particle size because this in turn affects the surface area and number

of catalytic active sites. To enhance the number of active sites per unit mass, most

commercial metal catalysts are dispersed in the pores of high-surface-area metal-oxide

supports in the form of nanoparticles. Although the primary function of metal-oxides that

are used as supports is to maintain metal dispersion, it has been demonstrated that contact

between an oxide support and the active metal can strongly influence the activity and

selectivity of the catalysts for some reactions. Therefore, understanding and controlling

metal-oxide interactions is crucial for developing optimal precious-metal based catalysts.

However, interactions between the metal and its oxide support are generally not well

understood and need to be further investigated with novel approaches and techniques.

The goal of my work was to understand and enhance these interactions by

maximizing the interfacial contact between the support oxide and the metal. In particular,

I prepared catalysts with core-shell structures where the active metal is encapsulated in a

layer of porous oxide. In addition to catalytic measurements, I also examined the

thermodynamic redox properties of the metal-oxide interfaces in these core-shell catalysts

2

with the metal oxide interface for the first time. A number of important

metal-oxide catalytic systems were examined in this work, including Pd-CeO2, Pd-ZrO2,

Pd-ZnO, Pt-CeO2, Pt-ZnO, and Au-TiO2. In addition to developing a better fundamental

understanding of the nature of metal-metal oxide interfaces, methods were developed for

improving catalyst stability at higher temperatures.

1.2 Evidence for Metal-Oxide Interactions

The metal-oxide interactions are complex functions of structure and composition

and will be different for different catalyst systems. While it is difficult to cover all

different types of interaction, in this section, I will choose several representative

examples to illustrate typical reactions where chemical and physical interactions between

the metal and the metal-oxide support play critical roles in determining the catalyst

properties.

1.2.1 Bi-Functional Catalysts

In some catalytic processes involving the petroleum and petrochemical industries,

the catalyst is considered to be bi-functional in that both the metal and the metal-oxide

are themselves catalytically active. One of the most important examples of this is

dehydroisomerization of methylcyclopentane over Al2O3-supported Pt in naphtha

reforming. Pt is well-known to be an efficient dehydrogenation catalyst while Al2O3 has

acid sites that are active for isomerization of olefins. For catalysts in which Pt and Al2O3

are in close contact, methylcyclopentane is first dehydrogenated on Pt to

3

cyclohexadiene. Finally, the cyclohexadiene migrates to Pt and is dehydrogenated to

benzene [1].

Although this type of metal-support interaction is certainly important, the function

of both components is well understood. Also, the support in this case does not change the

properties of the metal or affect reactions that occur on the metal. Indeed, it is known that

the metallic Pt and the alumina do not even need to be in direct contact for this reaction to

proceed. Therefore, I will not consider these types of metal-metal oxide interactions

further.

1.2.2 Strong Metal-Support Interaction (SMSI)

The concept of ‘Strong Metal-Support Interaction’ (SMSI) was first introduced in

1978 to refer to the drastic changes in the adsorption properties of group VIII metals that

were observed when deposited on a titanium oxide support after high temperature

reduction [2]. One of the characteristic properties of group VIII metals is that their

surface atoms can chemisorb H2 or CO molecules at ambient temperature and this

property is commonly used to measure the metal dispersion. However, it was found that

titania-supported metals exhibited strongly suppressed adsorption following

high-temperature reduction. It was suggested that a strong metal-support interaction between

the metal and the reduced titania modified the adsorption properties of the metal. Later, it

was confirmed by surface science investigations that reduced titania can migrate onto

metal particles and then form an overlayer over the metal surface [3], which blocked

4

are not changed by the reduced titania, the migration of a reduced oxide onto the metal

particles is still referred to as SMSI.

1.2.3 Oxygen Storage Capacitance (OSC)

The simultaneous removal of three primary exhaust pollutants (CO, unburned

hydrocarbons and NOx) remains a major challenge in emission control for automobile

engines. This is because conversion of CO and HC to CO2 and H2O requires oxidizing

conditions and conversion of NOx to N2 requires a reducing condition. This objective can

be achieved by using a so-called ‘three-way’ catalyst (TWC) within a

‘close-to-stoichiometric’ air/fuel ratio window. A typical TWC consists of a high surface area

support, such as Al2O3, catalytically active Group VIII metals that are impregnated into

the support, and an oxygen-storage component, CeO2. The facile reducibility of CeO2

makes it an efficient oxygen capacitor that is able to store oxygen under oxidizing

conditions and release oxygen under reducing conditions. Unlike the situation for

bi-functional catalysts, ceria reduction cannot occur in the automotive exhaust environment

without contact with the catalytic metal [4, 5].

However, there is still debate about how reduction of the ceria occurs, whether

oxygen is transferred from ceria to the metal or the reductant is transferred from the metal

to the ceria. There is some indication that oxygen is transferred to the metal in some cases

but it is not known if the transfer occurs only at peripheral sites or whether oxygen can be

5

1.2.4 Alloy Formation

Another possible metal-support interaction involves the formation of alloys. Some

oxides may be reduced to their metallic form and then react with the active metal to form

an alloy that has superior catalytic properties compared with the elementary metals. For

example, PtZn alloys can be formed from Pt/ZnO catalyst upon reduction. The alloy

catalysts have been shown to be more selective for hydrogenation of α, β-unsaturated

aldehydes to the corresponding saturated alcohols [6]. In another example, CO2

selectivity for the methanol-steam-reforming reaction was found to be greatly improved

when Pd or Pt is supported on ZnO, Ga2O3 and In2O3 due to the formation of Pd–Zn, Pd–

Ga, Pd–In, Pt–Zn, Pt–Ga and Pt–In alloys [7].

1.3 Mechanisms of Metal-Oxide Interactions

As pointed out earlier, the nature of metal-metal oxide interactions are not well

understood in many cases. Various mechanisms have been proposed to explain how the

oxide affects the metal [8-10]. Here, I will briefly discuss some of the more important

cases that have been proposed for understanding support effects. Some of these will be

relevant for explaining the work I have carried out in this thesis.

1.3.1 Schwab Effect

One of the first models developed for understanding how support oxides and

metals interact was proposed by Schwab and Koller [11]. They suggested that, when a

catalytic metal is supported on a semiconducting oxide, electrons could transfer between

6

was invoked initially when the SMSI phenomenon was first observed with

titania-supported catalysts. It was suggested at that time that titania became semiconducting

under reducing conditions and that it could then donate electrons to the supported metal.

Because electron densities of metals are orders of magnitude larger than electron

densities in semiconducting oxides, such long-range electron-transfer mechanisms are

difficult to explain. Also, electron-transfer mechanisms would imply that support effects

should depend on metal loading, which was not observed with SMSI in titania-supported

metals. Therefore, electron-transfer mechanisms have grown out-of-favor as a way for

explaining support effects.

1.3.2 Bonding Interactions

The effects observed with titania-supported metals are presently thought to arise

from bonding between the metal and reduced titania. The attraction between the metal

and reduced titania is analogous to wetting phenomena observed at liquid-solid interfaces

and results in migration of reduced titania onto the metal particles [3, 12]. When the

metal surface is completely covered, adsorption suppression is caused by simple site

blocking.

In less extreme cases, bonding interactions between a metal and its oxide support

could also induce changes in geometry of the metal particles. For example, it was shown

that the sublimation energy of Au on SiO2 is abnormally low (50 kcal mol-1) at 0.2

monolayers (mL), but increases rapidly with increasing Au coverage to the bulk value (90

kcal mol-1) at 5mL. The low value of sublimation energy at low Au coverage is

7

atoms are not attracted to silica; at the edge of small clusters, the Au atoms are bonded to

fewer Au neighbors and hence are weakly held to the surface. By contrast, the

sublimation energy remains at 50 kcal mol-1 with increasing Au coverage up to 2mL for

the case of Au/TiO2. This has been attributed to a stronger interaction between Au and

TiO2, which in turn leads to greater wetting of TiO2 by Au compared with the situation

for Au/SiO2. These bonding interactions result in higher Au dispersions and improved the

thermal stabilities of Au with TiO2.[13].

There is evidence that bonding interactions between an active metal and its oxide

support can also modify the thermodynamic redox properties of supported metal particles.

In a thermodynamic investigation of supported Co catalysts for Fischer-Tropsch synthesis

(FTS) [14], it was found that redox properties of Co that had been deposited onto a ZrO2

support can be affected significantly by the metal-support interface, while redox

properties of Co supported on mesoporous silica were indistinguishable from that found

for bulk Co. It was reported that this observation is critical for understanding FTS

reaction over supported Co catalyst because metallic Co is the active phase for

low-temperature FTS reaction. Although bulk thermodynamic calculations indicate that Co

should remain metallic under FTS conditions, redox isotherms obtained by coulometric

titration of Co/ZrO2 catalysts suggested that interactions between Co and ZrO2 can cause

particles to be oxidized under FTS conditions. It was further suggested that this effect is

due to bonding between highly dispersed Co and oxygen from the zirconia support [15].

It is important to notice that interfacial effects could be very different with metal

8

supported nanoparticles differ from bulk materials and this could change bonding

interactions with the oxide support. One case where this appears to occur is the situation

when Au is supported on titania. Au/TiO2 catalysts prepared by deposition-precipitation

were reported to be capable of catalyzing CO oxidation at temperatures as low as 90 K

[16], while neither unsupported Au nor TiO2 alone is active for this reaction. The activity

of Au nanoparticles is not dependent simply on Au particle size; the composition of the

support is also critically important, with rates for water-gas shift reaction over Au/TiO2

that are 20 times higher than rates over the same Au particles supported on Al2O3 [17].

In the Au and TiO2 example, there is a question whether the bonding interactions

are important over the entire interface between the metal and the oxide or just at edge

sites where the metal and oxide are both exposed to the gas phase. Although many

authors have proposed that only the peripheral sites are affected [18-23], it has also been

proposed that the active sites on Au particles are those that are separated from the titania

by one monolayer of Au [24]. In this case, the entire surface of a “flat” particle, two

monolayers thick, would be active. With either model, the active sites are in the

proximity of the TiO2 support and the enhanced catalytic activity has been ascribed to the

strong bonding interaction between Au and TiO2 support.

The manner by which titania bonding affects Au is uncertain. One recent study of

Au supported on highly reduced TiOx film has suggested that strong bonding between Au

and reduced Ti atoms leads to electron-rich Au and it is this form of Au that exhibits

exceptionally high activity for CO oxidation [25]. Theoretical studies also show that

9

electronic properties of Au clusters through charge transfer from TiO2 to Au [26, 27],

which in turn affects the catalytic properties of Au.

It should be emphasized that, while there are numerous studies reporting evidence

for electronic interactions between metal nanoparticles and the oxide support, the

situation is complicated by the fact that the properties of metal nanoparticles are already

intrinsically different from that of bulk materials. Separating effects of particles size and

metal-support interactions is challenging.

1.3.3 Oxygen Transfer

For reducible oxides, such as ceria, the role of the support also includes

transferring oxygen to and from the supported metal. The ability of ceria to donate

oxygen is crucial for three-way catalysis [28, 29], water-gas shift (WGS) catalysis

[30-33], hydrocarbon-reforming catalysis [34], and hydrocarbon oxidation catalysis [35, 36].

For example, reaction rates for the WGS reaction on ceria supported Pd has been shown

to be orders of magnitude higher than on non-reducible Al2O3 supported Pd [33].

Oxygen transfer appears to be also important for methane combustion over

supported-Pd catalysts [37, 38]. It is widely acknowledged that PdO is more active than

Pd for this reaction. However, the PdO phase tends to decompose to metallic Pd at high

temperatures (over 1073 K) resulting in decreased activity. The re-oxidation only occurs

until the temperature decreases to below 873 K [39]. It has been reported that PdO phase

can be stabilized when it is supported on reducible oxides such as TiO2 and CeO2, with a

10

The key reason for the special properties of ceria-based catalysts is the facile

redox shift between Ce4+ and Ce3+. Under reducing conditions, oxygen atoms can be

removed from ceria and result in a non-stoichiometric composition of partially reduced

CeO2-x. Each released O atom leaves behind an oxygen vacancy and creates two Ce3+

cations by transferring two electrons to two Ce4+ cations. Under oxidizing conditions, a

reverse process takes place.

It has been found that oxygen from the ceria support can be transferred to active

metal and then used to oxidize species that adsorbed on the metal. Reduced ceria can be

oxidized by molecular O2 or by O from another reactant such as water. This proposed

mechanism has been used successfully to explain the enhanced activity observed with

several reactions which can be carried out on these catalysts, including CO oxidation [40],

water-gas shift [30], and steam-reforming [34]. Considering WGS reaction over Pd/ceria,

the mechanism can be written as follows:

2 2 3

2CeO +PdPdO+Ce O (1.1)

2

CO+PdOPd+CO (1.2)

2 3 2 2 2

Ce O +H OH +2CeO (1.3)

Interestingly, this proposed mechanism appears to contradict the thermodynamic

redox properties of ceria. Thermodynamics indicates that CeO1.98 is the equilibrium

stoichiometry at 873 K and P(O2)~10-26 atm [41]. Therefore, ceria should not be able to

provide oxygen to the supported metal in most reactions, i.e. the reaction conditions are

too oxidizing and reduction of ceria should not occur. The likely explanation for these

11

Usually, ceria that is used in catalysis is in nanoparticle form [42-45] or is promoted by

other materials, such as zirconia [46, 47].

It is possible to rationalize why ‘catalytic’ forms of ceria might be more reducible.

With regards to pure ceria, Ce+4 is the most stable state in stoichiometric CeO2 because

the symmetry of the fluorite crystal places the Ce atoms in such a geometry that bonding

with the oxygen matches the direction of the 4f orbitals, which is critical for stabilizing

Ce+4. When ceria is nanostructured, the crystalline structure becomes highly defective

and Ce+4 are expected to be destabilized relative to Ce+3. The presence of additives (for

example, Ti+4) can also create distortions in the fluorite structures. In both cases, the

perfect fluorite structure of CeO2 can be interrupted, causing a relatively high stability of

Ce+3 that result in an increased reducibility. In the case of zirconia-doped ceria, it has

been suggested that Zr+4 can pair with Ce+3 to form Zr2Ce2O7 locally within the

mixed-oxide structure. Again, formation of such compounds would then stabilize Ce+3. Finally,

small cerium crystallites are expected to have a high surface energy. If this free energy of

the surface is large enough, the reducibility of ceria as a whole will be affected.

It should be noted that some have suggested certain crystal surfaces of ceria are

more easily reduced than others. For example, theoretical calculations have argued that

the (100) surface is preferentially reduced in ceria relative to the (111) surface [48]. Some

support for this idea has come from an experimental study which found that nano-rods

synthesized to preferentially expose (111) planes were easier to reduce than normal

12

the surface could only be reduced with great difficulty [50] (e.g. by sputtering with Ar+).

Therefore, crystal surface dependence on reducibility has yet to be proven.

While the reducibility of ceria can promote many reactions, questions have been

raised regarding the optimal level of reducibility. For example, a study by Bakhmutsky et

al. [51]has shown that making ceria too reducible does not always have a positive effect

on catalytic activity. In their work, addition of Pr to ceria in a Pd/ceria catalyst leads to a

mixed oxide that can give over-reduction of ceria, which in turn gives a much lower

activity for the WGS reaction. In this case, oxygen in the praseodymium-ceria mixed

oxide was so weakly bound that oxygen could not be restored by oxidation in steam.

Therefore, there appears to be an optimum reducibility for ceria that will lead to the most

active catalysts.

Zirconia is another support material that has attracted considerable interest in a

variety of catalyst systems. Even though ZrO2 is normally considered an irreducible

oxide, and should therefore not promote reaction in the same way that CeO2 does, there

are some indications that interaction between the active metal and ZrO2 support can

affect the catalytic activity for CO hydrogenation [52], methanol decomposition [53], and

methane-steam-reforming [54]. This may be associated with the fact that oxygen mobility

of ZrO2 supports is relatively high at moderate and high temperatures, so that oxygen can

be exchanged between the active metal and the support. For example, it has been

demonstrated that on a conventional Pd/ZrO2 catalyst, oxygen from a ZrO2 support may

contribute to methane-oxidation reaction, and the involvement of ZrO2 increases with

13

In metal-oxide catalytic systems, interactions between phases are crucial for

reactions. Whether the mechanism involves bonding interactions, oxygen transfer, or

both simultaneously, there must be direct contact between the metal and the oxide

support. Therefore, any potential advantages associated with these interactions require

maximizing the interface between the metal and the oxide. Some methods that have been

developed to maximize interfacial contact will be discussed in the next section.

1.4 Approaches to Improve Metal-Oxide Interaction

For traditional supported metal catalysts which consist of small metal particles

deposited onto high-surface-area oxide support, the metal-oxide interaction can be

enhanced by simply increasing the metal dispersion. Significant effort in the field of

catalysis has gone into synthesizing particles with sizes down to the nanometer scale in

order to enhance the specific surface area, the interaction with the support and,

consequently, the catalytic properties. However, such enhancement is limited by the

‘single interfacial perimeter’ that forms between the metal particles and the oxide support.

With the rise of nanotechnology, ‘multiple points of contact’ between the metal

and the oxide becomes possible; and this provides three dimensional control of the

reaction zone and greatly modifies the properties of the catalysts. For example, Pietron et

al. [56] formed isolated Au nanoparticles in Au-TiO2 composite aerogels by adding

alkanethiolate-monolayer-protected Au clusters to a titania sol before gelation. In the

resulting aerogel nanoarchitecture, each Au particle was in contact with multiple TiO2

14

with much larger Au particle sizes. Indeed, the particle size in their study was so large

that previous reports would have predicted the Au would be inactive.

The ‘3-D’ design can also be used to address another common problem in

catalysis: thermal stability of highly dispersed active metal. Nanoparticles tend to rapidly

sinter into larger clusters due to their high surface energy, resulting in a loss of activity. It

would be desirable to use new approaches to prevent such sintering by encapsulating the

dispersed metal nanoparticles with additional materials. Co-precipitation and

microemulsion are two of the most commonly used techniques to make encapsulated

nanostructures. In the former method, the preformed metal particles (or their precursors)

are precipitated together with the metal oxide precursor. The latter one involves using

micro-emulsions as a nano-reactor; metal particles are produced inside micelles, which

are in turn coated with the oxide precursor to form the encapsulated metal. However,

these methods cannot provide great control over the final structures. Our group used both

of these methods to prepare Pd in ceria nanostructures for water-gas shift reaction and

found that ceria layers made by co-precipitation method were insufficient to prevent

sintering of the metal, while with the microemulsion method, the ceria layer underwent

condensation that blocked the active sites of the metal [57].

Novel nanotechnologies have allowed great improvements in the synthesis of

catalysts with well-controlled size, shape, and surface properties. The deliberate tailoring

of the nanostructure can lead to unique catalytic properties, and provide the level of

control that is required to maximize the metal-support interface. The controlled structure

15

shown in the work of Yeung et al. [58], who prepared Pt@CeO2 core-shell structures by a

modified microemulsion procedure with controllable ceria thickness. The Pt core was

shown to interact with CeO2 shell in an optimum geometry to form a unique interface,

which exhibited high activity for the water-gas shift reaction, but was completely inactive

for the undesirable side reaction, methanation. In another example, Zhang et al. [59]

prepared Au nanoparticles supported on TiO2/SiO2 core-shell composites, which were in

turn encapsulated in mesoporous silica. The small TiO2 particles anchored on SiO2 beads

led to a better dispersion of Au and the encapsulation improved sinter-resistance during

calcination at 773 K.

Recently, our group used self-assembly method to achieve even more precise

control over core-shell structures, allowing finer tuning of the oxide shell and

maximizing the metal–oxide interactions [60-62]. A schematic of the method is shown in

Figure 1.1. Pd@CeO2 was prepared by reacting preformed 11-mercaptoundecanoic acid

(MUA)-protected Pd nanoparticles with cerium (IV) alkoxide, followed by a controlled

hydrolysis in the presence of dodecanoic acid.

Figure 1.1: Schematic representation of the procedure to obtain dispersible Pd@CeO2

16

After forming the dispersible Pd@CeO2 nanoparticles in solution, they could be

deposited onto Al2O3 supports by impregnation. However, Pd@CeO2 particles prepared

in this manner are slightly hydrophobic and tend to present as agglomerates rather than as

isolated particles adhering to the hydrophilic Al2O3 support. In an alternative method, the

dispersed Pd@CeO2 can be adsorbed onto a silane modified Al2O3. In this case, the

alumina surface is made hydrophobic by reaction with triethoxy(octyl)silane (TEOOS)

(Figure 1.2). After adsorption of the core-shell particles, the solid residue can be

recovered, crushed, and calcined.

In previous work, it was demonstrated that these core-shell catalysts exhibit very

exciting properties [63]. First, this material shows outstanding thermal stability, with the

Pd cores remaining isolated even after heating the catalyst to 1123 K. More importantly,

the methane-oxidation activity for the Pd@CeO2/Si-Al2O3 catalyst was exceptional,

exhibiting rates that were at least 50 times higher than that of a normal Pd/CeO2 catalyst,

well beyond what a simple optimization of interfacial site concentrations would provide.

Figure 1.2: Schematic representation of the agglomeration of Pd@CeO2 structures

17

While it has been inferred that this exceptional activity may result from improved

metal-oxide interaction between the Pd core and the ceria shell, many questions remain. A

further investigation on metal-oxide interaction and a better understanding of the

properties of this core-shell material are needed.

1.5 Scope of the Thesis

My thesis work fell into two categories. The first part focuses on Pd@CeO2

/Si-Al2O3 catalysts. The goal was to gain a better understanding of the properties of this

material that make it such good catalyst. The second category involved extending the

synthesis to other metal@oxide systems and into investigations of metal-oxide

interactions with different core-shell compositions.

The thesis is divided into 8 chapters. Chapter 2 provides descriptions of the

sample preparations, characterization techniques and experimental methods used in this

work. In Chapter 3, I describe an investigation of Pd@CeO2/Si-Al2O3 catalysts for the

methane-steam-reforming reaction. In this work, I looked at the effect of calcination

temperature for this catalyst and this reaction. The oxidation and reduction properties of

Pd@CeO2/Si-Al2O3 calcined at different temperatures were explored using pulse

measurements and related to the catalytic rates.

Chapter 4 focuses on the interactions between Pd and ZrO2 in Pd@ZrO2/Si-Al2O3

catalysts, and investigates how they relate to the observed high activity this material has

for the methane-oxidation reaction. This work provides for the first time a quantitative

18

addition, because steam has been reported to strongly inhibit catalytic reactions and cause

severe deactivation over Pd-based catalysts, the stability of Pd@ZrO2/Si-Al2O3 for

methane-oxidation in the presence of steam was also investigated.

Chapter 5 reports the synthesis and characterization of Au@TiO2/Si-Al2O3

core-shell catalysts. Two of the major issues with Au-based catalysts are poor thermal stability

due to the very low surface energy compared to other transitional-metal based catalysts

and a strong particle-size dependence on activity. The interaction between Au and TiO2

in the core-shell catalysts helped stabilize the materials against sintering, maintaining a

high activity.

In Chapter 6, the synthesis and characterization of Pt@ZnO/Si-Al2O3 and

Pd@ZnO/Si-Al2O3 core-shell catalysts are described. In order to investigate whether

Pt-Zn alloys can be formed upon mild reduction due to the intimate contact between the core

and the shell, in-situ TEM and coulometric titration experiments were conducted. The

applications of these catalysts in methanol-steam-reforming reactions were also discussed

and compared to that of the conventional supported catalysts.

Chapter 7 compares the catalytic and adsorption properties of Pd@CeO2/Si-Al2O3

with Pt@CeO2/Si-Al2O3 catalysts. The interactions between the ceria shell and the

different metal cores were inferred from their thermodynamic isotherms and used to

explain different stabilities that were observed on these two catalysts.

19

Chapter 2. Experimental Techniques

This chapter will describe the methods used to synthesize the catalysts, as well as

the experimental principles and applications of the various techniques used to

characterize the catalysts.

2.1 Catalyst Synthesis

All catalysts used in this thesis were synthesized in our laboratory. The catalysts

can be categorized into two types: core-shell catalysts supported on hydrophobic alumina

(referred as metal@oxide/Si-Al2O3); and metal-oxide, supported, precious-metal catalysts

(referred as metal/oxide). In this section, general synthesis methods will be discussed,

while the details of the preparation procedure, such as ingredients and calcination

temperatures for particular metal-metal oxide combinations, will be described in

corresponding chapters.

2.1.1 Core-Shell Catalysts

The general method for synthesis of the dispersible core-shell nanostructures

includes 3 steps [61, 62]: 1) preparation of 11-mercaptoundecanoic acid (MUA) protected

metal nanoparticles, 2) the self-assembly of a metal alkoxide on the MUA protected

metal particles by reaction of metal alkoxide with the acid functionality of the MUA

ligand, and 3) the controlled hydrolysis of the remaining alkoxide functionality in the

presence of protective ligands (dodecanoic acid) to obtain metal@oxide nanoparticles

20

The metal@oxide nanoparticles, dispersed in THF, were then adsorbed from

solution onto an Al2O3 support that had been modified by reaction with Triethoxy Octyl

Silane (TEOOS) [63]. This modification of the support is required to make the Al2O3

hydrophobic so that core-shell nanoparticles could adsorb onto the surface as isolated

units. The Al2O3 itself was purchased from Alfa Aesar as γ-Al2O3 and then stabilized by

calcining to 1173 K for 24 h. After removing the catalysts from solution by centrifugation

and drying, the resulting powders were calcined to various temperatures with a heating

ramp of 3 K min-1.

2.1.2 Supported Catalysts

For comparison purpose, two types of metal/oxide catalysts were prepared in this

thesis. Conventional types of supported catalysts were prepared by impregnation of

metal-oxide support with aqueous solutions of metal ammonium nitrate precursors. The

amount of precursor and support were carefully chosen to obtain the desired weight

loadings. The slurry was then dried and calcined in air to decompose the precursors and

obtain a catalyst in the oxidized state.

Nanoparticles deposited on metal-oxide support were also prepared from the

MUA-protected metal nanoparticles without oxide shells. In this case, oxide supports

were first dispersed in THF, and then an appropriate amount of MUA-protected metal

nanoparticles, also dispersed in THF, were added to the mixture dropwise. After stirring

overnight to allow complete adsorption, the solid residue was recovered by centrifugation,

21

2.2 Equilibrium Measurements 2.2.1 Coulometric Titration

The redox properties of the catalysts were measured using coulometric titration,

which is an electrochemical technique that provides the equilibrium oxygen

stoichiometry of the oxide sample as a function of P(O2) that above the sample. For

instance, for the Pd-PdO equilibrium:

( ) 2( ) ( )

2Pds O g 2PdOs (2.1)

The equilibrium constant can be calculated using:

2 -1 2 2 2 α

K = =P(O )

α ×P(O ) PdO eq

Pd

(2.2)

where the activity of solids is equal to 1. The differential Gibbs Free Energy of the

oxidation reaction can then be calculated using the following equation:

2

RT ln(K )eq RTln[P(O )]

G

(2.3)

It is important to recognize that the experimental P(O2) values are so low that

they are not actual partial pressures of O2 over most of the range reported in this thesis,

but rather oxygen fugacity established by an equilibrium with another reaction:

2 2 2

2H +O 2H O (2.4)

22

2 2

2

P(H O) log[P(O )] 2 log(K ) 2log[ ]

P(H ) eq

(2.5)

The coulometric titration setup used in this thesis is shown in Figure 2.1 [64]. The

setup consists of a YSZ (yttria-stabilized zirconia) tube with Ag electrodes painted on

both inside and outside. Pt wires were attached to the inner and outer electrode using Ag

paste. The inner Pt wire was then spot-welded to an Ultra-Torr Swagelok fitting which

had been fitted over one of the ends of the YSZ tube.

Figure 2.1: Schematic diagram of coulometric titration setup [64].

During measurements, approximately 1g of sample was placed in an alumina

crucible that was then inserted into the coulometric titration cell. The entire apparatus

was heated to 873 K; and a mixture of 5% O2, 11% H2O, and 84% Ar was allowed to

23

measurements were started from the oxidized state of the samples. After stopping the

flow, the ends of the YSZ tube were sealed using glass stoppers. To perform the actual

measurements, oxygen was electrochemically pumped out of the YSZ tube by applying a

potential across the electrodes with a Gamry Instruments potentiostat. The amount of

oxygen removed was determined by integrating the current as a function of time. After

removing the desired amount of oxygen, the system was allowed to come to equilibrium

with the electrodes at open-circuit. The criterion that used for establishing equilibrium

was that the open-circuit potential across the electrodes changed by less than 3 mV day-1,

which typically took 4 to 10 days. Finally, the equilibrium P(O2) was calculated from the

Nernst equation (equation 2.6) and the open-circuit voltage (OCV).

2 2

P(O )

OCV

ln(

)

4

P(O )

in out

RT

F

(2.6)As an additional check that equilibrium was achieved and that there were no

system leaks, most isotherms were measured again starting with the reduced sample and

pumping oxygen back into the electrochemical cell.

2.2.2 Transient-Pulse Measurement

The oxidation and reduction of some of the samples were also examined by the

transient-pulse experiments. By separating interactions between the catalyst and different

reactive molecules sequentially, pulse measurements could be used to investigate the

redox properties and deactivation mechanisms on the core-shell catalysts. These

24

spectrometer to analyze the concentrations of the effluent gases [65, 66].

Computer-controlled solenoid valves allowed step changes in the gas composition. In all

measurements, helium was the major component of the gas phase, with a total flow rate

of 20 mL min-1, while the concentrations of the reactive component (either CO, O2, H2, or

H2O) were chosen to be 10% of the total gas stream. Water was introduced to the reactor

by saturation of a He carrier gas flowing through deionized water and condensed with an

ice-trap before the products were analyzed. 1.0 g of catalyst was used for these

experiments. Prior to loading the samples in the reactor, each sample was pressed into

thin wafers that were then broken into smaller pieces. Integration of the partial pressures

of the reactor effluent as a function of time allows determination of the amounts of

oxygen that could be added or removed from the catalyst by the various reactive

components at different temperatures. No attempt was made to analyze the shapes of the

pulses because coupling between desorption, re-adsorption, reaction, and diffusion does

not allow for a unique determination of rate processes in transient experiments of this

type [67].

2.3 Other Characterization Techniques 2.3.1 TEM

Transmission Electron Microscopy (TEM) characterization was performed on a

Jeol JEM 2100 operating at 200 kV. Samples were prepared either by drop-casting the

particles directly from THF solution onto 300 mesh carbon-coated Cu grids (Electron

Microscopy Sciences) or by dispersing the powders into isopropanol and then

25

2.3.2 XRD

Powder X-ray Diffraction (XRD) was used to determine the structures and the

chemical phase composition of the core-shell catalysts. The XRD patterns were recorded

on a Rigaku Smartlab diffractometer equipped with a Cu Kα source (λ=1.5405 Å). The

sample powders were finely dispersed in 2-propanol by sonication and then drop-cast

onto glass slides. The intensities of the diffracted beam were measured while sampling

different diffraction angles. The crystallite particle size (d) could be estimated using the

Scherrer equation:

κλ d=

B(2θ)cosθ (2.7)

where κ is a shape factor usually equal to 1, λ is the X-ray wavelength, B is the peak

widthat half the maximum intensity, and θ is the diffraction angle.

2.3.3 Chemisorption

The apparent metal dispersions were measured using CO chemisorption at room

temperature in a home-built adsorption apparatus [68]. Two different protocols, with

different reducing temperatures, were used to pretreat the core-shell catalysts. The

calcined samples were first placed in the adsorption apparatus, oxidized at 673 K in 200

Torr O2 for two minutes, evacuated, and then re-oxidized. After repeating the oxidation

step three times, the samples were evacuated and then reduced by exposure to 200 Torr

H2 at either 423 K or 673 K for 5 minutes, followed by a second evacuation. The

26

observed. CO chemisorption was performed at room temperature by adding small pulses

of CO to the samples until a pressure rise in the sample cell was detected [69].

2.3.4 FTIR

Fourier Transform Infrared Spectroscopy (FTIR) was used to analyze the

adsorption properties on the catalyst surface. The spectra were recorded using Mattson

Galaxy 2020 FTIR spectrometer. The spectrometer was equipped with a Spectra-Tech

Collector II diffuse-reflectance accessory to allow measurements on powdered samples

with control over temperature and atmosphere.

2.3.5 TPO

In order to determine the temperature required for removing the organic

protecting agents from core-shell nanoparticles, Temperature Programmed Oxidation

(TPO) measurements were performed in the same system used in the transient-pulse

measurements on samples dried at 338 K. Experiments were conducted with either 0.1 g

or 1.0 g of sample to determine when most of the carbon leave the sample and to look for

the possibility of sulfur contamination from the 11-mercaptoundecanoic acid (MUA)

ligands used in preparing the metal nanoparticles. The gas-phase composition during

TPO was 20% O2 in He, with a total flow rate of 25 mL min-1; and the heating rate was 3

27

2.4 Catalytic Studies

2.4.1 Steady-State Rates Measurements

Several reactions were used in this thesis to characterize catalytic properties of the

core-shell catalysts with different metal-metal oxide compositions. The steady-state rates

were measured using 100 mg of sample in a ¼-in, quartz, flow reactor with an on-line gas

chromatograph (SRI8610C) equipped with a Hayesep Q column and a TCD detector. The

reactor pressure was always atmospheric. The partial pressure of each reactant was

controlled by adjusting the relative flow rate of each component, with a total flow rate of

120 ml min-1, corresponding to Gas Hourly Space Velocity of 72,000 mL g-1 h-1. Detailed

reactant gas-phase composition for each reaction was summarized in Table 2.1. For those

experiments in which H2O was added, H2O was introduced by bubbling He through a

H2O saturator and the content of H2O was controlled by the temperature of the saturator.

For all measurements where rates are reported, the conversions of reactant were kept well

below 15%, so that differential conditions could be assumed.

Table 2.1: Reactant gas-phase composition.

Reaction Catalyst Reactant composition (balanced in He)

Methane oxidation Pd@CeO2, Pd@ZrO2 3.8 torr (0.5%) CH4, 38 torr (5%) O2

Methane steam reforming Pd@CeO2 35 torr (4.6%) CH4, 70 torr (9.2%) H2O

CO oxidation Au@TiO2 25 torr (3.3%) CO, 12.5 torr(1.65%) O2

Water-gas shift Pd@CeO2, Pt@CeO2 25 torr (3.3%) CO, 25 torr(3.3%) H2O

28

2.4.2 Light-Off Measurements

The light-off measurements were performed in the same system used in the

transient-pulse measurements using 100 to 400 mg of sample. For CO oxidation reaction,

the composition of the reactant mixture was chosen to be 1% CO and 20% O2 in He and

the total flow rate was maintained at 60 ml min-1. For methane oxidation, the composition

of the reactant mixture was chosen to be 1% CH4 and 5% O2 in He and the total flow rate

was maintained at 120 ml min-1. In both cases, the conversions of reactant were measured

29

Chapter 3. High Temperature Calcination Improves the Catalytic

Properties of Alumina-Supported Pd@Ceria Prepared by Self Assembly

3.1 Introduction

High activity and thermal stability are required for catalysts used in

high-temperature reactions, such as oxidation. The most active catalysts for

methane-oxidation are based on Pd [38, 70], which is susceptible to sintering at high temperatures;

but both activity and thermal stability can be improved through the proper choice of

oxide support [71-77]. Ceria can affect rates on supported Pd catalysts because its redox

properties can provide an additional channel for oxygen on the Pd. Further improvement

of these catalysts requires the optimization of the Pd-support interactions and one

approach for accomplishing this is through the development of core-shell catalysts in

which a porous oxide “shell” surrounds the metal “core”.

Various methods have been reported for preparing catalysts with a core-shell

structure [78]; and, not surprisingly, the different preparation methods can result in

materials with vastly different structures and catalytic properties. For example, materials

having an “egg-yolk” structure, in which the metal core is in a void volume made from a

larger oxide shell [79], will have very different properties from materials prepared using

microemulsions, in which the metal core will be in physical contact and completely

surrounded by an oxide shell that is typically thicker [80]. Additionally, many of the