© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3017

STRUCTURAL PERFORMANCE OF FIBER REINFORCED

SELF COMPACTING CONCRETE (SCC) BEAMS WITH

OPENINGS

Senna M Varghese

1, Milu Mary Jacob

21

P.G.Student, Department of Civil Engineering, Saintgits College of Engineering, Kerala, India

2ABSTRACT - In modern building construction,utility ducts and pipes are accommodated in the space above the false ceiling. There will be high stress concentration around the openings due to the implementation of transverse opening in the web. These results in reduction in beam stiffness. Therefore, while providing large openings, the behaviour of the beam must be properly accounted. Most of the cases the conventional concrete cannot completely fill the congested reinforcement around the opening. Hence Self-compacting concrete (SCC) can be used in these beams, as it can easily fill those congested reinforcement without any vibration. It also prevents the local cracks around openings. The use of fibres extends its possibilities.

The study mainly involves the experimental investigation of compressive strength of cubes to obtain M 30 grade mix. The compressive strength of cubes by varying the percentage of Recron 3s fiber was investigated to obtain the optimum fiber content. The beams were tested by applying point load at one third points under the loading frame, which has a capacity of 50 tons .The first crack load, ultimate load and deflection of the specimens are tested. It was observed that the ultimate capacity was increased up to 11 % for flexure and 10.5% for shear when fiber was added. Also the ductility factor was increased up to 11.58% for flexure and 17.5% for shear when fiber was added.

The main objectives included are to obtain a SCC mix corresponding to M30 grade concrete; to study the flexural and shear behaviour of fiber (Recron 3s) reinforced SCC beams with and without openings.

Key Words: SCC, Recron 3S, ductility ratio,stiffness, stress-concentration.

1. INTRODUCTION

Self compacting concrete (SCC) or self levelling concrete or self consolidating concrete is a mix of a concrete with very low yield stress, good segregation résistance, high deformability and also moderate viscosity. External compaction is not provided for this type of concrete.

SCC is less labour-intensive compared to the conventional concrete mixes and in terms of its setting time and gaining strength it is similar to standard concrete. SCC mix is obtained by limiting the coarse aggregate content and its maximum size and to use lower water-powder ratios together with super plasticizers. The main disadvantages of SCC are its cost, associated with the use of chemical admixtures and use of high volumes of Portland cement. One of the best methods to reduce the cost is the use of mineral additives such as limestone powder, natural pozzolanas, fly ash and slag.

Recron 3 s is a type of polypropylene monofilament short fiber, which is used in concrete for the purpose of control and arrest cracks. This fiber reduces rebound splattering of concrete .also it reduces wastage of mortar and speeds up the space of work. They also have the capacity to increase the tensile strength. Its importance increases when plastering is in progress at higher floors, ceilings and outside surfaces of the buildings.

Many researchers have worked on fresh properties of self compacting concrete.

2. MATERIAL CHARACTERISTICS

(a) Cement: In this research Portland Pozzolona cement (ultra tech cement) was used and its properties are shown below in table 1

---***---© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3018 Table -1: Properties of cement

Test for Observed value

Specific gravity 3.125

Cement Initial setting time Consistency 45 min 33 % Final setting time 6 hrs

(b) Fine aggregate: For the present study M sand is used .the sieve analysis of FA has been carried out as per IS 383-1970 and from that it is confirmed to grading zone-1 and its specific gravity is 2.67.

(c) Coarse aggregate: Maximum nominal size of aggregate chosen was 12 mm and other properties are given –

Table -2: Properties of coarse aggregate

Coarse Test for Observed values aggregate Bulk density 1.5 g/m3

Specific gravity 2.68

(d) Fly ash: Fly ash is a by-product obtained during the process of combustion of pulverized coal in electric power generating plants. Fly ash produced from thermal power plant Pandalam, was used as partial addition for cement and its specific gravity is 2.2.

(e) Super plasticizer : Aura mix 300 plus super plasticising admixture procured from Fosroc Chemicals India Pvt. Ltd.is used and its properties are shown below.

Table- 3: Properties of Auramix 300 plus

Auramix Test for Observed value Colour Light yellow 300 plus

Density 1.05 Kg/l Alkali content Less than 1.5 Kg/l

(f) Fiber : Recron 3s fiber, modified polyester fibers, optimum percentage was found at 1.5 %.

Fig-1 Recron 3s fiber

3. EXPERIMENTAL INVESTIGATION

[A] General outline of experimental investigation:

[image:2.595.191.433.524.665.2]© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3019

of the openings provided was 80 x 100 mm. For the testing of the same, various properties of the materials used for concreting were also studied. The basic test on cement and aggregates were done.

[B] Workability test for fresh concrete (trial mix proportions):

The mix design for SCC were followed from the EFNARC (May 2005) guidelines. The recommended range for W/P ratio by volume is 0.85 to 1.1 and that for coarse aggregate is less than or equal to 50% of total aggregate.

The main properties of Self- Compacting Concrete are its filling ability, passing ability and resistance to segregation. Many methods have been developed to characterize the properties of SCC.

Table -4: The recommended limits for differentproperties according to EFNARC are:

TEST PROPERTY LIMITS

Slump flow Filling ability 650-800mm

V-funnel Segregation 6-12 sec resistance

L-box Passing ability 0.8-1

The slump flow test is carried out to find the horizontal free flow of SCC mix in the absence of obstructions. The concrete mix flows, on lifting the slump cone, which is filled with concrete. The average diameter of the concrete circle is measured from to two perpendicular

directions, which is a measure of filling ability of concrete.

Fig-2 Slump flow test

The viscosity and filling ability of self-compacting concrete is found out by v funnel test. The time taken by the concrete to flow out of the funnel after filling the v shaped funnel is measured and recorded as the v-funnel flow time.

[image:3.595.211.408.389.524.2] [image:3.595.218.409.589.737.2]© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3020

The L box test is used to test the passing ability of the SCC mix, by allowing the horizontal flow of fresh concrete through the gaps between vertical, smooth reinforcing bars of L box and height of the concrete beyond the reinforcement is measured.

Fig-4 L box test

From this works, concluded that, fly ash percentage that is used to replace cement is 28%.the cement used is 500 kg/m3 and water cement ratio was fixed at 0.38.The optimum percentage of fiber was 1.5 % by volume of concrete. With

[image:4.595.196.455.141.323.2]these, SCC trials have been done and are given below.

Table -5:-SCC Trials

Fin Coars Slump V- L- Comp. Remar

e % e% (mm) Funn bo strengt ks

el x h

(MPa)

50 50 890 4 1.5 - N

52 48 750 4.3 1.3 - N

54 46 724 6 0.9 22.1 Y

56 44 685 6.2 0.8 21.15 Y

58 42 655 13 0.7 - N

60 40 600 15 0.5 - N

53 47 730 4.7 0.7 - N

55 45 690 9 0.9 22.68 Y

57 43 680 11 0.8 20.89 Y

[C] Design of reinforcement

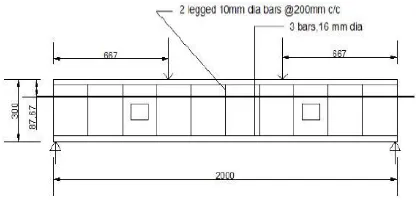

The reinforcement details of beams were obtained from IS 456 – 2000, and they are:-

[image:4.595.29.250.409.551.2] [image:4.595.214.422.605.705.2]© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3021 Fig- 6: Longitudinal section of beam withopenings for shear failure

[D] Preparation of test specimen

The mould of the beam was casted by using wood.. The concrete mix contains cement, sand, aggregate, fly ash, water and super plasticiser were weighted accurately. The mixing was done till uniform mix was obtained. The concrete mix was then placed into the mould immediately after mixing. Compaction was avoided in this case, as it is SCC mix. At the end of 7 days of casting the test specimen were remoulded. They were cured in water for 28 days. After 28 days of curing the specimen was dried in air.

Fig- 7: Arrangement of reinforcement for beamswith openings

[E] Experimental setup

The beams was tested in a 50 tons capacity loading frame and they were mounted as simply supported beams. Two dial gauges were placed, one at the mid span under the loading point and other at one third span. Demecs were placed at the centre of the beam and at right, towards tension zone to get maximum deflection. The load was applied at increment of one ton. While testing, the first cracking load and ultimate load was observed and cracks patterns were marked. Strains were noted by strain gauge. All beams were loaded till its failure.

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3022 4. TEST RESULTS AND DISCUSSIONS

[A] Load-Deflection curves

After the testing, the Load deflection curves were obtained for both flexural and shear SCC beams. It was observed that as load increased the deflection of the beam also increased. The maximum deflection was observed for beams with openings and minimum deflection was observed for beams with openings incorporating fibers.

Chart-1: Load deflection curve of SCC beam forflexure at mid span

Chart-2: Load deflection curve of SCC beam forflexure at right span

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3023

Chart-4: Load deflection curve of SCC beam forshear at right span

[B] Load carrying capacity of beams

The ultimate and the first cracking load taken by each of the beam were observed. It was observed that beyond the ultimate load the beam takes no load and further failure occurs. The load at which the first crack occurs is the first cracking load.

Table-6: Ultimate and first cracking load ofdifferent beams

Beam Specimen details First Ultimate

Notation crack load (kN)

s load

(kN)

Self-compacting 80 150

SCC-F concrete beams for flexure without

opening

SCC-F, Self-compacting 60 130

openings concrete beams for flexure with opening

Fiber reinforced Self 90 160 FR-SCC-F compacting concrete

beams for flexure with opening

Self-compacting 80 160

SCC-S concrete beams without openings for

shear

Fiber reinforced Self 90 175 FR-SCC-S compacting concrete

beams with opening for shear

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3024 [C] Comparison of Ductility factor in beams

Table -7: Ductility factor in beams

Beam Name Ultimate Yielding Ductility deflection( deflectio factor

mm) n (mm)

SCC-F,without 8 2.99 2.6

opening & fiber

SCC-F,with 7.6 3 2.5

openings

FR-SCC-F,with 8.5 2.9 2.9

openings &

From the above table ,it was observed that when openings was provided in beams the ductility factor of beams for both flexure and shear was reduced. On addition of fibers, the ductility factor increased. The ductility factor increased to 11.58 % in flexure beams .For flexural beams it was increased up to 17.5 %.

5. CONCLUSIONS

The presence of openings in the beams reduces the beams load carrying capacity and its overall behaviour. Use of SCC mix, reduced the efforts of vibration and addition of fiber in beams with openings, enhanced the beam capacity. From the experimental study it was concluded that, the first crack load was reduced to 25 % when openings were provided in beams for flexure. On addition of Recron 3s fibers enhanced the capacity up to 33% in beams, when compared with beams without fiber.

The ultimate load carrying capacity was reduced to 12.6 % in beams for flexure, when openings were provided. On addition of Recron 3s fibers enhanced the capacity up to 30.7%, when compared with beams without fiber. Ductility factor was increased up to 11.58% when fiber was added for flexure.

The first crack load was increased to 11% when fibers were provided in beams with openings for shear. The ultimate load carrying capacity was increased to 10.5 % in beams for shear, when fibers were provided. Ductility factor was increased up to 17.5% when fiber was added for shear.

REFERENCES

[1] Asha Deepthi. Deva, Gopala Krishna Sastry. K. V. S., A Comparative Study on Mechanical

Properties of Normal Vibrated Concrete and Self Compacting Concrete., “International Journal of Civil and Structural Engineering Research “.,

(2015)Vol. 2, pp: (93-100).

[2]Harsh Patel, Chintan Patel,Kishan Patel, Prof. Manjurali I, Balya, Prof. Vikrant A. Patel., Performance Evaluation of Polymer Fiber “RECRON-3S” in Pavement Quality Concrete.,

“International Journal for Scientific Research & Development”.,(2015)vol.2,pp(457-561).

[3] Maher A. Adam, Mohamed Said, Tamer. M. Elrakib., Shear performance of fiber reinforced self compacting concrete deep beams,

“International Journal of Civil Engineering andTechnology”,(2016) Vol 7, pp. 25-46

fiber

SCC-S,without 5.1 2.1 2.4

opening & fiber

SCC-S,with 4.8 1.7 2.82

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 3025

[4] Amit Bahuguna, Sanjay Sangwan, Avadhesh Chandra Mauli.,Experimental Studies on Properties Of Self-Compacting Concrete, “International Journal for Research in Applied Science & EngineeringTechnology” Volume 3 Issue VIII, August 2015.

[5] N R Gaywala ,D B Raijiwala.,Self compacting concrete: a concrete of next decade , “Journal ofEngineering Research and

Studies”,Vol. II,(2011)pp 213-21.

[6] S. Venkateswara Rao, M.V. Seshagiri Rao and P. Rathish Ku ma r, “Effect of Size of Aggregate and Fines on Standard and High Strength Self-Compacting Concrete”, Journal of AppliedSciences Research, 6(5), 2010, pp433-442.

[7] EFNARC. Specification and guidelines for self-compacting concrete, English edition. European Federation for Specialist Construction