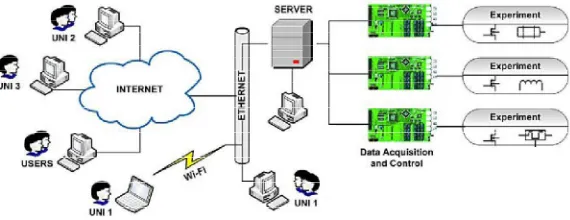

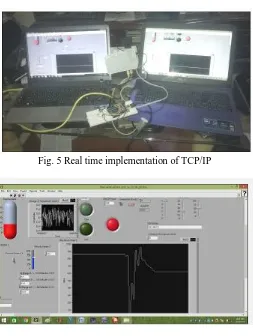

Virtual Remote Lab Access over TCP /IP Server

Full text

Figure

Related documents

A robust approximation is therefore required for the conversion to time domain of the constitutive line equations and the sub- sequent generation of a line macromodel to be employed

The browser stores the CA roots that can be trusted, therefore if a browser encounters a website using a SSL certificate issued by a CA root it does not trust, the browser will

Ne- tronome’s Agilio server networking platform will be utilized with OpenStack, OVS, Contrail vRouter and Linux Conntrack technologies to showcase an extended set of features made

Upon PCa recurrence and progression, and as the prognosis worsens, several second line treatment options are available, including taxane-based chemotherapy (like cabazitaxel

The focus of this chapter was on modelling and forecasting time-varying system- atic covariance (beta) risks, using a multivariate state space form of the time- varying Linear

12 in understanding IS adoption decision made by individuals, that is top management at the time HRIS was adopted at an organizational level and how it’s used by

od majke, od matenice, od sigurnosti, koje je povrh svega izrazito bolno kako za maj- ku tako i za dijete. To možemo vidjeti kao primaru transformaciju u fizičkom postoja- nju, dok

Each local server(s) has pointers to the central server(s) which can be used to dispatch the basic and essential EPR fields of information soon after creating it and storing