Iranian Journal of Chemical Engineering Vol. 11, No. 2 (Spring 2014), IAChE

Convective Heat Transfer Enhancement of CNT-Water

Nanofluids in Plain Tube Fitted with Wire Coil Inserts

M. Fallahiyekta1, M.R. Jafari Nasr2*, A. Rashidi2, M. Arjmand3

1- Department of Chemical Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran 2- Nanotechnology Research Center, Research Institute of Petroleum Industry (RIPI), Tehran, Iran 3- Department of Chemical Engineering, South Tehran Branch, Islamic Azad University, Tehran, Iran

Abstract

The turbulent convective heat transfer and pressure drop characteristics of CNT-water nanofluid in a horizontal tube fitted with wire coil inserts are studied experimentally. CNTs were synthesized by chemical vapor deposition (CVD) method with purity of more than 99%, functionalized by acid treatment and dispersed in distilled water in different concentrations. Also, the thermal conductivity and viscosity of synthesized nanofluids were measured experimentally. Convective heat transfer experiments are conducted with water and nanofluids in the range of 5000 < Re < 22000, CNT volume concentration 0 <ϕ< 0.1 % and wire coil with wire pitch of 2. The experimental results indicate that the convective heat transfer increases up to 23% in 0.05 vol% CNT-nanofluid and the heat transfer coefficient increases with CNT vol% and Reynolds number. Wire coil inserts increase the heat transfer coefficient of water and nanofluids up to 102% in Re=5700 but its performance decreases with Reynolds number. Experiments have shown that only use of wire coil inserts increases pressure drop of working fluid. Moreover, empirical correlations for Nusselt number and friction factor are proposed from nonlinear regression of the experimental data. Further, performance evaluation of enhanced tube is determined with considering opposing thermal resistance.

Keywords: CNT, Nanofluid, Heat Transfer Coefficient, Wire Coil Inserts

1. Introduction∗

From the past decades, researchers have studied development of enhancement techniques to reduce the size and costs of heat exchangers. Use of wire coil inserts, twisted tape inserts and other mechanical turbulators is one of the passive methods that change hydrodynamics and increase turbulence of the working fluid that leads to higher heat transfer coefficient [1-4].

∗Corresponding author: nasrmrj@ripi.ir

clogging in microchannels due to smaller size and larger interface area compared with micrometer-sized particles [5-8]. CNTs are excellent candidates as dispersions for preparing nanofluids, due to their very high thermal conductivity and very large aspect ratio [8]. Pak and Cho [9] studied TiO2-water and Al2O3-water nanofluids in turbulent convective heat transfer inside tubes. Yang et al. [10] studied laminar convective heat transfer of graphite nanofluids in a horizontal tube heat exchanger. Xuan and Li [11] considered convective heat transfer and flow features of CuO-water nanofluids. Wen and Ding focused on entry region under laminar flow condition using nanofluids containing Al2O3 and CNTs in horizontal tube [12, 13]. Ding et al. [14] reported significant enhancement in convective heat transfer of multi-wall carbon nanotube dispersion in water and found that amount of enhancement depends on the Reynolds number, CNT concentration, and pH. Xing et al. [15] found the laminar heat transfer enhancement of 70% and 190% for nanofluids containing 0.05 and 0.24 vol% CNT in water at Re=120. Also, Rashidi et al. [16] experimentally investigated heat transfer enhancement of CNT–water nanofluids in a horizontal shell and tube heat exchanger in laminar flow. They found an increase of overall heat transfer coefficient with Reynolds number. Using nanofluids and tube inserts together in horizontal tubes is considered by several researchers. Heat transfer enhancement for Fe3O4 nanofluid in a tube with twisted tape inserts has been experimentally investigated by Sundar et al. [17]. They found that 30.96% enhancement for 0.6 vol% of Fe3O4 in a plain tube and further enhancement of

18.49% in a plain tube with twisted tape (H/D=5) at the Re = 22000. The heat transfer enhancement of 23.69% for 0.1 vol% of Al2O3 nanofluid in a tube has been analyzed by Sharma et al. [18]. Further 44.71% heat transfer enhancement is observed with twisted tape insert with (H/D=5) inside a circular tube at Re = 9000. Sundar and Sharma [19] have observed 30.30% heat transfer enhancement for 0.5% of Al2O3 in a plain tube, further, 42.71% of heat transfer enhancement with twisted tape (H/D=5) is observed compared to water at Re = 22000. Laminar flow of CuO/base oil nanofluid in a tube with wire coil inserts has been estimated by Saeedinia et al. [20] experimentally and 45% enhancement was noted in heat transfer for 0.3 vol% CuO. Fully developed laminar flow of 0.1 vol% Al2O3 nanofluid in a tube with wire coil inserts has been analyzed by Chandrasekar et al. [21] who observed 21.53% heat transfer enhancement with wire coil pitch of 3. Noticeable increase of pressure drop of the nanofluids with inserts was found in all above-mentioned researches. Jafari Nasr et al. [22] investigated performance evaluation of heat transfer enhancement tubes fitted with turbulator devices such as twisted tape, wire coiled and so on. They developed a new performance index taking into consideration the effect of opposing thermal resistances such as fouling. Their results showed that the potential benefits of heat transfer enhancement cannot be analyzed from the effects of thermal resistances separately.

aim of t turbulen pressure constan CNT-w Also, enhance inserts a

2. Expe

2-1. Exp

The exp convect schemat a test se tank, an tube of 15.8 mm

electrica of 2000 heat flu a thick R the heat section.

this paper is nt heat tr e drop in nt heat flu

ater nanoflu the perfo ed tube with are consider

erimental

perimental s

perimental tive heat tra

tically in Fi ection, a cen nd a coolin f 1100 mm

m OD is us al heater w 0 W was ad ux condition Rockwool i ter to preve

Seven

K-Figure 1. Pu

Bypass flow Reservoir

tank

s based on ransfer enh

a horizon ux using c

uids and w ormance h nanofluid red.

system

system for ansfer coeff ig. 1. It ma ntrifugal pu ng part. A length, 12 sed as the t wire with m dopted to su n along the c

insolating la ent heat los -type therm

Experimental Calming sction

ump

investigatio hancement

ntal tube combination wire coil ins

evaluation ds and wire

r measuring ficient is sh ainly consis ump, a reser

straight co 2.2 mm ID

test section maximum po

upply a cons copper tube ayer surroun ss from the mocouples w

l system for th on of

and with n of serts.

of coil

g the hown

ts of rvoir opper and . An ower stant e and nded e test were

m d th in th t s s e f o f s r h t o s in v p f r

he measureme Therm

mounted on distance to he tube nserted into he heat emperature steady state section is al exchanger w forced throu of constant flow is con section and reservoir tan hydrodynam o eliminate of pump is straight tub nterring in volumetric f pressure dr flowmeter a respectively

ent of convecti mocouples T1-T7 Cooling syst

the test sec measure w and two o the flow at transfer s of passin conditions llowed to c with cooling ugh the test

flow pum ntrolled by d additional nk through mically fully

e the entran s initially be in calm nto the tes

flow rate of rop are me and U-tube y.

ive heat transf 7

tem

ction in equ wall tempera

thermocou t the inlet an section to ng fluid. T

, outlet flow ool in a coi g water. Th t section w mp. Flow ra

y a valve l fluid is r

bypass line y developed nce effects,

passed thr ming secti st section.

f inlet liqui easured by mercury m

fer coefficient

ually spaced ature along uples were nd outlet of o measure To achieve w from test il tube heat he liquid is with the aim ate of inlet before test returned to e. To make d flow and outlet flow rough 2 m

ion before Also, the id and fluid y magnetic monometer,

t.

d g e f e e t t s m t t o e d w

m

2-2. Nanofl

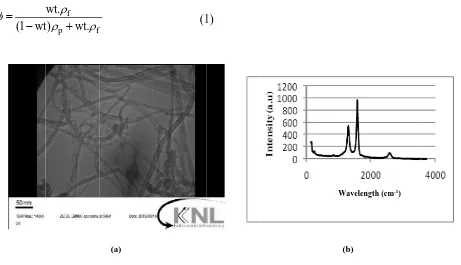

Distilled w (CNTs) w Initially hi in Researc (RIPI) by supported 800-900oC methane as than 99%. spectroscop have avera

nm and 10 Fig. 2 that band ove confirms t samples o dispersing concentrati by wt %

percent of

converted t

(1 wt

φ = −

luids prepar

water (DW) were used t igh purity C ch Institute y CVD p MgO nan C, 45 min

s a carbon . Fig. 2 sh py of produ age diamete 0μm, respec the value o r D-band) the high q of nanoflui

CNTs ion of 0.03,

(0.0142 –

f CNTs in to volume p

f

p f

wt.

t) wt.

ρ ρ + ρ

ration

) and carbo to produce CNTs were of Petrole process ov nostructured

n reaction source and hows TEM uced CNTs er and leng ctively. It is of IG/ID (Int ) is about quality of ids were p

in DW , 0.05, 0.1, – 0.095 vo

n nanoflui percent as fo

f

(a)

Figure 2. (a)

on nanotube e nanofluid e synthesize eum Industr ver Co-Mo d catalyst i

time wit purity mor and Rame s. The CNT gth of 10-2 s found from tensity of G t 2, whic

CNTs. Fiv prepared b with CN 0.15 and 0.

ol%). Weigh

ids can b follows:

(1

TEM. (b) Ram es ds. ed ry o, in th re en Ts 20 m

G-ch ve by NT .2

ht

be

1)

Whe are this Bec that DW trea acid hyd C, C the CNT are aggl DW aggl for 40 mad over or s

men spectrosc

ere wt is w density of D

work p

ρ is cause of hy t lead to ag W, CNTs atment with

d in a rati drophilic fun

C=O, and O CNTs surfa Ts in DW

entangled lomerates. W, to disent lomerates, n 1 hour at 1

kHz ultras de in this w

r 1 month ettling.

copy of produ

weight perc DW and CN

taken as 2. ydrophobic ggregation a are functi

mixture of o of 1:3. nctional gro O–H might

aces, which [23]. It wa and some After add angle nano nanofluids w 00% amplit sonic bath way were fou

with no vis

(b)

uced CNTs.

Wavelen

cent and

ρ

NTs respect1 g/cm3. surface o and precipit ionalized b f nitric and By acid tr oups such a be introduc h leads to di as found tha

are in the dition of C tubes and t were ultras tude using a . CNT na und to be st sible sedim

gth (cm-1)

f

ρ

andρp tively. Inof CNTs tation in by acid

sulfuric reatment as C–O– ced onto ispersing at CNTs form of CNTs to

3. Phys 3-1. The The th samples thermal Devices accurac the wor method DW as probe.

W / m.k instrum of each tempera conduct shown i of water vol% enhance achieve nanoflu Due to h in the noticeab works d on the nanoflu presente thermal water nanoflu were us heat tran 3-2. Visc Because 0.1%, Newton nanoflu Gallen ical proper ermal condu hermal con s were me

properti s, Inc., USA

y of 5%.Th rking princi . Initially,

a base flu For DW which prov ment. Theref h five samp atures. Fig.

tivity ratio in this figur

r was enhan and t ement of

d for 0 uids in 25 o high purity

experimen ble in co done by re ermal cond uids. More

ed by auth conductivi nanofluids uids therma

sed for each nsfer.

cosity

e CNT vol%

nanofluids nian fluid uids sample

Camp bath

rties of nan

uctivity

nductivity asured usin es analyz A) in 25oC he instrumen

iple of a tra thermal c id was mea kw was ob ves the acc fore therm ples was m 3 shows me

(knf/kf) of re, the therm nced with in temperature

25.5 % .2 wt%

o

C and 30oC of synthesi nts, this e omparison

esearchers ductivity o

details of hors in pre

ity enhance [27]. Th al conductiv h experimen

% in samp could be ds. The

es was m h viscometer

nofluids

of nanofl ng a KD2 zer (Deca

and 30oC nt was base ansient hot conductivity

asured by K btained as curacy of K al conduct measured in

easured the nanofluids mal conduct ncrease of C

. Maxim and 38.7%

(0.095 vo

C, respectiv ized CNTs u enhancemen with prev [5,13,14,24 of CNT-w this work vious work ement of C

he values vity in Fig nt of convec

les is less e assumed viscosity measured u

r in 20, 30 luids Pro agon with ed on wire y of KD2 0.6 KD2 ivity two rmal . As ivity CNT mum % is ol%) vely. used nt is vious 4-26] water k are k on CNT- of g. 3 ctive than d as of using and F D 4 f r p in s m v I v in w in f o s t n h n 3 T n l

Figure 3. The DW versus CN

40oC. In ea filled with n reach deter passing tim ndicators o stop watch multiplied b viscosity of Initially, to viscometer,

n 20 oC. Ob was 1.0042

n good agre for DW in 2 of about 2% samples wa

emperature nanofluids v heat transf nanofluids i 3-3. Specific To determin nanofluids, iterature we ermal conduct NT vol% and t

ach experim nanofluid a rminate tem me of nan

of viscome h. This m by viscome

nanofluid. o evaluate

viscosity o btained resu centi-stoke eement with 20oC (0.98 %. Thus visc as measured s accurate viscosity ar fer calcula

s taken from

heat and de

ne specific the foll ere used [28

tivity ratio of temperature.

ment visco and set in t mperature. ofluids bet eter was re

measured eter constan

e the ac of DW was ult for visco

s (1.0016 c h the data i cP) with a cosity of al d by visco ely. The re shown in ations, vis m Fig. 4.

ensity

c heat and lowing re 8];

nanofluids to

Figure 4. M CNT vol% an

nf

ρ =ϕ ρ

p,nf

C =ϕC

Where Cp nanopartic

4. Results

4-1. Heat tr

The energ could be ca

1

Q = V× I

In which Voltage an the flowing

2 p o

Q =m C (T&

Where

m

&

while Tout a of outlet a section of t ExperimenMeasured Vis nd temperatur

p (1 )

ρ + −ϕ ρ

p,p

C + −(1 ϕ)

p,p and Cp,f

les and base

and discus

ransfer calc

gy supplied alculated as

V and I nd Ampere.

g liquid is d

out in

T −T )

is mass flo and Tin are

and inlet flu the experim nts show th

cosity of nan re.

f

ρ

p,f

C

f are speci

e fluid respe

ssion

ulations

d by heati s follows:

are recorde Also, heat defined as:

ow rate of e measuring t uid flows in mental setup

hat the hea

nofluids versu

(2

(3

ific heat o ectively.

ing elemen

(4

ed electrica absorbed b

(5

entering flui temperature nto test tub p.

at loss from

us

2)

3)

of

nt

4)

al by

5)

id es be

m

elem diffe aver

Q=

Hea

'' q =

Whe leng The coef

exp

h

w

T

that

f T

prop

4-2.

Initi in p exp com Dat

1

N u

400 k f

= =

ment to surr ference of Q rage of them

1 2

(Q +Q ) / 2

at flux per u

o Q d L

π

=

ere do and gth of the erefore the

fficient is ca

'' p

w

q (T T =

−

is average

t are measu

is average

perties of w

Validation

ially, exper plain tube erimental mpared with

a Unit) equ

(

1 2

f R 8

k k

00 R e 5 1 13.6 f (1.82 L og R

⎛ ⎞ ⎜ ⎟ ⎝ ⎠ =

⎛

+ ⎜

⎝ < < × = +

rounding is Q1 and Q2 is

m was used

unit area is d

d L are ou e test sec experime alculated as

e

f

, Nu T )

value of 7

ured during

of Tout an

working fluid

of heat tran

riments wer to evaluat

system. h ESDU (E

ation as foll

)

(

0.5 2 / 3

6

2 2

R e 1000 P r

f

P r 8

10 , 0.5 k R e 1.64)−

−

⎞ −

⎟ ⎠

× <

= −

s negligible s less than 2 in calculati

defined as fo

utlet diame ction resp ental heat

s:

exp

exp h di

k =

7 wall temp

g experime

nd Tin. All

d are taken

nsfer system

re done wit te the accu The resu Engineering

lows:

)

r

1

P r 2000 11.7 1.8 P

−

< +

and the 2%. The ions as:

(6)

follows:

(7)

eter and ectively.

transfer

i (8)

peratures

ents and

physical

inTf .

m results

th water uracy of ults are

Science

1 / 3

P r−

Where f

into the (Re =50 water an heat flu of hea compare error of rather th from Fi heat tran used for

Figure 5 coefficien

4-3. Ex inserts

To stud heat tra length w

in Fig. 6 shows t transfer found fr heat tr Reynold and clea could be

f is friction e test sectio 000 - 2000

nd tube wa ux of 1500 W

at transfer ed with ES f experiment

han ESDU ig. 5 it is o

nsfer system r further exp

5. Validation nt of water wi

xperiments

dy the effec ansfer coef wire coil wi

6) is inserte the enhanc r coefficient from this Fi ransfer dec ds number. arly from F e useful in l

n factor. W on in diffe 0) and all t all are recor W. Fig. 5 sh

r coefficie DU equatio tal heat tran equation is bserved tha m are valid periments o

of experime ith the ESDU

with water

ct of wire fficient of

th wire pitc

ed into the t ement of c t with wire c igure that a creases wit It is observ Fig. 8 that w low Reynol

Water is ent erent flow r

temperature rded in cons hows the re ent of w on. The ave nsfer coeffic

s about 8% at the result

and it coul of nanofluid

ental heat tra equation.

r and wire

coil insert water, a ch of 2 (p / d

test tube. F convective coil inserts. augmentatio th increase ved from Fi wire coil in lds numbers

tered rates es of stant sults water erage cient and ts of ld be ds.

ansfer

coil

s on

full-d=2

ig. 7 heat It is on of e of

ig. 7 serts s and

h F o

F c

F c

F e in w th

h-ratio is eq Fig. 7 maxim observed in

Figuer 6. S

Figure 7. E coefficient wit

Figure 8. Hea coil to water v

From nonl experimenta n turbulent was propose he average

qual to unit mum enhan Re = 5700.

chematic diag

Enhancement th wire coil in

at transfer coe versus Re.

linear regr al data for

t flow an ed as a func

error of 2%

t in Re =20 ncement of

gram of wire c

of water h nserts.

efficient ratio

ression of water-wire empirical ction of Re a % as follows

0000. From 102 % was

coil inserts.

heat transfer

of water-wire

f obtained coil insets correlation and Pr with s:

m s

r

e

Nu

=

1.7

Presented c Nusselt nu inserts in R

4-4. Experi

Three nano 0.05, 0.1 a fluid and coefficient constant h the compar coefficient concentrati Fig. 9 that is enhance increase of transfer en number. nanofluids in all CN CNT- nan 23% was a

Figure 9. C coefficient o

An empiri nonlinear r of 0.1 wt%

of 2.5 % as

0.4028

795 Re

correlation umber in tu Re = 6000–1

iments with

ofluids with and 0.2 wt%

then con t was determ

eat flux of rison of exp t of wa

ion of nano t convective ed by use o f CNT conc nhancement Heat tra increases NT concentr

nofluid max achieved in

Comparison of f water and di

cal correlat regression

% nanofluid s follows:

0.1394

Pr

could be us ube fitted w

13000.

nanofluids

h CNT conc

% were used nvective h mined exper

1500 W. F perimental ater and ofluids. It is

e heat trans of nanofluid centration in t in the sam ansfer coe

with Reyno rations. Wi ximum enha

Re = 16000

f experimenta ifferent nanof

tion was ob of experim d with the a

(10

sed to predic with wire co

centration o d as workin heat transfe rimentally i Fig. 9 show heat transfe 3 weigh s found from sfer of wate ds. Also, th ncreases hea me Reynold efficient o olds numbe ith 0.1 wt%

ancement o 0.

al heat transf fluids.

btained from mental result

average erro 0)

ct oil

of ng er in ws er ht m er he at ds of er

%

of

fer

m ts or

Nu

Prop CNT

4-5. inse

Wir nano flow exp fluid obse heat pres the num heat with nano coil nano enh Mor adv high

Figu coeff wire

0.0119 R

=

posed corre T-water nan

Experimen erts

re coil was i ofluids of 0 w into te erimental h d in tube erved from t transfer o sence of wi

results with mber and C

t transfer h wire coil

ofluid and inserts enh ofluid by 7 ancement reover, it antage of w h Reynolds

ure 10. Comp fficient of wate

coil inserts.

0.8522 0.45

Re Pr

elation is v nofluid in R

nts with nan

inserted in t 0.1 and 0.2 est tube. heat transfer

are shown m this Figu of nanoflui ire coil inse h water in CNT concen

enhanceme and nanof wire coil hanced heat 72% in Re for water is found f wire coil ins

number.

parison of exp er, water-nano

572

valid for 0 Re = 6000 –

nofluid and w

test section 2 wt% are f

The res r coefficien n in Fig. 1 ure that co

ids is enha erts. Compa the same R ntration sho ent in com

fluids is mo individuall transfer of e = 6400 a

is about from Fig. serts is decr

perimental hea ofluid, water-n

(11)

0.1 wt%

19000.

wire coil

and two forced to

ults of nt of the 10. It is

nvective anced in arison of Reynolds ows that mbination

ore than ly. Wire 0.1 wt%

and this 100%. 10 that reased in

nanofluid-For 0.1 coil ano from n data in R

Nu =1.

4-6. Pr working

The fric horizon Darcy r

exp

2

f

=

ρ

Where calculat rate and Paramet diamete pressure evaluate

exp

P

12.55

Δ

=

=

To valid entered rates an tube m compari experim equation as follow

0.3 f

Re

=

wt% nano

other corre onlinear re Re = 6000–

0.3801

.591Re

ressure dro g fluid

ction factor ntal tube cou

elation as:

2

2 D

P

L

u

Δ

⋅ ⋅

ρ

u is averag ted from e d knowing t

ters of L,

er of the tu e drop of fl ed by U-tub

Hg w

w Hg

(

5

h

=

γ

−

γ

γ

date the pre into test nd pressure manometer. ison of mental frict

n for turbu ws:

0.25

316

e

fluids in pr lation coul egression o –19000 as fo

1 0.2865

Pr

op and fric

of a fluid e uld be deter

exp

2

ge velocity experimenta the cross ar

D are len ube, respec fluid and is be Mercury

w Hg

w w

)h

(13

,

=

=

γ

ρ

essure drop section in e drop mea

Fig. 11 obtained tion factor ulent flow in

resence of ld be prese of experime

ollows:

ction facto

entering into rmined from

y that could al volume

rea of test t ngth and in ctively.

Δ

Pexperimen manometer

w

w

3.55 1)

g

−

γ

system wat different sured using 1 shows

results r with Bla

n smooth p wire ented ental

(12)

r of

o the m the

(13)

d be flow tube. nside

P is

ntally r as:

w

h

Hg(14)

ter is flow g

U-the for asius pipes

(15)

A r r i w in

F

o

P w r c o o w th w

F

o

As shown results are in relation of B

s suitable working flu n this exper

Figure 11. Co of water with B

Pressure dro wire coil ex results of compared w observed fro of water inc wire coil ins

he needed working flui

Figure 12. Co of wire coil ins

in this Fig n good agre Blasius and for measur uids. The av

riment was

omparison of e Blasius equati

op of wate xperimenta

friction fa with plain t om this figu crease by 2

serts. This l pumping p id.

omparison of e serts with wat

gure the ex eement with d pressure d ring friction

verage obse less than 6%

experimental f ion.

er in tube lly measure actor calcu

tube in Fig ure that pre .5-3 times w leads to an power for t

experimental f ter in plain tub

xperimental h theoretical drop system n factor of erved error %.

friction factor

filled with ed and the ulation are g. 12. It is essure drop when using increase in the flowing

friction factor be.

l l m f r

r

h e e s p g n g

Nonlinear with wire with averag

exp

f

=

0.9

Presented water frict in Re = 50

The result nanofluids increase in correlation could be u wire coil fr

4-7. Perfor

To evalua transfer sy performanc performanc [22];

P.I ( 1 R

= +

Where Ropp

is heat tran is friction f Performan coil insert nanofluids 0.0001 are this figure Reynolds n with nan performanc the same analysis, resistance

regression coil inserts ge error of 2

0.26

527 Re

−correlation tion factor i

00 – 20000

ts of meas in all cases n pressure n for water– used to pre riction facto

mance Eval

ate the ad ystem using ce was det ce index (P

1.5

opp t

1 ) R ⋅h

p is opposin

nsfer coeffi factor, and S

ce index of ts and com

– wire co shown in F that P.I dec number. M nofluids–wir

ce than wa Reynolds n the effect on P.I was

of the resu s leads to a

2% as follo

626

is effectiv in presence

.

sured press s have show

drop of w –wire coil fr ediction of or.

luation

dvantages o enhanced t ermined wi P.I) of Jafar

3

St f

ng thermal r icient of flu

St is Stanton f tube enhan mbination o oil inserts Fig. 13. It is

creases with Moreover, th

re coil ater–wire co

number. Ba of oppos studied. De

ults for wate a correlatio ows:

(16

ve to predic of wire co

ure drop o wn negligibl water. So th riction facto f nanofluids

of the hea tube, therma ith propose ri Nasr et a

(17

resistance, h

uid in tube, n number. nced by wir

of 0.1 wt%

with Ropp

s found from h increase o he tube fille

has highe oil inserts i ased on tha

ing therma ecrease of P

er on

6)

ct oil

of le he or s–

at al ed

al.

7)

ht f

re

%

= m of ed er in at al P.I

with resu

Figu

wire

Figu

with

5. C Hig proc Aqu prep 0.1 cond exp show enh wor nano

h increase o ults of Fig. 1

ure 13. Comp coil and NF-w

ure 14. Perfor different Opp

Conclusions h purity C cess and fun ueous nano pared in f

vol % (0 ductivity a erimentally w highe ancement i rks done b ofluids and

of Ropp was

14.

parison perfor wire coil with

rmance index posing therma

s

CNTs was p nctionalized ofluids of five concen 0.2 wt%) and viscosi y. The ex er therm

in compari by research increase of

s obtained f

rmance index h Ropp=0.0001

of NF-wire c al resistance.

produced b d by acid tr

these CNT ntrations le and their ity were m xperiment's mal cond

ison with p ers on CN f nanofluids

from the

of water-.

coil inserts

by CVD eatment. Ts were

conductivity with CNT vol% and temperature. In 25oCwith 0.1 vol% (0.2 wt%) CNT in water, maximum thermal conductivity enhancement of 25% was observed in experiments. Also, obtained results of viscosity experiments in 20 – 40 oC show that viscosity of nanofluids increase with CNT vol% and temperature reduction. Turbulent convective heat transfer coefficient and pressure drop of water and nanofluids entering the plain tube and tube fitted with wire coil inserts were measured separately in constant heat flux of 1500 W for electrical element. To validate the experimental system, the result of Nusselt number of water was compared with ESDU equation and good agreement was achieved. Enhancement of convective heat transfer of water with wire coil inserts was observed from the experiment results. Heat transfer coefficient of water increases with Reynolds number but thermal enhancement by wire coil decreases in high Re.

Nanofluids with CNT concentration of 0.05, 0.1 and 0.2 wt% are entered into the test tube and enhancement of heat transfer with nanofluids was observed from experimental results. Also, heat transfer coefficient of nanofluids increases with Reynolds number and CNT concentration. With 0.1 wt% CNT-nanofluid maximum enhancement of 23% was achieved in Re = 16000. Nonlinear regression of experimental data leads to an empirical correlation for prediction of Nusselt number of 0.1 wt% CNT-water nanofluids. Using wire coil inserts in combination with nanofluids enhanced convective heat transfer more than wire coil and nanofluids alone, especially in low Re. The results of measuring pressure drop were

showed that presence of CNTs in water had negligible effect on friction factor of water. Also, wire coil inserts increase pressure drop by 2.5-3 times that of the increase needed for pumping power. Performance index of heat transfer system by using wire coil and combination of wire coil and nanofluid decreases with Re and performance of wire coil–nanofluid is higher than wire coil–water in the same Re. Also, performance index of enhanced tube decreases with increase of opposing thermal resistance.

Acknowledgements

The authors would like to express their gratitude toward Research Institute of Petroleum Industry (RIPI) for financial supported of this research and preparation of required facilities and the test rig.

References

[1] Godson, L., Raja, B., Mohan Lal, D. and Wongwises, S., "Enhancement of heat transfer using nanofluids—An overview", Renewable and Sustainable Energy Reviews, 14, 629, (2010).

[2] Jafari Nasr, M.R., Habibi Khalaj, A. and Mozaffari, S.H.," Modeling of heat transfer enhancement by wire coil inserts using artificial neural network analysis", Applied Thermal Engineering, 30, 143, (2010).

[4] Promvonge, P. and Eiamsa-ard, S.," Heat transfer enhancement in a tube with combined conical-nozzle inserts and swirl generator ", Energy Conversion and Management, 47, 2867, (2006).

[5] Assael, M.J., Metaxa, I.N., Arvanitidis, J., Christofilos, D. and Lioutas, C., "Thermal conductivity enhancement in aqueous suspensions of carbon multi-walled and double-multi-walled nanotubes in the presence of rwo different dispersants ", Int. J. Thermophys., 26, 647, (2005).

[6] Chen, L. and Xie, H., "Silicon oil based multi walled carbon nanotubes nanofluid with optimized thermal conductivity enhancement ", Colloids and Surfaces A: Physicochem. Eng. Aspects, 352, 136, (2009).

[7]. Murshed, S.M.S., Leong, K.C. and Yang, C., "A combined model for the effective thermal conductivity of nanofluids ", Applied Thermal Engineering, 29, 2477, (2009).

[8] Vajjha, R.S. and Das, D.K., "Experimental determination of thermal conductivity of three nanofluids and development of new correlations ", Int. J. Heat and Mass Transfer, 52, 4675, (2009).

[9] Pak, B.C., and Cho, Y.I., "Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles ", Exp. Heat transfer, 11, 151, (1998).

[10] Yang, Y., Zhang, Z.G., Grulke, E.A., Anderson, W.B. and Wu, G., "Heat transfer properties of nanoparticle-in-fluid dispersions (nanonanoparticle-in-fluid) in laminar

flow ", Int. J. Heat Mass Transfer, 48, 1107, (2005).

[11] Xuan, Y. and Li, Q., "Investigation on convective heat transfer and flow features of nanofluids", J. Heat Transfer, 125, 151, (2005).

[12] Wen, D. and Ding, Y., "experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions", Int. J. Heat Mass Transfer, 47, 5181, (2004).

[13] Wen, D. and Ding, Y., "Effective thermal conductivity of aqueous suspensions of carbon nanotubes (carbon nanotube nanofluids)", J. Thermophys Heat Transfer, 18 (4), 481, (2004).

[14] Ding, Y., Alias, H., Wen, D. and Williams, R.A., "Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids) ", Int. J. Heat Mass Transfer, 49, 240, (2006). [15] Wang, J., Zhu, J., Zhang, X. and Chen,

Y., "Heat transfer and pressure drop of nanofluids containing carbon nanotubes in laminar flows", Experimental Thermal and Fluid Science, 44, 716, (2013).

[16] Lotfi, R., Rashidi, A.M. and Amrollahi, A., "Experimental study on the heat transfer enhancement of MWNT-water nanofluid in a shell and tube heat exchanger", International Communica-tions in Heat and Mass Transfer, 39, 108, (2012).

nanofluid inside a plain tube: An experimental study", International Journal of Heat and Mass transfer, 55, 2761, (2012).

[18] Sharma, K.V., Sundar, L.S. and Sarma, P.K., " Estimation of heat transfer coefficient and friction factor in the transition flow with low volume concentration of Al2O3 nanofluid flowing in a circular tube and with twisted tape inserts", International Communications in Heat and Mass transfer, 36, 503, (2009).

[19] Sundar, L.S. and Sharma, K.V., "Turbulent heat transfer and friction factor of Al2O3 nanofluid in in a circular tube with twisted tape inserts", International Journal of Heat and Mass transfer, 53, 1409, (2010).

[20] Naik, M.T. and Sundar, L.S., "Investigation into thermophysical properties of glycol based CuO nanofluid for heat transfer applications", World Academy of Science, Engineering and Technology, 59, 440, (2011).

[21] Chandrasekar, M., Suresh, S. and Chandra, B., " Experimental studies on heat transfer and friction factor characteristics of Al2O3 – water nanofluids in a circular pipe under laminar flow with wire coil inserts", Experimental Thermal and fluid Science, 34, 122, (2010).

[22] Jafari Nasr, M.R., Polley, G.T. and Zoghi, A.T., "Performance evaluation of heat transfer enhancement (THE technology)", Proceeding of 14th International Chemical and Process Engineering Congress, CHISA, Parha,

Czech Republic, August 3-4, 27, (2000).

[23] Chen, H., Ding, Y. and Lapkin, A.A., "Rheological behavior of nanofluids containing tube/rod-like nanoparticles", Powder Tech., 194, 132, (2009).

[24] Xie, H., Lee, H., Youn, W. and Choi, M., "Nanofluids containing multi walled carbon nanotubes and their enhanced thermal conductivities", J. Appl. Phys., 94 (8), 4967, (2003).

[25] Murshed, S.M.S., Leong, K.C. and Yang, C., "Investigations of thermal conductivity and viscosity of nanofluids", Int. J. Thermal Sciences, 47, 560, (2008).

[26] Papari, M.M., Yousefi, F., Moghadasi, J., Karimi, H. and Campo, A., "Modeling thermal conductivity augumentation of nanofluids using diffusion neural network", Int. J. Thermal Sciences, 50, 44, (2011).

[27] Fallahiyekta, M., Jafari Nasr, M.R., Rashidi, A.M. and Arjmand, M., " An experimental study on thermal conductivity of nanofluids containing new produced carbon nanotubes in distilled water: Empirical model development", Proceeding of International Conference on Mechanical Engineering and Mechatronics, Toronto, Ontario, Canada, August 8-9, 42, (2013).