Continuous improvements in die-casting using a Six Sigma approach

Full text

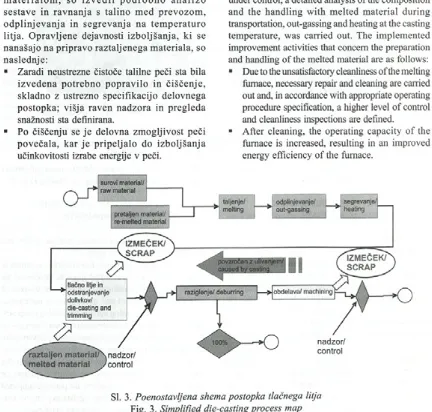

Figure

Related documents

Furthermore, for real-time applications, its fast version, the indefinite matrix-based sliding window FRLS I-SWFRLS algorithm, is developed using a shift property of the

Under arbetet med förstudien framkom växtlighet som en gemensam nämnare för såväl tri-valenta värden som för hållbar dagvattenhantering. Genom att jag i förslaget lade ett

implementation of CCSS in mathematics, and the shifts in instructional practices they entail may lead to teachers having greater success in shifting instructional practices

This research employes process time factor and customer satisfaction factor as performance evaluation on management process reengineering. It can also be applied to other

In government debt management (DeM), the categories of risk such as market risk (exchange rate and interest rate risk), credit risk, refinancing risk and liquidity risk are

(2004) The Role of National Qualifications Systems in Promoting Lifelong Learning, An OECD Activity: Report from Thematic Group 2: Standards and quality assurance in

The theoretical values of the lift coefficients of selected airfoil are compared with the simulated lift coefficients of three turbulence models respectively. 3 shows the comparison

Supply Chain Management – Research presentation: Purpose of this activity includes: • Do a thorough review of the paper assigned to your team to understand