Wear Rate vs Dynamic and Material Properties at Elevated Temperatures for a Copper-Graphite Brush

Full text

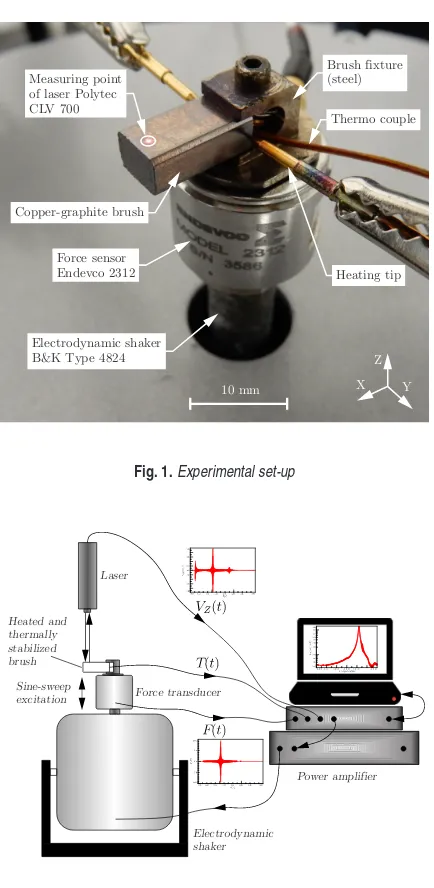

Figure

Related documents

There may be trade-offs between design alternatives with, on the one hand, high emissions in initial construction but low emissions in service life and disposal and, on the other

Wear rate and coefficient of friction of hybrid composites and unreinforced copper increases with increase in normal load and Wear rates and coefficient of friction of

Substituting in many of coke and graphite powder, an amorphous form graphite electrode market for your unique physical properties of artificial graphite products and acids.. Search

Since at low levels of spring pressure, mechanical wear is minimal while electrical wear is dramatically increased, it can be concluded that the lower limit is determined

The actual effect of any therapy will depend on the drug efficacy parameters but from this analysis, we infer that the reduction in specific growth rate of cells is prima- ry, and

The projected gains over the years 2000 to 2040 in life and active life expectancies, and expected years of dependency at age 65for males and females, for alternatives I, II, and

The difference between these 2 sets of estimates (a 3.3 per- centage point increase in insurance coverage, no statistically significant change in reporting having a primary