Comfort and Mechanical Properties of

Polyester/Bamboo and Polyester/Cotton Blended

Knitted Fabric

Uzair Hussain, Farhad Bin Younis, Faisal Usman, Tanveer Hussain, Faheem Ahmed

National Textile University, Yarn Manufacturing, Faisalabad, Punjab PAKISTAN

Correspondence to:

Uzair Hussain email: hussainuzairntu@gmail.com

ABSTRACT

The mechanical and comfort properties of polyester/bamboo and polyester/cotton knitted fabrics were studied. Four different ratios, P/B 65/35, P/B 50/50, P/B 35/65, P/B 20/80, P/C 65/35, P/C 50/50, P/C 35/65, P/C 20/80 of both blends were produced by mixing at the blow room stage. Then yarns of equal count Ne 20 were made on a ring spinning machine, and a knitted fabric was produced on a single jersey weft knitting machine.

It was observed that by increasing bamboo and cotton fiber content in the blends, yarn breaking force and tenacity were decreased. Bursting strength, bending rigidity, and thermal resistance of the blended fabrics decreased by increasing bamboo and cotton fiber content in the blends, while air permeability and moisture management capability was found to increase with the increase in bamboo and cotton fiber content. No antimicrobial activity was shown by any of the P/B blended fabric, but to some extent, 100% bamboo fiber showed antibacterial activity against gram negative bacteria while against gram positive bacteria, no activity was observed.

Keywords: bamboo, thermal resistance, moisture management, bursting strength

INTRODUCTION

Due to changes in technological trends and rapid pace in the area of textiles, there is significant change in taste regarding satisfaction. Consumers today, not only desire aesthetic appeal of apparel, but also its comfort and performance attributes. In fact these two attributes together with protection ability of the end product play a prominent role when selecting the desired product. Comfort aspect has become the need of almost every individual.

Knitting is a process of making a fabric by forming loops. A knitted fabric is characterized by courses and whales that run vertically and horizontally respectively. Knitting has many advantages because of its economical and relatively fast process together with comfort aspects of the end product. Knitted apparel is stretchable, permeable, and moisture absorbent which renders some feasible performance properties. Tight T-shirts, summer vests, and hosiery garments like socks and gloves all are the products of knitting due their comfort and performance attributes.

Bamboo fiber is a regenerated cellulosic fiber produced from bamboo. Starchy pulp is produced from bamboo stems and leaves through a process of alkaline hydrolysis and multi-phase bleaching. Further chemical processes produce bamboo fiber. Repeated technological analysis has proved that this kind of fiber has a thinness degree and whiteness degree close to normal finely bleached viscose and has strong durability, stability, and tenacity [1]. Most of the bamboo used to make bamboo fiber and bamboo clothing is grown in China by Hebei Jigao Chemical Fiber Company; they hold the patent on the process for turning bamboo into fiber. This facility produces all of the bamboo viscose on the market. The bamboo is certified organic by OCIA (The Organic Crop Improvement Association) [2] Following are its prominent features:

• Softer than cotton, with a texture similar to a blend of cashmere and silk.

• Because the cross-section of the fiber is filled with various micro-gaps and micro-holes, it has much better moisture absorption and ventilation. Moisture absorbency is twice than that of cotton with extraordinary soil release.

• Garments of bamboo fiber can absorb and evaporate human sweat in a split second just like breathing. Such a garment makes people feel extremely cool and comfortable and never sticks to skin even in hot summer.

• 100% bamboo yarns show great elasticity, nearly 20%. Even in 100% bamboo woven fabrics, a remarkable elasticity can be obtained wherein the use of elastomeric fibers like elastomers may be eliminated.

• Bamboo fabrics need less dyestuff than cotton, modal, or viscose. It seems that the absorption of dyestuffs is remarkably better. Bamboo absorbs the dyestuffs faster and shows the colors better. • Anti-ultraviolet nature of bamboo fiber makes it

it suitable for summer clothing, especially for the protection of pregnant ladies and children from the effect of ultraviolet radiation.

• Products of bamboo fiber are eco-friendly and bio-degradable [1].

Although there are some drawbacks of bamboo, even then it has many applications like:

• Intimate apparel, including sweaters, bath-suits, underwear, tight t-shirt, and socks.

• Due to its anti-bacterial nature, nonwoven fabric has wide prospects in the field of hygiene materials such as sanitary napkins, masks, mattress, and food packing bags.

• Sanitary materials include bandages, masks, surgical clothes, and nurse wear. It has incomparably wide foreground on application in sanitary material such as sanitary towels, gauze masks, absorbent pads, and food packing.

• Decorating items such as curtains, television covers, wallpaper, and sofa slipcovers.

• Bathroom products such as towels and bath robes [1].

Although natural fibers entail comfort properties to the users of textile apparel, the demands have been changed with rising technological trends and standards of living. Users of textile materials not only desire comfort, but aesthetic and functional properties as well. Also the product should be cost effective in order to meet the requirements of customers. The objective of this study was to manufacture a product that will not only be superior in comfort and performance, but also cost effective.

MATERIALS AND METHODS

For this study bamboo fiber was imported from Hebei Jigao Chemical Fiber Company Limited, China and polyester fibers from Ibrahim Fibers Faisalabad, Pakistan. Also cotton used for the study

was Pakistani cotton. Eight plain knitted (single-jersey) fabrics of 47 courses/inch and 35 wales/inch with a stitch length of 4.92 mm were produced using ring spun blended yarns of P/B 65/35, P/B 50/50, P/B 35/65, P/B 20/80, P/C 65/35, P/C 50/50, P/C 35/65, P/C 20/80, polyester/bamboo and polyester/cotton respectively. The GSM of the fabrics was found to be 235 (gm. /m2). Polyester and bamboo fibers of 1 denier and 1.2 denier and 38 mm staple length were used for the study, while cotton used had Micronaire value of 4.9 and staple length of 27 mm. Yarns of equal linear density 29.525 tex (Ne 20) nominal count were produced on a conventional ring spinning frame, RY-5 from Toyoda with a spindle speed of 16,400 rpm and a twist multiplier of 3.5. Blended yarns were then knitted on a single jersey weft knitting (Fukuhara Japan) machine with a 20 mm gauge, 2.5” diameter and 90 feeders.

Knitted fabrics were then bleached, in a single bath with 5 g/l NaOH, 8 g/l H2O2, 1 g/l wetting agent and

2 g/l stabilizer at 90o C for one hour.

After processing, the samples were tested for bursting strength according to standard test method for bursting strength ASTM D 3787-07

The liquid moisture management properties of a textile material were evaluated by AATCC TM 195-2009 using moisture management tester M-290 SDL Atlas, UK.

Air permeability of the fabric was measured by using standard test method for air permeability of Textile fabrics ASTM D737 – 04 (2008)

The stiffness of the fabric was measured using standard test method for stiffness of fabrics B.S. 3356-1961

Antibacterial characteristic of the samples was evaluated using standard test method for testing of antibacterial activity and efficacy on textile products JIS L 1902-2008.Thermal resistance of the samples was found using the sweating guarded hotplate standard test method for testing ISO 11092- 1993, ASTM F1868, and GB 11048.

RESULTS AND DISCUSSION Fiber and Yarn Results

Properties of cotton, polyester, and bamboo fiber used are shown in the Table I and Table II

TABLE I. Properties of cotton fiber used.

Units Cotton

μg/inch 4.9

g/tex 28.8

mm 27

% 82

% 8.2

% 5.1

- 71.7

- 9.7

Elongation

Rd value

+b value Length

Uniformity

Short Fiber Index(SFI)

Fiber Parameters

Micronaire

Strength

TABLE II. Properties of polyester and bamboo fibers used.

Fiber

Parameters Unit Polyester Bamboo

Linear density Denier (d) 1 1.2

Cut length mm 38 38

Tenacity g/d 7 2.27

Elongation % 22 20.5

No. of crimps - 12

-Moisture regain % 0.4 11.25

Color - Semi dull Semi dull

U% and IPI

The results regarding U% and imperfections were found as expected. U% and imperfection values of polyester, cotton blended yarns were found to increase with increase in proportion of cotton in the blend. The presence of short fiber content in the cotton leads to floating fibers in the drafting zone which causes thick, thin places in the drafted strand as the shorter fibers are not bound in the final strand and come out of the yarn salvage creating more imperfections and more unevenness in the yarn. As far as polyester, bamboo blended yarns are concerned, there is less unevenness and imperfections as compared to P/C blended yarns. But there is increase in unevenness and imperfections with increase in bamboo percentage in the blend.

Results of yarns blended are shown in Table III.

TABLE III. Yarn Results.

P/C 65/35 10.03 135.5 756.9 25.63

P/C 50/50 11.12 282.5 578.9 19.6

P/C 35/65 11.57 341 509.84 17.27

P/C 20/80 11.56 330 488.3 16.54

P/B 65/35 8.51 9.5 733.74 24.85

P/B 50/50 8.82 12 673 22.79

P/B 35/65 9.37 12.5 634.4 21.48

P/B 20/80 10.02 16 565.2 19.14

Blend Ratio U% IPI B-Force (cN) Tenacity

(cN/Tex)

Breaking Force and Tenacity

Table III shows the results of breaking force and tenacity of different ratios. Both breaking force and tenacity decrease with increase in proportion of cotton and bamboo in P/C and P/B blends respectively. This may be due to the low tenacity (Table I and Table II) and weak cohesion of cotton and bamboo fibers in the resultant yarn because fiber strength plays a vital role in the strength of yarn. Results of breaking force and tenacity are shown in

Figure 1 and Figure 2 respectively.

FIGURE 1. Breaking force different blended yarns.

Figure 3 shows the comparison of average tenacity between P/B and P/C blended yarns. It is clear from the figure that average tenacity of P/B blend is higher than that of P/C blend. Because P/C lends have more imperfections that leads to less overall tenacity.

FIGURE 3. Average Tenacity of different blended yarns.

Fabric Results and Analysis Bursting Strength

Bursting strength is an important property regarding functional behavior of knitted apparel. Knitted gloves and socks should have considerable bursting strength in order to provide sufficient resistance to bursting. Results of bursting strength tests are shown in Table IV.

TABLE IV. Bursting strength of P/B and P/C knitted fabrics.

Blend Ratio Mean Values

P/C 65/35 610

P/C 50/50 553.5

P/C 35/65 497

P/C 20/80 454

P/B 65/35 590

P/B 50/50 552

P/B 35/65 496.5

P/B 20/80 451.5

Bursting Strength (kPa)

Bursting strength of the blended fabrics was decreased by increasing bamboo fiber content in P/B blended fabric and cotton in P/C blended fabric.

These results can be attributed to low elongation at break of bamboo fiber as compared to polyester fiber [3]. As shown in (Table II) elongation% of polyester fiber is 22% which is more than bamboo fiber, resulting in less elongation of yarn and hence bursting strength of bamboo rich fabric deceased.

Also the tenacity of bamboo fiber is less than polyester fiber which further ads to the diminishing bursting strength.

The lower bursting strength of cotton rich P/C fabric can be attributed to low elongation of cotton fiber than polyester as shown in (Table I) that result in low elongation in yarn. Low tenacity of cotton fiber also contributes to the results achieved. Comparison of bursting strengths is also shown in Figure 4.

Bursting Strength (kPa)

800

600

400

200

FIGURE 4. Bursting Strength of P/B and P/C blended fabrics.

FIGURE 5. Average Bursting Strength of P/B and P/C blended fabrics.

Figure 5 shows that overall bursting strength of P/C blend is higher than P/B blend due to higher tenacity of cotton fiber as compared to bamboo fiber.

Air Permeability

It is an important property of knitted materials that allows transport of moisture from the fabric and flow of fresh air to the human skin. Air

p

ermeability values of P/B and P/C knitted fabrics are listed inTable V.

TABLE V. Air Permeability Results.

Blend Ratio Mean Value

P/C 65/35 400.5601

P/C 50/50 413.2601

P/C 35/65 420.2601

P/C 20/80 433.4

P/B 65/35 370.5

P/B 50/50 390.4101

P/B 35/65 410.4101

P/B 20/80 413.7

Air Permeability (mm/s)

It is clear from above values that, by increasing bamboo fiber content and cotton fiber content in the blend, air permeability were increased. It has been found in the literature that with the increase in bamboo fiber content in the blend, thickness and weight of the fabric tends to decrease [4]. Due to which air permeability of the bamboo rich fabric will increase. As bamboo rich fabric becomes thinner and light weight, so air permeability is increased due to less resistance to air flow. The air permeability results are shown in the Figure 6.

Air Permeability (mm/s)

450 400 350 300

FIGURE 6. Air Permeability of P/B and P/C blended fabrics.

Air permeability was also increased by increasing cotton fiber content in the P/C blended fabric.

This is due to the reason that with an increase in polyester fiber content in the fabric, yarn diameter is increased [5] and as a result, inter yarn spacing is reduced creating hindrance for the air flow through the fabric.

FIGURE 7. Average Air Permeability of P/B and P/C blended fabrics.

Figure 7 shows, that average air permeability of P/C blend is more than P/B blend because of micro gaps in the structure of cotton fiber it offers less air resistance.

Thermal Resistance

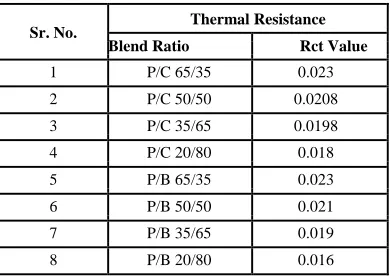

Thermal resistance is measure of the amount of resistance offered by the knitted material to the flow of heat from skin to the external environment. The results of thermal resistance of different blend ratios are shown in the Table VI.

TABLE VI. Thermal Resistance of P/B and P/C fabrics.

Sr. No. Thermal Resistance

Blend Ratio Rct Value

1 P/C 65/35 0.023

2 P/C 50/50 0.0208

3 P/C 35/65 0.0198

4 P/C 20/80 0.018

5 P/B 65/35 0.023

6 P/B 50/50 0.021

7 P/B 35/65 0.019

8 P/B 20/80 0.016

From the values of thermal resistance it is clear that by increasing bamboo fiber content in the fabric, thermal resistance is decreased. Thermal resistance is a function of thickness and thermal conductivity of the fabric [4]. As observed earlier with an increase in bamboo fiber proportion, the thickness of fabric is decreased which results in decreased thermal resistance of bamboo rich fabrics. This can also be attributed to the low diameter of bamboo fiber as compared to polyester fiber, which causes compression of layers reducing fabric thickness.

resistance. Also convolutions in cotton increase trapped air. The decrease in thermal resistance or insulation due to increase in cotton content is due to the result of more moisture content of cotton fiber [5]. Thermal resistance of different blends is shown in Figure 8.

FIGURE 8. Thermal resistance of P/B and P/C blended fabrics.

FIGURE 9. Average Thermal Resistance of P/B and P/C blended fabrics.

Figure 9 clearly demonstrates that overall thermal resistance of P/C blend is higher than P/B blended fabric as P/C blend offers more air permeability, so resistance to heat is increased because of more trapped air.

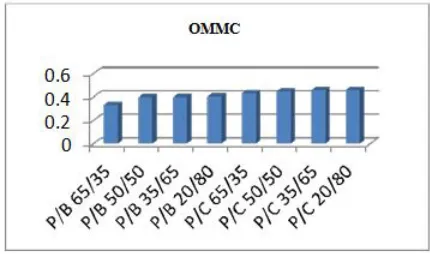

Moisture Management Capability

Moisture management is an essential feature of a textile material regarding its comfort appeal. Blending also has a vital role in moisture related capability of a textile material.

Moisture management values of different blend ratios are shown in the Table VII.

TABLE VII. OMMC values of P/B and P/C blend ratios.

Sr. No. Blend Ratio OMMC

1 P/B 65/35 0.3293

2 P/B 50/50 0.3972

3 P/B 35/65 0.3978

4 P/B 20/80 0.4061

5 P/C 65/35 0.4329

6 P/C 50/50 0.449

7 P/C 35/65 0.4592

8 P/C 20/80 0.4625

Table VII shows that moisture absorption increases with an increase in bamboo and cotton fiber content in the blends.

It was observed before that vapor permeability and absorbency of textile material increases with an increase in the hydrophilic proportion in the resultant material, because increasing hygroscopic proportion enhances drying of sweat close to the skin. The same is the case with P/B and P/C blends: increasing hygroscopic content in the blend increases moisture absorption and results faster drying of sweat from the skin [6].

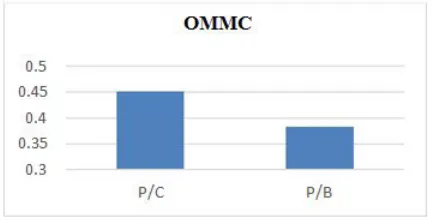

Too much moisture absorption can also lead to problems, because a material that absorbs more moisture can cause stickiness and dampness, due to less moisture spreading over the fabric surface. This may be reason that OMMC of P/C blended fabric is relatively higher than P/B blended fabrics. Results of OMMC are shown in the Figure 10.

FIGURE 11. Comparisons of average OMMC of blended fabrics.

Figure 11 shows that average OMMC of P/C Blends is higher than P/B blend as described before.

Bending Length

It is a property of a textile material determined by its resistance to bending in further processing and use. It is an important property regarding aesthetic and drape ability of textile materials. Bending Length results are shown in the Table VIII.

TABLE VIII. Bending Length of fabrics.

Sr. No. Blend Ratio Bending Rigidity

1 P/C 65/35 1.55

2 P/C 50/50 1.51

3 P/C 35/65 1.45

4 P/C 20/80 1.42

5 P/B 65/35 1.13

6 P/B 50/50 1.06

7 P/B 35/65 1.05

8 P/B 20/80 1.03

Table VIII shows that there is a decrease in the bending length of fabric with an increase in bamboo and cotton fiber content in the P/B and P/C blended fabrics.

As observed before there is a decrease in the thickness of bamboo rich fabric due to which it offers less resistance to bending. This may also be attributed to the larger diameter of polyester fiber which increases diameter of the yarn and increases the bending length of polyester rich fabric.

The same is the case with P/C blended fabric. An increase in cotton proportion reduces bending length. Here also by increasing cotton content, the diameter of yarn decreases and hence fabric stiffness in the end decreases. Also weak cohesion of fibers in cotton rich fabric causes the fabric to bend more easily. Comparison of bending length of different blends is shown in the Figure 12.

FIGURE 12. Bending length of fabric samples.

FIGURE 13. Average Bending length of fabric samples.

Figure 13 depicts that overall bending length of P/C blend is more than that of P/B blend as described before that due to compression of layers by increasing bamboo proportion, fabric becomes thinner so bending rigidity decreases.

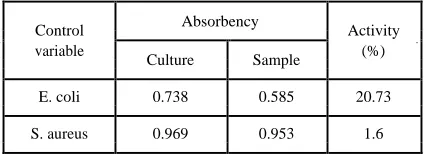

Antimicrobial Activity

One of the most important characteristic of bamboo fiber is its inherent antimicrobial efficacy. The most significant components in the bamboo’s chemical constitution are those providing its extraordinary fungal and bacterial resistance. The one responsible for antibacterial properties is 2.6-bimethoxy-p-benzoquinone, called ‘Bambookun’. The highly distinctive fungal resistance occurs due to a protein – dendrocin.

Antimicrobial activity of P/B blended fabric samples and 100% bamboo fiber was investigated using qualitative analysis.

The 100% bamboo fiber test was performed using absorbency method.

Findings of the test are as follows:

• As far as P/B blended samples are concerned, no antibacterial activity was shown by any of the samples, even most bamboo rich fabric sample (P/B 20/80) did not show any antibacterial efficacy.

• Results of 100% bamboo fiber are shown in the

Table IX.

TABLE IX. Results of antimicrobial activity.

Control Absorbency Activity

variable Culture Sample (%)

E. coli 0.738 0.585 20.73

S. aureus 0.969 0.953 1.6

Table XI shows that little (negligible) activity is

shown by 100% bamboo fiber towards

Staphylococcus (gram positive bacteria) while the efficacy of 100% bamboo fiber towards Escherichia coli is far better than Staphylococcus aurous, but not significant in terms of protection against bacteria and microbes. This indicates that bamboo fiber will not show any antibacterial activity if it is blended with cotton or polyester. This may be due to the reason that fiber used is not pure bamboo fiber rather it is a manmade viscose obtained from bamboo cellulose [7].

CONCLUSION

• With an increase in bamboo fiber content in the P/B fabric, generally there is increase in U% and, imperfections and a decline in breaking force and tenacity of the yarn with an increase in bamboo fiber content.

• With an increase in cotton fiber content in the P/C blend there is a considerable increase in imperfections and general decrease in tenacity and breaking force due to weak cohesion of cotton fibers.

• By increasing the bamboo fiber content in P/B blend, there is decrease in the bursting strength of the fabric. Same is the case with P/C blended fabric.

• Air permeability of P/B and P/C blended fabric increases by increasing bamboo and cotton fiber content in the blend, while thermal resistance of the fabric decreases with an increase in bamboo and cotton fiber content in the blends.

• Moisture management capability of the P/B and P/C blended fabrics was found to increase with an increase in the proportion of bamboo and cotton fiber content respectively.

• Enhanced air permeability and moisture

management property of P/B and P/C blended fabrics entail excellent comfort properties and fabric can be used as comfort apparel for summer. • Bending length of the blended fabrics was found

to decrease with an increase in bamboo and cotton fiber content providing another aspect to the aesthetic and drape ability of the fabric. • There was no antibacterial activity shown by any

of the P/B blend against any of the bacteria. But there was some sort of activity shown by 100% bamboo fiber against gram negative bacteria (Escherichia coli). These results show that the bamboo fiber used here do not possess effective antimicrobial efficacy.

REFERENCES

[1] Das, S, "Properties of Bamboo Fiber," [Online]. Available:

http://www.fiber2fashion.com/industry- article/textile-industry-articles/properties-of- bamboo-fiber/properties-of-bamboo-fiber1.asp. [Accessed April 4,2013].

[2] Wikipedia, “Bamboo Textiles (Source of raw material),” [online] Available: en.wikipedia.org/wiki/bamboo [accessed April 4, 2013].

[3] Chidambaram, P, Govindan, R, Venkatraman, K, C, "Study Of Thermal Comfort Properties Of Cotton/Regenerated Bamboo Knitted Fabrics," AfricanJournal of Basic & Applied Sciences ISSN 2079-203, Vol. 4(2), April 2012, pp. 60-66.

[4] Mahesh, S, S, Patra, A, K, Thakur, R,

[5] Tyagi, G, K, Bhattacharya, S, Kumar, P, "Hand Related Properties of Polyester-Cotton and Polyester-Viscose Ring and Mjs Yarn Fabrics", Indian Journal of Fiberand Textile Research, Vol. # 33, June 2008, pp. 126-131. [6] Das B, et al, “Moisture Flow through Blended

Fabrics-Effect of Hydrophobicity”, Journal of Engineered Fibersand Fabrics, Vol. 4(4), 2009, pp. 20-28.

[7] Erdumlu N, Ozipek B, “Investigation of Regenerated Bamboo Fiber and Yarn Characteristics”, Fibers &Textiles in Eastern Europe, Vol. # 16, 2008, pp. 43-47.

AUTHORS’ ADDRESSES Uzair Hussain

Farhad Bin Younis Faisal Usman Tanveer Hussain Faheem Ahmed