56

INVESTIGATION AND ANALYSIS OF DIESEL ENGINE

USING BIO DIESEL

Shankar Suthar1, Mangesh Kumar Chauhan2, Dr. Mohammad Israr3

1

Assist. Professor, Aravali Institute of technical studies, Udaipur, Rajasthan, India,

2

Associate Professor, Aravali Institute of technical studies, Udaipur, Rajasthan, India,

3

Principal, Dungarpur College of Engineering and Technology, Dungarpur, Rajasthan, India.

ABSTRACT

This study represents the analysis of smoke of biodiesel by using smoke tester. In this article biodiesel is taken as a fuel instead of diesel and quantity of emitted pollutants HC and CO is evaluated by taking different quantity of biodiesel at different load. Biodiesel is a diesel fuel that is made by reacting vegetable oil (cooking oil) with other common chemicals. Soybean oil is currently a major feedstock for production of biodiesel. The most common method of biodiesel production is a reaction of vegetable oils or animal fats with methanol or ethanol in the presence of sodium hydroxide (which acts as a catalyst). The transesterification reaction yields methyl or ethyl esters (biodiesel) and a byproduct of glycerin. Biodiesel is not straight vegetable oil burned in a diesel engine. Biodiesel has better lubricating properties and much higher cetane rating than today's low sulfur diesel fuels. Biodiesel addition reduces fuel system wear and in low levels in high pressure systems increases the life of the fuel injection equipment that relies on the fuel for its lubrication.

Biodiesel may be used in any diesel automotive engine in its pure form or blended with petroleum-based diesel. No modifications are required, and the result is a less-expensive, renewable, clean-burning fuel. This work shows how use of biodiesel will affect the emission of pollutants. Diesel Engine is compression ignition engine and use diesel as fuel, in this engine alternative fuel can be used. One alternate fuel is biodiesel. Biodiesel can be used in pure form or may be blended with petroleum diesel at any concentration in most injection pump diesel engines and also can be used in Vehicle, Railway, and Aircraft as heating oil.

ISSN 0976 – 6340 (Print) ISSN 0976 – 6359 (Online)

Volume 6, Issue 2, February (2015), pp. 56-61

© IAEME: www.iaeme.com/IJMET.asp

Journal Impact Factor (2015): 8.8293 (Calculated by GISI)

www.jifactor.com

IJMET

© I A E M E

57

Keywords: Biodiesel, Diesel Engine, HC, CO, Smoke Tester.

I. INTRODUCTION

Bio diesel is the ester based variety oxygenated fuels derived from natural renewable biological sources such as vegetable oils. Biodiesel fuel can be made from new or used vegetable oil and animal fats. Biodiesel is high quality fuel made through a chemical process called Trans esterification. Needed ingredients are vegetable oil, Methanol and Lye (NaOH).

The chemical reaction that occurs through this process breaks down the oil into a layer of biodiesel which rises to the top of the reactor, and a layer of Glycerine which falls to the bottom. The Glycerine is drained is drained off and used for other purposes, composted or otherwise disposed off. The biodiesel is then washed, dried and filtered to remove any extra impurities and its ready to be used as a fuel in diesel engines without any modifications to the engine.

Biodiesel is just twice as viscous as diesel having better lubricating properties and much higher cetane ratings than today's lower sulphur diesel fuels. Biodiesel addition reduces fuel system wear and in low levels in high pressure systems increases the life of the fuel injection equipment that relies on the fuel for its lubrication. Depending on the engine, this might include high pressure injection pumps, pump injectors (also called unit injectors) and fuel injectors.

Vegetable oils due to high biodegrability, low toxicity, renewability and excellent lubricating performance, have immense potential to replace petroleum oils as feedstock for lubricants. In these study vegetable oils like soybeanoil, castor oil, groundnut oil, and cottonseed oil was purchased from local super market. The different value of viscosity of different vegetable oils is shown in given table.

TABLE I: Quantity of Viscosity at different temperature

Sr.No. Temperature Viscosity of soybean oil Viscosity of castor oil Viscosity of groundnut oil Viscosity of cotton seed oil 1 30 78.83 609.22 81.92 75.73 2 40 62.21 405.76 57.74 55.53 3 50 48.20 201.40 44.56 39.63 4 60 38.20 120.30 34.28 32.81 5 70 32.34 93.49 26.16 28.27 6 80 26.28 89.67 22.21 24.28

It is clear that from the above table, the viscosity of the castor oil as compared to other vegetable oil is higher and as the temperature increases the viscosity goes on decreases.

II. ANALYSIS & FINDINGS

In this study soybeanis taken as vegetable oil mixed with and forms biodiesel used in different quantity at different load to take observations about emitted pollutants HC and CO.

58

TABLE II: Quantity of HC in ppm

Load(lbs.) Biodiesel Time of consumption HC(ppm)

20 20% 6 min 25 sec 2300 ppm 50% 6 min 20 sec 2050 ppm 80% 6 min 5sec 1940 ppm 100% 6 min 15 sec 1820 ppm 40 20% 5 min 20 sec 2450 ppm 50% 6 min 5 sec 2160 ppm 80% 5 min 50 sec 2010ppm 100% 5 min 35 sec 1950 ppm 60 20% 5 min 40 sec 2490 ppm 50% 6 min 20 sec 2310 ppm 80% 5 min 25 sec 2210 ppm 100% 5 min 10 sec 2110 ppm

Fig. 1 Graph between quantity of HC & Biodiesel %

0 1 2 3 4 5 6 7 8 20 50 80 100 20 lps 40 lps 60 lps

59

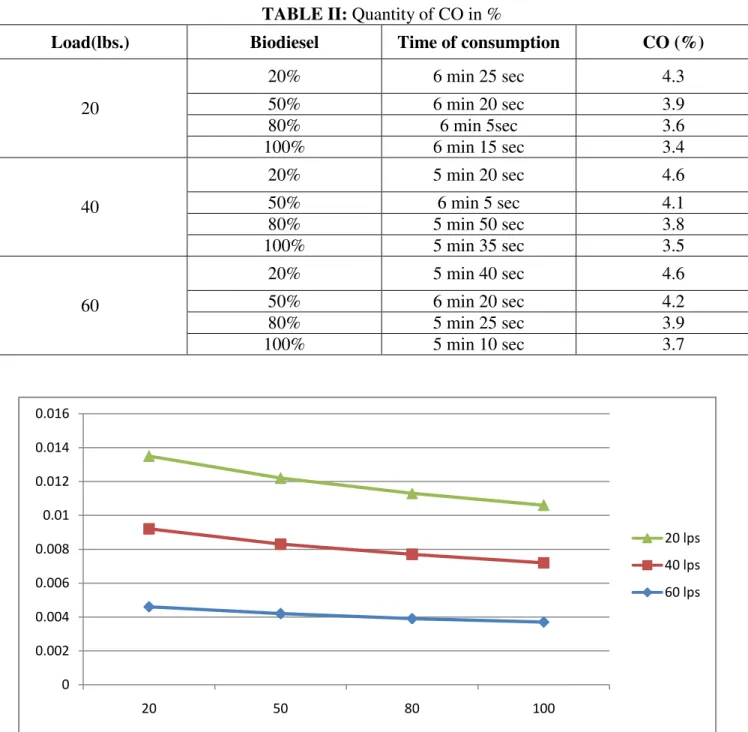

TABLE II: Quantity of CO in %

Load(lbs.) Biodiesel Time of consumption CO (%)

20 20% 6 min 25 sec 4.3 50% 6 min 20 sec 3.9 80% 6 min 5sec 3.6 100% 6 min 15 sec 3.4 40 20% 5 min 20 sec 4.6 50% 6 min 5 sec 4.1 80% 5 min 50 sec 3.8 100% 5 min 35 sec 3.5 60 20% 5 min 40 sec 4.6 50% 6 min 20 sec 4.2 80% 5 min 25 sec 3.9 100% 5 min 10 sec 3.7

Fig. 2 Graph between quantity of CO & Biodiesel %

III. RESULTS AND DISCUSSIONS

After experiment we find that hydrocarbons (HC) in ppm decreases with increasing of biodiesel percentage At 20 lbs. load – 20 % biodiesel emitted 2300 ppm HC 50 % biodiesel emitted2050 ppm HC 80 % biodiesel emitted 1940 ppm HC 100 % biodiesel emitted 1820 ppm HC 0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 20 50 80 100 20 lps 40 lps 60 lps

60 At 40 lbs. load – 20 % biodiesel emitted 2450 ppm HC 50 % biodiesel emitted 2160 ppm HC 80 % biodiesel emitted 2010ppm HC 100 % biodiesel emitted 1950 ppm HC At 60 lbs. load – 20 % biodiesel emitted 2490 ppm HC 50 % biodiesel emitted 2310 ppm HC 80 % biodiesel emitted 2210 ppm HC 100 % biodiesel emitted 2110 ppm HC

Hence, load increasing also affects the pollutants emission, % of HC increases with load increasing. And, carbonmonooxide (CO) percentage also decreases with increasing biodiesel percentage

Order of impact by CO –

Pure diesel > 20% biodiesel mixed diesel > 50% biodiesel mixed Diesel > 80% biodiesel mixed diesel > 100% pure biodiesel

At 20 lbs. load – 20 % biodiesel emitted 4.3% CO 50 % biodiesel emitted 3.9% CO 80 % biodiesel emitted 3.6% CO 100 % biodiesel emitted 3.4% CO At 40 lbs. load – 20 % biodiesel emitted 4.6% CO 50 % biodiesel emitted 4.1 % CO 80 % biodiesel emitted 3.8 % CO 100 % biodiesel emitted 3.5 % CO At 60 lbs. load – 20 % biodiesel emitted 4.6 % CO 50 % biodiesel emitted 4.2 % CO 80 % biodiesel emitted 3.9 % CO 100 % biodiesel emitted 3.7 % CO IV. CONCLUSION

During this study we find that use of Biodiesel in diesel engine reduces the percentage of emitted pollutants, hence with increasing quantity of biodiesel Emission of HC and CO decreases. In this experiment soybean oil is taken as vegetable oil and mixed with methanol makes Biodiesel and this biodiesel used in diesel engine instead of diesel to get the results about emission of HC (hydrocarbons) & CO (carbon monoxide). So we find quantity of HC & CO reduced with increasing quantity of biodiesel. But this quantity of pollutants increases with load increasing.

61

V. REFERENCES

1. RS Dwyer-Joyce; T Reddyhoff; J Zhu. Journal of tribology, 2011,133 (3), 1-25. 2. S Asaduskas; SZ Erhan. JAOCS, 1999, 76(3), 313-316.

3. LR Silva; EC Bianchi; RE Catai; RY Fusse; TV Franca; PR Aguir. J. Of Braz. Soc.Of mech.sci. and engg.2005,27(2), 192-199.

4. KH Park;B Ewald; PY Known. Journal of tribology, 2011, 133(1), 1-8.

5. BL Burris; B Bosel; GR Bourne; WG Sawyer. Journal of macromolecular materials and engineering, 2007, 292,387-402.

6. S Safin; MA Hisyan; S Aman. Journal of advanced manufacturing and technology, 2009, 3(2), 49-55.

7. A Suhane; A Rehman; HK Khaira. International journal of engineering research and application, 2012, 2(5), 1330-1335.

8. SO Ogbeide.Journal of engineering science and technology review, 2010, 3(1), 32-35.

9. D Lu; QK Tong; CP Wong. IEEE Transaction on components and packing technology, 1999,

22(3), 365-371.

10. E Adril; S Abdullah. European journal of scientific research, 2009, 30(2), 282-293.

11. HA Abdulbari; MY Rosli; HN Abdulrehman; MK Nizam. International journal of physical sciences, 2011, 6(20), 4695-4699.

12. YY Wu; WCTsui; TC Lui. Wear, 2006, 262, 819-825. 13. JM Perez.Thermochemica acta, 2000, 357 (358), 47-56.

14. MA Odeniyi; J Alfa; KT Jaiyeoba. J. Pharm. Sci., 2008, 33, 71-75.

15. N Boubekri; V Shaikh.International journal of applied science and technology, 2012, 2(1), 111-115.

16. S Syahrullail; BM Zubil; CSN Azwadi; MJM Ridzuan. International journal of mechanical sciences, 2011, 53,549-555.

17. DA Jilner.Journal of material processing technology, 1997, 7(4), 15-21. 18. DL Gong; B Zhang; QJ Xue; HL Wang. wear, 1990, 137, 25-29.

19. RF Shangraw; DA Demarest. Pharmaceuticals technology, 1993, 17(1), 32-44. 20. H Vromas; CF Lerk. International journal of pharmacy, 1988, 46(3), 183-192. 21. SJ Randles;M Right.Journal of synthetic lubricant, 1992, 9, 145-161.

22. AD Borakar. Journal of chemical and pharmaceutical research, 2012, 4(7), 3420-3426. 23. ZG Yassen. Journal of chemical and pharmaceutical research, 2012, 4(7), 3361-3367.

24. BA Rosy; PJ Rosakutty. Journal of chemical and pharmaceutical research, 2012, 4(7), 3420-3426.

25. RB Singh. Journal of chemical and pharmaceutical research, 2012, 4(8), 3765-3768.

26. R.P. Chowdary, M.V.S. Murali Krishna and T. Kishen Kumar Reddy, “Studies On Exhaust Emissions From Ceramic Coated Diesel Engine with Waste Fried Vegetable Oil Based Biodiesel” International Journal of Mechanical Engineering & Technology (IJMET), Volume 5, Issue 7, 2014, pp. 27 - 35, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

27. D. Srikanth, M.V.S. Murali Krishna and P.Ushasri, “Studies on Exhaust Emissions of Ceramic Coated Di Diesel Engine Fuelled with Cotton Seed Biodiesel” International Journal of Mechanical Engineering & Technology (IJMET), Volume 5, Issue 9, 2014, pp. 315 - 322, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

28. Prof. A.V.Mehta, M. G. Joshi, G. D. Patel and Saiyad M J. I., “Jatropha Oil with Exhaust Heat Recovery System In 4 Stroke Single Cylinder Diesel Engine” International Journal of Mechanical Engineering & Technology (IJMET), Volume 4, Issue 2, 2014, pp. 512 - 520, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.