International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 3, Issue 8, August 2013)

754

Development of Decision Support System for Jute Grading

Sujai Das

1, V. B. Shambhu

2, L. K. Nayak

3National Institute of Research on Jute & Allied Fibre Technology, 12, Regent Park, Kolkata – 700040

Abstract--It is well known that jute plays an important role in our daily life. Jute ranks next to cotton as the most important natural fibre. Corchorus capsularis is popularly known as White jute or 'tita' pat and Corchorus olitorius

known as Tossa jute or 'mitha' pat. Basically jute is regarded as cash crop. The role of jute in eastern part of India is important from economic point of view. India earns 1450 crores foreign exchange out of jute and its products. Approximately 40 lakh farmer families are depend it on jute cultivation. Apart from that more or less 20 lakh people are involved directly or indirectly in this trade. Jute has an important position in the packaging world for many years due to its cheapness, hardwearing properties and biodegradability. The fibre, which spins into the fine yarn, is considered to be of very good quality. The process of classification of the fibre quality on the basis of the physical properties of unsorted jute fibre is called Jute Grading. It is a process of establishment of certain standards based on the intrinsic physical properties of the fibre with a view to sub-divide it into several grades or classes. Quality of jute determines its end uses. For diversification of jute products supply of superior and fine quality of fibre has to be ensured. Thus improvement of quality of jute fibre has assumed much importance in the recent times. The ICT technique aimed at enabling the user to make faster and logical decisions.

Keywords-- Jute grading, database, Decision support system, ICT

I. INTRODUCTION

Jute cultivation is confined to West Bengal, Eastern Bihar, Assam, Orissa, Tripura and Andhra Pradesh where mostly Mesta is grown. Out of these states, West Bengal, Bihar and Assam contribute about 80% of the total production. Again, these three states may be further classified quality-wise in five principal jute growing areas, i.e. South Bengal, Semi-Northern, Northern, Assam and Junglee (Purnea region). The places of origin, i.e. Mokam was the basic guiding factor in the old system of grading, whereas in the new grading system introduced by BIS in 1975, six characteristics viz. strength, defects, root content, color, fineness and bulk density have been considered for grading Tossa and White jute. The raw jute have been classified into eight grades (08), starting from TD1 / W1 (most superior) to TD8/W8 (most inferior). Mesta on the other hand has been classified into six grades (M1 to M6). Raw jute is classified according to quality of jute and its application. The fine quality white raw jute is graded as W1, W2, W3, to W8. The Tossa raw jute is graded from TD1, TD2, -- to TD8.

Mesta raw jute is grades as Mesta Top, Mesta Mid, Mesta Bottom etc. Jute mills and jute brokers also grades the raw jute according to jute growing regions. As Assam1, Assam2 to Assam8. Bimali1 to Bimali8, Jungli1 to Jungli8 etc. The lowest grade is termed as cuttings.

Jute has an important position in the packaging world for many years due to its cheapness, hardwearing properties and biodegradability. Jute cultivation is mainly confined to West Bengal, Eastern Bihar, Assam, Orissa, Tripura, Uttar Pradesh and to some extant in Meghalaya. Out of these, West Bengal, Bihar, and Assam contribute about 80% of the total production of India. But presently it is facing challenges from synthetic fibres. Such adversities may be averted through diversification of products by maintaining quality in the raw jute itself. To remove that defective procedure ISI now BSI introduced eight grade grading system based on six physical parameters i.e. strength, Fineness, colour, root content, defects and density. Different score marks are fixed for each character according to the importance of these characters. The score marks for different characters however, vary from one grade to another according to the gradations of character. This grading system was found to be more scientific and helpful to jute growers. To introduce this new grading system National Institute of Research on Jute & Allied Fibre Technology (NIRJAFT) formerly Jute Technological Research Laboratories (JTRL) took the lead role. Bureau of Indian Standard (BIS), Jute Mills Association, Jute Balers Association, different Jute Development Organizations and farmers jointly endorsed this system. The present BIS system of grading is an outcome of detailed studies on various physical properties of fibres. The BIS grading incorporates a scoring system that aims at eliminating personal bias as far as practicable. Using the grading aids instruments and by hand & eye method one can easily determine the grades of the jute fibre. Fourth revision of BIS grading system was introduced from December 2003. Considering the present scenario, in this revision only score marks for different characters have been reallocated. Presently it is an essential system to grade the jute fibre.

II. WHAT IS JUTE GRADING?

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 3, Issue 8, August 2013) The BIS grading (Table 1) of jute envisages a score

card system of grading that aims at eliminating personal bias as far as practicable. Six physical parameters viz., strength, fineness, colour, root content, defects and density of jute fibres are assessed for sorting out the fibre into eight different grades. Relative weightage is given to each physical parameter by standard scoring system and the grade of fibre is determined by total score of the six parameters. In India with object of enabling the cultivators to get proper price for their fibre, Bureau of Indian Standards (BIS) introduced a standard for grading of raw jute on the basis of its quality. Both white and tossa jute fibres are classified into eight grades, W1-W8, and TD1-TD8. Each grade is assessed by scoring six characters - strength, fineness, defects, root contents, colour and density.

III. GRADING PROCESS

There are two systems for grading of jute Hand & Eye Method

Instrumental Method

Hand & Eye Method

An expert grader can assess the physical characteristics viz., fineness, density and strength of the fibre by his experience testing by hand only while visual assessment will judge colour, root content and defects by a close look at the fibre. 'Hand & Eye Method' is generally used in the market for on the spot assessment of the quality and grading of fibres. This method is subjective and assessment may vary from grader to grader.

Instrumental Method

In this method all the six physical characters of fibre essential for determining grade are measured by fibre testing instruments. The use of instrument is essential for an accurate and objective evaluation of grades. In this method all the six physical parameters of fibre essential for determining grade are measured by fibre testing instruments. The hand and eye method is a subjective method of assessment and there may be personal error in judgement of quality of a particular lot of fibre. To minimise such variation, instrumental method of grading is essential. For this NIRJAFT, Kolkata has developed the fibre testing instruments for assessing the quality of fibre quantitatively. Bundle Strength Tester, Air-flow Fineness Tester, Colour & Lustre Meter, and Bulk Density Meter were developed for estimate of strength, fineness, colour and bulk density respectively. For Root content the hard barky bottom region was cut and weighed. The root content was expressed in percentage of the total weight of the feeds. For assessment of defects the defective portions such as runners, knots, Specks, centre root, mossy fibre etc. were cut from a bundle of fibre reeds and weighed.

The weight expressed as percentage of the total weight of the reed bundle give a measure of defects. Total 100 marks have been distributed for the six characters accordingly. Grades were determined as per score marks.

IV. HAND &EYE METHOD FOR JUTE GRADING

The six physical characters of fibre viz. a) Strength, b) Fineness, c) Colour. d) Root content. e) Defects and f) Density are assessed by hand & eye method for grading following the BIS standard score card system of grading.

a)Strength

For measuring strength of fibre a bundle of 10-15 fibres from the middle region of the fibre reed is gripped between the thumb and forefinger of both hands and broken longitudinally without jerk. It gives an idea of fibre strength. Good lustre of fibre is also an indicator of good fibre strength. Strength of jute fibre is divided into six groups i.e., Very good. Good, Fairly good, fair average. Average and weak mixed. The scoring scheme for each.

b)Fineness

The fineness is a measure of the diameter (width) or weight per unit length of fibre filament. Fineness is a genetic property and depends on plant age also at harvest. Fineness can be estimated simply by a close look at the fibre. Finer fibre shows better spinning quality. Fineness is divided into four groups i.e., Very fine, Fine, fibre well separated and fibre separated.

c)Root content

The hard barky region at the lower end of the reed is called root. The roots are cut at the mill before processing of fibre and in commerce they are known as 'Cuttings'. Measuring the extent of bark along the length of the reed by a scale and doubling the length percentage value of the root content make an estimate of root content in terms of weight percentage. Normally white jute contains more roots than tossa jute.

d)Colour

Colour means the property of a fibre, which distinguishes its appearance as redness, yellowness. greyness etc. It is largely dependent on retting conditions, water quality and washing.

e)Defects

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 3, Issue 8, August 2013)

756

Major Defects Minor Defects

Over-retted fibre Dazed Fibre Centre Root

Runner

Knots

Entangled sticks Mossy fibre

Loose leaf Loose sticks Specks Gummy fibre Croppy fibre and

weak croppy ends

f) Density

Weight per unit volume of fibre considering all air space in the fibre is the measure of density. The density is judged by the feel of heaviness or lightness of a number of reeds from the middle region of bulk, held within a grip between two hands and raised up and down. The sample that feels compact and weighty is graded as 'heavy body' and loose and less weighty one is 'medium body', Heavy bodied sample generally spin into good quality yarn.

V. JUTE GRADING INFORMATION SYSTEM

Database management systems (DBMSs) are specially designed applications that interact with the user, other applications, and the database itself to capture and analyze data.

A general-purpose database management system (DBMS) is a software system designed to allow the definition, creation, querying, update, and administration of databases. A database is an organized collection of data. The data is typically organized to model relevant aspects of reality (for example, the availability of rooms in hotels), in a way that supports processes requiring this information. Database software is the phrase used to describe any software that is designed for creating databases and managing the information stored in them. Sometimes referred to as database management systems (DBMS), database software tools are primarily used for storing, modifying, extracting, and searching for information within a database.

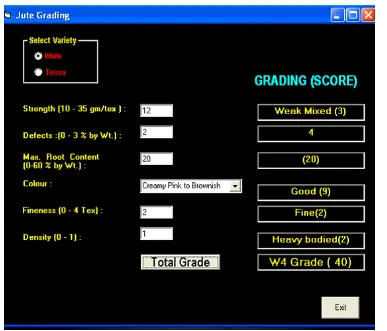

[image:3.595.58.270.133.238.2] [image:3.595.91.503.471.763.2]Jute grading information system has been developed (Fig. 1). Feature of this software is to select jute variety capsuluries or olitorius then select and enter six different parameter. As you enter the value of parameter simultaneously display its score value. On that basis display total grade of jute fiber. Grading calculation : Jute grading calculate its six parameter strength, defect, root content, colour, finesse and density. It grade w1 to w8 for white jute and td1 to td8 for tossa jute (Bandyopadhya, 1967). As enter the different parameter of grading display its grading value and finaly calculate its grading value. NIRJAFT has been developed online jute grading using PHP/Sql (Fig. 1 & Fig.2).

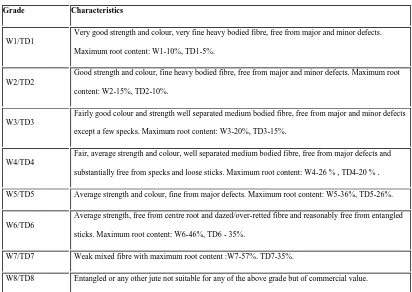

Table 1

Grades and grading of White Jute (W) and Tossa Jute (TD) in India

Grade Characteristics

W1/TD1

Very good strength and colour, very fine heavy bodied fibre, free from major and minor defects.

Maximum root content: W1-10%, TD1-5%.

W2/TD2

Good strength and colour, fine heavy bodied fibre, free from major and minor defects. Maximum root

content: W2-15%, TD2-10%.

W3/TD3

Fairly good colour and strength well separated medium bodied fibre, free from major and minor defects

except a few specks. Maximum root content: W3-20%, TD3-15%.

W4/TD4

Fair, average strength and colour, well separated medium bodied fibre, free from major defects and

substantially free from specks and loose sticks. Maximum root content: W4-26 % , TD4-20 % .

W5/TD5 Average strength and colour, fine from major defects. Maximum root content: W5-36%, TD5-26%.

W6/TD6

Average strength, free from centre root and dazed/over-retted fibre and reasonably free from entangled

sticks. Maximum root content: W6-46%, TD6 - 35%.

W7/TD7 Weak mixed fibre with maximum root content :W7-57%. TD7-35%.

International Journal of Emerging Technology and Advanced Engineering

[image:4.595.108.495.127.458.2]Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 3, Issue 8, August 2013)

Fig.1 : Screen shot of jute grding software

Fig. 2: Screen picture of online jute grading input

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 3, Issue 8, August 2013)

758 VI. CONCLUSION

The aim of the database is to enhance the capacities in improving the quality of their decision-making abilities using the latest decision science tools and by appropriate Decision Support Systems. A number of factors influence the ultimate quality of fibre, of these, soil, climate and amount and quality of retting water are termed, as non-controllable factors while variety, cultural practices and method of retting and extraction etc. are known as controllable factors. Soil, weather conditions, method of retting and the amount and quality of retting water are, however more important factors which influence the ultimate quality of fibre. Due to these factors quality of fibres vary from place to place. This lack of uniformity in quality has led to the classification and grading of fibre with a view to facilitate its marketing. In the previous grading system 'Place of origin' was the basic guideline for grading of jute fibre. A large number (about 70) of commercial grades were previously in vogue in the trade. The grades had also link with commercial classification in accordance with the place of origin of the fibre. such as. Selected Assam. Ordinary Assam. Assam Bottom. Murshidabad Middle. Nadia Top etc. It was very disadvantageous and inconvenient for the growers to follow such a system of grading. As a result. a cultivator was unable to find out quality of his produce. So the previous grading system was obviously very un scientific and arbitrary and acted against the interest of growers. Generally. jute growers know that hessian and sacking are the common end products of the fibre. But they should also know that various other special types of material such as carpet backing. wall covering. cushion-cloth. resin impregnated boards. etc. are also produced from jute. Better price is thus assured for better quality fibre. But in the absence of sufficient knowledge about the quality they produce. the cultivutor.is deprived. Further need for more scientific grading system development need Fuzzy based grading system.

REFERENCES

[1] Bandyopadhya, S.B. 1967. The grower and the grading of jute, Jute Bull., 29: 232-236.

[2] Basak, M.K. Ghosh, S.K., Sinha, A.K., Majumder, A. and Pandey, S.N.1989. Aspects of jute technology and its impact on rural development, Jute Dev. J, 9(2) : 1-4.

[3] Bhattacharyya, S.K. & Basu, M.K., 1986. Quality improvement of jute fibre, PTI Sci. Ser., 5, 15

[4] Das, B.K., Ray, P.K. and Chakravarty, A.C., 1977. Jute fibres at different stages of growth, Text. Trends, June, p.45.

[5] L.K., Nayak, A.K. Roy and S. Das 2011. Some characteristics of jute caddies with reference to briquetting and gasification, Journal of Indian Chemical society, Vol 88 : 599-601.

[6] L.K., Nayak, D. Nag, S. Das, Deb Prasad Ray and Lakshmanan Ammayappan, 2011. Utilization of sisal fibre(Agave Sisalana L.)-A review, L.)-Agriculture Review,Vol. 32(2):150-152.

[7] Shambhu, V. B. and Chaudhary, S. K. 2012. Utilization pattern of tractors in Nalanda district of Bihar – A case study, Agricultural Mechanization in Asia, Africa and Latin America (AMA), Japan, 2012; 43(1): 9-13.

[8] Shambhu, V. B., Bhattacharya, T. K. and Chaudhary, S. K. 2012. Compatibility of Jatropha oil bio-diesel and petro diesel as an engine fuel based on their characteristic fuel properties, Agricultural Mechanization in Asia, Africa and Latin America (AMA), Japan, 43(2): 43-49.

[9] Shambhu, V. B., Bhattacharya, T. K., Nayak, L. K. and Das S. 2013. Studies on Characterization of raw Jatropha oil and its biodiesels with relevance of diesel. International Journal of Emerging Technology and Advanced Engineering (IJETAE); (4):48-54.

[10] Nayak, L. K., Ray, D.P. and Shambhu, V. B. 2013. Appropriate Technologies for Conversion of Jute Biomass into Energy. International Journal of Emerging Technology and Advanced Engineering (IJETAE); 3(3): 570-574.

[11] Das.,P.K., Nag, D., Debnath, S. and Nayak, L.K. 2010. Machinery for extraction and traditional spinning of plant fibres, Indian Journal of Traditional Knowledge, Vol. 9(2): 386-393.

[12] Ray, D.P., Bhaduri, S.K., Nayak, L.K., Ammayappan, L., Manna, K., Das, K. 2012. Utilization and value addition of banana fibre – A Review, Agricultural Reviews, Vol. 33 (1): 46-53.

[13] Nayak, L.K., Ammayappan L. & Ray, D.P. 2012. Conversion of Jute caddies (mill waste) into value added products – A Review, Asian Journal of Textile, Vol. 2 (1): 1-5.

[14] Nayak, L. and Roy. A.K. 2011. Utilization of jute by-products: A Review, Agricultural Reviews, Vol. 32 (1): 63-69.

[15] Nayak, L.K., Samuel D.V.K and Pandey, H. 2004. Storage of Instant Dal in different packaging films under ambient conditions, Journal of Agricultural Engineering, Vol. 41(4) : 5-8.

[16] Das. S. and Nayak, L.K. 2013. Expert System for Agriculture Extension, Indian journal of Automation and Artificial Intelligence, Vol. 1(2): 62-64.

[17] Ray, D.P., Nayak, L.K., Ammayappan, L., Shambhu, V.B. and Nag, D. 2013. Energy conservation drives for efficient extraction and utilization of banana fibre, International Journal of Emerging Technology and Advanced Engineering, Vol. 3 (8) : 296-310. [18] Das, Sujai and Laxmikanta Nayak 2011. Development of