2016 Joint International Conference on Artificial Intelligence and Computer Engineering (AICE 2016) and International Conference on Network and Communication Security (NCS 2016)

ISBN: 978-1-60595-362-5

Surface Defect Inspection for Vehicle Heat Exchangers

Based on LBP and SVM

Wen-Jia ZANG

1,a, Wen-Bo XIANG

1,b,*, Yao-Bin MAO

1,c, Yue-Wei DAI

2,d1School of Automation, Nanjing University of Sci. & Tech.,

Nanjing, Jiangsu, China

2School of Electronics & Information, Jiangsu University of Sci. & Tech.,

Zhenjiang, Jiangsu, China

azang_wenjia@163.com, bmyb_nust@126.com,

cmaoyaobin@163.com, ddywjust@163.com

*Corresponding author

Keywords: Heat Exchanger, Surface Defect Inspection, Texture Description, LBP, SVM.

Abstract. To tackle the problems appeared in traditional surface defect inspection for vehicle heat exchangers which is mainly depended on manual execution, machine vision has been introduced due to its unparalleled characteristics of on-line, fast, high precision and non-contact. In this paper, an automatic surface defect detection algorithm employing machine vision technology has been presented. Treating the surface defect detection as a texture discrimination problem, the proposed method first uses an LBP (Local Binary Pattern) descriptor to represent the image of the heat exchanger, which has efficiently alleviated the effect of uneven illumination. Then the whole texture image has been partitioned into several non-overlapped 32×32 blocks and each block is subject to classification by an SVM (Support Vector Machine) to judge if it is a defect area. The experiments have been performed and the results have demonstrated the effectiveness and the efficiency of the proposed method.

Introduction

Heat exchanger is a key component in a vehicle, therefore, its quality is so important that it is necessary to inspect the surface of each heat exchanger during manufacture. However, till now, many manufacturers still use manual inspection which is of low efficiency and does not meet the demand of high speed and full automation in automobile industry. Surface defect inspection based on machine vision can improve the rate of production of high quality products, reduce production costs, and avoid many problems encountered in artificial detection.

each region, certain statistical features that reflect the two-dimensional distribution of gray values in image space can be extracted such as histograms, Gray Level Co-occurrence Matrix (GLCM), auto-correlations, or Local Binary Patterns (LBP). More advanced visual features like density, direction, consistency, frequency, and phase can be extracted further to reduce the dimension of the feature space. Then, each region is subject to a classifier to tell out the defect or non-defect. Typical classifiers include Bayesian classifier [3], neural networks [4] and distance measures [5].

[image:2.612.207.403.206.279.2]Defects on the surface of automobile heat exchangers are mainly caused by bumping in the procedure of production and transportation. As shown in Fig.1, the surface defects are small in size, brighter than their surroundings and mainly exhibit non-textural characteristics. However, the holistic surface image of the heat exchanger is of directional texture and suffers from uneven illumination.

Figure 1. The image of surface detects for heat exchanger.

In this paper, we use local features to perform surface defect inspection and have trained an SVM to distinguish defect and non-defect areas. To tackle the problem of uneven illumination, a LBP texture descriptor is employed which can effectively alleviate the negative influence on inspection.

The rest of the paper organized as follows: in section 2, a surface defect inspection algorithm based on LBP and SVM is introduced, then, the experimental results are reported in section 3, and finally, concluding remarks are drawn in section 4.

Surface Defect Inspection Based on LBP and SVM

The surface defect inspection system can be viewed as a binary pattern classification system which is divided into two working phases, namely training phase and detecting phase, as shown in Fig. 2. In training phase an SVM is trained so that it can be used in detecting phase to perform classification. While the detecting part consists of three operating steps, i.e., pre-processing, feature extraction and SVM classification. Here, in pre-processing step, we use LBP descriptor to convert an original image into an LBP one to eliminate the effect of uneven illumination. Then the holistic image is divided into several non-overlapped 32x32 sub-regions. Each region is described by an LBP histogram, which acts as texture features and is subject to SVM classification. We will detail each steps in the following subsections.

Figure 2. Diagram of the proposed surface defect inspection algorithm based on LBP and SVM.

LBP Based Image Pre-processing

[image:2.612.89.528.548.642.2]LBP (local binary pattern) [6-7] is a class of effective texture description operator, which usually measures and extracts the texture information in images. The original LBP was first proposed by Ojala et al [7], which is represented as follows:

1

0

, N 2p

c c p c

p

LBP x y s i i

(1)where

x yc, c

is the position of the center pixel under investigation, and its pixel value is denoted byc

i , p is ic’s adjacent pixel whose value is ip. N is the number of surrounding pixels around the center.

s x is a symbolic function defined as below:

1,0 0 . ,x

otherwise s x

(2)

The calculation process can be illustrated in Fig.3 which uses N=9 as an example. In this way, an

[image:3.612.153.433.322.392.2]original image can be transformed onto an LBP representation, by which the uneven illumination is suppressed.

Figure 3. The calculation process of LBP.

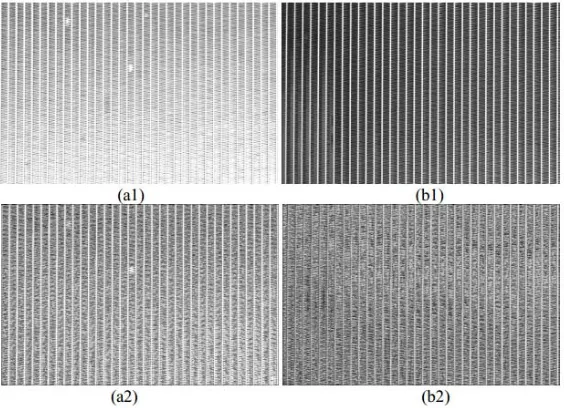

[image:3.612.166.448.470.674.2]Fig.4 has shown two typical results, where Fig.4(a1) and Fig.4(b1) are the original images collected under different illumination conditions, while Fig.4(a2) and Fig.4(b2) are their corresponding LBP images, on which the uneven illumination effect is significantly alleviated.

Histogram of LBP Image

In this paper, the texture feature used for defect detection is based on LBP. We calculate each pixel’s LBP descriptor using its 33 neighborhood and thus can get 256 kinds of patterns. In practical applications, too many patterns would make LBP histogram too large and too sparse, which is unfavorable for classification. Notice that in an image more than 90% LBP codes whose jumping times from 0 to 1 or 1 to 0 are less than 3, therefore, we can use a new coding scheme called Uniform LBP description [7] to reduce dimension. To obtain a Uniform LBP, the original LBPs with jumping times greater than or equal to 3 are merged into one class. By this way, the dimension of LBP histogram has decreased from 256 to 59.

To extract texture features using LBP, we first divide the surface image of the vehicle heat exchanger into several 32 32 non-overlapped regions and calculate the histogram of the LBP description in each small region. Then an LBP histogram can be established by accumulating the pixel number for each LBP value, which is denoted as below:

,

{ ( , ) }, 0,1,..., 1

i x y

h

I LBP x y i i L (3)where hi is the number of pixels whose LBP value are i,LBP x y( , ) is the LBP value at ( , )x y , L1 is the maximum LBP gray-scales.

1 ( ) 0 x true I x x false (4)

where xis of Boolean type. From Eq.(3) and Eq.(4), we can see that LBP histogram accumulates the

points with same structure, which provides sufficient information for defect detection. Defect Detection Using SVM

The Support Vector Machine (SVM) is developed based on statistical pattern recognition theory [8], which maps the input data onto a higher dimensional space through the kernel trick. Through learning sample data, the SVM generates a hyper-plane based on the principle of maximum margins between two classes. Since it is straightforward to make binary classification through SVMs, in this paper, a SVM classifier is used to discriminate the defect and non-defect image regions.

Assuming that one sample sets is

( , ), 1,..., , N i i

x y i l xR (5)

where, yi { 1, 1}is the class label. To design an SVM is just to minimize following functional

objective function:

1 1

min .

2 l T i i C

w w (6)

. . (( ) ) 1 , 1,..., . 0, 1,...,

T

i i i

i

s t y x b i l

i l w (7)

wherewand bare the weights, while C is a penalty factor used to balance the loss and objective

function that can be tuned by users. The larger the C, the higher the priority to training errors. i is

Then, the optimal discriminant function can be written as

1

( ) sgn( s ( , ) )

l

i i i i

f x y K x x b

(8)where lsis the number of support vectors, ( , )K x xi is a kernel function, and 0i C.

To perform defect detection, one should first train the SVM classifier offline. The training process is described as follows: 50 defect images and 100 non-defect images are first resized into 32×32, and then subject to training using libSVM. We choose linear kernel function ( , )K x xi x xi to train an

SVM, where C10. The system converged after 1000 rounds of iteration. Finally, the designed SVM classifier is obtained to distinguish the defect region from non-defect ones.

Experimental Results

We have constructed a practical vehicle heat exchanger inspection system using a Kodak IGV-B4820M-KF0 GigE camera along with a Schneider lens, by which a set of surface images were captured. 20 pieces of images which contain 43 true defects on the surface were cropped from above image set. Each image is normalized into 960x600 in size.

All the 20 images are subject to test, and the experimental results are shown in Table 1. The algorithm finds 46 defects in the images, among which 39 samples are true positives, while 7 samples are false positives. We use precision rate (P) and recall rate (R) to quantitatively evaluate the

performance, which are defined as follows:

A R

A C

(9)

A P

A B

(10)

where A is the number of detected true defects, C is the missing number, and B is the number of false

positive. In this case, 39 90.7% 43

R , and 39 84.8%

46

P . Fig.5 has shown the results for two

typical images where the red rectangles indicate the position of the surface defects.

Table 1. The detection results via the algorithm based on LBP and SVM.

true defects detected

defects false alarm Recall Precision

Figure 5. Two typical surface defect inspection results for vehicle heat exchangers.

The results have shown a relatively high recall and precision rate which demonstrates the accuracy and effectiveness of the proposed algorithm. However, there are still several false alarms and missing, due to the similarity between certain defects and textured regions.

Concluding Remarks

The paper has presented a defect detection approach for vehicle heat exchangers based on LBP and SVM. The proposed algorithm is simple and effective that is suitable for practical industrial application. A practical system has been constructed upon which the surface defect inspection experiments have been performed. A larger scale experiments will be done in the near future to further improve the accuracy and performance of the algorithm, which will help the automobile industry to enhance the production quality and decrease production costs.

Acknowledgement

This research was fully supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China under grant 2011ZX04002-051.

References

[1] Shiliang Nie, Hongying Zhang,Liping Zhang, Vertical scratches detection based on edge detection for old film, International Conference on Industrial and Information Systems.1 (2010) 257-260.

[2] I. Abdel-Qader, O. Abudayyeh, M. Kelly, Analysis of edge-Detection techniques for crack identification in bridges, Journal of Computing in Civil Engineering. 17 (2003) 255-263.

[3] D. Brzakovic, H. Beck, N. Sufi, An approach to defect detection in materials characterized by complex textures, Pattern Recognition. 23 (1990) 99-107.

[4] M.M. Van Hulle, T. Tollenaere, A modular artificial neural networks for texture processing, Neural Networks. 6 (1993) 7-32.

[5] A. Serdaroglu, A. Ertuzun, A. Ercil, Defect detection in textile fabric images using wavelet transforms and independent component analysis, Pattern Recognition & Image Analysis. 16 (2006) 61-64.

[6] M. Topi, O. Timo, P. Matti, Robust texture classification by subsets of local binary patterns, International Conference on Pattern Recognition. 3 (2000) 947-950.

[7] T. Ojala, M. Pietikainen, D. Harwood, A comparative study of texture measures with classification based on feature distributions, Pattern Recognition, 29 (1996) 51-59.

[9] B. Schölkopf, C.J.C. Burges, A.J. Smola, Advances in Kernel Methods-Support Vector Learning, MIT Press, Cambridge, Massachusetts, 1998.

[10] D.-M. Tsai, and C.-Y. Hsieh, Automated surface inspection for directional textures. Image and Vision Computing. 18 (1999) 49-62.

[11] Guang-Hua Hu. Automated defect detection in textured surfaces using optimal elliptical Gabor filters. Optik. 126 (2015) 1331-1340.