Abstract

--

In this paper initially we analyzed the market claims in ignition coils from after sale department of Motorbike assembling company. By using Pareto Diagram fault severity was noted down. Purpose of this research was to find out the one particular defect of crack propagation in lamination of araldite and polyester impregnated ignition coils. Both of these coils were compared on the basis of this Nonconformity (crack propagation in lamination) using SQC tools. This cracking of lamination gives result to a phenomenon known as corona effect. Corona effect is basically results in failure of high voltage electric equipments due to unnecessary sparking. S QC tools i.e Hypergeometric Distributions and Binomial Distribution were used in this paper to evaluate the probability of finding zero nonconformity (crack propagation in lamination) in the samples collected from both types of impregnated coils. On the basis of this analysis it was concluded that Polyester Impregnated Coils are better than Araldite impregnated ignition coils.Index Term

--

Market Claims, Cracking of lamination, Corona, S QCI. INT RODUCT ION

Polyesters and araldite are special type of polymers which has a very high significance in impregnation of high voltage equipments which are operating at very high voltages. These high voltages can cause corona effect which is caused due to two reasons. In one reason formation bubble formation inside the lamination causes this effect. Second, reason is due to formation of cracks or propagation of cracks. These cracks de path to air to enter in the cracked region and due to magnetic field on the secondary coil causing some entrapped portion of air to be oppositely charged [1]. This opposite charge causes failure of the ignition coils in the market.

Alferd Schwider [2] commented in his patent on potting method as inefficient due to crack formation in the rubbery plotting material. Plotting material can be polyester, araldite or certain kind of composite like or similar araldite and polyester. He stated to use oil for impregnation rather than using polyester. But in case of ignition coils oil cannot be used as an impregnating agent because of the danger of spilling out due to sudden atmospheric changes and dynamic motion of Motorbike.

R.O. Sanchez [3] in CART’S proceedings stated the problem of voltage breakdown and corona due to the stresses generated inside the core of the small transformers. Transformer cores

are laminated by impregnating material. He concluded to reduce the stresses of the core to reduce the cracking of the lamination.

L. Ringdahl 2003 [4] commented in his patent on using of paper as laminating material that has pores and is more prone to corona effect. He insisted on using epoxy resin or other resins for impregnation of capacitors and related equipments . According to Masayuki Oizumi [5] crack formation is due to following possible reasons i.e affinity between the substrate, manner of impregnation and impregnating material. Here in our case we have the data of two types of impregnating materials. These two materials are araldite and polyester. Techniques used by different people in such analysis can be Total Quality Management Philosophy, 6 Sigma Technique, different quality tools and Statistical Quality control techniques .M.A.Mehdi, Nabi Ahmad, Tanzeel Ur Rasheed [6] applied 6 sigma technique in hose pipe manufacturing facility. In this analysis they used quality control charts and histograms for recording and analyzing their data.

A.Plecko, N.Vujica Herzog, A. Polajnar [7] implementation of 6 sigma was done to improve the Manufacturing process of medium level manufacturing organization. They used quality tools like Cause & effect diagram to indicate all the problems that resulted in missing or wrong material component. These defects were traced by the customers when they were buying products. Problems highlighted by using Cause & effect diagram were that too many defects were detected at latest stages, no time was arranged to handle the nonconformities in a proper way, missing/ non confirm material at final inspection and delivery, mixing components between different units.

Quality defined D.Besterfield [8] as performance of the desired product divided by expectations of the target or specific customers. Non conformities which are known as reasons of rejection in customers perceptive are classified by same author as Critical, Major and Minor. Critical is the one which can result in unlike or unsafe event or main cause of damage in production or product. Major is the type of non conformities which can result in failure of the product or reduce its life or intended period of time. A minor nonconformity is the one that don’t effect material usability or its working rather they influence the appearance of a certain product like color, shape etc.

Comparison of Polyester and Araldite Impregnated

Ignition Coils Using SQC

D. C. Montgomery [9] discusses Successful implementation of SPC (Statistical Process Control) which is main part or constituent of SQC. He suggests following elements or key factors for the successful implementation of SPC. These factors include management leadership and their commitment towards the quality improvement, team approach, and education of the employees at all levels regarding introducing improvements and proper training and guidance before implementing any improvement, reduction of variability, quantitative measure of success, strong communication channels or method for communication of successful results throughout the organization.

A. Hussian [10] has also emphasized in his paper the role of research supervisor. According to his statement a PhD professor who is supervising many research projects should have skills of good management and leadership. A good research Professor should have the capability to train his student regarding the research problems . This study is closely related to study of an industry environment. More advanced company will always train their employees regarding the quality matters and other problems related to quality. On the other hand if Professor of university is able to supervise the research students and provide them with all the necessary guidance like a leading manager. Students (Product of the University) will be of high quality and will be capable of solving different problems at industrial level.

D. C. Montgomery [9] discusses a case study regarding a fault in copper plating and PCB fabrication facility. The defects were copper was brittle in nature, void entrapment in copper, long flow time which reduced the production from desired level. In this case studies SPC tools were discussed to successfully tackle the problems and their causes. Reason of fault was recognized using cause and effect diagram. 11 different reasons were recognized using cause & effect diagram analysis. Check sheets were made on daily basis mentioning all the faults and their description, actions taken and operator’s name. From this case study it is evident that while applying SPC or SQC the faults are to be recognized using Cause & Effect Diagrams, Pareto Diagrams, Histograms, and Control Charts.

The basic purpose to discuss different aspects was to get an over view of the problem and go through the necessary tools which different researchers have used in solving the problems in different industries. In first five paragraphs of the paper we discussed the problem of crack formation in the impregnation of high voltage equipments. In the next paragraphs we discussed different techniques used by different researchers for identifying the significant problems and then Qualit y tools for indicating them and solving them. In second last paragraph

summary how to apply different techniques in recognizing the problem and identifying its possible reasons. The process for recording and analyzing data is also discussed in the second last paragraph.

II.

MET HODOLOGYThis specific paper is basically based on the comparison of two types of impregnated ignition coils in which we have to analyze problem of crack propagation in both type of impregnated ignition coils. Secondly, we have to compare crack propagation in both types of impregnation. Thirdly, which type of impregnation is more exposed to corona effect. Nonconformity discussed in this paper is major and leads to the failure of the equipment.

First step will involve in collecting the data of the both type of impregnated ignition coils and analyze them by arranging fault data on pareto diagram by taking in consideration or case studies having two vendors of Ignition coils making it by two different methods i.e polyester impregnated and araldite impregnated. In which main focus will be on fault of crack propagation defect in araldite laminated and its comparison with polyester laminated ignition coils .

In second step two lots will be hired by two vendors making ignition coils from two different methods i.e araldite impregnated and polyester impregnated. A new method is used to trace the fault in which all the ignition coils after clearing form Quality control are to be assembled with product and send to market for sale. All Motor Bikes will be marked with special signs and all their customers name and addresses will be noted down. After three months all customers who bought those motorbikes will be recalled and all the coils will be collected and they will be provided with new Ignition coils. Binomial Distribution and Hypergeometric distributions will be used for analysis to calculate probability of getting zero nonconformity in a random sample of polyester and araldite impregnation coils. After the analysis on Hypergeometric we will be able to take three important decisions. Which lot is to be rejected after 3 months analysis and send back to the vendor? Which material is a better impregnating material and less resistant to corona? Which vendor should be given schedules in future for the company? Finally recommendation and results are discussed in the paper analyzing different graphs and tables. Acknowledgements are made to the assembling and vendor companies included in the research case studies.

Case Study 1

was analyzed using Pareto diagram. In proceeding step of analysis market claim was studied with focus on cracked lamination or crack propagation in lamination. After that a hypothetical assumption was done in which all the 250 coils lot was assumed to make it a Hypergeometric problem. Hypergeometric distribution was used to compute the probability distribution in this hypothetical situation.

Pareto Analysis (Araldite Impregnate d Case)

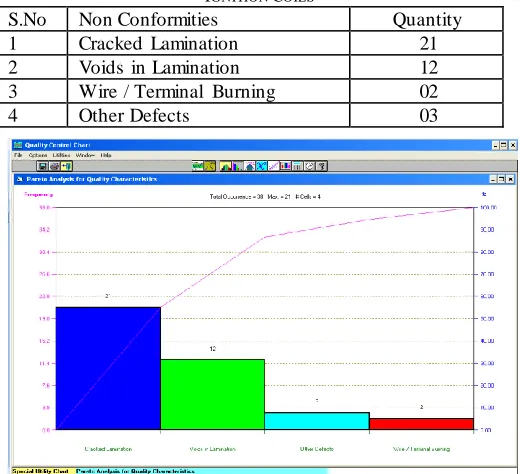

First important thing was how to record data in an organized manner. For this purpose tables were used to indicate data and graphs were used to represent the data in graphical form. Simple graph is used to indicate the effected coils of one month with different defects out of 250 in sold Motorbike from dealer and from 4 months they were used by customers .

TABLE I

INDICATING DIFFERENT NONCONFORMITIES OF ARALDITE IMP REGNATED IGNITION COILS

S.No Non Conformities Quantity

1 Cracked Lamination 21

2 Voids in Lamination 12

3 Wire / Terminal Burning 02

4 Other Defects 03

Graph. 1. Indicating number of Non-Conformities araldite impregnated ignition Coils with Pareto Diagram

Pareto Analysis (Polyester Impregnate d Case)

After that market claim of polyester impregnated ignition coils were analyzed using Pareto Analysis. 250 Motorbikes were sold and used by customers from 4 months market claim was noted down after 4 months and analyzed on Pareto.

Table 2: Indicating different nonconformities of Polyester Impregnated Ignition Coils

Graph. 2. Indicating number of Non-Conformities Polyester Impregnated ignition Coils with Pareto Diagram

Analysis # 01 (Araldite Impregnated Ignition Coils)

For a proper analysis on Software or for making it Hypergeometric problem we have to assume certain parameters. Ist Hypergeometric situation is applied when lot is in phase of inspection and decision is based on Hypergeometric analysis. In Hypergeometric situation we can only take one non-conformity or take different nonconformities as a single entity. To make it a Hypergeometric problem we assumed that there is a lot of 250 ignition coils in which a nonconformity of lamination cracking is present in 21 coils. In this case cracked lamination or crack propagation of lamination is non-conformity. So form above data we can put values in the Hypergeometric Probability Distribution. In that lot size of is N=250, non conformities D=21, and we take random sample n=5. X which is the probability of finding or getting those nonconformities in a sample which is zero. Meaning if out of this 250 ignition coil lot what is probability that inspector out of random sample of 5 ignition coils finds no sample with nonconformity of cracked lamination and in other words lot is accepted in this hypothetical situation. Analysis was done using WinQsb Software for Hypergeometric Probability Distribution.

TABLE II

INDICATING DIFFERENT NONCONFORMITIES OF POLYESTER IMP REGNATED IGNITION COILS

S.No Non Conformities Quantity

1 Cracked Lamination 02

2 Voids in Lamination 11

3 Wire / Terminal Burning 04

Analysis. 1. Showing us Probability of not getting cracked lamination or nonconformity free ignition coil from a random Sample of 5 ignition coils out

of 250.

Analysis #02 (Polyester Impregnate d Ignition Coils)

In case of polyester impregnated ignition coils we again made the same assumption that 250 ignition coils are in quality department for inspection market claims as a small lot of ignition coils received by quality department for inspection. In the case of polyester impregnated ignition coils we again considered cracked lamination as non-conformity. In this particular situation lot size N= 250. Non conformity D= 2 and we again take a random sample of n=5 ignition coils.

For analysis again WinQsb software used for Hypergeometric probability calculations. Again same value of X =0 for its comparison with previous case.

Analysis. 2. Showing us Probability of not getting cracked laminatio n or nonconformity free coil

Case Study 2

A company was selected (Motorbike Assembler Company) for Case study 2 by name of Pakstar Automobile which assembled Motorbike by brand name of Tezraftar. Second was a vendor company which made ignition coil by polyester impregnation and was registered in PAAPAM directory by name of Pecs Indus tries. Third Vendor Company named Mechanical Industries and was manufacturing ignition coils by impregnating them with araldite. Pakstar has give schedules to these two vendors for their monthly production and schedule was divided on half.

An experiment was designed to find out that which material is having more problem of lamination cracking. To conduct this experiment two lots of 250 (ignition coils) of both ignition coils were ordered to both the vendors. One extra lot from each vendor was bought. Production Target of theassembling company was 500 motorbikes. It was decided to take 250 araldite impregnated ignition coils and 250 polyester S .No Lot

Qty

Impregnation

type

Crack Propagation

Defect

(A)

Corona / Failure

Caused due to

Defect (A)

Void Formation

Defect

(B)

Corona / Failure

Caused due to

Defect (B)

Other Defects/ Failures

1

250

Araldite

70

27

35

8

12

2

250

Polyester

12

01

40

9

7

TABLE III

Addresses and contact details of all the customers were n oted down. Customers were also guided and directed that if ignition coil fail keep it with them and take new one in claim until company retrieves the effected coil back. After 3 months all customers were contacted and all the coils were recovered from customers by providing them with new ones. Coils were send to Quality Department for inspection.

As all coils of lot were received all the quality staff analyzed each and every coil and noted there defects. In the table below the data is noted down in systematic order.

Table III Results after lot is received back for inspection from the customers after 3 months time.

Binomial Distribution Analysis

Binomial Analysis was done for both the cases by considering the crack propagation or cracked lamination as the non conformity because in this paper our main focus is on this defect. We considered total lot size as 250 out of which sample consisted of only 25 coils. Out of 250 coils crack propagation was observed in 70 coils. Which means that P=0.28 and n= 25.

P=0.28, n=25 (n is 0.1 of lot size in Binomial Distribution function)

X = 0 (probability of finding zero defective item)

Analysis. 3. Indicating probability that zero faulty coils can be traced during inspection of 25 samples in case of araldite impregnated ignition coils

In case of polyester impregnated ignition coils lot size remains the same as 250 and its sample will become 25. Success probability is 12/250 as we considered major nonconformity in our analysis as crack propagation.

So P=0.048, n=25, X=0 (probability of finding zero defective item in sample)

Analysis. 4. Indicating probability that zero faulty coil can be traced during inspection of 25 samples in case of Polyester impregnated ignition coils

Hypergeometric Distribution Analysis

Analysis. 5. Indicating probability that no faulty coils can be traced during inspection of 25 samples in case of Araldite impregnated ignition coils

Analysis. 6. Indicating probability that no faulty coils can be traced during inspection of 25 samples in case of Polyester impregnated

ignition coils III. RESULT S &DISCUSSION S

Results include the main theme of proving the fact that Polyester Impregnated ignition coils are better in Quality than araldite impregnated ignition coils. The above analysis will be discussed and results will be shown graphically.

Table4 clearly indicates that Polyester impregnated Ignition coil is better than araldite impregnated coil because table shows us the results clearly that when quality department in first case Study selects random sample of 5 ignition coils so it

is 0.6448 probability that we don’t get defective coil out of 250 coils. While in the same case study if we select 5 samples of ignition coils probability of getting zero defective coil is 0.9606. 0.9606>0.6448 meaning that polyester impregnated coil is less defective in case of cracking lamination than araldite impregnation.

In Case Study 2 we again analyze the data using Binomial and Hypergeometric that probability of getting zero nonconformity coil in Polyester case is much greater than in araldite case. The results are 0.27400 > 0.00016 (Hypergeometric Distribution) and similarly in case of Binomial 0.29236 > 0.00027. Lot acceptance chance in case study 1 for polyester impregnated is 96.06% and on other hand 64.48% for Araldite impregnated. In case study 2 lot acceptance in case of araldite is 0.016% and 27.4% in case of polyester impregnated. Both these results lead to a similar conclusion that Polyester impregnated coil is better than Araldite impregnated ignition coils.

Table4 quite evidently shows us the result that cracked lamination problem was in 28% coils which were araldite impregnated while in case of polyester impregnated the cracking problem was 4.4% (Case Study2). This shows that the Araldite Impregnated coil is more exposed to cracking problem than polyester lamination.

S.N o

Lot Size Case Study# Impregnation type

Value of X=

Hypergeometric

Result

Binomial

Result

Crack Lamination

/Lot

1 250 1 Araldite 0 0.6448 N/A 8.40%

2 250 1 Polyester 0 0.9606 N/A 0.80%

3 250 2 Araldite 0 0.00016 0.00027 28.0%

4 250 2 Polyester 0 0.27400 0.29236 4.44%

TABLE IV

Next table will show that when coils were first received for inspection there was not any problem of cracks or crack propagation. Table 6 will show us the initial quality report when the lot was checked for first time.

TABLE VI

INDICATING INITIAL LOT INSP ECTION REP ORT

This table (table6) clearly indicates that initially this problem is not present in the product this problem is introduced in the product as it is used for some time by customer. After usage of atleast 3 to 4 months the problem is introduced in some ignition coils (evident in Case Study1 & Case Study2). This indicates to the logic of (T.Weege, 1993) that difference in coefficient of expansion causes crack propagation in impregnation. As coil works it heats up its winding heats up and pushes impregnated compound. Impregnated compound resists the winding and as a result it cracks.

ACKNOWLEDGEMENT S

Our full Acknowledgements to Mr Waqas Ahmad Butt (CEO Pakstar Automobiles) and Engr. Gulzar Ahmed Butt (Director Pakstar Automobiles) for providing us full support in resolving this issue. We also acknowledge to Prof. Javaid Iqbal (Technical Director Pecs Industries) and Engr. Abid Iqbal (CEO Pecs Industries) for their generous support.

CONCLUSION

Cracking of lamination or crack propagation in lamination provides path for air to enter into the lamination. Wet portion of air or dust particles becomes charged by the high voltage magnetic field of secondary coil. This leads to failure of the ignition coil. The main reason that araldite lamination crack is due to difference in coefficient of expansion. Secondly, capsule used in manufacturing of Araldite impregnated

ignition coils becomes a part of the final product which also increases stress concentration. In case of polyester laminated coil chances of crack propagation are less due to the fact that capsule used is not a part of final product. Capsule used in case of polyester lamination are reusable. Crack propagation in lamination causes less failure due to the fact that over molding of coil Fontalba [11] is done by some polymer which blocks air to enter inside the lamination area.

From all these evident facts and from the analysis of Binomial and Hypergeometric distributions we conclude that polyester impregnated ignition coils are better than araldite impregnated ignition coils.

FUT URE WORK

In future this problem can be reduced if research is conducted on araldite to pour it in reusable molds. So that difference in coefficient of expansion is reduced and crack propagation is eliminated. So in future work there is a need to find material that don’t make permanent bond with araldite. Secondly, it is required to investigate and determine optimum values of the hardener and araldite for the required properties of the ignition coil so that the brittleness comes to an acceptable level at which no cracks produced in the ignition coil.

REFERENCES

[1] Weege T , (1993) Basic Impregnation T echniques www.scribd.com/doc/59270257/Basic-T

echniques-Of-Impregnation

[2] Schwider. A, Burnham.J, Buritz.R.S (1976) Polyester Fiber Vacuum Impregnated epoxy resin Insulation system for high voltage transformers, US Patent No3979530

[3] Sanchez.O.R, (1991) A method for encapsulating High Voltage Power T ransformers CART S Proceedings: 42-47 [4] Ringdahl.L, Ljungbyholm S.E, (2003) Method for making impregnated electrical components,US Patent No 6629344 B2

[5] Masayuki Oizumi, Masaharu Abe, Yasuo Fushiki, (1983) Production of Bubble free electrical laminates, US Patent No 4388129

[6] Muhammad Ammar Mehdi, Nabi Ahmad, T anzeel Ur Rasheed (2007)Six Sigma Implementation in manufacturing organization, Technical Journal, University Of Engineering &T echnology T axila: 58-63

S.No Lot Size Impregnation Type Cracked

Lamination

Failure due to Cracked Lamination

% Failure of Lamination

1 250 Araldite 70 35 50.0%

2 250 Polyester 12 1 8.33%

S.No Lot

Size

Impregnation

Type

Sample

Size

Crack

Lamination

Defect

1

250

Araldite

50

Nil

2

250

Polyester

50

Nil

TABLE V

[7] Plecko, N.Vujica Herzog, A. Polajnar, (2009) An Application of six sigma in manufacturing Company, Advances in Production Engineering & Management 4(4): 243-254 ISSN: 1854-6250

[8] Besterfield.H.D (2004) Quality Control, 7th edition,Pearson Prentice Hall publishers,Newyork, NY

[9] Montgomery.C.D (2002) Introduction to Statistical Quality Control, 4th edition John Wiley & sons Inc, United Kingdom, UK

[10] A.Hussain (2011) Supervision & evaluation of research projects of graduate students- realities & Requirements, Journal of quality & technology management, Vol 7, Issue2, pp: 123-136