New product warranty:A literature review

D.N.P. Murthy

a,b,*, I. Djamaludin

a,1aDepartment of Mechanical Engineering, The University of Queensland, St. Lucia, Qld. 4072, Australia

bDepartment of Quality and Production Engineering, Norwegian University of Science and Technology, Trondheim, Norway

Received 12 September 2001; accepted 2 April 2002

Abstract

Warranty is an important element of marketing new products as better warranty signals higher product quality and provides greater assurance to customers. Servicing warranty involves additional costs to the manufacturer and this cost depends on product reliability and warranty terms. Product reliability is influenced by the decisions made during the design and manufacturing of the product. As such warranty is very important in the context of new products. Product warranty has received the attention of researchers from many different disciplines and the literature on warranties is vast. This paper carries out a review of the literature that has appeared in the last ten years. It highlights issues of interest to manufacturers in the context of managing new products from an overall business perspective. r 2002 Elsevier Science B.V. All rights reserved.

Keywords: New products; Product warranty; Manufacturing; Management

1. Introduction

Modern manufacturing is characterised by (i) rapidly changing technologies, (ii) global markets, (iii) fierce competition, (iv) often nearly identical products due to common components and tech-nology being used and, (v) better educated and more demanding customers. This has posed serious challenges for buyers, manufacturers and policy makers at national and regional levels.

In the purchase decision of a product, buyers typically compare characteristics of comparable models of competing brands. When competing brands are nearly identical, it is very difficult, in

many instances, to choose a particular product solely on the basis of the product related characteristics such as product price, special features, perceived product quality and reliability, financing offered by the manufacturer and so on. In such situations, post-sale factors – warranty, parts availability and cost, service, maintenance, and so forth – take on added importance in product choice (see Lele [1], Lele and Karmarkar [2], Ives and Vitale [3,4], and Ritchken et al. [5]). Of these, warranty is one that is known (or at least potentially known) to the buyer at the time of purchase.

In the case of new products, another feature is that each new generation is more complex than the earlier generation it replaces. Often customers are uncertain about new product performance. Here warranties play an important role in providing *Corresponding author.

E-mail address:murthy@mech.uq.edu.au (D.N.P. Murthy). 1This was formerly this author’s affiliation.

0925-5273/02/$ - see front matterr2002 Elsevier Science B.V. All rights reserved. PII:S 0 9 2 5 - 5 2 7 3 ( 0 2 ) 0 0 1 5 3 - 6

product assurance to customers and different types of warranties are offered depending on the product and the buyer.

The notion of post-sale support is becoming an important feature of any product sale. In this context, warranty (and extended warranty) is an element of post-sale support and manufacturing business needs to view it as part of the post-sale service strategy. A warranty of any type, since it involves an additional service associated with a product, will lead to potential costs beyond those associated with the design, manufacture and sale of the product. These costs, in fact, are unpredict-able future costs, which typically range from 2% to as much as 15% of net sales McGuire [6]. As a result, warranty has a significant impact on the total profits for a manufacturing business. Simi-larly, for businesses where new products purchased constitute a major component of their total operating budget ineffective management of war-ranties can have a significant impact on the total operating costs.

As a result, product warranty plays an increas-ingly important role in consumer and commercial transactions. The use of warranties is widespread and they serve many purposes. These include protection for manufacturer and buyer, signalling of product quality, an important element of marketing strategy, assuring buyers against items which do not perform as promised and play an important role in the dispute resolution between buyer and manufacturer. These in turn pose serious challenges to legislators in terms of formulating sensible warranty policy legislation that will protect the societal (buyers and manu-facturers) interests. In the USA, the Congress passed the Magnusson Moss Act and recently the European Union (EU) passed new legislation requiring all a two-year warranty for all products. The concept of warranty has been around for almost as long as there has been trade and there have been many representations of warranty throughout history. It has existed in some form or another from the early civilisations (Babylo-nian, Assyrian, and Egyptian Eras, Ancient Hindu and early Islamic periods), through the European Period (Roman Era, Germanic, Jewish, and early English periods, and the early Russian Era), the

Middle Ages, the Industrial Revolution and beyond. Until the sixteenth century, the general purpose of warranty was to protect the buyer from fraud and faulty workmanship. When trade policy reversed around the dawn of the industrial revolution to favour the manufacturer, it was not a pressing issue since products were still produced locally by people known personally to buyers. Products were still relatively simple and easily evaluated, and any dissatisfaction was addressed directly to the manufacturer, with word of mouth travelling fast in local and tight knit communities. As communities grew, so did the acceptance of

caveat emptor or ‘‘let the buyer beware’’. For further details of warranty evolution over this long period, see Loomba (PWH, Chapter 2)2

Late in the nineteenth century, standardised product warranties became more common, although many were extremely limited in coverage. As deceit became more widespread, consumers began to see warranties as indicators of poor quality, with manufacturers offering contracts with no intention of honouring them, and no legal incentive to do so. This was the basis of the exploitation theory of warranty. According to this theory, the warranty terms are developed for the manufacturer’s benefit, while the consumer has few rights and bears the risks. Buyers who believe this theory often feel that if a product is sold, it should last a certain amount of time, and the warranty is seen to serve the manufacturer by adding to the price of the product; i.e., by offering a service which should be provided anyway. Because a warranty is offered, it is reasoned, these buyers feel that the manufacturer does not have confidence in its own product.

In 1914, to counter this trend, the Federal Trade Commission (FTC) was established, which set forth codes to govern the sale of goods. By 1952, all but one state in the United States had introduced the Uniform Commercial Code (UCC) which specified the obligations of those parties involved in the sale of goods. This code also covers both explicit and implied warranties.

2Two books that will be cited often are Warranty Cost Analysis [26] and Product Warranty Handbook [186] and these will be referred to as WCA and PHW respectively in the paper.

Before 1975, consumers were still at the mercy of manufacturers for several reasons. Warranties did not provide notice of consumer rights, disclaimers were couched in legal jargon, admin-istration of warranty was confusing and ineffec-tive, remedies were impractical for defective items, and excessive and unjustified claims often resulted from consumer frustration and hostility (Burton, PWH, Chapter 28).

The Magnuson–Moss Warranty Act aimed to provide American consumers with information, improve the quality of warranties and to provide procedures for consumer remedies. The readability of warranties has been found to have increased slightly, however the act’s standard of ‘‘simply and readily understood’’ is still a fair distance off (Burton, PWH, Chapter 28). Another aim of the act was to ensure that warranty was a good indicator of reliability, leading to the signal theory of Warranty.

As products become more complex, and less easily evaluated by consumers, warranties are used to indicate the product’s performance and relia-bility. The product performance and the warranty terms together determine the costs incurred by the manufacturer, so it follows that a longer warranty period will result in more costs unless the product performance is of a correspondingly higher qual-ity. This theory [7] proposes that if a manufacturer offers a better warranty than a competitor, then the reliability of the product should also be better to reduce costs associated with warranty claims. Due to this signalling characteristic, warranty is an important product feature and can be used by marketing to promote sales.

More recently, warranty has been viewed as both an insurance policy and a repair contract. This has given rise to a third theory of warranty, the investment theory. Under this theory, the warranty is seen as an investment by the buyer to reduce the risk of early failure. Manufacturers are insured against having to rectify problems caused by inappropriate use while the buyer is covered for repair costs of premature failures. The aim is to extend the useful life of the product by specifying responsibilities of the manufacturer and the buyer. Blischke’s [8] was the first review paper on warranties and it dealt with mathematical models

for warranty cost analysis. The three-part review paper (Product Warranty Management – I–III; Blischke and Murthy [9], Murthy and Blischke [10,11]) proposed a taxonomy for new product warranties and discussed various issues. Since then the literature on warranties (for both new and used products) has grown considerably with two review papers, three books and many journals and conference papers. The review paper by Chukova et al. [12], is a translation of a paper in Russian and deals with warranty analysis and contains references to papers that have appeared in the East European journals. A more recent review paper by Thomas and Rao [13] deals with warranty economic models, discusses some warranty man-agement issues and suggests few topics for future research.

In this paper we review the literature that has appeared over the last 10 years. It builds on the 1992 review paper by the first author. The review looks at all different aspects of warranties for new products.3The main thrust is on issues that are of high relevance to manufacturer from a product life cycle perspective. Our scope and focus is broader than that in Thomas and Rao [13].

The outline of the paper is as follows. Section 2 discusses warranties in a general and highlights the concept and role of warranties. Section 3 deals with the framework used for reviewing the literature on warranties since 1990. It involves six key elements. These are discussed in the next six sections (Sections 4–9). Section 10 deals briefly with topics not covered in the earlier sections.

2. Warranties: An overview 2.1. Warranty concept

A warranty is a manufacturer’s assurance to a buyer that a product or service is or shall be as represented. It may be considered to be a contractual agreement between the buyer and 3The authors have been reasonably thorough in their search of the literature on warranty for the period 1990 onwards. The search was confined to journals and conference papers and books in English.

manufacturer entered into upon the sale of the product or service. A warranty may be implicit or it may be explicitly stated.

In broad terms, the purpose of a warranty is to establish liability among the two parties (manufacturer and buyer) in the event that an item fails. An item is said to fail when it is unable to perform satisfactorily its intended function when properly used. The contract spe-cifies both the performance that is to be expected and the redress available to the buyer if a failure occurs.

In this paper, we consider warranties for both new and used products. New products can be divided into the following three categories:

1. Consumer durables (e.g., household appli-ances, cars) bought by individual households as a single item.

2. Industrial and commercial products bought by businesses for the production of services (e.g., equipment used in a hospital to provide medical care, aircraft’s used by airline opera-tors) or products (e.g., components bought by a manufacturer). These are bought either individually (e.g., a single X-ray machine bought by a hospital) or as a batch of L

(L>1) items (e.g., batteries bought by a car manufacturer, fleet of trucks bought by a car rental agency). One needs to differentiate ‘‘standard’’ off-the-shelf products from ‘‘cus-tom-built’’ products built to buyer’s specifica-tions.

3. Government acquisitions (e.g., new fleet of tanks or jet fighters) involving new and evolving technologies. As such, they are characterised by a high degree of uncertainty in the product development process. (Note:A government is also a large buyer of ‘‘stan-dard’’ industrial and commercial products but these do not involve product development as part of the warranty.)

Used products can be either consumer durables or industrial and commercial products and these are in general bought individually although some times they can also be bought in lots.

Another related concept is that of an ‘‘extended warranty’’ or a ‘‘service contract’’. The difference

between a warranty and a service contract is that the latter is entered into voluntarily and is purchased separately – the buyer may even have a choice of terms, whereas a warranty is part of product purchase and integral to the sale.

2.2. Role of warranty

Warranties are an integral part of nearly all commercial and many government transactions that involve product purchases. The buyer (in-dividual, corporation, or government agency) point of view of a warranty is different from that of the manufacturer (or distributor, retailer, and so forth). Another is the societal point of view and this includes legislators, consumer affairs groups, the courts, and public policy decision-makers.

2.2.1. Buyer’s point of view

From the buyer’s point of view, the main role of a warranty in these transactions is protectional – it provides a means of redress if the item, when properly used, fails to perform as intended or as specified by the seller. Specifically, the warranty assures the buyer that a faulty item will either be repaired or replaced at no cost or at reduced cost. A second role is informational. Many buyers infer that a product with a relatively longer warranty period is more reliable and long lasting than one with a shorter warranty period.

2.2.2. Manufacturer’s point of view

One of the main roles of warranty from the manufacturer’s point of view is also protectional. Warranty terms may, and often do, specify the use and conditions of use for which the product is intended and provide for limited coverage or no coverage at all in the event of misuse of the product. The manufacturer may be provided further protection by specification of requirements for care and maintenance of the product. A second important purpose of warranties for the manufac-turer is promotional. Since buyers often infer a more reliable product when a long warranty is offered, this has been used as an effective advertising tool. This is often particularly impor-tant when marketing new and innovative products, which may be viewed with a degree of uncertainty

by many potential consumers. In addition, war-ranty has become an instrument, similar to product performance and price, used in competi-tion with other manufacturers in the marketplace.

2.2.3. Warranty in government contracting

In simple transactions involving consumer or commercial goods, a government agency may be dealt with in basically the same way as any other customer obtaining the standard product warranty for the purchased item. Often, however, the government, as a large entity wielding substantial power as well as a very large consumer, will be dealt with considerably differently, with warranty terms negotiated at the time of purchase rather than specified unilaterally by the seller. The role of warranty in these transactions is usually primarily protectional for both parties.

In some instances, particularly in the procure-ment of complex military equipprocure-ment, warranties of a certain type play a very different and important role, that of an incentive to the seller to increase the reliability of the items after they are put into service. This is accomplished by requiring that the contractor service the items in the field and make design changes as failures are observed and analysed. The incentive is an increased fee paid to the contractor if it can be demonstrated that the reliability of the items has, in fact, been increased. Warranties of this type are called Reliability Improvement Warranties (RIW).

2.3. Warranty study

Because of this diversity of purpose, product warranty has received the attention of researchers from many diverse disciplines. Warranties have been studied from many different perspectives and they deal with different issues as illustrated by the following list.

1. Historical:Origin and use of the notion. 2. Legal:Court action, dispute resolution,

pro-duct liability.

3. Legislative:Magnusson–Moss Act; Federal Trade Commission, warranty requirements in government acquisition (particularly military) in the USA and the latest EU legislation.

4. Economic:Market equilibrium, social welfare. 5. Behavioural:Buyer reaction, influence on purchase decision, perceived role of warranty, claims behaviour.

6. Consumerist:Product information, consumer protection.

7. Engineering:Design, manufacturing, quality control, testing.

8. Statistics:Data acquisition and analysis, data-based reliability analysis.

9. Operations Research:Cost modelling, optimi-sation.

10. Accounting:Tracking of costs, time of ac-crual.

11. Marketing:Assessment of consumer attitudes, assessment of the marketplace, use of war-ranty as a marketing tool, warwar-ranty and sales. 12. Management:Integration of many of the previous items, determination of warranty policy, warranty servicing decisions.

13. Societal:public policy issues.

The bibliography by Djamaludin et al. (PWH, Chapter 33) lists over 1500 papers dealing with the above issues and since then the list has increased significantly.

3. Framework for review

Warranties are offered with the sale of products, services, software and live stock. Bulk of the literature deals with product warranty and in this paper we confine our attention to such warranties. Our review of this literature deals with the following topics:

1. Warranty policies. 2. Warranty cost analysis. 3. Warranty and engineering. 4. Warranty and marketing. 5. Warranty and logistics. 6. Warranty management.

Engineering deals with issues prior to the sale (such as product concept, design and development, manufacturing), marketing deals with issues re-lated to the sale and logistic deals with post-sale

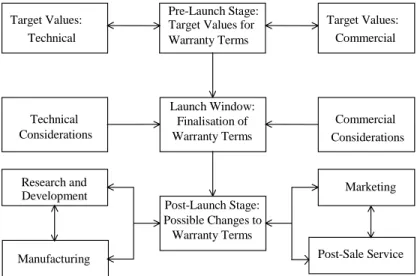

issues (such as servicing, spares etc). In the context of product life cycle, these three are sequentially linked. Management deals with decision making at strategic and operational levels. This requires taking into account the interactions between engineering, marketing and post-sale support elements of the manufacturing firms. As a result, the logical connections between the six topics of warranty reviewed in this paper are as shown in Fig. 1.

Our focus is on both qualitative and quantita-tive models so that the review would be of greater interest to a wider group of researchers involved with different issues in manufacturing. We omit giving any mathematical details and interested readers can find them in the references cited.

These six different topics are reviewed sepa-rately in the next six sections. Other topics are briefly reviewed in a later section.

As mentioned earlier, this review does not deal with software warranties or warranties associated with live stock and veterinary sales. Interested readers can find more details of software warranty in Gomulkiewicz [14], Zhang and Pham [15], Kimura et al. [16], Pham and Zhang [17] and Sahin and Zahedi [18], and of warranties relating to live stock and veterinary sales in Emswiller [19] and Hannah [20]. Vlatas [21] discusses warranty in the context of commercial lease.

The market for second-hand products has been increasing Genesove [22]. As a result,

warranties for second-hand product has become an important issue for certain products (such as cars). We do not deal with this topic. Interested readers should consult Chatto-padhyay [23], Murthy and ChattoChatto-padhyay [24], Chattopadhyay and Murthy [25, 183] for more on this topic.

4. Warranty policies

Many different types of warranty policies for new products have been proposed and studied. Blischke and Murthy [9] proposed a taxonomy to integrate these policies. The policies are grouped into three categories (Types A, B and C) and the details of the different policies can be found in above reference and also in WCA (Chapter 2).

The Type A policies (single item sale and not involving product development) can be di-vided into one- and two-dimensional policies. In the two-dimensional policies, the warranty is characterised by a region in the two-dimensional plane where one axis represents age and the other usage. Blischke and Murthy [9,26] define four different shapes for the warranty regions. Sing-purwalla and Wilson [27] suggest many other shapes.

Under a non-renewing warranty, the terms of the warranty do not change during the warranty period. As a result, if an item fails during the warranty period, it is rectified by the dealer and returned to the buyer without any changes to the original warranty terms. Under a renewing warranty, the warranty terms can change, for example, after failure, the item is returned with a new warranty either identical to, or different from, the original warranty terms. Each of these can be further subdivided into two sub-groups – simple policies and combination po-licies. The two simple policies are the free replacement warranty (FRW) and the pro-rata warranty (PRW). Combination warranties involve different FRW or PRW terms over different periods of the warranty. For more details, see WCA.

WARRANTY COST ANALYSIS

WARRANTY AND ENGINEERING WARRANTY AND MARKETING WARRANTY AND LOGISTICS WARRANTY POLICIES WARRANTY MANAGEMENT

5. Warranty cost analysis

For products sold with warranty the manufac-turer incurs additional cost resulting from the servicing of claims under warranty. Warranty claims occur due to item failures (real or perceived). An item is said to have failed when it is unable to perform its function in a satisfactory manner. Item failures are influenced by several factors. These include the engineering decisions during design and manufacture that determine the inherent reliability of the product, the usage intensity and environment and the maintenance effort expended by buyers.

Blischke and Murthy [26] define several costs of interest to manufacturers and buyers. They include the following:

1. Warranty cost per unit sale.

2. Warranty cost over the lifetime of an item (Life cycle cost – LCC-I):This is buyer oriented and includes elements such as purchase cost, maintenance and repair costs following ex-piration of the warranty coverage, operating costs and disposal costs.

3. Warranty costs over the product life cycle (Life cycle cost – LCC-II):This is dependent on the interval over which buyers purchase the product. This life cycle begins with the launch of the product onto the marketplace and ends when it is withdrawn.

4. Cost per unit time:This is useful for managing warranty servicing resources such as parts inventories, labour and costs over time with dynamic sales.

The costs clearly are different for buyer and manufacturer. These costs are random vari-ables, since claims under warranty and the cost to rectify each claim are uncertain. The warranty cost per unit sale is important in the context of pricing the product. The sale price must exceed the manufacturing cost plus the warranty cost or the manufacturer incurs a loss. On average, warranty cost per item decreases as reliability increases. When a buyer has the option of choosing between different warranty policies, then this cost is of relevance. The life cycle cost of a product is relevant to both buyer and

manufac-turer in the context of complex and expensive products.

5.1. One-dimensional warranties

The first step in the warranty cost analysis is the modelling of failures and the costs of rectification actions over the warranty period (or the life of the product in the case of life cycle costs).

5.1.1. Modelling failures

Failures over the warranty period can be modelled either at the component level or at the product (or item) level.

Component level modelling:Here the item is characterised in terms of its components and failure of each component modelled separately. The modelling of first failure needs to be treated different from that for subsequent failures. It depends on whether the component is repairable or not, the type of repair action used in the case of repairable item and, the type of item (used or new) used in the case of replacement of a failed item.

The time to first failure is modelled by a probability distribution function. The type of formulation needed for modelling subsequent failure depends on the nature of rectification (repair or replace) action. When every failure results in a replacement by a new item and the replacement times are negligible then the formula-tion is a renewal process. If all failures are minimally repaired and the repair times are negligible then the formulation is a point process formulation with specified intensity function. For further details, see Blischke and Murthy (WCA, Chapter 2) or Murthy (PWH, Chapter 3).

When the rectification can involve either mini-mal repair or replacement by new, then the formulation needed is more complex and is given by the G-Renewal process (see, Kijima and Sumita [28]).

System (product) level modelling:Here the item state is modelled as a binary variable (working or failed) and failures over time are modelled by a non-stationary Poisson process formulation with an intensity function LðtÞ: It is an increasing function of t implying more failures (in a probabilistic sense) as the item ages.

5.1.2. Modelling rectification costs

The cost of each rectification is comprised of several cost elements (handling, material, labour, facilities, etc). Often it is modelled by a single variable which is the aggregate of the different costs. In general the aggregate cost is a random variable and needs to be modelled by a probability distribution function.

5.1.3. Cost analysis

Most analysis is based the following simplifying assumptions:

* All buyers are alike in their usage. * All items are statistically similar.

* Whenever a failure occurs, it results in an immediate claim.

* All claims are valid.

* The time to rectify a failed item (either through repair or replacement) is sufficiently small in relation to the mean time between failures so that it can be approximated as being zero. The manufacturer has the logistic support (spares and facilities) needed to carry out the rectification actions without any delays.

The product life cycle, L; is modelled as a deterministic variable. One can easily relax this assumption and treat it as a random variable with a specified distribution.

All the model parameters (cost and of the various distributions involved) are known.

Bulk of the literature deals with expected warranty costs and few deal with higher moments or characterisation through a distribu-tion funcdistribu-tion. Blischke (PWH, Chapter 8) dis-cusses the statistical techniques for warranty cost analysis.

Free replacement warranties:Blischke and Murthy (WCA, Chapter 4) and Blischke (PWH, Chapter 10) deal with expected warranty costs for both repairable and non-repairable products. Kaminsky and Krivstov [29] deal with the case where failures are modelled by a G-Renewal process. Sahin and Polatoglu [30], Polatoglu and Sahin [31] and Sahin and Polatoglu [32] derive the probability distribution for warranty cost and some related variables.

Pro-rata warranties:Blischke and Murthy (WCA, Chapter 5) and Patankar and Mitra (PWH, Chapter 11) deal with the expected cost analysis. Menzefricke [33,34] deal with both the mean and variance of total warranty cost. Sahin and Polatoglu [30], Polatoglu and Sahin [31] and Sahin and Polatoglu [32] derive the probability distribution for warranty cost and some related variables.

Combination warranties:The expected warranty cost analysis for a variety of combination policies can be found in Blischke and Murthy (WCA, Chapter 6) and Blischke (PWH, Chapter 12). Bohoris and Young [35] deal with the warranty cost analysis of a hybrid warranty.

Simulation approach:The warranty cost analysis requires solving complicated renewal functions. An alternate approach is to obtain estimates of the costs through simulation. Hill et al. [36] and Murthy et al. [37] deal with this topic.

Extended warranties:The warranty that is an integral part of product sale is called the base warranty. It is offered by the manufacturer at no additional cost and is factored into the sale price. Extended warranty provides additional coverage over the base warranty and is obtained by the buyer by paying a premium. Extended warranties are optional warranties which are not tied to the sale process and can be either offered by the manufacturer or a third party (for example, several credit card companies offer extended warranties for products bought using their credit cards and some large merchants offer extended warranties).

The expected cost to the provider of extended warranties can be calculated using models similar to those for the cost analysis of base warranties. The cost of extended warranty is related to product reliability and usage intensity. The rea-sons for purchase of extended warranties have been analysed extensively in the marketing litera-ture. Padmanabhan (PWH, Chapter 18) discusses alternate theories and the design of extended warranty policies.

Padmanabhan and Rao [38] examine extended warranty with heterogeneous customers with different attitude to risk and captured through a utility function. Patankar and Mitra [39] consider the case where items are sold with pro-rata

warranty where the customer is given the option of renewing the initial warranty by paying a premium should the product not fail during the initial warranty period.

Mitra and Patankar [40] deal with model where the product is sold with a rebate policy and the buyer has the option to extend the warranty should the product not fail during the initial warranty period.

Yeh and Peggo [41] look at extended warranty policies with different options for consumers. Rinsaka and Sandoh [42] deal with the extension of the warranty period.

Service contracts:A service contract is similar to an extended warranty. Bulk of the literature on service contracts is mainly qualitative. Murthy and Asgharizadeh [43] and Murthy [44] deal with the modelling and analysis of service contracts using a game-theoretic approach.

5.1.4. Related issues and models

In this section we briefly review the literature dealing with some other models and issues related to warranty cost analysis.

Intermittent usage:When components are used intermittently, Murthy [45] proposed a model formulation where the failure rates are different depending on whether the item is in use or idle. Murthy [46] deals with a model when the usage is for short periods so that it can be modelled as a point process formulation and the item can be either in working or failed state when put into use mode. Some systems (such as defence missiles) are dormant for a long period before being put into use. For an analysis of warranties for dormant system, see Gomez [47].

Multi-component systems:Chukova and Dimi-trov (PWH, Chapter 22) discuss warranty analysis for complex systems.

Varying usage:Varying usage in the context of two-dimensional warranties has received consider-able attention. Kim et al. [48] deal with varying usage for one-dimensional warranties.

Warranty execution:Most of the models dis-cussed earlier assume that the buyer executes a warranty claim whenever a failure occurs. When this is not the case, the analysis needs to be modified. Patankar and Mitra [49] model the

non-execution through a probability that increases the warranty period remaining decreases. See also, Patankar and Mitra (PWH, Chapter 17).

Sensitivity studies:For the same mean and variance for failure distribution, the expected warranty costs vary significantly with form of the distribution. Blischke and Vij [50] study this issue and this highlight the need to have good data to model the failure distributions properly.

Phase type distributions:The cost analysis of free replacement warranties for non-repairable product involves solving the renewal function associated the failure distribution for the product. In general, it is not possible to derive analytical expressions for the renewal function. Phase type distributions provide the flexibility to approximate any arbi-trary distribution and offer some computational advantages. For more on this, see Kao and Smith [51,52] and Rao [53].

Maintenance:Bulk of the cost analysis deals with failures over the warranty period and corrective actions to rectify the failures. Preventive maintenance actions are actions taken to reduce the occurrence of failures. A variety of models have been proposed. These include Chun and Lee [54], Chun [55], Jack and Dagpunar [56], Dagpu-nar and Jack [57], Sahin and Polatoglu [58] and Monga and Zuo [59]. Djamaludin et al. [184] reviews this literature and develops a framework to study warranty and maintenance. Gi et al. [60] deals with maintenance following the expiration of warranty. Yeh and Lo [61] deals with a model where preventive maintenance reduces the age of the system. The age reduction at each preventive maintenance action is a decision variable to be optimally selected along with the number and time instants at which maintenance actions are carried out.

Data driven models:The models discussed so far assume a failure model (either at component or system level) and then obtain estimates for number of failures over the warranty period. These models can be called as ‘‘theoretical’’ models. As high-lighted by Blischke and Vij [50], the distributional assumptions have a significant impact on the expected values of failures and costs. An alternate approach is to build models based on failure data and these can be called ‘‘empirical’’ models.

The empirical models require the analysis of warranty data (failures and costs over the war-ranty period). This topic has received some attention in the literature, see for example, Robinson and McDonald [62], Kalbfleisch et al. [63], Kalbfleisch and Lawless [64] and PWH; Chapter 9; Lawless [65], Lawless and Kalbfleisch [66], Hu and Lawless [67,68], Escobar and Meeker [69]. Complicating issues include the data being truncated, delay in failure reporting etc.

The warranty claims over time occur according to a point process and depends on the reliability of the product and the sales over time. The failure data is incomplete (due not censoring) and often grouped or aggregated. The sales information might be either incomplete or aggregated. These raise several interesting and challenging problems for modelling and estimation. Suzuki and his associates have looked at some of these problems and for further details, see Suzuki [70], Karim et al. [71–73]; Suzuki et al. [74], Wang and Suzuki [75,76] and Suzuki et al. [77].

An alternative approach to modelling the aggregate claims over time is based on time series models. Linear dynamic models based on Kalman filtering approach have been studied by Wasser-man [78], Singpurwalla and Wilson [27] and Chen et al. (PWH, Chapter 31). Wasserman and Sudjianto [79] discuss the time series approach and compare it with two other approaches (static predictive models and non-parametric models). They also discuss the use of artificial intelligence and neural networks in the modelling process.

Finally, for some discussion on the data acquisition system, see Jauw and Vassilou [80] where they discuss the system at Amway.

5.2. Two-dimensional policies

The two-dimensional warranties have received a lot less attention relative to the one-dimensional case.

5.2.1. Modelling failures

Here item failures are points on a plane with one axis representing ageðtÞand the other representing usage ðxÞ: Two different approaches have been used to modelling item failures. The first is to

model item failure by a two-dimensional distribu-tion funcdistribu-tion. In this case failures are modelled by a two-dimensional point process formulation (see, Iskandar [81], Murthy et al. [82] and Hunter (PWH, Chapter 7)). The second approach involves modelling usage as a function of time so that failures are effectively modelled by a one-dimen-sional point process formulation. Iskandar [81] suggests a linear model for usage given by xðtÞ ¼ LtwhereLis the usage rate and is modelled as a random variable to model the varying usage across the consumer population. Moskowitz and Chun [83] also use a one-dimensional approach between usage and age. They model the failures by a Poisson process with intensity function being a linear function of age and usage.

Singpurwalla and Wilson [27] follow a different approach. Conditional on the total usage, the time to failure is modelled by a univariate distribution function. The total usage as a function of age is modelled by another univariate distribution. Combining these two, they derive a two-dimen-sional distribution for failure involving both age and usage. See also, Singpurwalla and Wilson [84]. Singpurwalla [85] deals with modelling the survival under multiple time scales in dynamic environ-ments with the usage rate changing dynamically.

Gertsbakh and Kordonsky [86] and Ahn et al. [87] reduce the usage and time to a single scale. The former uses a linear relationship and the latter has a linear relationship after log transformation.

5.2.2. Cost analysis

A two-dimensional warranty is characterised by a region in a two-dimensional plane. Different shapes for the region characterise different policies and many different shapes have been proposed (see Blischke and Murthy (WCA, Chapter 8) and Singpurwalla and Wilson [84]).

Free replacement warranties:The expected war-ranty costs for a variety of policies can be found in Moskowitz and Chun [83] and PWH; Chapter 13; Singpurwalla and Wilson [84], Blischke and Murthy (WCA, Chapter 8), Murthy et al. [88] and Chun and Tang [89]. Kim and Rao [90] deal with the cost analysis based on a bivariate exponential distribution.

Pro-rata warranties:The expected warranty cost analysis for a variety of policies can be found in Iskandar [81], Blischke and Murthy (WCA, Chapter 8), Wilson and Murthy (PWH, Chapter 14) and Chun and Tang [89]. Patankar and Mitra [49] and Eliashberg et al. [91] deal with warranty reserve problem.

Combination warranties:The expected warranty cost analysis for combination policies can be found in Iskandar et al. [92] and Wilson and Murthy (PWH, Chapter 14).

5.3. Fleet warranties

These are also referred to as cumulative warranties. Berke and Zaino [93] and Zaino and Berke [94] and Blischke and Murthy [26] deal with the warranty cost analysis for a variety of such policies. Yeh and Chen [95] deals with economic ordering quantities for items bought in lots with a cumulative free-replacement warranty.

6. Warranty and engineering

The warranty costs depend on the reliability of the product and this in turn is influenced by the decisions made during the design and manufactur-ing stages. By improvmanufactur-ing product reliability, the expected warranty cost can be reduced. The reliability of a product can be improved during design stage through development and the degra-dation in reliability during manufacturing can be controlled through better quality control. Both of these involve additional costs and are worthwhile only if the reductions in the expected warranty costs exceed the additional costs incurred. The warranty and engineering literature deals with these issues.

6.1. Warranty and design

6.1.1. Reliability improvement during design

There are basically two approaches to improv-ing product reliability. These are (i) usimprov-ing redun-dancy and (ii) reliability growth through development programme.

6.1.1.1. Redundancy. Here one or more compo-nents are replicated to improve the reliability of the product. As such, for a component that is replicated we have a module ofkðX2Þcomponents instead of a single component. The three different types of redundancy that have been used are (i) hot standby, (ii) cold standby and (iii) warm standby. In the hot standby allkreplicates are connected in parallel and in use so that the module failure time is the largest of thekcomponent failure times. In cold standby, only one component is in use at any given time. When it fails, it is replaced by a working component (if available) through a switching mechanism. If the switch is perfect and components do not degrade when not in-use, then the module failure time is the sum of the k

component failure times. In warm standby the failure distribution of the non-failed components (in partially energised state as opposed to fully energised state when put into operation) have a failure distribution which is different from that in fully energised state. As a result, a component in partially energised state can fail before it is put into use. For further details, see Hussain [96] and Blischke and Murthy [97].

For all three types of redundancy the module is more reliable than a single component. The reliability increases with k; the number of repli-cates in a module. However, this is achieved at a cost for the cost of a module depends on the number of replicates used and the type of redundancy (as both cold and warm standby redundancies involve a switching mechanism).

6.1.1.2. Reliability growth. This involves research and development (R&D) effort where the product is subjected to an iterative process of test, analyse and fix cycles. During this process, an item is tested for a certain period of time or until a failure occurs. Based on the analysis of the test run and failure mode, design and/or engineering modifica-tions are made to improve the reliability. The process is repeated resulting in reliability improve-ment (or growth) of the product. The reliability growth models can be broadly grouped into two groups – continuous and discrete models. Fries and Sen [98] give a comprehensive review of the discrete models and a discussion of continuous

time models can be found in Blischke and Murthy [97].

In continuous time models, the improvement in reliability is modelled through a parameter ðyÞ of the distribution which decreases with develop-ment. Most models are deterministic, where the reliability improvement is a deterministic function of the development. In real life, the reliability improvement at the end of the development period is uncertain. As a result, the reliability achieved at the end of the development period is uncertain.

Hussain and Murthy [99] propose a model where the outcome of the development process is uncertain. Their model is as follows. As the development programme continues, y decreases thereby improving the reliability of the product but the outcomey*ðtÞafter a development period of

tis uncertain. Lety0denote the initial value of y; that is, the value before the development pro-gramme is initiated, and let ym be the limiting minimum value after development for an infinite time.y*ðtÞis given byy*ðtÞ ¼y0 ðy0ymÞZt:Ztis a random variable which is a function of the development time t and given by Zt¼ ½1expðrtÞY; where YA½0;1 is a random variable distributed according to a beta distribu-tion with parameters a and b: This implies that conditional on Y;E½Zt increases and E½y*ðtÞ

decreases as tincreases.

6.1.2. Optimal reliability and warranty

Murthy [100] deals with optimal reliability choice for products sold with warranty. Murthy and Hussain [101] and Murthy (PWH, Chapter 21) examine optimal hot and cold standby redundancy to achieve an optimal tradeoff between manufac-turing cost and expected warranty cost. Hussain [96] looks at all three types of redundancy and optimal choice between redundancy and no redundancy.

Vintr [102] looks at two cases for optimal reliability for products sold with warranty. In the first, the warranty period is specified and optimal reliability is determined to minimise the manufac-turer’s cost. In the second, the warranty period is a decision variable to be selected optimally.

Majeske and Herrin [103] deal with design changes and their impact on warranty costs.

Monga and Zuo [59] look at system design taking into account maintenance and warranty. Goering and Read [104] look at reliability in the micro-economics context.

For a more detailed discussion on reliability and warranty, see Murthy and Blischke [105].

6.2. Warranty and manufacturing quality 6.2.1. Quality variations

Due to variability in manufacturing process, some of the items do not conform to design specifications and these are termed ‘‘non-conform-ing’’ in contrast to the remaining which are termed ‘‘conforming’’. The reliability characteristics of a non-conforming item are inferior to a conforming item. We call this as ‘‘manufacturing quality’’ and higher quality implies fewer non-conforming items being produced in a probabilistic sense. The probability that an item produced is conforming or non-conforming depends on the state of the manufacturing process. In the simplest character-isation, the state can be modelled as being either control or out-of-control. When the state is in-control, all the assignable causes are under control and, although non-conformance cannot be avoided entirely, the probability that an item produced is non-conforming is very small. When the state changes to out-of-control, this probabil-ity increases significantly. The manufacturing process starts in-control and after a random length of time it changes to out-of-control.

One needs to differentiate two types (called TN1 and TN2) of conforming items. A TN1 non-conforming item has distribution FðxÞ ¼1 for

x>0:This implies that the item is non-functional and is detected immediately after it is put in use. Such type of non-conformance is usually due to defects in assembly (e.g., dry solder joint). For a TN2 non-conforming item, the mean to first failure is greater than zero and hence cannot be detected easily as a TN1 non-conforming item. For further details, see Djamaludin [106].

Many different models for quality variation have been proposed. A review of these can be found in Murthy and Djamaludin [107].

6.2.2. Quality control and warranty

The occurrence of non-conforming items during manufacturing can be controlled using one or more of the following approaches – weeding, pre-vention and process improvement. The first two are ‘‘on-line’’ approaches and the third one is an ‘‘off-line’’ approach.

6.2.2.1. Weeding out non-conforming items through inspection. The aim of inspection is to weed out non-conforming items before they are released for sale. This requires testing the items produced. For TN1 non-conformance, testing takes very little time, since a non-conforming item is detected immediately after it is put into operation. In contrast, the detection of non-conforming items for TN2 non-conformance involves testing for a significant length of time.

In life testing the testing is often terminated before all the items fail. These lead to two types of censoring – Types I and II, respectively. In Type I censoring, all items in the sample are tested for a fixed period of time T;and in Type II censoring, the testing is terminated when a specified number of items on the test fail. Note that in Type I censoring, the number of failed items at the end of the testing period is a random number and in Type II censoring, the total duration of testing is a random variable. Another issue is the level of testing. It can be either 100% or less than 100%.

For TN1 non-conformance, Chen [108] exam-ines various inspection schemes such as single, double and sequential sampling plans, using a model proposed by Balcer and Sahin [109] to calculate the expected warranty cost, and studies the effect of inspection scheme on the total cost.

For TN2 non-conformance, Murthy et al. [110] study the optimal testing period (with Type I censoring) for items sold with warranty. They consider three different warranty policies and determine conditions to determine if testing is the optimal strategy or not. Kwon [111] deals with a method to find the optimal sampling plans that minimise the expected average cost per lot for items sold with pro-rata warranty (PRW).

6.2.2.2. Burn-in. Burn-in is used for weeding out Type II non-conforming items. Burn-in involves

testing items for a periodt:Those that fail during testing are scrapped. The rationale for this is that non-conforming items are more likely to fail than conforming items and hence are weeded out. Ast

increases, probability that an item released is conforming increases, and hence the outgoing quality is improved. However, this is achieved at the expense of the useful life of conforming items released being reduced by an amount t: Burn-in costs money and the optimal burn-in achieves a tradeoff between the burn-in cost and the resulting reduction in the expected warranty cost. Blischke and Murthy (WCA, Chapter 10), Murthy (PWH, Chapter 23), Mi [112,113] discuss the optimal burn-in period for different warranty policies.

6.2.2.3. Environmental stress screening (ESS). Cole-man [114] suggests the use ESS to improve product reliability. The screening process can be applied at various stages during production e.g. component, assembly or on a complete system. The type of stress used depends on the type of faults to be detected, and should be selected for maximum effectiveness on weak unit without causing damage to good units. The ESS facilities usually represent a significant capital investment and increased operating costs which its benefit can only be justified if the field servicing and repair costs are high.

Kar and Nachlas [115] study a net-profit model to optimally select the warranty period, burn-in and stress variables to minimise the expected net-profit. Pohl and Dietrich [116] deal with the optimal screening duration and develop a three level environmental stress screen-ing (ESS) model for a complex electronic system (an electronic printed circuit board). Pohl and Dietrich [117] deal with a model that is an extension of their earlier model. Here the detection of failures is imperfect so that a failed item may escape to the next level of assembly before being detected.

6.2.2.4. Preventing occurrence of non-conforming items. For batch production, the fraction of non-conforming items is a function of the lot size. This increases with lot size as the likelihood of items being produced with the state being out-of-control increases. As a result, the lot size can be

used to control the occurrence of non-conforming items.

Djamaludin et al. [118] study the quality of product warranted is controlled through lot sizing. Djamaludin et al. [119] deal with a model similar to that in Djamaludin et al. [118], except that it also involves testing a fraction of items in some lots. Djamaludin et al. [120] deal with model similar to that in Djamaludin et al. [119], except that at the end of production of a lot, the process state is not known. They consider three different warranty policies (i) FRW for repairable product, (ii) PRW for non-repairable product and (iii) FRW for non-repairable product.

Yeh and Lo [121] use lot size and burn-in to control quality for products sold with free replacement policy. They determine the optimal burn-in and lot size to achieve a balance between quality control and warranty costs. Yeh et al. [122] extend the results of Djamaludin et al. [118] to include inventory holding costs under the assump-tion that the demand rate and producassump-tion rates are constants. For a different model formulation, see Chen et al. [123].

6.2.2.5. Release without testing. Murthy et al. [82] deal with the case where the manufacturer is unable to carry out life testing before releasing the items for sale. As a result, both conforming and non-conforming items are released for sale. Since non-conforming items have a higher failure rate, they tend to fail early and this affects consumer satisfaction. One way of overcoming this is through a consumer incentive warranty policy. Under this policy, should the first failure occur within a periodT (TpW) the customer is offered the following two options. Option 1 is a total refund (money back guarantee) and Option 2 is a new replacement item with a new warranty identical to the original warranty and a lump sum Cls as compensation for the inconvenience caused due to the early failure. All failures beyond

T and within warranty are repaired minimally at no cost to the consumer.

6.2.3. Process improvement

The design of the manufacturing process has a significant impact on pin; the probability that an

item is conforming when the process is in-control. Ideally, one would like to have this probability one, so that no item produced is non-conforming. This involves proper design of experiment to determine the optimal settings for the various controllable factors.

6.3. Warranty, design and manufacturing

When component quality is uncertain then use of redundancy as a way of improving reliability also offers the option of testing to weed out non-conforming items. The testing can be done either at component or module level. As such, the models involve both design and manufacturing integrated with warranty.

Hussain and Murthy [124,99,125] deal with redundancy decisions when there are variations in the quality of components and examine testing at component and module level for weeding out non-conforming items.

Majeske et al. [126] deals with evaluating product and process design changes with warranty data, and Majeske and Herrin [103] deals with determining the warranty benefits with design changes, in the context of the audio system for an automobile.

For a review, see Murthy and Djamaludin [185].

7. Warranty and marketing

The consumer buying process (for both con-sumer durables and industrial and commercial products) is a multi-stage process. In a simplified characterisation it involves the following stages: * Recognition of the need for the product. * Obtaining information regarding the different

product brands.

* Evaluating the different brands to decide on the brand to purchase in terms of price, perfor-mance, assurance, post-sale support etc. * Final purchase.

To help the process, manufacturers need to promote their brand and provide the information to help consumers in the decision-making process.

As discussed earlier, warranties (and extended warranties) serve both promotional and protec-tional roles.

The literature on warranty and marketing can be grouped into several categories as indicated below:

(1) Warranty and consumer behaviour

(2) Product price and sales for warranted pro-ducts

(3) Warranty and market outcome (4) Warranty as a marketing strategy

7.1. Warranty and consumer behaviour

The behaviour of consumers depends on the type of product since the purchase process for consumer durables is totally different from that for industrial and commercial products. Discussion on how warranty is viewed during the purchase decision making process and post purchase re-sponses of dissatisfied buyers can be found in Kelley (PWH, Chapter 16). Of particular relevance are the empirical studies that show that warranties have a significant impact on consumer product choice and that they would pay a premium for products with better warranty terms.

Boulding and Kirmani [127] carry out an experimental investigation to answer the ques-tion – do consumers perceive warranties as signals of quality? The results indicate that consumer responses to warranties are consistent with the behavioural assumptions of signalling theory of warranty. Agrawal et al. [128] study warranty as a source of information regarding product reliability in the context of household appliances.

One anticipated outcome of the Magnusson– Moss Warranty Act was to make warranties ‘‘easy to read and understand’’. Moore and Shuptrine [129] look at this issue by examining 121 warran-ties and conclude that the readability level requirements are well beyond most Americans and that the thrust has been away from full warranty to limited warranty.

Blair and Innis [130] examine the effects of product knowledge on the evaluation of warranted brands. Lassar et al. [131] deal with consumer

reactions to product failures when the timing of warranty expiration varies.

7.2. Sale price and sales for warranted products

The price for a product sold with warranty needs to take into account the cost of servicing the warranty. The sales for a product sold with warranty needs to take into account the negative impact of warranty on the sale price and the positive impact as a promotional tool.

Blischke and Murthy (WCA, Chapter 10) discuss one of the earliest models (due to Glickman and Berger [132]) which uses a Cobb–Douglas function with sales being a function of price and warranty duration. Menezes and Currim [133] model the total sales by a more general formulation that is a function of several variables that include price, warranty period, quality, advertising and competitor’s actions. They derive expressions for the optimal price and warranty as functions of the price and warranty elasticities. They illustrate it with an application to historical data on auto-mobiles.

Mesak [134] models sales through a continuous time diffusion model. The demand rate is modelled as a function of price and warranty length that can vary with time. Mesak examines different struc-tures for the diffusion model and characterises the optimal price and warranty length.

Chun and Tang [135] deal with a model where the buyer has the choice of buying a product with or without warranty. They examine the optimal warranty price taking into account the producer’s and consumers’ risk aversion.

Marcellus and Pirojboot (PWH, Chapter 20) discuss the design of warranty policies that takes into account the risks and benefits of offering warranty and examine the choice of warranty price.

Loomba and Kumar (PWH, Chapter 19) deal with warranty and alternate product distribution channels. The decentralised distribution and de-centralised service support channel structure in-volves retailer and an independent service provider to service warranties. As a result, there are three players making decisions. The model involves

several decision variables with the sale price decided by the retailer and the warranty duration decided by the manufacturer. They derive the optimal pricing and warranty period as a function of several marketing parameters.

DeCroix [136] deals with the optimal warranties, reliabilities and prices for durable goods in an oligopoly. He uses a game-theoretic approach to obtain the optimal solutions for each firm. Under general assumptions, it is shown that each firm can set its warranty and reliability independently of price and competitor’s actions and a study of the impact of different market factors on optimal warranty and reliability is carried out.

7.3. Warranty and market outcome

The market outcome is determined by the interaction between individual consumers and manufacturers. Microeconomics deals with this topic and examines the effect of the decisions made by individual consumers and manufacturers and other market related factors on the market out-come. The literature on warranties and market outcome is extensive and is reviewed under Warranty and economics in Section 9.

7.4. Warranty as a marketing strategy

As a marketing tool, warranty plays many roles. One of the most important of these is that it provides the buyer with a degree of assurance against uncertainty. Warranty decisions as a marketing tool depend on whether the manufac-turer is a leader or a follower with the product being introduced and the warranty being offered, i.e., whether an offensive or a defensive warranty strategy, as defined by Menezes and Quelch [137], is being pursued.

Warranty is viewed as an offensive tool when it is used as a signal of reliability. Better warranty terms imply higher product quality and the manufacturer will stand behind the product. A longer warranty requires higher reliability for cost control and as such higher reliability gives a competitive advantage (as long as the customer is convinced that the product is, in fact, more reliable). Producers of lower quality products

cannot meet the competition or can do so only at substantially higher cost. Warranty in this situation is an offensive marketing tool in that the manufacturer is able to take a pro-active stance in setting warranty terms. If, instead, the manu-facturer is reacting to the competition, warranty will be used as a defensive tool. The objective here is (i) to meet competition to avoid losing sales; (ii) correct possible consumer misperceptions concern-ing the quality of the item; and (iii) limit liability. The FRW is sometimes thought of as an offensive strategy, while the PRW is defensive Menezes and Quelch [137]. In this context, a combination FRW/PRW would be a reasonable compromise between these two strategies. Menezes and Quelch focus mainly on warranty as a marketing strategy. There are many other issues involved in the strategic management of warranty and these are discussed in the next section.

Mitra and Patankar [40] examine market share as a function of warranty and the option of extending the warranty at the end of the base warranty should the item not fail in the base warranty period. They study the effect of warranty decisions on the market share.

8. Warranty and logistics

For products sold with warranty, the manufac-turer is obligated to service all claims made under warranty. The actions taken by the manufacturer to accomplish this depend on the type and the terms of the warranty. This implies that the manufacturer incurs additional costs in the servi-cing of warranty. This cost can be minimised through optimal servicing strategies and effective warranty logistic management. Warranty servicing deals with study of such actions and related planning issues. In this section, we briefly discuss some of these issues.

8.1. Warranty servicing [single item] 8.1.1. Replace versus repair

When a repairable item is returned to the manufacturer for repair under free replacement warranty, the manufacturer has the option of

either repairing it or replacing it by a new one. The optimal strategy is one that minimises the expected cost of servicing the warranty over the warranty period. Blischke and Murthy (WCA, Chapter 9) and Murthy (PWH, Chapter 24) discuss the two sub-optimal strategies for one-dimensional war-ranties and Iskandar and Murthy [138] look at the two-dimensional case. Jack and van der Duyn Schouten [139] deal with the optimal repair– replace strategies. Here the decision to repair or replace is based on the age of the item at failure. Jack and Murthy [140] examine at a sub-optimal policy which is very close to the optimal strategy and involves at most one replacement over the warranty period. Iskandar et al. [141] deal with a similar strategy in the context of two-dimensional warranties.

8.1.2. Cost repair limit strategy

In general, the cost to repair a failed item is a random variable which can be characterised by a distribution function HðzÞ: Analogous to the notion of a failure rate, one can define a repair cost rate given by fhðzÞ=½1HðzÞg; wherehðzÞis the derivative of HðzÞ:Depending on the form of

HðzÞ;the repair cost rate can increase, decrease or remain constant with z: A decreasing repair cost rate is usually an appropriate characterisation for the repair cost distribution Mahon and Bailey [142]. Optimal repair limit strategy is discussed in Blischke and Murthy (WCA, Chapter 9), Chung [143], Murthy (PWH, Chapter 24) and Zuo et al. [144].

8.2. Warranty servicing (dynamic sales)

Under a non-renewing PRW policy the manu-facturer is required to refund a fraction of the sale price on failure of an item in the warranty period. In order to carry this out, the manufacturer must set aside a fraction of the sale price. This is called warranty reserving. For non-repairable items sold with an FRW policy the manufacturer is required to supply a replacement item for failures under warranty. In this case, the number of spares needed is of interest and this is of importance in the context of production and inventory control. For repairable products sold with an FRW policy

planning of repair facilities requires evaluation of the demand for repairs over the warranty period. This depends on the type of repair action and on anticipated sales over the product life cycle.

8.2.1. Product sales over the life cycle

Let L denote the product life cycle and sðtÞ;

0ptpL;denote the sales rate (i.e., sales per unit time) over the life cycle. This includes both first and repeat purchases for the total consuming population. It is assumed that the life cycle L

exceedsW;the warranty period, and that items are put into use immediately after they are purchased. Since the manufacturer must provide a refund or replacements for items that fail before reaching age W;and since the last sale occurs at or before time L; the manufacturer has an obligation to service warranty claims over the interval

½0;LþW:

8.2.2. Warranty reserves

When items are sold with pro-rata warranties, the manufacturer has to refund a fraction of the sale price should an item fail within the warranty period. This implies that the manufacturer needs to set aside a fraction of the sale price to cover for subsequent refunds. Murthy (PWH, Chapter 24) deals with this problem taking into account the option of investing the reserve to generate addi-tional income.

8.2.3. Demand for spares and repairs

Most products are multi-component systems where the product failure is due to the failure of one or more components. If the component is non-repairable, then failed items need to be replaced by new ones. Murthy (PWH, Chapter 24) deals with this problem to compute the expected number of spares needed to service warranty over the product life cycle.

When the failed item is repairable, then the demand for repairs is needed for effective planning of repair facilities. Murthy (PWH, Chapter 24) deals with this problem and derives expressions for the expected number of repairs under warranty over the product life cycle.

8.2.4. Service contracts

The servicing of service contract has received very little attention. Asgharizadeh and Murthy [145] deal with the problem where the service agent has to decide on the optimal number of customers that a service agent should have and Murthy and Asgharizadeh [146] extend this model and look at the optimal number of repair facilities to service the customers.

8.3. Logistics related issues

The logistics of post-sale service has received some attention in the literature (see for example, Agnihothri and Karmarkar [147] and Cohen et al. [148]) and some of it is relevant in the context of servicing. However, the literature dealing specifi-cally with warranty servicing is limited. In this section we discuss various logistic related issues in the context of warranty servicing.

8.3.1. Inventory management

The expected demand for spares varies over the product life cycle. Carrying excess inventory results in higher servicing cost. With a small inventory, servicing under warranty can be de-layed and this affects customer satisfaction. Thus the inventory level must be managed in an effective manner. This requires building models and a critical variable in doing so is product reliability. Many models have been developed for inventory management, but very few of these deal with inventory management in the context of product warranty.

8.3.2. Use of loaners

A critical issue in warranty servicing is the time to service a warranty claim. Quality warranty service requires that this should not exceed some specified value. In some warranty contracts there is a penalty should this happen. One way for the manufacturer (or agent) to reduce the probability of this happening is to have a stock of loaners which are issued to the owners of failed items when they are undergoing repair. This implies additional servicing costs and the manufacturer must opti-mally decide on the number of loaners to be held in stock. Again, because of the complexity of the

model needed to study this problem, the optimal number can only be determined by simulation studies. For models dealing with this, see Karma-kar and Kubat [149].

8.3.3. Product recall

Occasionally, a manufacturer finds it necessary to recall either a fraction or all of the items sold, for some rectification action as a way of reducing the overall warranty servicing costs. The recall of only a fraction of the total production arises when items are produced in batches and some of the batches are defective due to inferior component(s) having been used and this is not detected under quality control. A total recall situation usually arises because of poor design specifications that can lead to malfunction under certain conditions and is discovered only after the items have been produced and sold. In such cases, the manufac-turer can be held responsible for damages caused under the terms of warranty for fitness and the recall is to replace one or more old components by newly designed ones.

8.3.4. Principal–agent problem

Most products are sold by agents (for example, dealers in the case of automobiles) rather than directly by the manufacturer. Often warranty servicing is carried out by these agents. The manufacturer is unable to monitor directly the quality of service provided which has an impact on product sales. This leads to the ‘‘principal–agent’’ problem. The behaviour of the agent is influenced by the contract between the manufacturer and agent.

Where service is to be provided by a dealer or a third party, mechanisms must be put in place to guard against the following undesirable actions on the part of agents or dealers:

* Providing poor quality of service.

* Over charging (either the manufacturer or, in case of less than full warranty coverage, the customer).

9. Warranty management

Many manufacturers have failed to recognise the importance of warranties, to say nothing of warranty strategy, and have, in fact, reduced factory warranties and attempted to maximise profits by selling extended warranties instead Murthy and Blischke [150]. In a discussion of this phenomenon, Cope and Pellitier [151] state that ‘‘American business, in other words, has divorced the warranty from the product, making it just another saleable item. Sadly, this only reinforces the impression that US companies have no confidence in their products.’’ In the long run, this strategy will not work. The authors provide some guidelines for formulating ‘‘warranties that work’’.

The management of warranty has received very little attention, at least as far as consumer products are concerned. Brennan [152] deals almost exclu-sively with the administration of warranties in the context of government acquisition. Menezes and Quelch [137] discuss the use of warranty as a

strategic offensive weapon to increase sales and profits in the context of consumer products.

9.1. Strategic warranty management

Murthy and Blischke [150] deal with the broader and strategic management aspects of warranty. Strategic warranty management deals with decision making with regard to all aspects of warranty from an overall business viewpoint and over the product life cycle, which encompasses the period from initial conception to manufacture and marketing to product obsolescence. It involves formulating a warranty strategy that is coherent and well integrated with other strategies of the organisation. Warranty strategy formulation must take into account the impact of warranty on the activities of the various sections of the organisa-tion and vice-versa.

An appropriate warranty strategy depends on the type of product, the type of customer, and the overall business strategy. It also depends on a

BUSINESS STRATEGY

NEW PRODUCT STRATEGY

R & D STRATEGY TESTING STRATEGY DEVELOPMENT STRATEGY MANUFACTURING STRATEGY PROCESS STRATEGY QUALITY CONTROL STRATEGY MARKETING STRATEGY ADVERTISING STRATEGY PRICING STRATEGY POST-SALE SERVICE STRATEGY WARRANTY STRATEGY EXTENDED WARRANTY STRATEGY TECHNOLOGY ISSUES COMMERCIAL ISSUES