Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

4-1-2002

An Investigation into the sources of vehicle tire

noise

John Paoff

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion in Theses by an authorized administrator of RIT Scholar Works. For more information, please contactritscholarworks@rit.edu.

Recommended Citation

An Investigation into the Sources of Vehicle

Tire Noise

By

John M. Paoff

A Thesis Submitted in

Partial Fulfillment of the

Requirements for the

Master of Science

In

Mechanical Engineering

Approved

by:

Dr. Josef S. Torok

Department of Mechanical Engineering

Dr. Ag Crassidis

Department of Mechanical Engineering

Dr. Alan Nye

Department of Mechanical Engineering

Dr. Ed Hensel

Department Head, Mechanical Engineering

(Thesis Advisor)

Department of Mechanical Engineering

Rochester Institute of Technology

Permission Granted

Investigation of Tire Noise

I, John Paoff, hereby grant permission to the Wallace Library of the Rochester Institute of

Technology to reproduce my thesis whole or in part. Any reproduction will not be for

commercial use or profit.

Date:

5

p/o

d-

Signature of Author:

_

Acknowledgments

Writing

this thesishas been avery challenging lifeexperienceforme,andthoughI almost gaveup and walkedaway from

it,

Ifelt Icould notlet downthose whohelpedme outalongtheway.

First,

Iwouldliketothankmyparentsfor supportingmethroughoutmy academic career. Inthemechanicalengineering department Iwantto

thankmythesis advisor,Dr.

Torok,

for stickingwithme onthis thesis andfor makinglearning

moreinteresting

thanIeverimagined itcouldbe. Iwould alsoliketo thankDr.Kempsifor

letting

meinfesttheGraduate Lab foraquarterorso.Iwouldliketo thankallthe teachers who putupwithcountlessvisitsto theirofficeand me askingamillion

questions (youknowwho youare!).I wouldalsoliketo thank thosewhoI hadthe

privilegetobecolleagues andfriends with eventhoughI probablyannoyed a-lot of you

(Big

Mike,

Bret,

andothers).Iwouldliketo give aspecialthanksto thosewho cametoRIT from Alfred State withme,itwasa

long

strangetrip, andthoughwehad ourdisagreements,

Iwill neverforgetthefuntimes.Thanks,

Abstract

Noiseproduced

by

arollingtireon pavementhasplagued automakersforyearsduetoits complexity.Tirenoiseis dependentonmanythingssuch astirematerial, tire

construction,road surfacetexture,etc. Inthis

investigation,

an acousticalapproachtomodelingtirenoiseispresented.Basedonthemechanicsof arotating tire, acoustical

modelscanbe developed.

This,

alongwith some acoustical analysis, leadstomathematicalmodels thatonecanutilizein ordertopredictthenoisethat the tirewill

produce.These models willprovide a goodbasisandstartingpointforreduction oftire

Table

of

contents

Chapter

PageChapter I Introduction

5

Chapter II General DiscussionofSound 7

Chapter III Sound Measure 1 1

Chapter IV Tire Construction 14

Chapter V Tiresand

Elasticity

17Chapter VI InfluenceofMaterial Properties onTire Noise 22

Chapter VII TireConstructionandNoise 35

Chapter VIII Section 1: Road Texture andTire/Road Noise 42

Chapter VIII Section 2: Air

Pumping

as aNoise Source 43Chapter IX Methodsof

Measuring

Tire Noise 44Chapter X Patch

Frequency

53Chapter XI TireBulge 56

Chapter XII The

Rubbing Theory

59ChapterXIII Conclusions andFuture Recommendations 69

Resources 74

Chapter 1

-Introduction

Inthelast

twenty

years orso,tire noise,has been modeledthroughmethods suchas: vibrationanalysis, acoustical

holography,

andothertechniques usingvariouslaboratory

set-ups.Ofallthemethods outthereisn't anyonetheory

thatcompletelycaptures

everything

thatis producingnoisedueto thecomplexityoftheautomobiletire.Basicacoustical principles andmeasuringtechniquesallowonetodeterminea

soundlevelof a source andtodistinguish it from backgroundorothersimultaneously

occurringnoises.This is done

by

anaddition and/or subtraction of sound pressure levels.Thegoal ofthisworkistoprovide abasic understandingofacoustics andapply

theprinciplesto aneverydayproblem, tirenoise.Thisobjectivewaschosenbecause

thereis nocompletemathematical or acoustical modelfortirenoise.This isnotan

attempttocreatetheperfectmodel,butthrough observations andbasic acoustical

principles,morepieces ofthetire noisepuzzlecanbeadded.

Chapter 2 begins

by

goingoverthebasicsofsound;whatitis,

how it ismeasured,and some acoustical terminology.Chapter 3 goesinto detail onhowtomanipulate, add,

and subtractsoundlevels. Chapter 4givesbasic information ontireconstruction.Chapter

5 isabouttiresand elasticity. Itcovershowtires react under aloadandits resulting

deformations. Chapter

6

looks at workdone in thepastby

M. Muthukrishnan[12]

forSAE in 1990titled"Effects ofMaterial Propertieson TireNoise." Theauthor shows

how noiselevels goupwith

increasing

speedandincreasing

weight.He alsodescribes

indetail howtirenoise is affected

by

tireproperties suchas modulus ofelasticityandTannoise

levels.

Chapter 7 isonthepaper"Investigation intotheInfluence of TireConstruction

onCoast-by

Noise"by

DonBrackin, Nishuhata,

andSauerZapf [18]. Themain points madeintheirinvestigation arethat tire treadvibrationis greatestnearthe

contact patch ofthetire. It isalso concludedthatshouldertreadvibrationis thenoise

sourcethatbestcorrelatestomeasuredtirenoise.

They

also statehowlowering

thecentercontact pressure and or

increasing

theshouldertreadbending

stiffness will decreasethetiretreadvibration and reducetirenoise generated. Chapter 8coverstherelationship

betweenroadtextureandtirenoise. Written ina conferencepaperfrom Noise-Con96

by

Yasuo OshinoandHideki Tachibana

[7], they

concludethat tire/roadnoiseincreaseswithanincreaseof roadtexturedepth. Chapter 9 ison

Plotkin,

Montroll,

andFuller's[4]

studyonnoise sourcesthatare consistentwith airpumping.

They

describe how sound pressuredueto airpumping is

directly

relatedto thesecondderivative ofthevolumeof airdisplaced fromtreadvoids.Chapter 10goesintothemethods ofmeasuringtirenoise that

arecommonlyused.Thesemethodsinclude "The

Coast

By

Method," "The TrailerMethod,"

and"The

Laboratory

DrumMethod."

Chapters 11-14arewherethe

mathematicalmodelingthrough observationand experimentationis presented.Chapter

1 1 discussestirepatch

frequency

and astire patchfrequency

increasessodoesthe soundlevel. Chapter 12 isabouttirebulge anditseffect on tirenoise. Chapter 13 takesyou

through thedevelopmentoftherubbing theory,whichis thenbacked upthrough

experimentation. Chapter 14concludesthisinvestigation and givesfuture

Chapter

II

-General

Discussion

of

Sound

Sound

canbedescribed

as adisturbance spreadingthrough aphysicalmedium,such as air. Theear perceivesitas a pressure wave superimposed upontheambientair

pressuretothe

listener.

Thesound pressureistherefore theincrementalvariation abouttheambient atmospheric pressure. Todescribethesepressurewaveswe callsound,

mathematically,it is besttolookattheattributesof a puretone. Apuretoneisa

sinusoidal pressurewave of aspecific

frequency

andamplitude,propagating at avelocitydetermined

by

thetemperatureand pressure of air.A hypothetical soundgenerator, asdescribed

by

IrwinandGraf,

in IndustrialNoiseandVibration

Control,

is shownbelow:o

Figure 1

-[17]

Thesourcemay bethoughtofas anelastic sphere,like a

balloon,

thatexpandsandcontracts sinusoi

dally

at afrequency

f.astheballoon expands, thesurroundingairmolecules arecompressed.Whentheballooncontracts, theair molecules spreadapart;

thegas israrefied.The sound wave generated willhave a

frequency

equalto thenumberoftimesper secondinwhichtheballoon expandsand contracts. The

Amplitude

oftheThe

frequency,

f,

of anoscillating disturbance isequal to thenumberoftimespersecondthat the

disturbance

passesthroughboth its positiveandnegativeexcursions.Thenumber of cyclespersecondis termed

Hertz

(cycles/sec). Thefrequency

of a simplepuretone sound waveis recognized asthepitch ofthe tone.

Theperiod,

T,

ofthesinusoidal waveisthe timerequiredforone completecycle,andis relatedtothe

frequency,/,

by:r=J_ [I7]pg.3

/

Thewavelength,

A,

is thedistance between likepoints ontwosuccessive waves.Thewavelengthisrelatedto the

frequency

andvelocityof propagationby:A

=- =cT [l7]Pg.3/

inwhich thevelocity ofpropagation, c,is inturn afunctionofthecharacteristics ofthe

propagation-supportingmedium.The velocityofpropagation or speed ofsoundinairis

given

by

theequationbelow:y*P

c=\- 2. [17]pg.3

Here y isspecificheatatconstant pressure over specific heatat constant volume.

specificheat

(c.p.)

Y

=[17]pg.3 specificheat

(c.v.)

Pa

=Ambientor equilibrium pressurep

=Ambientorequilibriumdensity

\Al/2.

c=

49.03*(R)

whereR is thetemperatureindegrees Rankin

or c =

20.05*(K)

whereK isthe temperaturein degrees KelvinThesound power

level

describestheacoustical power radiatedby

a givensourcewith respecttothe

international

referenceof 10A-12W. Thesound pressurelevel isproportional to the

logarithm

oftheratio ofpressures squared.This is important inthatthepressure squaredisproportionaltosomesoundpower;thus, boththesoundpower

level and sound pressurelevelare associatedwithpower. Soundpowersandsound

pressures are commonlyexpressedina

logarithmic,

ratherthanalinearscale calleddecibels. The decibel isthe

logarithm,

to thebase10,

oftheratioofthequantity inquestion,toan arbitrarilychosenreference quantity.Theargument ofthelogarithm is

dimensionless.

Level=10

log

<

Xs-KZ,

Z =

quantity inquestion

Z0

=chosenreferencequantity

Thesound power

level, Lw,

is definedas:[17]pg.6

'W\

*w=101og

W =powerinquestion

Wre

=10-12wattThesound pressure

level, Lp,

expressedin decibels is:[17]pg.6

LP

=10log

' p^

LP

=20log

P v reJ

f P\

[17]

pg.8P - Root

-mean

-square

(RMS)

sound pressurein

question (Pa.orN/m

2)

Pre

=InternationalReference Pressure ofThe

human

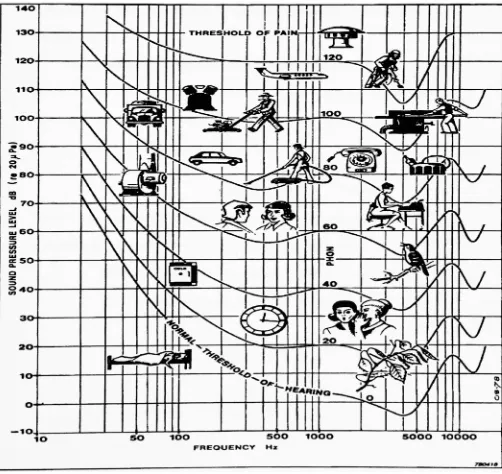

ear cannot respondtoallfrequencies

in anunbiased manner.Audiblerange of a

human

being

rangesfrom

20 Hzto20,000Hz,

whichinfactwill vary withage,

health,

past exposureto noises, and soforth.

Theear also actslikeafilterand willfavor

certainfrequencies

overtheothers. Theearis most sensitivetosounds attherangeof1,000to

5,000

Hz,

andparticularly

at about4,000 Hz. Theperceived sound pressurelevel or

loudness

isfrequency

dependent.

Figure2

-[19]

[image:12.557.32.534.223.697.2]Chapter

III

-Sound Measure

The

understanding

of noise problemscommonly demandsthatpressuresandpowersbemanipulated

by

means ofdecibel additions andsubtractions.Sound Pressurelevels

(indecibels)

are averagedinthecalculation ofsourcedirectivity. For adding andsubtractingandaveraging

decibels,

quantitative analysis areusedas well ascharts andapproximations.Inthis

investigation,

theappropriate quantitative analysis willbeconcentrated on.

Soundpowerlevels arecommonly addedwhen

determining

the total sound powerlevelofasource. Becausenoise canberandom withrespecttophasemeasurements, it is

added on an energy basis. Assumethesound pressurelevels

Lpl, Lp2, Lp3,

through Lpiaretobe added.The sound pressurelevel

by

definition,

is:'P*

yPreJ

[17]pg. 10

LPi=10Log

Where P istheroot meansquare

(rms)

sound pressureinquestion (PaorN/mA2)

andPreistheInternationalreference pressure of20*10A6 Paor.0002uBar

Thenextstep is todeterminethesquareofthepressureratio;

Thetotalsoundpressure

Lpt,

is simply(

V

P_

yPre J

fl \

=

antilog

v10,

Ln

=10

log

n1

[

"

)

2

"

i'=l

[p

Or intermsof sound pressure

levels,

Lpt

=10

log

X

antilog

1=1

Simplifying

further,

v10

;

LPt

=10

log

S10

101=1

[17]pg. 10

Theexpressionforsound powerlevels may beexpressedas

n Lwj

Lwt

= 10log

5>

10 i=i[17]pg. 10

Where

Lwt

=totalsound powerth

Lwi

=i sound powerlevelIn manycases,it isdesiredtosubtractbackgroundor ambient sound pressure

level from atotalmeasuredleveltoobtainthe sound pressurelevelproducedfroma

single source. Theprocedure for subtracting decibels issimilarto thatofaddition.

Thetotalsound pressureindecibels is

Lft=101og

Intermsofthemean-squarepressureratio,

f \2

__

yPre

j

[17]

pg. 13(

V

I _p_KPreJ

=antilog

(L

pt10

=

10

10The

background

or ambient noisemay berepresentedby

(

V

v

Pre

J-antilog

(\^.\

pBV

10

=10

upBLpB

=sound pressureleveloftheambient orbackground noise.The sought-after sound pressureleveloftheambient orbackgroundnoisein decibels is:

Lr

= psLPS

=10

log

j

P"2 ( p >

2

{Pre)

t KPre Jb10

log

10 10 - 10 10^

J

or

[17]pg. 13

When averaging decibels it follows

directly

fromthesummationthat,LPt

=10

log

10

101=1

[17]pg. 16

theaveragedecibel

level, Lp,

isdeterminedby dividing

thesumby

thenumber oflevels,

that

is,

LD

=10log

(

i ntlL\

-y

io

io

n /=1

[17]pg. 16

Chapter IV

-Tire

Construction

Pneumatic

tires servethreemain purposes.They

supporttheweight ofavehicle,absorb road surface

irregularities,

and providetraction ontheroad. Tires haveatoroidalshape and are usually

filled

with compressed air.Thecarcass ofthe tireprovidesthestructural supportforthetire.Thecarcassismade upofmany flexible filamentsofhigh

moduluscord,embeddedinandbondedtoa matrix oflowmodulus material,usually

[image:16.556.168.365.534.664.2]rubber.Thechordsofthetire are made ofnaturaltextile,syntheticpolymer,glass

fiber,

Figure 3 Filamentarrangementsthatareusedinpneumatictires, a)wovencord

b)

weftless cord c) Cordwith lightwefts[1]

pg.360orfine hard drawn steel.

Thechords areanchoredon thebeads ofthetire,whicharehightensile steelwiresthat

seatontherimofthe tire.Thebeadsserve as afoundation forthecarcass and provideit

(a)

(h)

(c)

Figure 4

Essentialsofbead construction(a)

Lowturn-up

construction(b)

highturn-up

construction(c)

Overlap

construction(d)

Detailoftypicalbead[1]

pg.361

with adequate

seating

ontherim. Thematerialin whichthebeads areincased in ispressed againstthe

flange

oftherimby

inflationpressure.Mostofthe tire'svibrations anddeformationoccurinthesidewalkThetreadof

thetireis made of various typesof rubber

depending

onthe tireapplication. Whenthetireis inflatedwithair, thepressure causestensioninthe chordswithinthecarcass.Load

fromtheweight oftheautomobile placedon therimto the wheel,hangs primarilyonthe

chordsinthesidewallsthrough thebeads. Thechords or plies runat an anglefromthe

centerline(circumfrentialcenterof

treads)

ofthe tire.Thenumber oflayers is determinedby

the tiretype,

the tiresize, andtheinflationpressuretobeused. Atypical tirewillhavefrom 2-20plies with each layer running inoppositedirections. This angleiscalledthe

crown angle.This angle playsaroleintherideand

handling

ofthe tire.There aretwobasic typesoftires, Bias plyandRadialply. InaBias ply tire, the

chords extend

diagonally

acrossthecarcassfrom beadto beadwithacrown angleofabout40 degrees. Whenthe tireisrolling, the diagonalpliesflex andrub,thiselongates

thediamondshapedelementsformed

by

thechords andtherubberfiller. Thisflexing

action producesawipingmotionbetweenthe tread andtheroad.

Figure

5 Conventionalcross-biastire.[1]

pg.369Ina radialply tire, thereisone ormore layersofchordsextending radiallyfrom

beadto

bead,

resulting in a crown angle of90 degrees. Underthetread,atalowcrownangle of about 20

degrees,

arefittedseverallayeredbeltsmadeofhighelasticitymaterial,usuallysteel. All together,there aretworadialpliesof rayonorpolyester, twoplies of

steelcords, andtwoplies of synthetic materiallikenylon. Aradial plytirehasarelatively

uniformground pressuredistributionunderthecontact patch (no wipingmotion).The

ground pressureforabias plytirevariesgreatly frompointtopoint astreadelements

passingthrough thecontact regiongothrough acomplexwipingmotion.

Chapter V Tires

andElasticity

In

Mechanics

ofPneumatic

Tires,

by

S K. Clark[1]

(section3.8),

themechanismofload

carrying

of atoroidalortire-likestructure ofaninfinitely

flexiblemembranewith arigidtubularrim forthecentral zone orboreofthe toroidis

discussed,

seefigure below.CZ)

[image:19.556.228.370.219.330.2]Co) bl

Figure 7 Toroidalmembrane on cylindrical rim

[1]

pg. 396It isassumedthat thejunction betweenthe thinflexiblemembrane andtherigid

tubularrimorbase haszero

bending

rigidity. Inflationofthestructure putstensionsinthemembrane andittakesa shape asdetermined

by

equilibrium andcompatibilityconditions.Themembranetensionsare resisted

by

reactions atthe edge ofthetubularrim. Forthepresentpurpose, thesecan be discussed interms oftwocomponents;

radiallyoutwardtension andtensionin an axialdirection (that isparalleledtotheaxis of

rotational symmetryorrotationofsurfacegenerators) at each point aroundtheedge of

therim.Ifaflatplateis pressed againstthemembrane whilethestructureis supported

by

therim areactionwill

develop

betweenmembrane and plate wheretheloadwillbeequalAs seeninthe

figure

below,

thecurvature ofthewallofthemembraneincreasesintheregion

between

theloading

plate andtheadjacentrim.i.J/'

Figure

8

Perspectivesketch oftoroidalshell contact[1]

pg.397Hence,

becauseofthe increasedcurvature, themembranestressesin thisregionarelowerthanelsewhereinthemembrane walls. The deflectionalso causes themembrane

todistort

locally,

increasing

theanglebetweenthedirection ofthewall and alinenormalto theplatefromthe

rim;

thisistruewhateverthecross sectionalshape, seefigure below.Figure

9

Crosssections ofFigure 7 showingdeflections

of sidewallswhich reducethe tension componentradially

outwardattheinnercylinder edge

[1]

pg.397This increaseof anglereducesalgebraicallythecosine ofthe angle

between

thewallandthelineof action oftheappliedloadontheplate.

Thenet effect ofthereducedtensionand reduced component atthedeflectedregion

isto

develop

therequired reaction. Ineffect, therimhangs inthe tensionsoftheundeflected walls as shown,see

figure below.

[image:21.556.195.351.148.297.2]TTTTT

Figure 10 Polarplot ofradiallyoutward component of

walltensionofmembranetoroidon innercylinder

[1]

pg.397

The radiallyoutward components ofthewalltensionsare greaterintheundeflected

regionsthaninthedeflectedregion.

Theusefulinformation wegetfromthis isthat thereducedtension inthe

deflectedregion causesthestiffnessintheshoulder regiontodrop.

Decreasing

pressureon atirewill increasetheamountthe tire

deflects,

this deflectionwill increasethebulgeof atire.Asaresult,tirebulge increaseswithtire

deflection,

which meanstherewillbelesstire stiffnessinthedeflectedregion (thetire shoulder)whichmeans therewillbe

morevibrationoftheshouldertreadsproducingmore noise. Theelastic effects ofthe tire

causethistohappen. The deflectedsidewallwill snap back intoshape upon

leaving

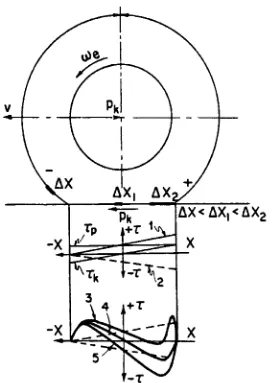

theFrom Samuel K.

Clark's,

Mechanics

of PneumaticTires,

November 1971[1],

Figure10,

showstherotation of a wheel

transmitting

torque, Mt. Asaresult ofthe torquetransmittedthrough thewheel,two sets offorcesact uponit. One isthereactionofthe

wheel axis

Pk,

and equaltoitandintheoppositedirection,

thereaction oftheroadactingin theplaneofcontact. Asafirstapproximation,it may beassumedthatthereactionof

theroad

Pk

is evenly distributed overthe areaof contact.The componentoftangentialstressfrom

Pk

isdenotedasxp.t-T

Figure

11

RotationofaDriving

Wheel (theDistributionofLongitudinal TangentialStress

in theContact

Region

ofDriven,

Driving

andBraked Wheels).[1]

pg.490 [image:22.556.138.410.262.645.2]There isa certain amount of adhesion overthecontact region.Thetirepossesses

longitudinal

tangential elasticity, allowingthe torqueofthe tirewill compressthe treadelementsinthezone

immediately

beforethecontact region(-)

andatthesametimewillstretchtheelementsin theareajust afterthecontactregion (+). Again

looking

atFigure1

1,

aninitially

compressed elementAx,

ofthe treadisreleasedfrom longitudinalcompression asitpassesthrough thecontactarea, revertingtoits normalstate

Axi,

thenitundergoes

stretching

and emergesfromthecontact regionin astretchedstateAx2. Sincethe elements,as

they

passintothecontact area,are in directcontact withtheroad,anychange intheirdimensions isprevented

by

theforcewith whichelement gripstheroadsurface, andlongitudinal tangentialstressxkariseintheplane of contact. Thesestresses

causethere tobean area of slippage attherearofthecontactpatchdue to the tension

pullingthe treadsout ofthecontact patch.

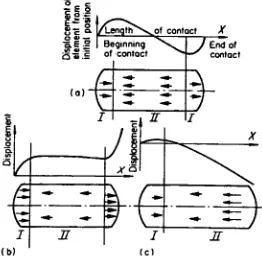

Lenqtnsv^of contact X

Figure

12 Displacementoftreadelementsalongcontactlengthoftire:(a)

free

rolling,(b)

driving,

(c)

braked.

[1]

pg.465ZoneI Longitudinaltangentialstressactingfromtiretoroadway in directionof motion.

[image:23.556.126.388.388.644.2]Chapter

VI

-Influence

of

Material

Properties

onTire Noise

In thearticle

"Effects

of Material Propertieson TireNoise"

by

M. Muthukrishnan[12],

SAE, 1990,

theresults of an experimentalstudytodeterminetheeffectofmaterialproperties ontirenoise are

discussed.

Thepropertiesthey

usecoverawide rangeofmoduli andtandelta fortreadand sidewalkAn explanation oftan delta is locatedon page

25. Thetiresweretestedatdifferentspeeds,loads andinflationpressures.From this,

they

obtained overall noiselevels andfrequency

content.Thetestsindicatealargerinfluenceoftreadmodulusontirenoise, anditwas observedthat theinteractionbetween

treadand sidewallproperties affecttirenoise levelssignificantly.

Theresultsofthisreportare presentedin twoparts:

(1)

the effects ofload,

pressure,and speed on tire noise,and

(2)

Material propertyeffects ontirenoise.Theresultsofvaryingtheloadshowthatloadchangesdonotaffectnoiselevel in any

significant way.The

testing

wasdone atfive differentspeeds,andfive differentmicrophone locations.

ROADWHEEL.NOISETEST

TJE

f

si

I

I I \

^_

2,1m4

V

\ s

V

MlcrophuntLocation

"~" }

Figure 13 microphonelocationsaroundthetire

[12]

pg.3

Load EffectsonTire Noise

(dBA)

RoadwheelTesting

Inflation Pressure: 35psi.MicrophoneLocation 1 MicrophoneLocation 2 Microphone Location 3 Microphone Location 4 MicrophoneLocation 5 Speed

(MPH)

30636 Lbs. 1190 Lbs. 636 Lbs. 1190 Lbs. 636 Lbs. 1190 Lbs. 636 Lbs. 11 90 Lbs. 636 Lbs. 1190 Lbs.

76.6 77.2 74.5 75.2 74.5 76.2 74.6 76.2 74.2 74.5

40 80.9 81.4 79.4 79.3 79.2 79.5 78.2 78.4 76.5 75.6

45 83 83 81.4 80.5 81.3 79.6 80 79.2 78.5 76.6

50 84.4 83.9 82.4 81.4 81.7 80 80.5 79.5 79 77.5

60 83.6 85.3 82.4 83.4 82 82.4 81.3 82.1 78.8 80.5

Figure

14Load Effects

onTireNoise

(dBA) [12]

pg.3Thechanges innoiselevelswere atmost+- 2 dBA.

Next,

pressureeffectsontirenoise,were shown

by

comparingnoise levelsattwodifferentpressuresfor differentloadsand speeds. Atthelighter

load,

anincrease in 15 psiledtoan increase innoiselevelsofaboutoneto three dBA. Atthelarger

load,

thereis areversal andtheincrease in inflationpressureis accompanied

by

adecrease inthenoiselevelby

as much astwodBA.!1SfiLJ*OJSE

P^Ss.jEE CPF""? m M1

& Oll LoC-d; S-Ift *.. .i Si **,:

^s*kHi^

20**.5

K-UJ *t- ^^n * ^^^^^^ Ul flCM fa- *~*m. ^---****^^*^*^

E JO'?

*-.? TT' **

jr*J

**

U>flJ: 1ISC Dl.

a s 4

UlCA&PMOH'E lOCatiom

Figure 15 Pressure Effectson Tire Noise

[12]

pg.4

[image:25.576.147.395.380.651.2]Theeffect of speed on noise level isshownin thefigure below. With

increasing

speed, thenoiselevel

generally

increases. There isalarge increase from 30to40mphsatbothloads. After 40mph, theincrease isnot uniform andis even reducedatcertain

speed ranges.

S

IP -r"

-P

1J

T

UJ

5

8

GO

T1RE

NOISE

epeiici

Effects

4

ED [image:26.556.76.487.156.569.2]&PEEU

(MPHJ

Figure 16 Speed EffectonTire Noise

[12]

pg.5Forthematerialpropertyparametersontire/roadnoise, a widerangeof moduli

andtandeltaare used.Ninegroupsoftireswere

built,

thesegroups canbe seenintheTable below.

Experimental Design

(Fractional

Factorial)

4

Variables:

Tread Modulus

Tread Tan Delta

Sidewall Package Modulus

Sidewall Package

Tan Delta

The

Group

ID

Mod

ulusTan Delta

Tread

Sidewall

Package

Tread

Sidewall

Package

A

Control

Control

Control

Control

B

Low

Low

Control

Control

C

High

Low

Control

Control

D

Low

High

Control

Control

E

High

High

Control

Control

F

Control

Control

Low

Low

G

Control

Control

High

Low

H

Control

Control

Low

High

1

Control

Control

High

High

Figure 17 Tire

Groups

[12]

pg.2There isone control group,

A,

fourgroups(B, C, D,

andE)

with varyingmoduli,andfourmore groups

(F, G, H,

andJ)

withvaryingtan deltaandconstant moduli for boththe treadandsidewall.

Looking

attandelta,

theelasticmodulusisE',

andtheE" isthelossmodulus. Thetwocasescanbeseen in Figure 18.

[image:27.556.126.410.57.376.2]Varying

ElasticModulus/ConstantTan DeltaVarying

TanDelta/ Constant

ElasticModulus

Figure 18 Tan DeltaandElastic

Modulus

[12]

pg.225

i

H,

In Figure

18,

E' istheElasticModulus

orStorage

Modulus,

E"is theloss

modulus,E*isthecomplexmodulus,

5

is theloss

angle, and 1,2arethetwoconditions. Allmaterialshave aviscoelasticity,whichis a combination ofviscosityandelasticity in varying

amounts. When viscoelasticity ismeasured

dynamically,

thereis a phaseshiftbetweenthe

force

applied as stimulus(stress)

andthestrain(skew)

whichoccursinresponse.Generally,

themeasurement results are represented asa complexelasticitymodulus toinsure accurate expression.This relationship is shownbelow.

Iftherelationship betweenE* andTan5 isplotted, the result,isagraph liketheone

shown below.

E* = E'

+iE"

E"

tan

8

= E'[12]

pg.6E"

Figure 19

Fromtheresults ofthemodulus

testing

itcanbe seenthat treadmodulushasalargerinfluence

on overall noiselevels

than thesidewallmodulus. Anincrease in treadmoduluswhen averaged over allthevaryingconditions causednoise level increasesfrom 2to7

dBA,

and anincrease

insidewall modulus caused anoise level increasefrom 1 to3 dBA.Tread Modulus S.W. Modulus Interactions

Speed Mic. No. Low High Low High Extreme Gross

1 82.7 89.5 86.1 87.4 87.7 85.7

2 82 87.5 84.7 85.6 86.3 83.9

60MPH 3 82.3 87.2 84.2 86 86.1 84.1

4 80.7 84.5 81.3 84.1 83.8 81.7

5 80.1 82.6 80.7 82.1 82.2 80.5

1 80.1 85.9 82.4 84.4 84.6 82.2

2 78 84 80.8 82.7 82.9 80.4

45MPH 3 79.2 84.4 80.9 83.3 83.2 81

4 76.9 81.9 78.5 80.8 80.6 78.7

5 76 80.2 77.2 79.4 79.4 77.2

1 75.6 79.4 76.7 78.6 78.3 77.1

2 74.6 78.1 75.7 77.3 77.2 75.8

30MPH 3 74.8 79 75.7 78.4 78 76.2

4 73.9 77.3 74.4 76.9 76.6 74.8

5 73 76.4 74.1 75.5 75.7 73.8

avg.ofB&D avg.ofC&E avg. ofB&C avg. ofD&E avg. ofB&E avg. ofC&D

[image:29.556.52.509.204.427.2]Thisexperiment also shows that thereis a crosscoupling betweentreadandsidewall

effects. Forexample,

going from

low tohightreadmoduluswithlow sidewall modulusincreases noise

level

by

five

dBA. Whereasdoing

thesame with ahigh sidewall modulusproduces an increaseof

8.6

dBA. The influenceoftreadmodulus on sidewall moduluseffects are shownin thelasttwocolumns ofFigure 17:

Low to High Tread Modulus Lowto HighSidewall Modulus

Speed Mic. No. LowS.W. High S.W. Low TR. High TR.

1 5.0 8.6 -1.1 2.5

2 3.2 7.9 -2.2 2.5

60MPH 3 3.1 6.2 -0.1 3.0

4 2.0 5.2 0.9 4.1

5 0.8 3.9 -0.4 2.7

1 3.8 7.6 -0.5 3.3

2 2.9 7.1 -0.8 3.4

45MPH 3 3.3 6.7 0.2 3.6

4 3.5 6.3 0.5 3.3

5 2.3 5.8 0.0 3.5

1 2.9 4.6 0.9 2.6

2 2.2 4.6 0.2 2.6

30MPH 3 2.8 5.4 1.1 3.7

4 1.8 4.7 0.7 3.6

[image:30.556.66.498.207.434.2]5 1.6 5.0 -0.7 2.7

Figure 21 Interaction Effects

Change

in Noise Level(dBA) [12]

pg.7Thenoiselevel spectrum wasthenintegratedand plottedit as afunctionof

frequency.

[image:31.556.134.415.192.401.2]qooo 1CHXS

Figure 22 IntegratedSpectrum

[12]

pg.8The integratedspectrum at agiven

frequency

givesthe totalnoisecontributionuptothatfrequency

starting fromthefrequency

ofinterest. This is donefor differentmoduliMV

Tire Noise

(moduluseffects)

Speed=60mph

J

Tread Modulus Sidewall Modulus

B Low Low

c High Low

D Low High

E High High

itto 2000

Frequency

(Hz)Figure

23 Integrated NoiseSpectra

[12]

pg.8

icfe*

Itcanbeseenfromthis thatinthe

frequency

rangefrom 750to 1500Hz,

thecontributions vary significantly

depending

ontheparticulartread/sidewallmoduluscombination.In this

frequency

range, many noise-generatingmechanisms areinvolved.Themajorsourcesof noise are saidtobe

(a)

tread patterns, and(b)

radial andtangentialvibrationsofthe treadelements atthe entryand exit ofthe contact patch.It is also

described inthisreportthatvibrations generated atthecontactpatch dependon stiffness

(modulus)

andthedamping

ofthe treadelements. It isthenreasonedthathighmodulustreadblocksproducelarger levels ofvibration, resulting inmore noisefrom 750to 1500

Hz. Italsois observedthatahighmodulus sidewall amplifies thevibrations ofthehigh

modulustreadelements more effectively. Thisexplainsthecrosscoupling effect

observedin Figure 15 & 16.

Figure

29,

showstheoveralleffects oftreadand sidewalltandeltaontire noiseforall

testing

conditions. Itcan be seenthatthe tandeltaof eitherthe treads or sidewallhas negligible effectonoveralltirenoise levels.

Muthukrishnan

concludesthefollowing

from hisexperiments:1. Treadmodulushas a much larger influenceonexteriortirenoiselevelthan

sidewall modulus.

2. Tan deltaof eithertreador sidewall hastheleasteffect ontirenoiselevel.

3. Significant interactions existbetweentreadand sidewall properties. Noise

levels dependonthetreadand sidewallconditionstogether.

Thenextfewpagesincludeother

interesting

graphsfrom "EffectsofMaterialTERg

NQI5ETraca

To-nifc

tf'eCtSas -i

?e

Tira-E NQ1

aio#wgll T"on&- E^^eCi?

e-s -n

Figure

24,

25

Tread Tan Delta EffectsonTire

Noise,

Sidewall

Tan

Delta

EffectsonTire Noise

[12]

pg.9

[image:34.556.77.482.44.663.2]Pressure EffectsonTire Noise

(dBA)

RoadwheelTesting

Load: 636 Lbs.Microphone Location 1 MicrophoneLocation 2 Microphone Location 3 Microphone Location 4 Microphone Location 5 Speed

(MPH)

30 40 45 50 6020psi 35psi 20psi 35 psi 20psi 35psi 20psi 35psi 20psi 35psi

75.4 79.6 80 80.1 81.9 76.6 80.9 83 84.4 83.6 73.5 78.2 78.6 79 80.5 74.5 79.4 81.4 82.4 82.4 73.8 78.8 79.2 78.9 79.9 74.5 79.2 81.3 81.7 82 73.8 78 78.2 78 79.6 74.6 78.2 80 80.5 81.3 72.9 76.4 76.4 75.8 77.8 74.2 76.5 78.5 79 78.8

Roadwheel

Testing

Load:1190 Lbs.Microphone Location 1 Microphone Location 2 Microphone Location 3 Microphone Location 4 MicrophoneLocation 5 Speed

(MPH)

30 40 45 50 6020psi 35 psi 20psi 35psi 20 psi 35 psi 20psi 35psi 20psi 35psi

78.4 83.1 83.6 84.4 86.2 77.2 81.4 83 83.9 85.3 76.3 80.3 81.6 83.9 85.4 75.2 79.3 80.8 81.4 83.4 76 79.2 80 80.8 83.2 76.2 79.5 79.6 80 82.4 75.5 78.1 78.9 80.4 83.9 76.2 78.4 79.2 79.5 82.1 73.8 76.5 77.5 78.9 82.7 74.5 75.6 76.6 77.5 80.5

Figure 26 Pressure EffectsonTire Noise

(dBA)

[12]

Testing

at12

Hz.

Item

M

Control

odulus(p

Low

si)

High

Control

Tan

Delta

Low

High

Tread

2250

938

5048

0.22

0.11

0.265

Sidewall

100

530

2504

0.144

0.123

0.218

Rimstrip

2790

1444

8250

0.292

0.189

0.327

[image:35.576.16.565.56.310.2]Bead

Filler

5350

3901

23555

0.197

0.037

1.14

Figure 27 Material

Property

Values[12]

Tire Noise

(dBA)

Levels forallModulusandTan DeltaCombinations:RoadwheelTesting

Inflation Pressure: 35psi Load: 11 90 Lbs.

Low Tread LowSidewall

(B)

ModulusCombinations High Tread Low Tread Low Sidewall HighSidewall

(C)

(D)

High Tread High Sidewall(E)

Low Tread LowSidewall(F)

Modulus CombinationsHigh Tread LowTread

Low Sidewall High Sidewall

(G)

(H)

High Tread High Sidewall(J)

Speed(MPH)

Mic. No. Control(A)

601 85.3 83.2 88.2 82.1 90.7 86.0 87.1 86.2 85.8

2 83.7 83.0 86.2 80.8 88.7 84.4 85.7 85.1 84.1

3 82.9 82.5 85.6 82.4 88.6 84.3 84.2 84.9 84.1

4 82.3 80.2 82.2 81.1 86.3 83.4 83.0 83.0 82.7

5 81.1 80.3 81.1 79.9 83.8 82.5 82.2 81.7 82.0

45

1 82.9 80.3 84.1 79.8 87.4 82.2 83.4 83.2 82.7

2 81.0 79.2 82.1 78.4 85.5 81.0 81.8 82.4 81.4

3 79.9 79.1 82.4 79.3 86.0 81.9 81.0 81.7 80.1

4 79.0 76.6 80.1 77.1 83.4 80.6 79.1 79.5 77.6

5 76.7 76.0 78.3 76.0 81.8 77.9 77.0 77.2 76.4

30

1 77.0 75.1 78.0 76.0 80.6 77.2 79.1 77.7 79.1

2 75.3 74.5 76.7 74.7 79.3 75.8 77.5 76.3 77.9

|

3 75.9 74.2 77.0 75.3 80.7 76.6 77.2 75.9 77.6

4 75.6 73.5 75.3 74.2 78.9 76.1 76.7 75.8 76.8

5 74.4 73.3 74.9 72.6 77.6 74.6 74.2 75.4 74.1

Figure28 Tire

Noise,

AllCombinations

[12]

Speed

(MPH)

Mic. No.Tread T Low an delta High Sidewall Low Tan delta High Interactions Extreme Cross 60

1 86.1 86.5 86.6 86.0 85.9 86.7

2 84.8 84.9 85.1 84.6 84.3 85.4

3 84.6 84.2 84.3 84.5 84.2 84.6

4 83.2 82.9 83.2 82.9 83.1 83.0

5 82.1 82.1 82.4 81.9 82.3 82.0

45

1 82.3 83.1 82.8 83.0 82.5 83.3

2 81.7 81.6 81.4 81.9 81.2 82.1

3 81.8 80.6 81.5 80.9 81.0 81.4

4 80.1 78.4 79.9 78.6 79.2 79.3

5 77.6 76.7 77.5 76.8 77.2 77.1

30

1 77.5 79.1 78.2 78.4 78.2 78.4

2 76.1 77.7 76.7 77.1 76.9 76.9

3 76.3 77.4 76.9 76.8 77.1 76.6

4 76.0 76.8 76.4 76.3 76.5 76.3

5 75.0 74.2 74.4 74.8 74.4 74.8

tJ

Avg.of F&BtJ

Avg.of G&Jtr

Avg.of F&Gtr

Avg. of H&JtJ

Avg.of F&Jtr

Avg.of G&HFigure 29 Tan Delta Effectsontire

Noise

(dBA) [12]

[image:36.581.86.486.353.629.2]Chapter

VII

-Tire

Construction

and

Noise

In thearticle"Investigation intotheInfluence of Tire Construction on

Coast-by

Noise"

by

Doan,

Brackin, Nishihata,

andSauer Zapf[18],

the dominantsource oftirenoiseis identifiedas shouldertiretreadvibration.It is generally knownthatahighpeak

value exists at around onekHz. Inthecoast-bynoisespectrum andthis

frequency

dominatesthecoast-bynoiselevel. Thisphenomenon occursin tires

having

treadedpatterns and alsofor blanktires. Rib-styletreadpatternedtires areusuallyquieterand

showthe smallestdifference innoiselevelsas comparedtoblanktires. Tireconstruction

and materials will havetobetakenintoaccounttoreduce noiselevels. Noise is notonly

generated

by

tread patterns,butalsoby

thevibration ofthe tirecomponents.

&-<-1

a

-63

J

^

f

fi

0 0

1.1

u

I- ! ', v

II

i'iflftSnjIO0* Cixi*a 7aotftQE"-ii*

Tinic (Soc] O fiK

Figure

30

Excitation LevelofTreadsasThey

Pass

Through theContact

Region,

[image:37.556.83.445.406.661.2]Thevibrations were measured with accelerometersmounted atthecenter ofthe

belt,

nearthebeltedge,andthe sidewall ofthe tire.Thevibrations atthecenterandbeltedges are referredtoas 'tread

part'

vibrations.

Looking

atFigure 31below,

at 1 kHz itcanbeseen thatthe

leading

andtrailing

edges arenoise sources. Resultsshowthat tirenoise around 1 kHz is generated

by

treadpartvibration attheleading

edge,trailing

edge,and shouldertreads, andthattheacceleration ofthe treadpartis greaterthanthatofthe

sidewall especiallyaround 1 kHz. The

following

graphs showthattire treadbandvibrationdoes in factgenerate noisesources relatedto thesound produced

by

coast-bytests.

Size: 2IS/70R16

,. Putcra: Maingroovesoc.ly

9

0Srral 57 bet

I

MJf

v.[5

Lcodng&3D

Trading E<J*

5 t SsMh "-'"v-.

(at MeanendOmi-<S<isLevsis.

.IL

V

'

I JX 2.5K

i,V,MrctrtiiTicd VB&rKdeeAzcc:rc~<:.r.Leuela.

HG.il.

-Gr^lhmwf^tofottb^tenCMW-hyxoB*l^si^t^y(br*t<>iiIm>s

Figure

31 Graphs

Showing

Correlation BetweenCoast-By

Noise

andtread Vibration Levels[18]

[image:38.556.84.499.325.570.2]Thecorrelation coefficientsthat

they

reportedfortheshouldertreadvibration andthegeneratedtirenoiseis

relatively

high,

as comparedto thecentertreadvibrationandthegeneratedtirenoise.

I,J>HUE 1 t"'^TvfeiY.-uj/nit,r<il v.AiYnv.-.n d!Ikeshotftdkr

irriii"

SMJc.>.-W->'imliS5awAwr<*-Mrirxfiitose,

C;.m I'V-aii Noise ImlivJ.

L"'I'JJVoivc

40 5fl "HI 70 " 5D >*0

km.ti km^ km.-. K-nirt. km." klt^, ki/b ^'^

Figure 32

Correlation

betweenvibrationattheshouldertreadand coast-bynoise/indoordrumtirenoise

[18]

They

found highaccelerationlevelsattheleading

andtrailing

edges andrelatively lowlevels in thecontactregion.

They

also say,"Thecontactpressure andtirestiffnessmaybeusedtodescribe thissystem ofvibration,becausethecontactpressure canbe thought

ofas aforcewhich acts onthetire, andtheamplitudeoftirevibration canthoughtofas

being

dependentontirestiffness.Thismeansthat treadvibrationisequaltotheinputforcesmultiplied

by

some vibration transferproperties."

Thetreadvibration mechanism

model couldbeexplainedin detail asfollows: The inputforcecanbeseenin Figure 33

foj TJw VitratumMedianhm

t

(b)Context Prrrsvr*

Itf

yJ

iii

Simian tfTiodPuI

CWirfTjMdftn

Figure 33 Tire Forcesatthe

Leading

andTrailing

Edgescausedby

ContactPressure Variation andRoad Surface Roughness

[18]

The dynamicpressureincreasesatthe

leading

edge(AB),

staysnearlyconstantduring

contact

(BC),

andthendecreases atthetrailing

edge(CD). Thiscontactdistribution canbe assumedtoberepresentative oftheforcesthatexcitethe tirestructure. The amplitude

ofthemaximumdynamic contact pressure aroundB andC canbeconsidered asthe

maximum amplitude oftheexcitationforcespresent. In addition,theroad surface

roughnesstends to amplifytheexcitation forcesand mustbe considered.Thetirein

Figure33 isapproximated

by

the springmassdamperandstep inputsystemofFigure 349

fr

if

r~

JPt^SfiSwfwBWlOS

c ;>

I

.tC'***iWt

i'.v.i,J^-.,iimtft f^-v

Ur<4fFrequency <Hi)

Figure

34A

typicaltire transferfunctionand systemused torepresenttirepropertiesa) theWherethemaximum

dynamic

contactpressure, attheleading

andtrailing

edges,representsthe

input forces.

Ifthishypothesis

isused, thedisplacementresponsestepfunction

x(t) inthe timedomain

can beexpressed as:x(t)=F*

(

1-e-a>t cosXn4l-C2t)+y=L=sin

[18]

Where:

x(t) =

displacement

responseF=input force

K=stiffness

t\

=damping

ratioC0n=natural radial

frequency

Dueto the

difficulty

ofcalculatingthedamping

ratio andthemass effects,they

furthersimplifythemodel

by

assumingthedisplacementresponseis onlyproportionalto theinputforcemultiplied

by

thereciprocal ofthestiffness,as shownintheequationbelow:x{t) - F*

[18]

KInthis equation,Frepresentstheinputforceand1/K isthe transfer

function. Further

theinput

force,

F,

canbeapproximatedby

usingthemaximumdynamic

contact pressure andtheroad surfaceroughness,and canbe representedin therelation

below:

*(0=ar*P*

[18]

lv

Inwhich:

a=road roughness coefficient

P=

dynamic

contact pressureK=tire stiffness

Theauthors also saythat thecenter contact pressure andthetread

bending

stiffnessattheshoulderhave themostinfluenceon theshouldertreadvibration.

Therefore,

having

atirewith alowercontactpressurearoundthecenter andanincreasedtread

bending

stiffnessatthe shouldershould reducetheshouldertread vibration, thusreducingthenoiseit

produces.Thetiretreadvibration onthe shoulder was obtainedusing linearregression

analysis.

14

.--i

MtrsA

I

r-CJ?rtJ!;-r

71 3 Zi

ft

,s> s

s

" V-1-1

3 "3

.C t

s^ K*fr

!_*;<:>* W.iJ.1.

C

I

small[

i^reaMEASUREDVALUE

i*

J

Figure35 Calculatedcorrelationvaluestableand graphshowingactual versus

estimatedtreadvibration

for

aspeed of60 km/hr.

[image:42.556.77.470.442.667.2]and resultsinthe

following

equation:x{t) =

a0

+ ai*Pa*--[18]

Ksh

inwhich:ao,ai = single regression constants

Pce

=static pressure around centerKsh

=treadbending

stiffness aroundtheshoulderBasedontheir research,

they

madethefollowing

conclusions:1. Theregionofthe tire inthevicinityofthe contactpatchdominatestire treadvibration

2. The A-weightedspectra oftreadpartacceleration,coast-bynoise, andindoordrum

testnoise

display

thesametendency

(ahighpeak around1 kHz.).3. Shouldertreadvibrationisthenoise source thathasthemost relation to tirenoise

produced.

4.

Lowering

thecenter contact pressure and/orincreasing

theshouldertreadbending

Chapter VIII

-Section 1: Road Texture

and

Tire/Road Noise

Intheconference paper

"Relationships

between Road TextureandTire/RoadNoise"

from Noise-Con

96,

Yasuo OshinoandHideki Tachibana[7],

performedastudyof noise radiatedfroma passenger car andamedium sizedtruckanddifferentroad

surfaces

(paving

materials,chipping sized grain andsurfacetexture).Fromthisinvestigation,

relationshipsbetweentire/roadnoiseandroadsurfacecharacteristics weredeveloped. Inthisstudy, twokinds ofmeasurements were made.Thefirstonewas

performed on atest trackpaved withfive kindsof constructions

by

usingapassenger carand a medium sizedtruck.

Therefore,

it has been confirmedthat thesoundpowerspectrum oftire/roadnoise variesquite abit duetodifferences intheroad surface

materials.

They

also statedthat theopen graded asphaltsurfaceisthe best amongalltested toreducethe tire/roadnoise.

Tire/roadnoise was alsomeasuredatsixteen sites of publicroads paved with

denseasphalt concrete

by

usingthesame passenger carequipped withfourtypesoftireandthesame medium sizedtruckequippedwithtwo types oftire.

They

foundthat thegeneral

tendency

impliedthat tire/roadnoiseincreaseswiththeincreaseoftexturedepth.This has been found foralmost alltiresbuttherelationshipvaries dueto the typeoftire.

Theseresults suggestthat thereis a greaterexciting forceonthetread

bands

attheleading

andtrailing

edges. Sothedeeperthetexturedepth,

themorethe treadbandsgetexcited, andhence thegreaterthenoise produced.

Chapter

VIII

-Section 1: Air

Pumping

as aNoise

Source

Anothersource oftirenoiseis air pumping. Airpumping,occurswhen air

movementfromtreadvoids give risetomonopole sound radiation.Itis acousticallya

local source, with sound radiated

directly

asthe void compresses.This is validatedas asound sourcein thearticle"The Generation of Tire NoiseandCarcass

Vibration",

Plotkin,

Montroll,

Fuller,

Intemoise-1980 [4]. Intheir study,they

foundthat there areconcentrated noise sources consistent with air pumping.These wereidentifiedatthe

entranceto thecontactpatch.Thesoundpressureduetoairpumping is

directly

relatedtothesecondderivativeofthevolume ofairdisplaced fromtreadvoids.The void profiles

were

directly

measuredforthe test tires. Thiswas accomplishedby

measuringthevolume of waterdisplacedfromabladder inthevoidasthe tirewas advancedthrough

thecontactpatch.Themeasured profiles werethendifferentiatednumerically.The

calculated results showed good agreement withthemeasured sound pressure. The

calculationsstrongly suggestthattheconcentrated sources observed wereduetoair

pumping.

Chapter

IX

-Methods

of

Measuring

Tire

Noise

Tire/pavement

interaction

produces a non-uniform noiseradiation. There arethreeareasin which noiseis radiated;

they

aretheleading

edge,trailing

edge, and sidewallregions,nearthecontact region(see Figure 31).w

Trailing

Edge

Leading

Edge

Contact

Region

Figure36

Therearethreeprominentmethodsfor measuringtire/roadnoise:The Coast

by

Method,

TheLaboratory

DrumMethod,

andThe Trailermethod.The Coast

by

Method isthemost representativeof actualfield operatingconditions and soundpropagationto the road environment. Inthismethod, the testvehiclecoastsby

a roadside microphone,whichis placed1.2m abovetheroadlevel and7.5 mfromthe centerline ofthevehicle's path. Theengineis switchedoff.Using

atimeconstantnicknamedfast anda

frequency

rating"A,"

themaximum soundlevel

during

thecoast-by

is recorded.It isrecommendedthatthefrequency

spectrum also berecorded atthemaximum sound

level,

althoughthisisnotmandatory.Usually,

fiveruns are made andaveraged. Asforall methods, therecommendedspeedis 70

km/hr.

Iflower

orhigher

[image:46.556.146.410.208.412.2]speeds arerequired,it isrecommendedthat

they

be chosenfrom30,

50, 90,

or 110 km/hr.Themain reasonsfor

choosing

70km/hr

arethatthisspeed givesgoodsignaltonoiseratio andlow

influence

of external variables(suchastestvehicledesign)

aswell as safeand practical

driving

conditions. Inaddition, 70km/hr isa speed atwhichtire/roadnoiseis

likely

tobea great nuisanceto theenvironmentinmosttypesoftraffic. Thismethodcanbeusedfortype

testing

oftiresand roadsurfaces,andforalltesting

wherehighprecision and representative operation are essential. TheCoast

by

Methoddoes have itsdisadvantages,

such as:a specialtest trackor aroadwith suitablesurfaceisrequired;

atestvehicle equippedwith4-6test tiresisrequired; the testvehicle mustbe

coasted alongthe test area;

unlesscareis taken theremay bean influence fromvehicletype,

brakes,

transmissionandsuspension.

There may bepracticalandsafetyproblemsforsomevehicles when

they

arecoasted.

In addition,itis necessarytominimize:

climatic andmeteorological

influences;

Sensitivity

todisturbance fromothertraffic, ifany, and otherbackground

noises.

IntheTrailer

Method,

atest tireis mountedon atrailer,

whichistowedby

a carortruck. Thetrailermay be ofasingle-wheeltypeorhaveextra

supporting

wheels. Amicrophoneispositioned closeto the tire/roadinterfaceandthearticulated vehicleis

driven alongatesttrack or a road

having

asuitable surface. The microphone positionis0.2moutsidetheundeflectedtire sidewall, .lmabovetheroadleveland0.2m behindthe

vertical axle plane. The 0.2m distances are changedto0.4m fortruck tires. In orderto

increasethesignal/noise ratio and reduce climatic

influence,

an enclosure aroundthe testtireand microphoneissometimes used. Specialcareconcerning acoustical reflections

mustthenbeobserved. Thismethodis suitable whererelatively highprecisionis

requiredbutsome lackofrealistic operationcanbe accepted. It is especially

recommendedinenvironmentswith

disturbing

traffic, for instanceonhighly

traffickedroads where no other methodis possiblewithoutclosingtheroad.

Long

measuringtimescanbeusedtoreduceerrors. The disadvantages ofthismethodare:

Itrequiresaspecialtowedtrailer;

Backgroundnoisefromwindturbulenceinthemicrophone canbe a problem

atlow

frequencies;

Theclose measurement position gives somelackof realismduetoacoustical

reflections; and

Thenear-field microphonelocation is unsuitableforroadsurfaces

having

asignificant sound absorption.

In the

Laboratory

DrumMethod,

atest tireis mounted sothatitcan roll against adrumsurface. Special care mustbetakenconcerningtheacoustical environment. The

microphoneispositionedas inthe trailermethod. A drumdiameterof atleast 1.5m is

requiredforan "outer drum"

facility,

whenthetireisrolledagainsttheouter part ofthedrumshell. Thismethodis suitable wherehigh precisionis important

but

lack of realisticoperation canbeaccepted.

Surveys

of noise emissionfrom largenumbers oftiresundervariousoperatingconditions canbecarried outin a shorttime. Thismethod could also

beusefulforresearch and

development

work andfordetecting

smalldifferences innoiseemission

from different

tires. It isindependent

of weather conditions andrequireslittlespace andonlyonetiresample pertest.

Long

measuringtimescanbeusedtoreduceerrors. The

disadvantages

ofthismethodare:Aspecialdrum

facility

is required;The drum isnot a good representativeofroad surfacedue toitscurvature.

Inallthree methods,many factors influencethemeasurednoise. Thesefactors

includetiretype,road surfacetype,area ofcontactpatch,tireinflationpressure,and

vehicle speed. In general,withanycombination oftheabovevariablesthesoundlevel

increases asthevehicle speedincreases.

InthereportTire/Pavement Interaction Noise Source Identification using

Multi-PlanarNearfield Acoustical

Holography

by

Richard J. RuhalaandCourtney

B.Burroughs

(1999)

[16],

theauthors usedthe trailermethod andidentifiedthemajor areasofmaximum noise radiationtobethe

trailing

edge,leading

edge, and sidewallregionsnearthecontactpatch.Twotiresweretestedinthis experiment, a monopitchtire and a

[image:49.557.191.384.576.643.2]productiontire.

Figure 37. Photographofmonopitch

(left)

and productiontirethreads.[14]

Themonopitchtire

has

64 equally spacedtransversegroovescutinit,

alongwiththreecircumfrential grooves.Thetreadpassage

frequency

isequalto:_

NV

Where N isthenumberoftransverse grooves,V isthevehiclespeed, andC isthe

circumference ofthetire.Theproductiontirehastreadblocksthatvary insize and

spacing aroundthecircumference ofthe tire. Thetire alsohas fourcircumfrential

groovesthatseparatethreerowsof55treadblocksandtworowsof89 blocks. The

sidewallhasoneplypolyestercord;the treadhas three, one polyester cordandtwosteel

cords. Thistestshowedthat thereis speeddependenceon sound pressure levels.

Overall,

bothtiresshowedincreasedsound pressurelevelswithincreasedspeed,butthesound

pressurelevel fromthemonopitch tiredidnot alwaysincreasewith speed.

This, they

sayis probably dueto the treadpassageharmonics cyclingthroughvarious resonances.

Thenoise

levels

oftheleading

edge,trailing

edge,andsidewall change withspeed.Thenoise level forthemonopitchtireincreasedwith speed above40 km/hrat

(a)

120 -110 !Loading

-D-Trailing

00 1oo -A-Sidewall u c 90 BO 1 Q. 70 j-so _,10 56 ioo

Spaed

(km/hr)

(b)

m a. 120 i HO +-t 10O 90 80 70 60\

1?-Leading

j

">Trailing

k-Si

dwall10

Speed

(km/hr)

100

Figure

38

Sound pressurelevels in dB. Ref. 20uPainthefrequency

range2600

Hz. for(a)

monopitchand(b)

productiontires.[14]

[image:51.556.51.498.136.643.2]40*log(speed).

Fortheproductiontire,

theleading

andtrailing

edgesdominatethesidewall noise above40

km/hr.

Theoverall noise level increasesat arateof40*log(speed)

below 56km/hr,

and20*log(speed)

above56 km/hr.For

further

analysis, themonopitch andtheproductiontiresweretestedata speedof58 km/hron smooth asphalt pavement. Forthemonopitchtire,theareas of maximum

radiation were

localized

tothesidewall neartheleading

edge,centerline oftheleading

(a)

side 1 , > ,i \\ J~ rx^*** f^>>M7S '.* ''>\l*\'~,*

[image:52.556.93.465.235.600.2]* |V'"SJ<*.-,'

'

"

: X

\ffl-fr'Y Jg

-'

W/^>^=r^f^ :A

-0> 0.1 8 4 0

J

fror(

it^4\

/ :HI

(((

fror t " rear

"

Cn

^

\Figure 39 Threeviews of active acoustic

intensity

frommonopitchtirerunning

on smoothasphalt at56 km/hr.

Frequency

ranges are(a)

450 Hz. To550

Hz.(tread

passagefrequency),

(b)

900to 1100Hz.,

and(c)

1400 Hz.To

1600 Hz.Data

arereconstructed[14]

edge,and centerline ofthe

trailing

edge. Thespectrumwasdominatedby

theharmonicsofthetreadpassage events.Atthetreadpassage

frequency

of500Hz,

radiationfromthesidewalldominatedthesoundpower.Thisnoise wasmainly generated

by

the vibrationofthesidewall dueto theradial

(normal)

displacementofthe treadblocks passingthroughthecontact region. AtonekHzthenoiseisgenerated

by

thesamemeans,but has nearlyequal radiationalongthe

leading

edgetrailing

edge,andthe sideofthecontact patch.At1.5

kHz,

noise radiationis localizedtotheleading

andtrailing

edges.Theprobable causeofthisis vibrationenhanced

by

airpumpingandthe second mode ofthecircumfrentialFortheproduction

tire, less

radiationis observedfromthesidewall and morefromthe

leading

andtrailing

edges.Between 500 Hz and onekHzthefrequenciesincreasewithspeed,

showing

thatthey

are relatedto thetreadpassage events.Thesoundpoweris highest from

650

Hzto950Hz,

whichis probablyamplifiedby

thefirstmode ofcircumfrential groove resonance and air pumping.

Again,

thenoiseislikely

generated'

rear

s * i t.

ft

(b)

(c)

front

1

m

!vlFigure 40 Threeviews of activeacoustic

intensity

from

production tirerunning

onsmooth asphaltat56 km/hr.

Frequency

rangesare(a)

300

Hz.To 600

Hz.(tread

passage

frequency), (b)

650

Hz. to 950Hz.,

and(c)

1300Hz.

To1500 Hz. Data

arereconstructedon planes

touching

surface oftire.Contour lines

arein 2 dB.increments

beginning

at78

dB.Solid

contourlines are positiveanddashedlines

represent negative directionnormaltotheplane.[14]

[image:54.556.102.484.196.582.2]fromvibrations ofthe treadband duetoradial

(normal)

displacementofthe treadblockspassingthrough thecontact region atthe

leading

andtrailing

edges.Thesecond modeofthecircumfrentialgroove resonance canbeseeninthe

frequency

region from (1300 Hzto 1500 Hz). Ateven higher

frequencies,

generationis localizedto thecontact patch nearthe

leading

edge andmay becausedby

treadsbeing

forced intothecontact region.Chapter

X

-Patch

Frequency

Inthissection, a

dynamic

model of atireisdeveloped.

Thetire hasa radius('R')

inmeters, and angular speed

(to)

inradians/sec.Theouter circumferenceofthe tireisW

Trailing

Edge

Leading

Edge

Contact

Region

Figure 41

madeupof,

NPi

numberof patches. Apatch consists of atreadpattern anda gap.Thetotallengthofthepatch isthecircumfrential

length

ofthe tread(I)

plusthecircumfrentiallength ofthegap (y).

[image:56.556.123.445.199.435.2]I

Figure 42 Patch

Thenumber of patches on atire

(Np)

is thecircumference ofthe tiredividedby

thepatchlength. (This is always a wholenumber)

tire

circumference

2nR

Np

= =patch

length

/

+

y

The

frequency

ofpatches passingthrough thecontact regionistheangularspeedtimesthenumber of patchesdivided

by

theperiod,27t:fi)N

f

=J n

In

Another formofthisequationis:

VN

f,

= p2nR

In whichV is thevehicle speedandR isthe tireradius.

Frequencieswerethengraphedfor

increasing

speedsand agivenNp.

Tofindanappropriate rangeofangularvelocities,carspeeds, 0to 180

km/hr,

were chosenandconvertedtom/s.

Next,

aradius of.2159m(17")

waschosen;anywheelradius couldhave beenchosen.The speed wasthen convertedtoangularvelocity usingtheequation

(0=V/R, which has unitsofradians/second.

Next,

randomvaluesofNp

werechosenstarting from Np=10toNp=100. Thesegraphs showthelinearrelation betweenpatch

f(hz)

vs. N &W(rad/sec)

300000

250000

200000

r 150000

100000

50000

- N=10 -N=20

N=30 N=40 *-N=50 --N=60

+-N=70

N=80 N=90 N=100

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

[image:58.585.22.536.26.408.2]w(rad/sec)

Figure 43

Frequency

inHz. vs.AngularSpeed,

u)Theamplitudeofnoise producedfrompatches wouldbeafunctionofthedepthorlength

ofthe treads onthe tire. Thegreaterthe treadlengththegreatertheexcitationwhengoing

through thecontact region.

Chapter

XI

-Tire Bulge

When atireisrolling, thetirecarcass nearthecontact patchbulges out.

Figure 44

Theextentofthebulge dependsonthelateralstiffness,

KL,

ofthe tire. Itcanbeobservedthat themorebulgeatirehasthelouderthenoiseitradiates(flattire). Sincethe amount

ofbulge is

inversely

proportionalto thelateralstiffness ofthetire,theamplitude ofthenoiseisproportionalto tirebulge and

inversely

proportionalto thelateral stiffness.A

noise ~Tire

Bule

K

KL

ocItcan alsobesaidthat thelengthofthecontactregion,

Cp,

isinversely

proportionaltothelateralstiffness.

cp~

1

KL

Asimple analysis canbeusedtodeterminethe

frequency

ofthebulgewith varyingangulartirespeeds.

Figure45

Where: to=theangular speedofthe tire.

R=theradius to theoutside ofthe tire

Cp

= lengthof contact regionSp

=Arc lengthoftirewithincontact region0

=AngleofArcSp

Nsp

=numberofSp'spertireThearclength

Sp

equalsR*9 .Next,

usingthelaw ofcosines:2_td2 or.2

CP

=2R2-2R2cos(6)

Solving

for0,

9

=cos"1

(-CP2+2R2^

2R2

Substituting

intoSp,

Sp

f-Cp2+2R2^

2R2

V. J

Theamplitude of noiseis proportionalto thevelocityofthetire,whichisequalto the

tire'sangularvelocitytimes theradiusofthetire,

Ano,seoc^

=*^

In which ct)istheangularvelocityofthetire, R istheouterradius ofthetire, andV isthe

Chapter

XII

-The

Rubbing

Theory

Atirerubbingor

sliding

on a surfaceisanother source oftirenoise.Thiscanbeexplained

by

whati

![Figure 3 Filament arrangements that are used in pneumatic tires, a) woven cordb) weftlesscordc) Cord with light wefts [1] pg.360](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/16.556.168.365.534.664/figure-filament-arrangements-pneumatic-tires-woven-cordb-weftlesscordc.webp)

![Figure 7 Toroidal membrane on cylindrical rim [1] pg. 396](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/19.556.228.370.219.330/figure-toroidal-membrane-on-cylindrical-rim-pg.webp)

![Figure 10 Polar plot of radially outward component ofwall tension of membrane toroid on inner cylinder [1]pg.397](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/21.556.195.351.148.297/figure-polar-radially-outward-component-tension-membrane-cylinder.webp)

![Figure 14Load Effects on Tire Noise (dBA) [12] pg. 3](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/25.576.147.395.380.651/figure-load-effects-tire-noise-dba-pg.webp)

![Figure 16 Speed Effect on Tire Noise [12] pg. 5](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/26.556.76.487.156.569/figure-speed-effect-tire-noise-pg.webp)

![Figure 18 Tan Delta and Elastic Modulus [12] pg. 2](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/27.556.126.410.57.376/figure-tan-delta-and-elastic-modulus-pg.webp)

![Figure 20 Modulus Effects on Tire Road Noise (dBA) [12] pg. 6](https://thumb-us.123doks.com/thumbv2/123dok_us/123540.11974/29.556.52.509.204.427/figure-modulus-effects-tire-road-noise-dba-pg.webp)