Rapid assessment of wood chemical properties and pulp yield of Eucalyptus camaldulensis in Thailand tree plantations by near infrared spectroscopy for improving wood selection for high quality pulp

Full text

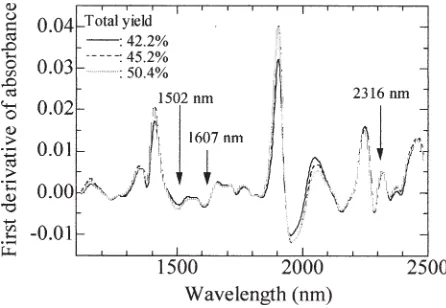

Figure

Related documents

Federal Government's Trust Framework Solutions, which enables government agencies to deliver citizen facing services in a secure and privacy respecting manner while utilizing

§ 424.14 and 424.20, the Center for Biological Diversity, Miami Blue Chapter of the North American Butterfly Association, South Florida Wildlands Association, Tropical Audubon

Joint Hypermobility Syndrome/Ehlers-Danlos Syndrome — Hypermobility Type (JHS/EDS-HT) is a complex and multisystemic condition which significantly impacts on a person ’ s health

49 The EU has capitalised on this possibility, creating an internal market for the trading of emission rights between companies in different Member States.. 3.2 The EU

The observed modulation of hepatic gene expression may explain the reduction of cholesterol level in the plasma possibly via an increased elimination as bile acid. They may also

And for the acting agents in the so called margins of the West, in former colonial societies, it makes little sense the established differences made by Hans Belting

Numerous different types of generalized ordinal models can be estimated by Williams’ gologit2 procedure, including the commonly used partial proportional odds model (PPO),

[r]