Enterprise Resource Planning and Integration

Karl Kurbel

European University - Frankfurt (Oder), Germany

IntroductIon

Enterprise resource planning (ERP) is a state-of-the-art

approach to running organizations with the help of com-prehensive information systems, providing support for key business processes and more general, for electronic

business (e-business). ERP has evolved from earlier ap -proaches, in particular, materials requirement planning

(MRP) and manufacturing resource planning (called MRP II) in the 1980s. The focus of MRP and MRP II was on manufacturing firms. The essential problem that MRP

attacked was to determine suitable quantities of all parts and materials needed to produce a given master

produc-tion schedule (also called a “producproduc-tion program”), plus

the dates and times when those quantities had to be

avail-able. Application packages for MRP have been available from the 1960s on. In the beginning, they were mostly provided by hardware vendors like IBM, Honeywell Bull, Digital Equipment, Siemens, etc. MRP was later expanded

to closed-loop MRP to include capacity planning, shop floor control, and purchasing, because as Oliver Wight (1884) puts it: “Knowing what material was needed was fine,

but if the capacity wasn’t available, the proper material

couldn’t be produced” (p. 48).

The next step in the evolution was MRP II (manufactur

-ing resource plann-ing). According to the father of MRP II,

Oliver Wight, top management involvement in the planning

is indispensable. Therefore, MRP II expands closed-loop MRP “to include the financial numbers that management

needs to run the business and a simulation capability”

(Wight, 1984, p. 54).

Enterprise resource planning (ERP) has its roots in the earlier MRP II concepts, but it extends those concepts

substantially into two directions. ERP takes into account that other types of enterprises than those producing physical

goods need comprehensive information system (IS) support

as well, and even in the manufacturing industry, there are more areas than those directly related to the production of goods that are critical for the success of a business.

Background oF erp

The key issue of ERP is integration (Langenwalter, 1999). While stand-alone solutions—sometimes quite

sophisticated information systems—for various areas of a

business have been available before, ERP takes a holistic approach. Instead of isolated views—on procurement, on manufacturing, on sales and distribution, on accounting, etc.—the focus is now on integrating those functional

ar-eas (Scheer & Habermann, 2000). The need for integrated systems has been recognized by many, but Germany-based SAP AG was the first to put them into reality. SAP’s early

success as worldwide market leader comes largely from the fact that this company actually designed and implemented business-wide integrated information systems. The lack of integration of information systems has created a variety of problems. The most serious ones are the following:

• Redundancy (i.e., the same information is stored and

maintained several times)

• Inconsistency (i.e., information about the same entity

stored in different places is not the same)

• Lack of integrity (i.e., databases where such informa

-tion is stored are not correct)

Mistakes, wrong decisions, and additional work are

some of the consequences resulting from these problems. Consider, for example, data about customers. Such data are often entered and maintained in a sales and

distribu-tion informadistribu-tion system (customer orders), then again in the dispatching system (delivery orders), and perhaps once more in a financial accounting system (invoices).

Not only is this redundant and means additional work, but also the same attributes may even stand for

differ-ent things. For example, an “address” field in the sales

and distribution system may represent the address of the customer’s procurement department, whereas “address” in the dispatching system is the place where the goods have to be delivered.

Integration of information systems can be considered from several perspectives: from the data, the functions, the operations, the processes, the methods, and the soft-ware perspectives. The most important aspects are data integration, operations integration, process integration, and software integration:

• Integration of data means that data models and

databases are unified so that all departments of an

enterprise use the same data entities, with the same values.

E

• Integration of operations requires connecting indi-vidual operations, or steps of a business process, with preceding or succeeding operations, respectively.

• Integration of processes means that interfaces between different business processes are explicitly considered (e.g., connections between order

pro-cessing and flow of material control).

• Integration of software means that different pro-grams (e.g., information systems for different busi-ness functions, can run together and use each other’s data and operations.

Those aspects of integration have always been considered important requirements for effective business information processing, but how does one actually obtain

enterprise-wide integrated information systems?

Because most organizations have been using information systems in various business areas for quite some time, one way is to integrate those stand-alone systems subsequently. This approach has been discussed and practiced under the concept of “software reengineering,” often related to the term “legacy systems” for the information systems to be

integrated (Miller, 1997; Seacord et al., 2003).

The other approach to obtain integrated information systems is obviously to start developing them from scratch. In such a situation, information structures can be modelled and designed on the drawing board in an enterprise-wide manner, at least in theory. Practical experiences have shown that developing comprehensive information systems for all areas of a business is a giant task. That is why such systems have rarely been developed as individual solutions. Not only is the investment needed very high, but also manpower and know-how to develop such systems are often beyond the means of a single company. Therefore, comprehensive integrated information systems have mostly been developed by dedicated software and consulting companies. In the 1970s and 1980s, those systems were named with rather general terms, like standard packages or integrated business information systems, until the terms “enterprise resource planning” and “ERP system” emerged in the 1990s. In fact, the term “enterprise resource planning” has been coined by the software industry and not by academia.

Today there is a common understanding of what the

term stands for. The definition used in this article is as

follows: An enterprise resource planning system (ERP

system) is a comprehensive information system that col -lects, processes, and provides information about all parts of an enterprise, automating business processes and busi-ness rules within and across busibusi-ness functions partly or completely.

Alternatively, an ERP system may be defined as a

set of integrated information systems rather than as one

enterprise-wide information system, with one database, and one common user interface. Nevertheless, such a system may be composed of many subsystems and many databases, as long as they are well integrated.

coMponents oF an erp systeM

horizontal and Vertical Views of

enterprise resource planning

An ERP system integrates information, processes, func-tions, and people into one coherent system (Brady et al.,

2001). Such a system supports all horizontal business

functions and all vertical levels of a business (operational,

tactical, and strategic). Figure 1 illustrates this view in a simplified information systems pyramid. Each component

may be seen as a functional subsystem. In a horizontal per-spective, systems are integrated along the value chain. The vertical direction asks for integration of operative sys-tems with their corresponding value-oriented accounting

systems; reporting and controlling systems; analysis and management information systems; and long-term planning and decision support systems (Scheer, 1994, p. 5).

A typical ERP system provides components like the

ones shown in Figure 1, arranged and extended in one way or

another. As an example of integrated information systems, the mySAP ERP system is described subsequently.

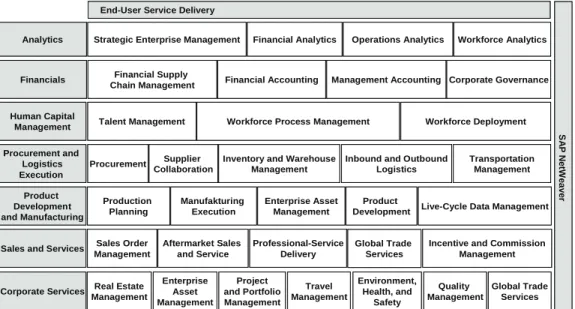

an example: sap erp

SAP ERP has evolved from SAP R/3 which is still the most frequently installed ERP system. SAP ERP is based on SAP

NetWeaver as technology platform (SAP, 2006b). Encom -passing all levels of the pyramid, SAP ERP is logically structured into the following modules (short descriptions

are taken from SAP, 2006a, 2006b):

Analytics

• Strategic enterprise management—Supports the top

level of the pyramid in Figure 1: integrated strategic

planning, performance monitoring, business

con-solidation, and stakeholder communication; provides

tools for planning and executing the strategies:

bal-anced scorecard, value-based management, financial

statement planning, risk management, investment planning, and more

• Business analytics (financial, operations, workforce analytics)—Supports managers with methods and tools for financial and management reporting, finan

-Figure 1. Integrated business information systems (Scheer, 1994, p. 5)

Production Engineering Purchasing MarketingSales/ Personnelplacement Inventory accounting Fixed-asset accounting Accounts

receivable accountingPersonnel

Pro duct ion cont rollin g Inve stm ent cont rollin g Pur chas ing P urch asin g IS Prod uctio n IS Inve stm ent IS Accounts payable Sa les and M ark eting IS Pe rsonn el IS C on tro lli ng Sa le s/ M ark eting co ntro lling Pe rso nn el co ntrolli ng

Long-term planning and decision-support systems

Analysis and information systems

Value-oriented job accounting systems Reporting and controlling systems

Quantity-oriented operative systems (administrative and scheduling systems)

Production Engineering Purchasing MarketingSales/ Personnelplacement Inventory accounting Fixed-asset accounting Accounts

receivable accountingPersonnel

Pro duct ion cont rollin g Inve stm ent cont rollin g Pur chas ing P urch asin g IS Prod uctio n IS Inve stm ent IS Accounts payable Sa les and M ark eting IS Pe rsonn el IS C on tro lli ng Sa le s/ M ark eting co ntro lling Pe rso nn el co ntrolli ng

Long-term planning and decision-support systems

Analysis and information systems

Value-oriented job accounting systems Reporting and controlling systems

Quantity-oriented operative systems (administrative and scheduling systems)

Figure 2. Application domains and modules of SAP ERP (SAP, 2006b)

analytics strategic enterprise Management Financial analytics operations analytics Workforce analytics Financials chain ManagementFinancial supply Financial accounting Management accounting corporate governance human capital

Management talent Management Workforce process Management Workforce deployment

procurement and logistics

execution procurement

supplier

collaboration Inventory and WarehouseManagement Inbound and outboundlogistics transportationManagement product

development and Manufacturing

production

planning Manufakturingexecution enterprise assetManagement live-cycle data Management sales and services sales orderManagement aftermarket sales and service global trade services Incentive and commissionManagement

corporate services product development professional-service delivery real estate Management enterprise asset Management project and portfolio Management environment, health, and safety Quality Management end-user service delivery

sa p n etW ea ve r global trade services travel Management

analytics strategic enterprise Management Financial analytics operations analytics Workforce analytics Financials chain ManagementFinancial supply Financial accounting Management accounting corporate governance human capital

Management talent Management Workforce process Management Workforce deployment

procurement and logistics

execution procurement

supplier

collaboration Inventory and WarehouseManagement Inbound and outboundlogistics transportationManagement product

development and Manufacturing

production

planning Manufakturingexecution enterprise assetManagement live-cycle data Management sales and services sales orderManagement aftermarket sales and service global trade services Incentive and commissionManagement

corporate services product development professional-service delivery real estate Management enterprise asset Management project and portfolio Management environment, health, and safety Quality Management end-user service delivery

sa p n etW ea ve r global trade services travel Management

E

overhead cost management, working capital and

cash-flow management, etc.; provides analytical

functions for procurement, inventory and warehouse management, manufacturing, transport, sales, cus-tomer service, quality management, enterprise asset management, program and project management,

and more. [In Figure 1, those functions, tools, and methods belong mostly to levels 2 (analysis and in

-formation systems) and 3 (reporting and controlling information systems).]

Financials

The Financials module supports several application areas

that are located on level 4 of the pyramid:

• Financial accounting: Processing of incoming and

outgoing payments, cash flows; provides general ledger, accounts receivable, accounts payable, fixed

assets accounting, inventory accounting, tax

ac-counting, financial statements, and more; helps to monitor financial transactions; supports business

analysis through combined planning, reporting, and analysis of competitive measures

• Managerial accounting: Provides profit center ac -counting, cost center and internal order ac-counting,

project accounting, product cost accounting, profit

-ability accounting; supports investment management,

revenue and cost planning, transfer pricing, etc.

• Financial supply chain management: Supports

financial collaboration within the enterprise and its business networks; provides credit management,

cash and liquidity management, treasury and risk management, and more

• Corporate governance: Helps to ensure that the objectives, rules and regulations under which the cor-poration is directed and controlled are being followed and met.

Human Resources

The human resources module is comprehensive, including functionalities of the operative, administrative level (level

5) and the value-oriented level (level 4).

• Talent management: Supports recruiting and talent management, performance management, compensa-tion management for various modes (e.g.,

perfor-mance- and competency-based pay)

• Workforce process management: Provides the

central repository for employee data; integrates the

information with other SAP business applications,

evaluating the working times and activities of

inter-nal and exterinter-nal employees); handles working-time

provisions determined by companies themselves, by

standard agreements, or required by law; handles all

payroll processes, supports current legal regulations

and collective agreement specifications, and ensures

compliance with regulatory changes

• Workforce deployment: Provides project resource planning, resource and program management (i.e., resource management, project portfolio

manage-ment, project execution, and skills management) and specific solutions for retail personnel and call

centers.

Procurement and Logistics Execution

This module supports the bottom level of the pyramid through quantity-oriented operative subsystems for daily operations, including support for planning and execu-tion.

• Purchase order management: Provides conversion from demands to purchase orders, issuance, and

con-firmation of purchase orders; supports purchasing of

materials and services (for example, subcontracting

for components)

• Supplier cooperation: Helps to streamline infor-mation supply and communication with and among suppliers

• Inventory and warehouse management: Comprises warehousing and storing (warehouse-internal

move-ments and storage of materials) and managing physical

inventory for the company’s own stocks (periodic,

continous, etc.)

• Inbound and outbound logistics: Supports inbound processing (all the steps of an external procurement

process that occur when the goods are received) and

outbound processing (all steps to prepare and ship goods to their destination)

• Transportation management: Provides

transpor-tation planning (routing, carrier selection, etc.) and execution (shipment orders), freight costing, and legal

services

Product Development and Manufacturing

With the help of this module, engineering and design, creating relevant product data, and planning and executing manufacturing operations are supported.

• Product planning: Provides typical MRP (materi

depending on buffers, operation times, lot-sizing rules and so on

• Manufacturing execution: Supports the process of capturing actual production information from the

shop floor to support production control and costing processes; supports a variety of concepts: make-to-order, repetitive manufacturing, flow manufactur

-ing, shop-floor manufactur-ing, lean manufactur-ing,

process manufacturing, and batch manufacturing

• Product development and life-cycle management:

Cover the life-cycle of product related master data such as product structures, routings and documents from invention to phase-out. Provide document man-agement, product structure management (including

bills of materials), recipe management, integration of CAD (computer-aided design), PDM (product data management), and GIS (geographical information system) data, and more.

Sales and Services

The Sales and service module addresses the customer focusing processes like selling products and services and providing aftermarket services.

• Sales order management: Supports quotation and order management (creating and processing orders, including pricing and scheduling orders for

fulfillment) including inquiries and follow-up orders;

provides mobile-sales, billing, and contract-manage-ment functionalities

• Aftermarket sales end service: Helps to manage a

customer’s product configuration (installation and configuration management, including definition of

the product hierarchy, management of serial num-bers, measurements, document management, and

engineering change management), service contracts,

planned services, warranties, and so on

• Professional-service delivery: Provides ca-pabilities for selling, planning, delivering and billing project-based services

• Incentive and commission management: Helps to design incentive compensation plans, calculate

vari-able compensation (e.g., direct sales commissions),

carry out evaluations of performance and cost results, and more.

Corporate Services

The Corporate Services module provides comprehensive support for resource-intensive corporate functions includ-ing the followinclud-ing:

• Real estate management: Provides tools to sup-port real-estate property acquisition and disposal, property portfolios, functions to help users lease and manage the real estate portfolio, etc.

• Project and portfolio: Provides functions for proj-ect (projproj-ect structures, costs, budgets, workforce

and resource planning, scheduling activities, etc.),

project execution (monitoring project progress analysis/earned value analysis, progress tracking,

etc.)

• Travel management: Provides functions for travel request and pre-trip approval, travel planning and online booking, travel expense management, ser-vices for mobile staff, and more

• Environment, health, and safety: Supports a variety of functions for product safety, handling of hazard-ous substances, transportation of dangerhazard-ous goods,

waste management, etc.; allows companies to take preventive care of their employees’ health; schedules medical examinations and testing for workers; man

-ages emissions for air, water, and soil; monitors and

controls plant emission sources.

• Quality management: Supports quality engineering according to the ISO 9000 standard, quality assurance and control (quality inspections, statistical process

control, traceability, etc.), quality improvement (audit

management according to ISO 19011, problem/com-plaint management, corrective and preventive action,

etc.)

This overview of components of the SAP ERP system illustrates the wide range of functions that support ERP nowadays. The reader interested in details of ERP func-tionality is encouraged to study the products’ Web sites. Descriptions of the above functions can be found in SAP’s

electronic and printed documentation (e.g., SAP, 2006a, 2006b). Other vendors’ ERP systems are outlined below.

the Market For erp

ERP systems have been around for about two decades now. All large and medium-size companies use such sys-tems today, and more small companies are catching up. Well-known ERP systems in use include R/3 Enterprise,

and SAP ERP (by SAP AG, Germany), Oracle’s E-Business Suite (by Oracle, USA), Microsoft Dynamics, and infor: COM (by Infor Global Solutions, formerly Germany, now USA). Well-known ERP systems such as iBaan Enterprise,

J.D. Edwards, PeopleSoft, Navision and many more have disappeared, either bought by competitors or gone up into other systems of the vendor.

E

Names and vendors are changing, as there is plenty

of dynamic in the ERP market. Mergers and acquisitions

and an ongoing market concentration can be observed year by year.

Although there is still a fairly large number of ERP vendors, a handful of them dominate the ERP market

worldwide. The global market leader by far is SAP AG from Walldorf (Germany). Followers are Oracle, Microsoft,

Infor, and Sage.

Future trends

While ERP continues to be the core of any integrated busi-ness software, the focus has shifted toward advanced user

support, like Business Intelligence (Biere, 2003) and Knowledge Management (Davenport et al., 1998; Earl, 2001), and inter-organizational support of electronic busi -ness, in particular, supply chain management and customer relationship management. As those areas are closely related to ERP, all major vendors have extended their systems to support them as well. Customer Relationship Management (CRM) is an approach to develop a coherent, integrated

view of all relationships a firm maintains with its existing and potential customers (Laudon, 2007, p. 59). Nowadays,

many channels are available for enterprises and customers to be in contact with each other: retail stores, telephone, e-mail, electronic shopping on the Web, mobile devices, etc.

CRM systems try to consolidate customer information from all those channels and integrate the firm’s diverse

customer-related processes.

The major focus of ERP is to support the internal busi-ness processes of an organization. However, busibusi-ness activities do not end at the limits of one’s own company. A natural extension of ERP is, therefore, supply chain manage -ment (SCM; Ayers, 2001). SCM looks at the organization’s

business partners, in particular at the suppliers and their suppliers. In addition, many methodological and technical shortcomings of ERP have been removed or at least

im-proved in SCM. Those improvements have been discussed

in the literature under “Advanced Planning and

Schedul-ing” (e.g., Meyr et al., 2002) and were implemented in SCM solutions by SCM vendors.

One example of such improvements is the use of opti-mization methods, like linear programming, mixed- integer programming, constraint propagation, and heuristics like genetic algorithms to solve production and distribution planning problems. Another example is pegging, i.e., cre-ating, maintaining, and evaluating relationships between purchasing orders, production orders, transportation or-ders, and customer orders across entire supply networks worldwide.

conclusIon

ERP is a comprehensive approach to running organizations with the help of computer-based information systems. Such systems, so-called ERP systems, support all major areas of a business. ERP systems are integrated systems, with respect to information, processes, functions, and people. Usually, those systems are very large, developed by

spe-cialized software firms. The worldwide market leader is, by far, Germany-based SAP AG, with its current systems

R/3 Enterprise and SAP ERP. Except for small enterprises, almost all of today’s companies use ERP systems for their ongoing business.

Extensions of ERP systems can be observed at the

former limits of ERP: in CRM, the focus is on dedicated customer support; the focus of SCM is to help organiza

-tions plan worldwide supplier–buyer networks and to act successfully within such networks; business intelligence

enables enterprises to behave in an “intelligent” way (e.g.,

addressing the most promising customers well-aimed);

knowledge management helps to formalize and preserve

important knowledge in an organization; and information

system support for key areas, like the before-mentioned areas, is provided both by ERP vendors and by specialized

software and consulting firms

reFerences

Arnold, R. S. (1993). Software reengineering. Los Alamitos,

CA: IEEE Computer Society Press.

Ayers, J. B. (2001). Handbook of supply chain manage -ment. Boca Raton, FL: St. Lucie Press.

Biere, M. (2003). Business intelligence for the enterprise. Upper Saddle River, NJ: Prentice Hall.

Brady, J., Monk, E. F., & Wagner, B. J. (2001). Concepts

in enterprise resource planning. Boston: Course Techno-logy.

Davenport, T. H., Delong, D. W., & Beers, M. C. (1998).

Successful knowledge management projects. Sloan Man

-agement Review, 39(2), 43–57.

Earl, M. (2001). Knowledge management strategies: To -ward a taxonomy. Journal of Management Information Systems, 18(1), 215-233.

Langenwalter, G. A. (1999). Enterprise resources planning and beyond: Integrating your entire organization. Boca

Raton, FL: Saint Lucie Press.

-Meyr, H., Wagner, M., & Rohde, J. (2002). Structure of

advanced planning systems. In H. Stadtler & C. Kilger

(Eds.), Supply chain management and advanced planning (2nded.) (pp. 99-104). New York: Springer.

Miller, H. (1997). Reengineering legacy software systems.

Woburn, MA: Digital Press.

SAP. (2006a). MySAP ERP—Solution overview. Walldorf,

Germany: SAP AG.

SAP. (2006b). MySAP ERP business maps. Retrieved July

2, 2006, from http://www50.sap.com/solutions/

businessmaps/

Scheer, A. -W. (1994). Business process engineering—Ref -erence models for industrial companies (2nded.). Berlin:

Springer.

Scheer, A. -W., & Habermann, F. (2000). Making ERP a

success. Communications of the ACM, 43(5), 57-61. Seacord, R. C., Plakosh, D., & Lewis, G. A. (2003).

Modern-izing Legacy Systems: Software technologies, engineer

-ing processes, and business practices. Reading, MA:

Addison-Wesley.

Wight, O. W. (1984). Manufacturing resource planning: MRP II. Unlocking America’s productivity potential

(re-vised ed. 1984). New York: John Wiley & Sons.

key terMs

Data Integration: Unifying data models and databases so that all departments of an enterprise use the same data entities, with the same values.

Enterprise Resource Planning (ERP): The current state-of-the-art approach to running organizations with the help of information systems that provide support for key business processes and, more general, for electronic

business (e-business).

ERP System (Enterprise Resource Planning Sys-tem): A comprehensive information system that collects, processes, and provides information about all parts of an enterprise, automating business processes and busi-ness rules within and across busibusi-ness functions, partly or completely.

Operations Integration: Creating logical connections of individual operations, or steps of a business process, with preceding or succeeding operations, respectively.

Process Integration: Defining and automating in -terfaces between different business processes explicitly.

SAP: Software company based in Walldorf (Germany);

market leader in ERP software worldwide. SAP is an

ab-breviation of the company’s German name “Systeme, An -wendungen, Produkte in der Datenverarbeitung” (systems,

applications, products in data processing).

Software Integration: Connecting different programs so that they can run together and use each other’s data and operations.