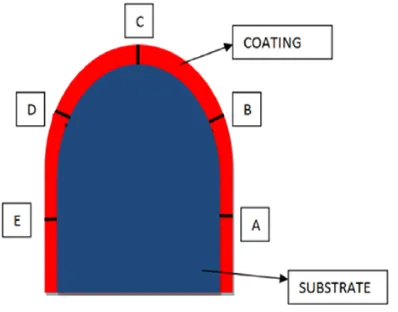

Abrasive wear failure analysis of tungsten carbide hard facing on carbon steel blade

Full text

Figure

Related documents

For analyzing the uniqueness of hand waving, we collect the waving action data from 200 distinct smart phone users.. The subjects producing these data sets are selected

For any Structural analysis, the evaluation of the stress- strain relationship of concrete is required. Though a number of expressions are available, yet it may not be

We propose an approach to biodiversity assessment for organisations implementing biodiversity conservation work in New Zealand that unifies (1) biodiversity conservation

Figure 31: Cropped horizon time map (top of basement) which is focused on the area of interest.. In order to have a good horizon interpretation, the interpretation was

The relative fluxes from the primary carbon pool to krill and salps were dependent on the carbon in each phytoplankton assemblage and transfer efficiencies

The molecular weight of rhsp10-His6 appeared to be lower than that of native serovar E/Bour chsp10 despite the fact that the recombinant protein migrated at the molecular mass of

ENGINE FEATURES • Reinforced beam • Automated Media registration pins 7 horizontal / 2 vertical • 2 separate controlable vacuum tables with each 4 vacuum compartments (total

Although the Department has an integrated financial system with the implementation of CAMS and the Corporate Database, there is still a need to look forward to ensure that it