2019 International Conference on Applied Mathematics, Modeling, Simulation and Optimization (AMMSO 2019) ISBN: 978-1-60595-631-2

Investigation on Arc Behavior of Interrupted Pulsed Argon Arc Welding

Jun-wei YANG

*, Ling-dong MENG, Qing ZHANG and Si-jie WANG

Army Academy of Armored Forces, Beijing, China *Corresponding author

Keywords: Interrupted pulsed argon arc welding, Arc behavior, Simulation.

Abstract. Interrupted pulsed argon arc welding and pulsed arc welding are different in principle, and their arc behavior is also different. According to the theory of magnetohydrodynamics and multi-physics coupling analysis finite element technology, this paper establishes a numerical analysis model of arc in micro-heat repair process, and obtains the distribution of parameters such as arc temperature field, velocity field and electromagnetic force and voltage in arc. The mechanism of the arc is analyzed, and the image signal of the arc change during the welding process is collected by the high-speed camera system, which is basically consistent with the simulation results.

Introduction

Interrupted pulsed argon arc welding is a new type of welding repair technology based on tungsten inert gas shielded welding. It uses a pulse-shunt DC pulse power supply to create a stable transient pulse arc between the tungsten electrode and the workpiece. This arc rapidly melts the base metal and fills the wire to form a molten pool, thereby achieving a metallurgical bond of the smaller heat affected zone.[1]

The energy concentration and short acting time of the Interrupted pulsed pulse argon arc welding make the metal in the heat-affected zone superheated, and the micro-heat recovery of the failed surface can be realized, and the deformation caused by the repair of the thin-walled parts can be effectively avoided. For its droplet transfer, the electric signal and arc resistance of the droplet transition arc are nonlinear, and the droplet size itself is statistically distributed. Studying the arc behavior has a very important influence on improving the repair quality.[2]

Simulation Analysis of Arc

According to the theory of magnetohydrodynamics and multi-physics coupling analysis finite element technology, the numerical analysis model of arc in the process of micro-heat repair is established. The distribution of parameters such as electromagnetic field and velocity in arc and the electromagnetic force and voltage in arc are obtained. And the mechanism of action of the arc.

Model Establishment

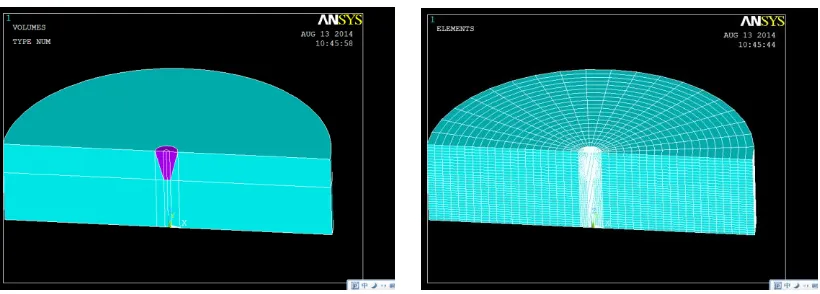

The established numerical analysis geometry model consists of two parts, the electrode and the arc zone, and the geometry is divided by the mapping method hexahedral element (Figure 1-2).

[image:1.595.94.504.630.777.2]

The multi-physics field includes the electric field, the magnetic field and the flow field, the temperature distribution result in the electric field is substituted into the flow field, and the current density distribution and the Joule heat distribution are solved; the magnetic field is responsible for calculating the electromagnetic force distribution; the flow field is responsible for solving the temperature distribution. The three physics fields are iteratively distributed until they converge.

Simulation Result Analysis

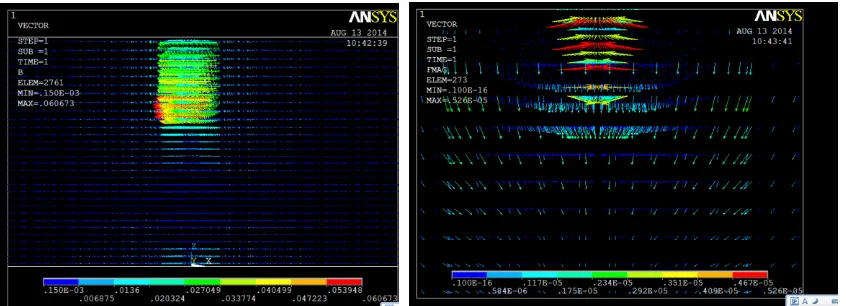

[image:2.595.83.512.229.380.2]Figure 3 shows the temperature field distribution over the entire area. The maximum temperature at the electrode attachment is about 25000 K. The high arc temperature causes the filler wire to melt rapidly.

Figure 4 shows the simulation results of the plasma flow velocity distribution.

Figure 3. Temperature field distribution. Figure 4. Plasma flow velocity distribution.

The plasma flows from the electrode to the workpiece, and a certain arc force is applied to the anode workpiece pool. The maximum flow rate is 386 m/s. The distribution of other parameters such as current density and geomagnetism of the arc is shown in Figures 5-10.

[image:2.595.80.515.446.768.2]

Figure 5. Current Density. Figure 6. Voltage.

Figure 9. Magnetic induction. Figure 10. Electromagnetic force distribution.

Using High-Speed Camera to Study the Arc Change Process

[image:3.595.153.460.402.581.2]The shape of the interrupted pulsed argon arc welding arc is taken by a high-speed camera method, and the shooting process is continuously performed during the arc combustion process to ensure the consistency of the welding parameters when the arc shape is photographed. During the interrupted pulsed argon arc welding process, the image of the welding area is filtered by the filter, transmitted to the computer by the high-speed camera, and recorded and saved. The laser provides the background light for the high-speed camera, and the aluminum foil is used to shield the electromagnetic signal generated by the pulse power of the repair machine. The high speed camera system is shown in Figure 11.[3]

Figure 11. High-speed camera system.

The high-speed camera of this system uses the Acuteye high-speed camera system CL600X2 from Germany Optronis. The high-speed camera system consists of a light source and illumination system, an imaging and high-speed photography system, a workbench, a high-speed data acquisition and display analysis system. Select the laser as the background light source. The laser has good directionality, and it is easy to use the small aperture diaphragm to eliminate the influence of arc and laser interference fringes. The laser generator has a laser power of 15 mW and a wavelength of 635 nm. According to the imaging characteristics and precision requirements of welding arc and droplet transfer, the Japanese Tamron and Nikon objective lenses are used as the core imaging system, covering the imaging magnification requirement of 1:10 to 1:1, working distance, optical resolution, The grayscale recognition range can meet the requirements.

It adopts automatic control mode and automatically repairs with micro-pulse repair machine. The pulse current is 170A, the pulse time is 0.05s, the argon flow rate is 5L/min, the welding torch speed is

Interrupted pulsed argon

arc welding Feeder Wire

Welding Gun

Workpiece Tungsten Electrode

Argon Gas

Optical Filter High-speed

3.25mm/min, and the tungsten pole distance is 1.2mm. Study the droplet transfer process during high-energy pulse welding under this condition.

Figure 12 is an image of a droplet transfer and arc process taken by a digital high speed camera, with (1) → (6) being a set of unfiltered background sources. The center wavelength of the interference bandpass filter is 46nm, the transmission width is about 1%, the peak transmittance is 50%; the image resolution is 1280*1024pixel, the dynamic range is 90dB, and the highest imaging speed is 100000 frames/s. Acquisition speed Set to 2000 frames/s; camera angle is 15°, and shooting distance is 200mm.

It can be seen from Fig. 12 that: (1)→(2) is the arcing phase, and there is no droplet at this time; the interval time is 0.5-1 ms, and the arcing time of the ordinary TIG welding is 8 ms, which is (3)→(5) It is the arc phase. At this time, the arc light is relatively strong, and the droplet transfer behavior cannot be observed, and the interval time is 52 ms. (5) → (6) is the arc extinguishing phase. At this stage, the droplets are shaken, spread out under the action of gravity and surface tension, and rapidly cooled and solidified to achieve metallurgical fusion.

[image:4.595.62.534.281.373.2]

(1) (2) (3) (4) (5) (6)

[image:4.595.224.372.481.590.2]Figure 12. Arc picture of the welding process obtained by high-speed camera.

Figure 13 shows the ordinary TIG arc profile [4] observed after filtering the arc radiation with a central wavelength of 484 nm filter, and the arc shape is a fan shape. The arc-breaking pulse argon-arc welding arc has an "apple" shape in the arcing stage and gradually becomes a triangle. Each pulse of arc-break pulse argon arc welding requires a "high-frequency high-voltage" pilot arc, so the arc surrounds the end of the electrode.

Figure 13. Ordinary TIG arc profile.

Discussion of Results

1. The simulation results show that there is a maximum temperature near the electrode, and the maximum temperature is about 2500 K. The high arc temperature causes the filler wire to melt rapidly. The electrode damage is relatively large during the actual experiment.

2. Each pulse in the welding process requires "high-frequency high-voltage" arc-starting, so it has a great influence on the shape of the arc and the distribution of temperature and magnetic field.

Acknowledgements

References

[1] Yang Junwei, Zhang Qing, Meng Lingdong: Laser-welding-like High-Pulse Precision Cold Repairing Used in the Repair of Casting Defects. Foundry Technology, Vol. 32 (2011), pp. 622-625.

[2] Zhang Qing, Meng Lingdong, Junwei Yang, etc.: High Energy Pulse Precision Cold -Welding Technology for Repairing Local Surface Default of Metal Parts. China Surface Engineering, Vol. 24 (2011), pp. 79-83.

[3] Junwei Yang, Jiaxu Teng, Xiaohui Zhang. Droplet Transfer Analysis of Intermittent Pulsed arc welding used to Repair the Metal Defects. Advanced Materials Research, Vol. 915-916 (2014), pp. 1078-1081.

![Figure 13 shows the ordinary TIG arc profile [4]arc-break pulse argon arc welding requires a "high-frequency high-voltage" pilot arc, so the arc central wavelength of 484 nm filter, and the arc shape is a fan shape](https://thumb-us.123doks.com/thumbv2/123dok_us/248167.1024722/4.595.224.372.481.590/figure-ordinary-welding-requires-frequency-voltage-central-wavelength.webp)