THERMAL STUDY OF A SUPERIOR LITHIUM ION POLYMER BATTERY

THERMAL STUDY OF A S

THERMAL STUDY OF A S

THERMAL STUDY OF A S

THERMAL STUDY OF A SUPERIOR LITHIUM ION

UPERIOR LITHIUM ION

UPERIOR LITHIUM ION POLYMER

UPERIOR LITHIUM ION

POLYMER

POLYMER

POLYMER

BATTERY

BATTERY

BATTERY

BATTERY

Eng. Andrei PRUTEANU, PhD Student1,.Eng. Vlad-Andrei SCARLATACHE PhD Student1,

Prof. Eng. Romeo Cristian CIOBANU PhD2, Eng. Georgiana VIZITEU PhD Student1 1

Gheorghe Asachi Technical University of Iaşi 2

S.C. Comfrac R&D Project Expert S.R.L. Bucharest

REZUMAT. REZUMAT. REZUMAT.

REZUMAT. Această lucrare prezintă o analiză a comportamentului termic a unei baterii litium ionAceastă lucrare prezintă o analiză a comportamentului termic a unei baterii litium ionAceastă lucrare prezintă o analiză a comportamentului termic a unei baterii litium ion----polimer, baterie Această lucrare prezintă o analiză a comportamentului termic a unei baterii litium ionpolimer, baterie polimer, baterie cepolimer, baterie cece este ceeste este este mai des utilizată în domeniul auto datorită densită

mai des utilizată în domeniul auto datorită densită mai des utilizată în domeniul auto datorită densită

mai des utilizată în domeniul auto datorită densităţţţţii sale ridicate de enerii sale ridicate de enerii sale ridicate de enerii sale ridicate de energie precum gie precum gie precum gie precum şşşşi a densităi a densităi a densităţţţţii de putere. i a densităii de putere. ii de putere. ii de putere. Comportamentul termic al bateriei constă în descrierea distribuţiei temperaturii utilizând diverse configuraţii ale Comportamentul termic al bateriei constă în descrierea distribuţiei temperaturii utilizând diverse configuraţii ale Comportamentul termic al bateriei constă în descrierea distribuţiei temperaturii utilizând diverse configuraţii ale Comportamentul termic al bateriei constă în descrierea distribuţiei temperaturii utilizând diverse configuraţii ale termocuplurilor şi o analiză termografică. A fost demonstrat că

termocuplurilor şi o analiză termografică. A fost demonstrat că termocuplurilor şi o analiză termografică. A fost demonstrat că

termocuplurilor şi o analiză termografică. A fost demonstrat că utilizândutilizândutilizândutilizând diverse configuraţii ale terdiverse configuraţii ale terdiverse configuraţii ale termocuplurilor diverse configuraţii ale termocuplurilor mocuplurilor se poate mocuplurilor se poate se poate se poate ob

ob ob

obţţţţineine distribuţiineinedistribuţidistribuţidistribuţia a a a temperaturii temperaturii temperaturii temperaturii pe suprafape suprafape suprafape suprafaţţţţaa baterieiaabaterieibateriei, precum bateriei, precum , precum şi influenţele , precum şi influenţele şi influenţele şi influenţele temperaturiitemperaturiitemperaturii asupra performanţei bateriei.temperaturiiasupra performanţei bateriei.asupra performanţei bateriei.asupra performanţei bateriei.

Cuvinte cheie: Cuvinte cheie: Cuvinte cheie:

Cuvinte cheie: comportament termic, Li-Ion polimer, distribuţia temperaturii

ABSTRACT. ABSTRACT. ABSTRACT.

ABSTRACT. This paper presents a thThis paper presents a thThis paper presents a thThis paper presents a thermal behavior analysis of a Liermal behavior analysis of a Liermal behavior analysis of a Liermal behavior analysis of a Li----ion polymer batteryion polymer batteryion polymer battery that is more often used in ion polymer battery that is more often used in that is more often used in that is more often used in automotive domain due to its high energy and power density. The thermal behavior of battery consists in describing the automotive domain due to its high energy and power density. The thermal behavior of battery consists in describing the automotive domain due to its high energy and power density. The thermal behavior of battery consists in describing the automotive domain due to its high energy and power density. The thermal behavior of battery consists in describing the temperature distribution using different configuratio

temperature distribution using different configuratio temperature distribution using different configuratio

temperature distribution using different configuration of n of n of thermocouples and a thermon of thermocouples and a thermothermocouples and a thermothermocouples and a thermographic analysis. It was shown that graphic analysis. It was shown that graphic analysis. It was shown that graphic analysis. It was shown that using different configuration of thermocouples reveals the distribution of battery temperature and the influence which this using different configuration of thermocouples reveals the distribution of battery temperature and the influence which this using different configuration of thermocouples reveals the distribution of battery temperature and the influence which this using different configuration of thermocouples reveals the distribution of battery temperature and the influence which this may have on its performance.

may have on its performance. may have on its performance. may have on its performance.

Keywords: Keywords: Keywords:

Keywords: thermal behavior, Li-Ion polymer, temperature distribution.

1. INTRODUCTION

The need to reduce the vehicle emissions combined with the decreasing oil resources has made automotive industry to find pure electric vehicles (EVs) in order to solve these global demands [1]. Electric vehicles depend on the batteries type [2] and improving the their life-time will reduce the runtime and the costs for the vehicle. Also, it is very important to know and manage the battery status, for achieving a better level of reliability and safety. Taking into consideration these aspects, it can be said that the battery performance, cost and life affect directly the life and performance of the electric vehicles. Therefore, the need to extend the battery lifetime and to use it at their full capacity, is of the most importance.

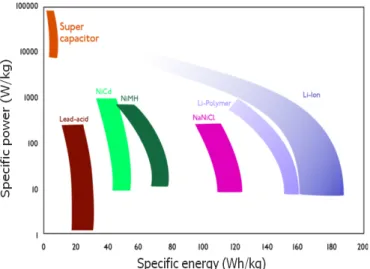

The most significant parameters of the battery technology for EVs are the power density and energy density. Power density is the amount of energy that can be provided in a time interval and energy density represents the capacity to store the energy. In Figure 1 are presented various storage devices with different energy and power. Thus, due to their high energy density, high voltage, good stability and slow loss of charge when are not used, Li-Ion polymer batteries are quiqly becoming the most used technologies for the

next generation of EVs industry. Also, these cells are very good for the high rate-of-discharge applications such as acceleration of EVs. Despite these positive aspects, which justify the recent spread of this technology, it is important to notice that during operation, Li-Ion polymer batteries must be carefully monitored and managed (electrically and thermally) for avoiding problems related to safety (inflammability) and performance [3].

The main parameter, the temperature, has also a

Fig. 1. Ragone chart comparing different storage devises incuding supercapacitors

WORLD ENERGY SYSTEM CONFERENCE – WESC 2012

important influence on the battery which can affect both the time life and energy of the battery, and automotive drive-ability and fuel economy. For these reasons the battery temperature should be within a temperature range which is considered optimum to achieve good performance and long life, for both use and storage. This temperature range differs between technologies and manufacturer. In Figure 2 is shown the impact of different temperatures on battery capacity.

Usually, batteries are grouped in packs when are used for EVs, so an uneven temperature distribution in a pack should be taking into account. This temperature deviation in a pack could drive to various charge/discharge behavior. Also, storing pack in a too hot or cold climate can affect them and cause a decrease in their total capacity shortening their shelf-life [4].

As it was described above, the battery temperature distribution is an important parameter for effective operation in all environments. Thus, many study have been made over the last years for the thermal management of battery for the EVs to find better active and passive, air and liquid cooling. For example in [5] it is examined a passive thermal management for EVs battery, consisting of embedded phase change material (PCM) which dissolves during an operation to absorb the heat obtained from the battery. In [6] is evaluate the thermal loss of a Li-ion battery for EVs based on electric parameters and experiments. In [7] a thermal management of a Li-ion battery pack is realized in order to observe the link between battery thermal comportment and design parameters.

This paper presents a thermal behavior analysis of a Li-ion polymer battery, which consists in describing the temperature distribution using different configuration of thermocouples and a thermographic analysis.

2. DESCRIPTION OF THE THERMAL

ANALYSIS TEST PROCEDURE

In order to study the battery temperature distribution, a thermal analysis was performed.

The test bench used for the thermal analysis of the Li-ion polymer battery consists in the following devices: a power supply, an electronic load, data acquisition and a environmental chamber. The first three devices are represented in a block diagram shown in Figure 3. The power supply is used to provide electricity for the entire test system. The electronic load is a device used to absorb the power produced and the acquisition system measures the parameters of interest (ex. temperature) and converts it into an electrical signal and also provides data storage (DAQ). All these components are linked together through GPIB interface (General Purpose Interface Bus) that allows the communication with a computer for their programming and control.

Fig. 3. The block diagram used for the experimental results.

Fig. 2. The various characteristics of capacity affected by the

Fig. 4. Inside of environmental chamber during testing to an

_____________________________________________________________________________________

WORLD ENERGY SYSTEM CONFERENCE - WESC

THERMAL STUDY OF A SUPERIOR LITHIUM ION POLYMER BATTERY

For thermal conditioning it is use the environmental chamber, which is a device that simulates an environment with different temperature and humidity as shown in Figure 4 The device allows running tests for temperatures ranging between -40˚C to +100˚C with a humidity gamma modification from 15% to 98%. In general, these chambers are used in the industries domain and mostly useful for testing of electronic components to see how they perform in different kinds of conditions and to identify manufacturing flaws and weaknesses.

All the devices described above (Figure 3), are connected to a computer for both control and management and for data storing and processing. The software used to make this connection is the LabVIEW program, provided by National Instruments.

The battery technical specifications used for the experimental tests in this paper are listed in the Table 1. The battery has a specific shape, also named pouch cell with a capacity of 41 Ah, a rated voltage of 3,7 V with an approximate weight of 1030g. It can be observed that the thickness of the battery is approximately twenty times less than the other dimensions (length and width).

For the thermal analysis, different configurations with several thermocouples were placed on both battery outer surfaces and also on the contacts and supply cables, in order to determine their temperature distribution.

The configuration presented in Figure 5 shows the first arrangement of thermocouples on the battery. This configuration with a large number of sensors, has allowed the evaluation of the temperature difference along the battery outer surfaces.

Table 1

Technical specification of the battery

For this arrangement it was observed that the most significant heat peaks occur at higher values of discharge current.

In order to find the optimal number of sensors (thermocouples) that can be placed on the battery which can provide significant results and can reveal the hottest zones of the battery considering also external contacts and power cables a new configuration (case I) was realized as shown in Figure 6.

This arrangement provides different results, for the sensors placed in the same area, similar to the one from Figure 5.

In Figure 7 is presented the evolution of the discharge current of the battery for Case I. The most important change in this case refers to the power cables heating, at which were placed sensors T6 and T12 and to the external contacts warming, where sensors T2 and T14 were attach. It was seen that even if the external contacts are metallic and heat up rapidly, their warming does not have a major influence over the temperature of the battery body as shown in Figure 8.

It was notice that it would be better to positioned the external contacts on both opposite sides of the battery,

Parameters Values Cell Dimension Length: Max. 223 mm Width: Max. 213mm Thickness: Max. 10,6mm Weight Max. 1030 g

Capacity Tip. 41 Ah, Min. 40 Ah

Voltage 3,7 V

Upper limit voltage 4,16 ± 0,03 V

Lower limit voltage 3 V

Operation Temperature Range

Charge: 11 ÷ 45 °C

Discharge: -21 ÷ 56 °C

Max. Cont. Discharge Current 320 A

Max. Cont. Charge Current 120 A

Fig. 5. Distribution of thermocouples on faces of the cell:front side respectively, back side.

Fig. 6. First arrangement of thermocuples distribution including power cables (Case I).

WORLD ENERGY SYSTEM CONFERENCE – WESC 2012

in order to make more uniform the battery temperature level.

The second arrangement for power cables (Case II) is realized by placing sensors only on the most significant thermal zones like in Figure 9. Due to this simplified configuration, in Figure 10 are presented the temperature evolution and the current characteristics and it can be observed that the discharge current is increased until it reaches the value of 320 A.

Then, for the same discharge current (120 A), for both Case I and Case II, it was observed that for the Case I the T14 indicates a maximum temperature of 37,5°C and for Case II, T2 indicates only approx. 30°C. For Case I, the high temperature of T14, occurs due to the power cables warming and in Case II, the power cables warming influence less the external contacts of the battery. The both thermocouples T14 and T2, mentioned above, are positioned on the positive battery contact. At a high value of discharge current (320 A), it can be observed (Figure 10) that the T2 reaches a temperature value more than 80°C. Thus, for a better temperature distribution it is indicated to increase the number of power cables at the battery positive external contact.

In Figure 11 it is shown the temperature distribution for the entirely surface of the battery where it can be seen better that the highest heating zone appears near the battery positive contact.

3. DESCRIPTION OF THERMOGRAPHIC

ANALYSIS

The thermographic analysis, made through the use of thermal cameras, detects the radiation in the infrared range of the electromagnetic spectrum (from 9 to 14 nanometers), producing images that are called thermograms. Because infrared radiation is emitted by all objects in environment conditions, according to the

Fig. 11. Temperature distribution on the outer surface of the Li ion polymer battery

Fig. 8. Temperature evolution depending by the second arrangement of thermocouples

Fig. 9. Second arrangement of thermocuples distribution including power cables (Case II).

Fig. 10. Evolution of discharge current (max. 320A) and

Fig. 7. Evolution of the discharge current of the battery.

THERMAL STUDY OF A SUPERIOR LITHIUM ION POLYMER BATTERY

these radiation which otherwise, will be invisible to the human eye. The amount of radiation emitted by an object increases with temperature.

Emissivity is the ability of an object to emit thermal radiation. Mainly, the range variation of emissivity is from 0 (complete absence of emission) to 1 (complete emission). This property varies according to the variation of the temperature, making it very difficult to identify a value for the complex objects and varied as a battery.

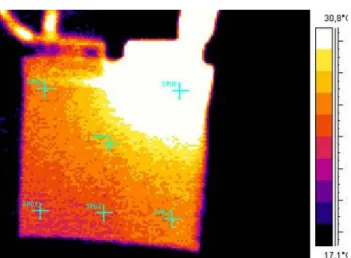

In the tests conducted it has been supposed an emissivity with a value of 0.5 for the battery. Referring to Figure 12 is important to note that, since it is possible to setup the instrument to a single value of emissivity at a time, only the temperatures that refer to the surface of the battery are significant, therefore the color scale refers only to these. The observed values for the black background, electrodes and cables, are not significant, because they are objects with different emissivity values. Based on the data obtained experimental, in

Figure 13 it is shown the temperature evolution, which refers to the temperature at the center of the surface of the battery. It is possible to say that there is similarity

with the values obtained with the other measurement techniques (using thermocouple T8), that confirm the emissivity value chosen is reasonably close to real.

4. CONCLUSIONS

This paper presents a thermal behavior analysis of a Li-ion polymer battery where the main concern its represented by the difference of temperature distribution along the outer surface of the battery.

The results obtained regarding the heat distribution on the outer surface of the battery indicates a several concerns related to construction of cells, especially the positioning of the external contacts. Therefore, from the thermal point of view, it was notice that it would be better to positioned the external contacts on both opposite sides of the battery, in order to make more uniform the battery temperature level.

A study regarding the heating module-level of the battery pack should be performed for further investigations, due to the fact that usually, when are used for electric vehicle the batteries are used being connected in series/parallel.

ACKNOWLEDGMENT

This work was supported by:-EURODOC “Doctoral Scholarships for research performance at European level” project, financed by the European Social Found and Romanian Government. - Project MNT-ERA.NET 2011 with acronym CarPolCap.

BIBLIOGRAPHY

[1]Teratani, Tatsuo, et al. Energy-saving Technologies for

Automobiles. s.l. : Wiley InterScience, 2007

[2]Sun Kai, Shu Qifang, Overview of the types of battery

models, Control conference (CCC), 2011

[3]Yinjiao Xing, Qiang Miao, K. L. Tsui, M. Pecht, Prognostics

and health monitoring for lithium-ion battery, IEEE Intelligence

and Security Informatics, 2011

[4]Lewis, Richard. Sax's Dangerous Properties of Industrial

Materials, John Wiley & Sons, 2004

[5]M. Y. Ramandi, I. Dincer, G.F. Naterer, Heat transfer and

thermal management of electric vehicle batteries with phase

change materials, Heat Mass Transfer, 2011

[6]C. Mi, Li Ben, D. Buck, N. Ota, Advanced Electro-thermal

Modeling of Lithium-Ion Battery System for Hybrid Electric

Vehicle Applications, Vehicle Power and Propulsion Conference

IEEE, 2008

[7]G. Karimi, X. Li, Thermal management of lithium-ion batteries for

electric vehicles, International Journal of Energy Research, 2012

Fig. 13. Temperature evolution during the life cycle, based on the detection of the thermocamera

Fig. 12. Capture of a thermogram of the Li-ion polymer battery

WORLD ENERGY SYSTEM CONFERENCE – WESC 2012

About the authors

Eng. Andrei PRUTEANU,

Gheorghe Asachi" Technical University of Iasi

email:apruteanu@ee.tuiasi.ro

Was born in Iasi, Romania in 1985. He received B.Sc. in 2009 and M.Sc. degrees in Information Systems for Environment Monitoring in 2010 both from the Faculty of Electrical Engineering from the „Gheorghe Asachi” Technical University of Iasi. Since October 2009 he is a PhD Student at „Gheorghe Asachi” Technical University of Iasi, Faculty of Electrical Engineering at Department of Electrical Measurements and Materials. His main research is related to new energy materials for batteries, supercapacitors and dielectric analysis.

Eng. Vlad-Andrei SCARLATACHE, Gheorghe Asachi" Technical University of Iasi

email:vscarlatache@ee.tuiasi.ro

Was born in Bîrlad, Vaslui, Romania in 1985. He received B.Sc. in Electrical Engineering Specialization from the Technical University “Gheorghe Asachi” of Iasi in 2009, and M.Sc. studies in Information Systems for Environment Monitoring from the Technical University “Gheorghe Asachi” of Iasi in 2010. Since October 2009 he is a PhD Student at Technical University “Gheorghe Asachi” of Iasi, Faculty of Electrical Engineering, Department of Electrical Measurements and Materials.

Prof. Eng. Romeo Cristian CIOBANU, PhD, S.C. Comfrac R&D Project Expert S.R.L. Bucharest

email:rciobanu@yahoo.com

Was born in Piatra-Neamt, Romania, in 1961. He received a PhD degree in Electrical Engineering from the University Politehnica of Bucharest and a PhD degree in Chemistry from the Technical University of Iasi. He is currently a Professor at the Technical University of Iasi, Electrical Engineering Department. His research focuses on Industrial Diagnosis, Dielectric Measurements, Quality and Maintenance, Composite Technologies.

Eng. Georgiana VIZITEU,

Gheorghe Asachi" Technical University of Iasi

email:gviziteu@ee.tuiasi.ro

Was born in Vaslui, Romania in 1985. She received B.Sc. in Electrical Engineering Specialization from the Technical University “Gheorghe Asachi” of Iasi in 2009, and M.Sc. studies in Energy Management Systems from the Technical University “Gheorghe Asachi” of Iasi in 2010. Since October 2010 she is a PhD Student at Technical University “Gheorghe Asachi” of Iasi, Faculty of Electrical Engineering, Department of Electrical Measurements and Materials.