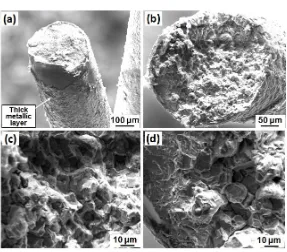

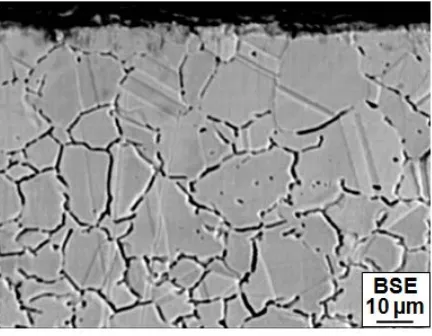

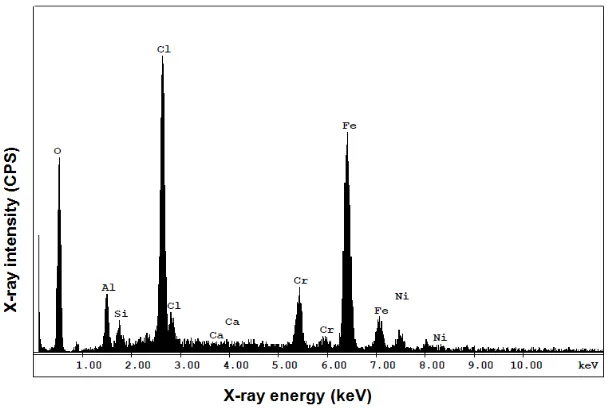

Failure Analysis of Stainless Steel Lanyard Wire Rope

Full text

Figure

Related documents

With the reported high levels of anxiety in BMS patient populations and the increasing use of the Internet for health information, the aims of this study

Via phone number above company contact channel guide magazine subscription to collect submissions from our support team provides support. Know if you can subscribe to know more

owner occupiers. 3) Alternative property provision for owner occupiers. Through the Joint Working Group, arrangements were made for home owners to swap houses. In

At low temperatures, the transport in a-Si:H is dominated by hopping conduction of electrons and holes via their respective tail states, as was concluded from the low-

(CFE-DMHA): An Assessment of Roles and Missions,”RAND Corporation, 2016.. The predictions of bureaucratic theory roughly match the character of the learning observed in OUA.

The goal of the present study was to develop a strategy for designing anatomy-based algorithms for multiple anatomic sites. Although the spectral prop- erties of different

The coupling of this factual assertion, however, with the statement that those experiences give the firm's attorneys "unique perspective" in representing clients before

23) 27 PERMANENT MAGNETS MOUNTED INSIDE PARTS #22, EACH BEING 3½" LONG, 2" WIDE, ¼" THICK. A very special coil and water charging event takes place as these magnets