Technology of Making Tablets

Advantages

• Production aspectProduction aspect

– Large scale production at Large scale production at lowest cost

lowest cost

– Easiest and cheapest to Easiest and cheapest to package and ship

package and ship – High stabilityHigh stability

• User aspect (doctor, User aspect (doctor, pharmacist, patient) pharmacist, patient) – Easy to handlingEasy to handling

– Lightest and most compactLightest and most compact – Greatest dose precision & Greatest dose precision &

Disadvantages

• Some drugs resist Some drugs resist

compression into dense compression into dense compacts

compacts

• Drugs with poor wetting, slow Drugs with poor wetting, slow dissolution, intermediate to dissolution, intermediate to large dosages may be difficult large dosages may be difficult or impossible to formulate and or impossible to formulate and manufacture as a tablet that manufacture as a tablet that provide adequate or full drug provide adequate or full drug bioavailability

bioavailability

• Bitter taste drugs, drugs with Bitter taste drugs, drugs with an objectionable odor, or an objectionable odor, or

Types of tablets

• 1)compressed tablets

• 2)sugar coated tablets

• 3)film coated tablets

• 4)enteric coated tablets

• 5)effervescent tablets

• 6)chewable tablets

• 7)dispersible tablets

• 9)multilayer tablets

• 10)sublingual tablets

• 11)toroches

• 12)buccal tablets

• 13)implant tablets

• 14)hypodermic tablets

• 15)solution tabletc

EXCIPIENTS FOR COMPRESSED

TABLETS

A. DILUENTS

Diluents increase the volume to a formulation to

prepare tablets of the desired size. Widely used

fillers are lactose, dextrin, microcrystalline

cellu-lose starch, pregelatinized starch, powdered

• The diluent is selected based on various factors, such as the experience of the manufacturer in the preparation of other tablets, its cost, and compatibility with other

formulation ingredients. For example, in the preparation of tablets or capsules of tetracycline antibiotics, a

calcium salt should not be used as a diluent since

B.BINDERS

Examples of Binders Carboxymethylcellulose, sodium Karaya gum

Cellulose,microcrystalline(Avicel®) Starch, pregelatinized

Ethylcellulose Tragacanth gum

Hydroxypropyl methylcellulose Poly(acrylic acid)

Methylcellulose Polypvinylpyrrolidone

Acacia gum Gelatin

Agar Dextrin

Algin acid Glucose

C. LUBRICANTS

• Lubricant is a substance capable of reducing or

preventing friction, heat, and wear when introduced as a film between solid surfaces. It works by coating on the surface of particles, and thus preventing adhesion of the tablet material to the dies and punches.

• 1. Lubricants improve the flow of granules in the hopper to the die cavity.

• 2. Lubricants prevent sticking of tablet formulation to the punches and dies during formulation.

• 3. Lubricants reduce the friction between the tablet and the die wall during the tablet’s ejection from the tablet machine.

D. DISINTEGRATORS

•

The breakup of the tablets to smaller particles is important for dissolution of the drug and subsequent bioavailability.Disintegrators promote such breakup. To rupture or breakup of tablets, disintegrating agents must swell or expand on exposure to aqueous solution. Thus, the most effective disintegrating agents in most tablet systems are those with the highest wa-ter uptake

E. WETTING AGENTS

• Water molecules attract each other equally in all directions. Water

molecules on the surface, however, can only be pulled into the bulk water by water molecules underneath, since there are no water molecules to pull in the opposite direction. The surface tension of water is strong

enough to support the weight of tiny insects such as water striders. The surface ten-sion in action can be visualized by placing a small drop of alcohol on a thin layer of water. Alcohol with lower surface tension mixes with water causing reduction in the surface tension in the local region. Owing to the higher surface tension of water in the neighbor, water is

Compressed tablet manufacture

•The classification of manufacturing methods

wet granulation: suitable for drugs that are stable to moistur e and heat

dry granulation: suitable for drugs that are sensitive to moi sture and heat

powder compression : suitable for drugs that are sensitive to moisture and heat, fill material possessing, good flowabilit

granulation

drug

excipients

smash sieving mix

adhesive

prilling

dry processing granule

lubricant

mix press

dry granulation

drug

excipient

smash sieving mix press

cake smash

processing granule

adhesive

drugs

excipients

smash sieving mix

adhesive

mix press

•

crystal compression

drugs

excipients

smash sieving

mix mix press

• wet granulation technology

• ( 一 )wet granulation methods and equipment:

Compressed tablet manufacture

—— wet granulation

• The steps of wet granulation

weighing and blending the ingredients(disintegrant)

preparing a damp mass

screening the damp mass into pellets or granules

drying the granulation

sizing the granulation by dry screening

adding lubricant and disintegrant, and blending

tableting by compression

(liquid binder)

Internal( 内加

法 )

External( 外加

The classification of tablet presses

• Tablet presses:

a. single-punch presses

The main components of single-punch

tablet presses

h o p p e r

f e e d s h o e

l o w e r p u n c h d i e

u p p e r p u n c h

t a b l e t w e i g h t a d j u s t o r

t a b l e t e j e c t o r a d j u s t o r

t a b l e t h a r d n e s s a d j u s t o r

S c h e m a t i c d i a g r a m o f t h e m a i n

c o m p o n e n t s o f s i n g l e - p u n c h p r e s s d i e

c a v i t y

Core components: die

The basic mechanical process of tableting

with single-punch presses

a) filling material

b) scraping away the excessive granulation

c) forming a tablet by compression

d) pushing up the tablet to stage surface

e) shoving the tablet aside

u p p e r p u n c h

d ie lo w e r

p u n c h

ta b le t

fill m a te ria l

a ) b ) c )

A picture of multi-station rotary press

Z P 1 9 r o t a r y t a b l e t p r e s s

hopper feed-frame

head: upper turret, lower turret, die table

The core components and compression

cycle of rotary presses

A: upper punch B: die cavity C: die

D: lower punch

The compression is applied by both the upper punch and the lower punch.

Compressed tablet manufacture

—— Direct compression tableting

Suitable for

1) granular chemicals possessing free flowing and cohesive properties

e.g. potassium chloride

2) chemicals added with special pharmaceutical

The direct compression tableting excipients include:

a) fillers, as spray-dried lactose, microcrystals of alphamonohydrate lacto

se, sucroseinvert ,sugar – corn starch mixtures, microcrystalline cellulos

e, crystalline malt and dicalcium phosphate;

d) disintegrants, as direct-compression starch, sodium carboxymethyl star

ch, cross-linked carboxymethylcellulose fiber, and cross-linked polyvinyl

powder of sophora

AIopecuroides L . Seed mix 制软材

prilling 、

processing granule

mix

press

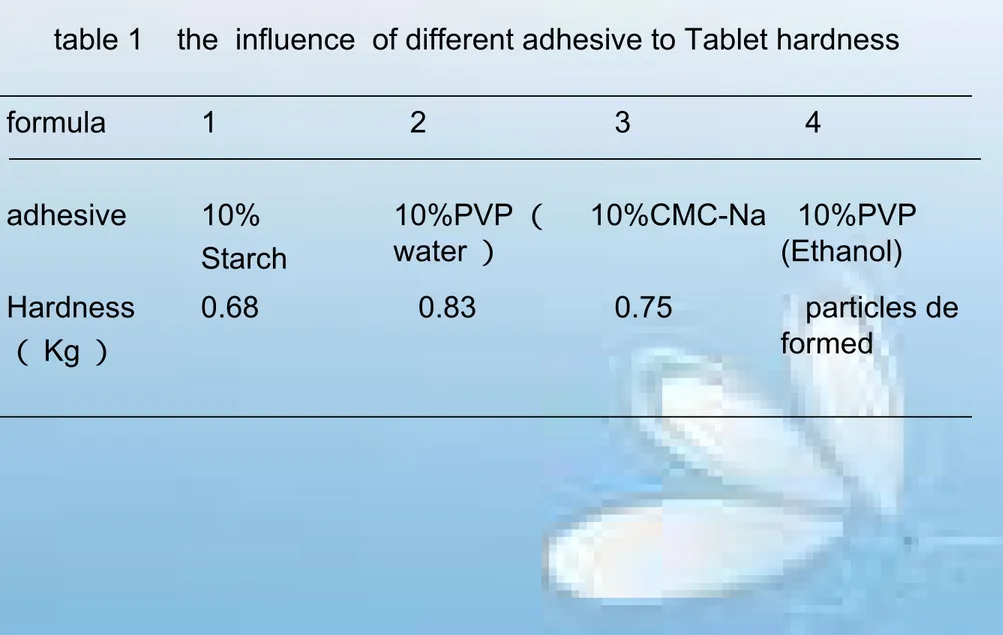

table 1 the influence of different adhesive to Tablet hardness

formula 1 2 3 4

adhesive 10%

Starch

10%PVP ( water )

10%CMC-Na 10%PVP (Ethanol)

Hardness

( Kg )

0.68 0.83 0.75 particles de

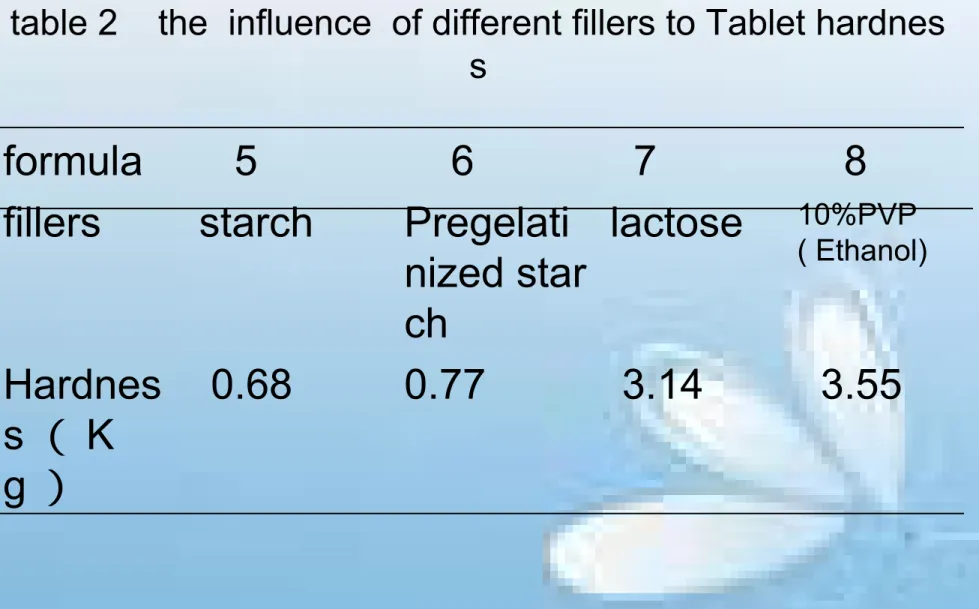

table 2 the influence of different fillers to Tablet hardnes s

formula

5

6

7

8

fillers

starch

Pregelati

nized star

ch

lactose

10%PVP( Ethanol)

Hardnes

s

(

K

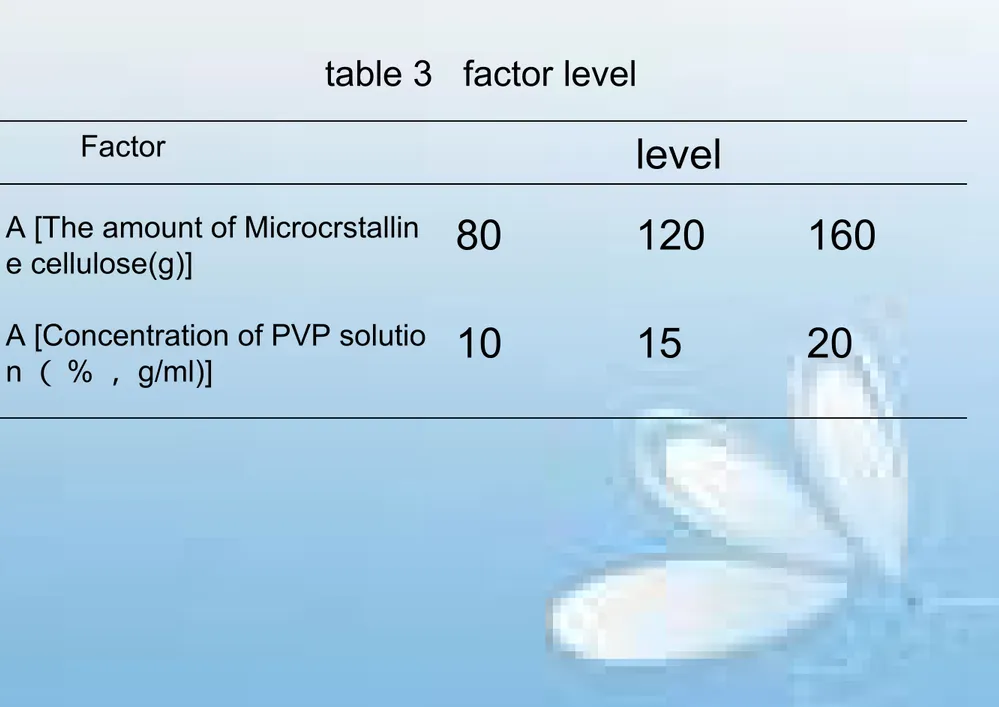

table 3 factor level

Factor

level

A [The amount of Microcrstallin

e cellulose(g)]

80

120

160

A [Concentration of PVP solutio

table 4 Result of Orthogonal test

Test NO. A B

A×B Result 1 2

Ⅰ Ⅱ Total

1 2 3 4 5 6 7 8 9 K1 K2 1 1 1 2 2 2 3 3 3 17.8 24.2 1 2 3 1 2 3 1 2 3 23.0 21.8 1 2 3 2 3 1 3 1 2 21.4 22.5 1 2 3 3 1 2 2 3 1 22.2 22.0

3.1 2.9 6.0 2.8 3.1 5.9 3.2 2.7 5.9 4.1 4.4 8.5 4.0 4.1 8.1 4.2 3.4 8.5 4.0 3.8 7.8

table5 Analysis of variance table

variance source SS V MS F P

total variance 5.658

A 4.698 2 2.349 33.562 0.0001

B 0.191 2 0.096 1.366 0.3034

A×B 0.139 4 0.035 0.993 0.4077

table 6 微晶纤维素用量影响苦豆子片硬度的q检验(n=6)

Comparison group

两均数之

差 standard value of q error

Number of

group α =0.05 α= 0.01

P

A1andA3 -1.1 0.1074 -10.241 3 4.34 6.33 <0.01

A1andA2 -1.0 0.1074 -9.310 2 3.46 5.24 <0.01

Tablet coating

The reasons for tablet coating

1) to protect the medicinal agent against destructive exposure to air and/or humidity;

2) to mask the taste of the drug;

3) to provide special characteristics of drug release;

4) to provide aesthetics or distinction to the product;

The general methods involved in coating tablets are as follows

1) sugarcoating tablets

2) film-coating tablets

3) enteric coating

4) pan coating

The sugarcoating of tablets may be divided into the following steps:

1) waterproofing and sealing (if needed)

2) subcoating

3) smoothing and final rounding

4) finishing and coloring (if desired)

—— —— —— —— ——

1) waterproofing and sealing (if needed)

aim: to prevent the components from being adversely affected by moisture; one or more coats; shellac , zein , or a polymer

as cellulose acetate phthalate

2) Subcoating aim: to bond the sugar coating to the tablet and provide rounding

b) When the tablets are partially dry they are sprinkled with a dusting powder, usually a mixture of powdered sugar and starch but sometimes talc, acacia, or precipitated chalk as well.

3) smoothing and final rounding

aim: to complete the rounding and smooth the coatings

5 to 10 additional coatings of a thick syrup; This syrup is sucrose-based with or without additional components as starch and calcium carbonate.

4) finishing and coloring

5) imprinting

aim: to impart identification codes and other distinctive symbols to the product

The imprint may be debossed, embossed, engraved, or printed on the surface with ink.

6) polishing

aim: to render the tablets the desired sheen/gloss/luster

a) pans lined with canvas cloth impregnated with carnauba waxand/or beeswax

b) Pieces of wax may be placed in a polishing pan

Tablet coating

——

film-coating tablets

1) The disadvantages of sugarcoating process

a) time-consuming

b) requiring the expertise of highly skilled technicians

c) doubling the size and weight of the original uncoated tablets

d) may vary in size from batch to batch and within a batch

2) The advantages of film-coating process

a) coated tablets having essentially the same weight, shape, and size as the originally compressed tablet

b) The coating is thin enough to reveal any identifying monograms.

c) far more resistant to destruction by abrasion than are sugar-coated tablets

3) The components of nonaqueous film-coating solutions: a) film former: e.g. CAP

b) alloying substance: to provide water solubility or permeability to the film e.g. PEG

c) plasticizer: to render flexibility and elasticity to the coating e.g. castor oil

d) surfactant: to enhance spreadability of the film e.g. polyoxyethylene sorbitan derivatives

e) opaquants and colorants: e.g. titanium dioxide, FD&C or D&C dyes

4) The components of a typical aqueous film-coating solutions:

a) film-forming polymer (7-18%): e.g. cellulose ether polymers as HPMC, HPC and MC

b) plasticizer (0.5-2.0%): e.g. glycerin, propylene glycol, PEG, diethyl phthalate, and dibutyl subacetate

c) colorant and opacifier (2.5-8%): FD&C or D&C lakes and iron oxide pigments

5) Some problems with aqueous film-coating

a) picking and peeling the appearance of small amounts or large am ounts of film fragments flaking from the tablet surface

b) orange peel effect roughness of the tablet surface due to failure of spray droplets to coalesce

c) mottling an uneven distribution of color on the tablet surface d) bridging

filling-in of the score-line or indented logo on the tablet by the film e) tablet erosion

5) Some problems with aqueous film-coating

a) picking and peeling the appearance of small amounts or large am ounts of film fragments flaking from the tablet surface

b) orange peel effect roughness of the tablet surface due to failure of spray droplets to coalesce

c) mottling an uneven distribution of color on the tablet surface d) bridging

filling-in of the score-line or indented logo on the tablet by the film e) tablet erosion

The reasons for capping,

splitting or laminating of

tablets

1) air entrapment

2) not immaculately cleaned or not perfectly smoothed punches

3) too great a proportion of fine powder

quality standards and compendial

requirements

The apparent physical features of compressed tablets:

1) shape: round, oblong, unique 2) thickness: thick or thin 3) diameter: large or small 4) flat or convex

5) unscored or scored in halves, thirds and quadrants

6) engraved or imprinted with an identifying symbol and/or code number 7) coated or uncoated 8)colored or uncolored 9) number of layer.

quality standards and compendial

requirements

Other physical specifications and quality standards:

tablet weight weight variation

content uniformity tablet thickness

tablet hardness tablet disintegration

quality standards and compendial requirements

—— tablet weight and Chp weight variation

Chp weight variation:

sample amount 20 tablets

Tablets should comply with the following

requirements stated in the table below.

Average

weight

Weight

variation

limit

Less than

0.3 g

± 7.5%

0.3 g or

more

quality standards and compendial requirements

—— tablet weight and Chp weight variation

The procedure of weight variation determination in Chp:

quality standards and compendial requirements

—— tablet hardness and friability

Tablet hardness

1)The greater the pressure applied, the harder the tablets.

2) The hardness required by different tablets

a) lozenges and buccal tablets: hard (dissolve slowly)

b) the tablets for immediate drug release: soft

quality standards and compendial requirements

—— content uniformity

applys to potent drug of low dose.

USP method, 10 tablets are individually assayed for their content.

quality standards and compendial requirements

—— tablet hardness and friability

(continued)

Friability

1) It is used to determine a tablet’s durability

2) Method: allowing the tablets to roll and fall within the rotating apparatus (friabilator); determine the loss in weight;

quality standards and compendial requirements

—— tablet dissolution

1) The importance of in vitro dissolution test

a) to guide the formulation and product development process toward product optimization

b) to monitor the performance of manufacturing process

c) to assure bioequivalence from batch to batch

2) The goal of in vitro dissolution is to provide a

reasonable prediction of the product’s in vivo

bioavailability.

Basis: The combinations of a drug’s solubility and

its intestinal permeability are supposed as a

Considered are drugs determined to have:

a) high solubility and high permeability (IVIVC

may be expected.)

b) low solubility and high permeability (IVIVC

may be expected.)

3) The formulation and manufacturing factors

affecting the dissolution of a tablet

a) the particle size of the drug substance

b) the solubility and hygroscopicity of the formulation

c) the type and concentration of the disintegrant,

binder, and lubricant used

d) the manufacturing method, particularly, the

compactness of the granulation and the

compression force

4) Test method

a) A volume of the dissolution medium is placed in the ves sel and allowed to come to 37℃±0.5℃.

b) The stirrer is rotate at the specified speed.

c) At stated intervals, samples of the medium are withdraw n for chemical analysis

5) Requirement for rate of dissolution

6) Inconsistencies in dissolution

occur not between dosage units from the same production batch, but rather between batches or between products f rom different manufacturers.