Influence Of Relative Density Of Granular

Material On Pull Out Capacity Of Granular

Anchor Pile Foundation

Jaswant Singh, Dr. Anupam Mital, Dr. V.K. AroraAbstract: The objective of current experimental study is to extend the utility of granular piles t o resist the effect of pullout forces by using the mild steel anchor plate at the base & reinforcing the same by steel tie rod to the footing. This type of assembly are described as Granular anchor pile (GAP). To estimate the pullout capacity and displacements in GAP under vertical loadings, detail investigation were carried out with different soil characteristics like relative density of granular fill material and diameter of granular pile. By enhancing the diameter of granular pile which results increasing the weight of pile and it help to resist the pullout forces and hence increases the uplift capacity. The other parameter of the soil which may influence the pullout capacity of GAP was observed due to modification in relative density in terms of voids ratio, unit weight & frication angle etc. The obvious benefit of increasing weight of pile is due to high relative density. The test results expressed that the pull-out capacity of the granular anchor pile increased with increasing diameter of the pile anchor and relative density of the granular material. For a pile diameter of 100 mm the maximum percentage increase in ultimate pullout load was 37% when the relative density was increased from 55% to 75% respectively. At a relative density of 75% the percentage increase in ultimate pullout load was 72% when the diameter when the diameter was increased from 50 to 100 mm. In the present paper, the experimental investigation have been carried out to study the behavior of Granular Anchor Pile, soil characteristics & their influences on pullout capacities of GAP foundation.

Keywords: Relative density, Pullout Capacity, Shearing Resistance, Diameter of Pile, Fill Material

—————————— ——————————

1.

INTRODUCTION

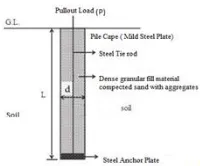

To improve the performance of soil which varies based on soft, loose sand deposits, nature of soil granular piles is considered as most effective and structured method of ground improvement due to its conventional form and uses, but this form is not yet advised to use under tall structures such as transmission towers, overhead tanks or other similar structures to offer resistance to pullout or uplift forces. The basic properties of the granular pile is altered by surfacing a metallic plate at the bottom of the pile and attaching it to the footing with a cable or rod. The pullout or tensile forces generated are transmitted to the base of the granular pile with the change at the base of the granular pile. The major reasons, responsible for uplift resistance are i) weight of the granular pile and, ii) the shearing resistance along with the soil granular pile interface. The uplift capacity of footing resting over soft sandy soil can be improved because of GAP. Economy and efficiency are two important factors, required for the successful implementation of this technique on experimental projects and sites. Present study also aims at finding the better use of GAP in future.

Figure 1: schematic of single GAP system

2.

BRIEF

REVIEW

OF

THE

LITERATURE

This concept has been researched by various experimentalists. The factors which have been studded are: failure mechanism, anchor sizes, embedment depth, ratio of embedment length and pile diameter etc. Alamgir [1] has

reported that granular pile either reinforced by or enveloped by geo-membrane perform better as building is prevented and ultimate capacity is increased. The researcher i.e. Ranjan and Kumar [2] had put forwarded an opinion that foundation technique has limited scope to control heave and resist uplift forces. Another researcher, Das and Pise [3] tested it, to study the effect of compressive load on the pile and its effect on the magnitude of compressive load by combining granular pile with other soil improvement technique will provide better results. Sharma et al [4] has suggested the foundation technique with the observation that the resistance to uplift can be increased by placing a base geo synthetic above the anchor plate. Vidyaranya et al [5] has observed the displacements in groups numbered as two, three and four based on Poulous and Davis (1980) for rigid piles. Phanykumar B.R. [6] concluded pullout tests and compressive load test on the engineering behavior of GAP system based on length, diameter and relative density of GAP system. Extension theoretical and experimental investigation have been carried out over the last few decades to study the behavior of granular anchor pile & subjected to axial pullout load. Nevertheless, the model is not validated well due to lack of good experimental data based on rigorous experiments. Hence, a details investigation is very much essential by varying soil characteristics & pile parameters to quantify their influences on pullout capacity of GAP under vertical loading.

3.

EXPERIMENTAL

STUDY

3.1 Materials Used

2956 Table 1: Soil Characteristics

Sr. No. Soil Characteristics Local Tibba Sand

1. Unit Weight of Sand - γd 18.10 kN/m3

2. Maximum Void Ratio - emax 0.90

3. Minimum Void Ratio - emin 0.50

4. Specific Gravity - Gs 2.60

5. Relative Density - ID 65%

6. Effective size - D10 0.12 mm

7. Uniformity Coefficient - Cu 1.75

8. Coefficient of Curvature, - Cc 0.59

9. Poorly Graded Sand SP

10. Angle of Internal Friction - Φ 38.7o

The granular materials that were used for the installation of the granular piles were sand and aggregates. The properties of sand were given in table 2 and testing conditions were given in Table No.3 respectively.

Table 2: Properties of Sand

Sr. No. Parameter Values 1. Specific Gravity 2.7

2. Maximum Density ϒd

(kN/m3) 18.1

3. Minimum density ϒd min

(kN/m3) 14.5

4. IS classification Poorly Graded

Table 3: Testing conditions performed in analyzing GAP

Sr. No. Test Conditions Influence Parameters

1.

GAP varying relative Density-ID

Constant :Length=700mm Dia.= 50mm Variable: ID = 55%,65% and 75%

2.

GAP varying Diameter-D

Constant : Length = 700mm ID = 55% Variable : Dia. = 50 mm and 100 mm

4.

TEST

DESCRIPTION

The square steel test tank with pullout loading frame was fabricated and utilized for construction and testing of GAP system. The casing material for GAP consisted of PVC hollow pipe of diameter 50 mm and 100 mm was adopted. A steel tank of plan dimension 1250x1250 mm and depth 1000 mm was designed and fabricated in laboratory. The experimental test assembly with the testing of single GAP is shown through Fig 1. The dimensions of the tank used for deposition of sand were selected in such a manner that the behavior of soil and GAP does not alter the boundaries of the tank. A strainer having size 1.1 m x 1.1 m in plan having 3 mm circular holes

at 10 mm spacing from each other was used for deposition of sand. Sand was filled in layers of 100 mm each by keeping the same height of fall as 0.65 m for all the layers. An initial layer of sand at the bottom of tank for each test has been laid before depositing the subsequent layers of sand over the previous layers [7]. The homogeneous soil deposit was obtained by gradually pouring the soil into the Model Test Tank by rainfall technique at an appropriate height to achieve the desired density. Initially, dry sand in layers of 100 mm was filled through a strainer at a height of 0.65 mm at the bottom of the tank for each test. Before depositing the subsequent layers of soil over the previous layers, a hollow pipe of diameter 50 mm or 100 mm was used as casing with steel anchor plate having the diameter slightly less than the diameter of bore hole / casing pipe allowing the steel tie rod having diameter 10 mm to pass through exactly at the middle of the pipe. The thickness of steel anchor plate is kept as 6 mm in case of 50 mm diameter and 8 mm in case of 100 mm diameter. The subsequent layers of sand were also deposited in the tank attaining the same height of fall up to desired length of soil and the lid of casing pipe was removed. The granular pile material was a mixture of 40% of 5 mm , 40% of 2 to 5 mm and 20% of sand at unit weight of 18.10 kN/m3. The Two series conducted in the laboratory were on 50 mm and 100 mm diameter of GAP [8]. Designed & calculated quantity of crushed stone aggregate sand mixture was poured into the casing pipe and compacted through a fixed number of blows to each layer. The above procedure was then repeated till the full length of GAP was installed and simultaneously casing pipe was pulled out. After installation of GAP system, the pile cap made of mild steel plate was placed at the top of the GAP and one end of steel tie rod was connected to the pile cap holding the group of GAP system & then pullout load was applied gradually through the loading cell arrangement. The displacements of GAP were recorded by dial gauges fixed at the top of pile cap along with the pullout load [9].

Figure 2: Experimental Test Assembly

5.

TEST

RESULTS

AND

DISCUSSIONS

5.1 Influence of Relative Density of Granular Fill Material

The relative density of the sand indicates how it could behave under loads. If the deposit is dense, it can take heavy loads with very little settlements. Experimental tests were conducted to study the influence relative density of granular fill material on the pullout behaviour of the GAP. The relative density of sand was varied as 55%, 65% and 75% by keeping diameter as consistent factor. The pullout tests were also conducted for by changing the diameter as 50 mm and 100 mm of granular anchor pile at a water content of 40% for surrounding [10].

Table 4 (a): Test Results GAP system length = 700 mm

Relative Density ID- 55% to 65% and 75%

Diameter D (mm)

Relative Density ID (%)

Pullout Load P (kN)

1 2 3

50 55 0.23

50 55 0.27

50 55 0.30

50 65 0.31

50 65 0.33

50 65 0.35

50 75 0.37

50 75 0.39

50 75 0.40

Figure 3: Pullout Load versus displacement curve of single

GAP with 50 mm. diameter at different relative Density 55% to 65% & 75%

Table 4(b): Test Results GAP system length = 700 mm

Relative Density ID- 55% to 65% and 75%

Diameter D (mm)

Relative Density ID (%)

Pullout Load P (kN)

1 2 3

100 55 0.48

100 55 0.50

100 55 0.51

100 65 0.54

100 65 0.57

100 65 0.59

100 75 0.65

100 75 0.67

100 75 0.70

Figure 4: Pullout Load versus displacement curve of single

GAP with 100 mm. diameter at different relative Density 55% to 65% & 75%

Fig. 3 and Fig. 4 show that the ultimate pullout load increases with increase in the relative density of the fill material. For 50 mm anchor pile the ultimate load increases from 0.30 kN to 0.35kN and 040 kN. It shows a percentage increase of 17% and 32% when the relative density was increased from 55% to 65% and 75% respectively. For 100 mm anchor pile the ultimate load increases from 0.51kN to 0.59 kN and 0.70 kN. It shows a percentage increase of 15% and 37% when the relative density increases from 55% to 65% and 75% respectively [11]. With increase in the relative density the fill material will become denser and hence the weight of the granular pile will increase resulting in more pullout capacity. The pullout failure is sharp, i.e., once the limit load is attained the GAP gets pulled out of the soil as is the case for piles in tension. The displacement increased sharply during the last load increment i.e., ultimate load in all the pullout tests [12].

6.

INFLUENCE

OF

VARIATION

OF

DIAMETER

OF

PILE

The pullout test was conducted to study the influence of variation of the diameter of anchor pile on the pullout behavior. The pullout behavior was studied by keeping the water content of surrounding and relative density fill material as constant parameters and the diameter of anchor pile was varied as 50 mm and 100 mm. Also, the effect of change in diameter of pile was studied for different relative densities. Fig. 5 shows the load- displacement graph of anchor piles at water content 40% and relative density 55% with different diameter 50 mm and 100 mm [13]. Performance of GAP in case of variation of Diameter of pile

Table-5 (a): Test Results GAP system length = 700 mm

Relative Density ID- 55%

Diameter D (mm)

Relative Density ID (%)

Pullout Load P (kN)

1 2 3

50 55 0.23

50 55 0.27

50 55 0.30

50 55 0.35

100 55 0.48

100 55 0.49

100 55 0.50

100 55 0.52

Figure 5: Pullout Load versus displacement curve of single

2958

Table 5(b): Test Results GAP system length = 700 mm

Relative Density ID- 65%

Diameter D (mm)

Relative Density ID (%)

Pullout Load P (kN)

1 2 3

50 65 0.31

50 65 0.33

50 65 0.35

50 65 0.36

100 65 0.54

100 65 0.57

100 65 0.59

100 65 0.60

Figure 6: Pullout Load versus displacement curve of single

GAP at Relative Denisty 65% varying the diameter 50 mm. to 100 mm.

Table 5(c): Test Results GAP system length = 700 mm

Relative Density ID-75%

Diameter D (mm)

Relative Density ID (%)

Pullout Load P (kN)

1 2 3

50 75 0.37

50 75 0.39

50 75 0.40

50 75 0.42

100 75 0.65

100 75 0.67

100 75 0.70

100 75 0.72

Figure 7: Pullout Load versus displacement curve of single

GAP at Relative Denisty 75% varying the diameter 50 mm. to 100 mm.

Fig. 5, Fig. 6 and Fig. 7 show that the ultimate pullout load increases with increase in the diameter of the granular pile anchor. For relative density of 55% there is a percentage increase of 49% when the diameter was increased from 50 mm to 100 mm. For relative density of 65% there is a percentage increase of 66% when the diameter was increased from 50 mm to 100mm. For relative density of 75% there is a percentage increase of 72% when the diameter was increased from 50 mm to 100 mm. As the diameter increases the surface area of the granular pile increases. Hence the weight of the granular pile and area for the interface friction will increase[14].

7.

CONCLUSIONS

Based on the laboratory Experiments the following conclusions are drawn:-

It is inferred with the present experimental works that the pull-out capacity of the granular anchor pile increased with increase in the relative density of granular fill material with the same diameter of GAP and also pullout capacity increased with increased in diameter of pile with constant relative density.

For a pile diameter of 50 mm the percentage increase in ultimate pullout load was 17% and 22% when the relative density was increased from 55% to 65% and 75% respectively.

For a pile diameter of 100 mm the percentage increase in ultimate pullout load was 15% and 37% when the relative density was increased from 55% to 65% and 75% respectively.

The maximum increase in the percentage ultimate pullout load was obtained at a relative density of 75%.

At a relative density of 75% the percentage increase in ultimate pullout load was 72% when the diameter was increased from 50 mm to 100 mm.

8

RERFERENCES

[1] M. Alamgir, “Analysis and design of plain and jacketed stone columns in clays. M.Sc. Engg.,” Thesis Department of Civil Engineering Blet. Dhaka, Bangladesh, 1989.

[2] G. Ranjan, and Kumar, “Behaviour of granular piles under compressive and tensile loads,” Geotechnical Engg journal. South-East Asian Geotechnical society. AIT Banglok (Thailand), Vol.31, No.3, pp.209, 2000. [3] B.K. Das, and P.J. Pise, “Effect to compressive load

on uplift capacity of model piles,” Journal of Geotechnical Engg ASCE, Vol.129, No.11, pp.987-992, 2003.

[4] R.S. Sharma, Phani Kumar and G. Nagendra, “Compressive load response of granular piles reinforced with Geogrids,” Canadian Geotechnical Journal, Vol.41, pp.187-192, 2004.

[5] B. Vidyaranya, M. Kumar, Madhav, Madhira, Sivakumar, Vinayagamoorthy, “Interaction analysis of displacements two Granular Pile Anchors,” Japanese Geotechnical Society Special Publication, Vol.2, pp.1358-1361, 2009.

[6] B.R. Phani Kumar, “Expensive Soil-Problems and remedies IGC,” Guntur India, 907-913, 2009.

piles in layered sand,” Proceedings of Indian Geotechnical Conference, pp.13-15, 2012.

[8] M.R. Madhav, and B. Vidyaranya, “Granular pile anchors - Ultimate capacity and displacements at working loads,” Proceedings of Indian Geotechnical Conference IGC, December Kakinada, India, pp.18-20, 2014.

[9] B. Vani, and P.D. Arumairaj, “Evaluation of settlement and load carrying capacity of footing with micropiles on sand”, Vol.4, pp.2277-8179, 2015.

[10]Johnson Neenu and M.N. sandeep, “Pullout behaviour of granular pile Anchor Foundation in expansive soil,” 50th

Indian Geotechnical Conference, pp.1-6, 2015.

[11]Johnson Neenu and M.N. Sandeep, “Ground Improvement using granular pile anchor foundation,” Procedia Technology, Vol.24, pp.263-270, 2016. [12]K. Bharathi, M.E.M. Swatantra, Ramakrishan, P.

Gopalakrishna, “Experimental Study Granular pile Anchor foundation institutional journal for technological Research in Engineering,” 2017. [13]Singh, Vaibhav Kumar, Gaurav Shashank and Meena

Roop Narayan, “Finite Element Analysis of Granular Pile Anchor foundation for expensive soil. Indian Geotechnical Conference,” pp.1-4, 2017.