© 2015, IRJET ISO 9001:2008 Certified Journal Page 379

Experimental Investigation of Bending strength Of Banana Fibre

Reinforced Epoxy Composites

Siddanagouda B Biradar

1,

Santosh S Chappar

21

PG student, Department of mechanical engineering, BLDEA’s V P DR. P G H CET VIJAYPUR, KARNATAKA, INDIA.

2Professor, Department of mechanical engineering, BLDEA’s V P DR. P G H CET VIJAYPUR, KARNATAKA, INDIA.

---***---

Abstract

- The prime objective of this presentwork is to study bending behaviour of banana fibre reinforced epoxy composite material. Different specimens we prepared using different fibre orientations & volume. Bending tests have been carried out on Universal Testing machine. It has been observed that the bending strength of Banana Fibre Reinforced Epoxy Composites is better than pure epoxy.

Key Words

: Banana fibre, Bending Strength, Deflection.1. Introduction to composites

Now a day's composite materials are the most progressive and common material. In The later part of the twentieth century has given a help to the manufacturing field. Composites are developed mainly with the deliberation of high strength to weight proportion. The protection and aerospace sectors are accountable for this development, which for all time gave significance for elevated strength and light weight materials. However, these days, all the fields like Civil, transportation, health and production industries are also using the composite resources.

The composite material is characterized as two or more materials are consolidated on a macroscopic scale to get a valuable third material with an attractive properties.

Different materials can be collective on a microscopic scale, for example, in alloying of metals, however the following material is macroscopically homogeneous, that is the parts can't be recognized by the naked eye and fundamentally act together. The improvement of composite materials is that, if fine planed, they frequently exhibit the best qualities of their parts or constituents and repeatedly some qualities that neither constituent possesses. Some of the properties that can be better by forming a composite material are

• Strength • fatigue life • Stiffness

• Temperature-subordinate conduct • Corrosion resistance

• Thermal protection • wear resistance • Thermal conductivity • Attractiveness • Acoustical protection • Weight

© 2015, IRJET ISO 9001:2008 Certified Journal Page 380

2.METHODOLOGY

2.1. Extraction of banana fibres

There are different methods to extract the banana fibres. Stem of the banana plant chopped and it is dried under the sunlight for 2 to 3 weeks to remove the moisture contents. The stem is then washed and soaked in water for a week and again it is dried under sun light for 15 days then after all the moisture is taken out then the fibre are taken off manually.

The other method for extracting the fibre is to chop the stem of banana plant and then long flaxes taken out and it is kept under the load due to the load applied on the flax maximum moisture content is taken off. Then with the help of chopper the uppermost layer is peel off then remaining part will be fibres having less moisture content.

[image:2.595.307.554.401.542.2]Another method of extracting fibres is feeding the pseudo stem directly into the machine and the fibres are extracted. Many researchers are using readymade prepegs for investigation. The property of fibres changes from soil to soil.

Fig. Banana fibres extracted from stem

2.2 Mould preparation

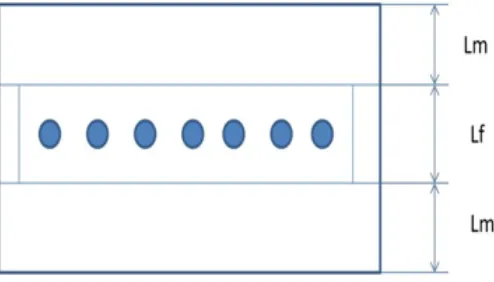

The mould used for composite fibres is made from rectangular plywood 150 mm in length and 60 mm in width and second mould box is 200mm in length, 60mm in width it is coated with plastic by using glue. For the upper side of the mould is also made in a rectangular form using plywood of 150 mm in length, and 60mm in width and second is 200mm length, 60mm width and it has to be coated with plastic. The functions of this upper side of plywood are to cover the fibre after the epoxy is supplied and also to avoid the debris from entering into the composite parts during the curing time. To hold the fibres in the same orientation while curing process the hole are drilled at equal spacing in all sides of mould box as shown in figure. The fibres are passed through the holes and tied with some tension.

Fig. Holes drilled on the mould box

[image:2.595.29.560.472.730.2]© 2015, IRJET ISO 9001:2008 Certified Journal Page 381

2.3 Banana fibre preparation

Fig. Banana fibre

[image:3.595.305.533.284.535.2]2.4 Preparation of composites

Fig. Hand lay-up technique

Hand layup process:

Fibre reinforcement is placed in the mould.

Base resin mixed with catalysts is applied by pouring and brushing.

Layup is made by building layer upon layer to obtain the desired thickness.

2.5 Preparation of testing Specimens.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 382

[image:4.595.305.536.102.379.2]Double laminated Specimens

Fig. Specimen with Banana fibre

2.6 Mechanical properties

After fabrication, the test specimens will be subjected to various mechanical test as per ASTM standards. The standards followed are ASTM D 638-03 for tensile test with the test speed of 5 mm/min and the flexural strength is determined as per ASTM D 790 [10] procedure.

Procedure

© 2015, IRJET ISO 9001:2008 Certified Journal Page 383 remove the burrs from the material. Specimen dimensions

are noted down and then the specimen is fixed inside the jaws of universal testing machine. One end of the jaw is fixed and another end is movable at constant speed. Deformation is noted down for the corresponding load applied until failure occurs. Finally, the tensile strength is determined using suitable equations.

3.RESULTS AND DISCUSSION

Investigation is done to study the bending properties of Banana fibre reinforced epoxy composite for treated and untreated fibres. Surface treatment is done on the fibres by applying a thin layer of coating with acetate. Fibres are also treated with sodium hydroxide (NaOH) and potassium permanganate (KMnO4) which is reinforced in epoxy composite.

Bending test is carried out in Universal testing machine at constant speed

.

SPECIMEN -1

Line Diagram without fibre.

Note: This graph indicates 6mm Deflection under the Load of 3.2KN.

SPECIMEN-2

Line Diagram with fibre.

10mm 60

mm

50

60mm

50

© 2015, IRJET ISO 9001:2008 Certified Journal Page 384

Note: This graph indicates 7.2mm Deflection under the Load of 5.2KN

SPECIMEN-3

Line Diagram with fibre.

Note: This graph indicates 6.2mm Deflection under the Load of 4.96KN

.

SPECIMEN-4

Line Diagram with double layer fibre.

60

mm

50

10mm

5mm 60

mm

50

© 2015, IRJET ISO 9001:2008 Certified Journal Page 385

Note: This graph indicates 14.5mm Deflection under the Load of 7.76KN

SPECIMEN-5

Line Diagram with double layer fibre.

Note: This graph indicates 13.2mm Deflection under the Load of 7.24KN

.

CONCLUSIONS

From the results obtained, it can be concluded that,

Resin has less load carrying capacity as compared to the fiber reinenforced material.

As the number of fibers increases load carrying capacity of the material will also increases.

SCOPE FOR FUTURE WORK

For the given bending strength of the banana reinforced epoxy composite several products may be fabricated in the field of aerospace, automotive, Sports, Leisure household

5mm 60

mm

50

© 2015, IRJET ISO 9001:2008 Certified Journal Page 386 Equipments etc. Further from chemical treatments for

different concentration of chemicals may enhance the strength of the composites and attracts many researchers for the improvement of this composite. Studies can be carried out on impact properties, thermal properties of banana fibre reinforced epoxy composites. In future study can be carried out on the influence of volume fraction of fibres on banana fibre reinforced epoxy composites.

REFERENCES

[1] Kulkarni A.G, Satyanarayan, Rothagi., “Mechanical properties of banana fibres” journalof materials science 18 (1983) 2290-2296.

[2] Pothan L.A, Sabu Thomas., “Polarity parameters and

dynamic mechanical behaviour ofchemically modified banana fiber reinforced polyester composites” Composites Scienceand Technology 63 (2003) 1231–1240.

[3] Pothan L A., Zachariah Oommen, Sabu Thomas., “Dynamic mechanical analysis of

banana fibre reinforced polyester composites” Composites Science and Technology 63

(2003) 283–293.

[4] S.M. Sapuan, A. Leenie, M. Harimi and Y.K. Beng, Mechanical properties of woven banana fibre reinforced epoxy composites, Materials and Design volume 27, Issue 8,2006, Pages 689–693.

[5] Sherely Annie Paul , Abderrahim Boudenne b, Laurent Ibos , Yves Candau ,Kuruvilla Joseph, Sabu Thomas Effect of fiber loading and chemical treatments on thermo physical properties of banana fiber/polypropylene commingled composite materials Composites:Part A 39 (2008) 1582–1588.

[6] Mukhopadhyay, Raul Fangueiro, Yusuf Arpac, Ulku senturk , Banana Fibers – Variability and Fracture Behaviour , Volume 3,Issue 2—2008.

[7] Manish Kumar and Deepak Kumar., “Comparative study of pulping of banana stem”

International Journal of Fiber and Textile Research 2011; 1(1): 1-5.

[8] Sakthive. M, S.Ramesh, Mechanical Properties of Natural Fibre (Banana, Coir, and Sisal) Polymer Composites, science park ISSN: 2321–8045 Vol-1, Issue-1, July 2013.

[9] Ashwani Kumar, Deepak Choudhary., “Development of Glass/Banana Fibers reinforced

Epoxy Composite” Int. Journal of Engineering Research and Applications ISSN : 2248-9622, Vol. 3, Issue 6, Nov-Dec 2013, pp.1230-123.

[10]

Shashi Shankar, Dr.K.Thirupathi Reddy and V.Chandra Sekhar, Mechanical Performance and Analysis of Banana Fiber Reinforced Epoxy Composites,

AUTHOR PROFILE

1.Siddanagouda B Biradar