Plants

Individual Heating Plants and Energy

Transport - hybrid gas technologies

Energinet.dk

Data note for Energy Plants

Individual Heating Plants and Energy

Transport - hybrid gas technologies

Version Aug 2013

Project No. A035817 Document no.

Version 2 Date of issue Aug 2013 Prepared COWI, TI, DGC Checked COWI, TI, DGC Approved COWI

Table of Contents

1 Guidelines and manual 2

1.1 Introduction 2

1.2 Qualitative description 2

1.3 Quantitative description 3

2 Technology sheets 8

2.1 Solar-assisted gas boiler 8

1

Guidelines and manual

1.1

Introduction

This chapter serves to assist readers in understanding and assessing the presented information. Each technology is described by a separate technology sheet following the same overall format as ex-plained below.

1.2

Qualitative description

One to three pages give the key characteristics of the technology. Typical paragraphs are:

Brief technology description

Brief description on how the technology works and for which purpose.

Input

The main raw materials, primarily fuels, consumed by the technology.

Output

The forms of generated energy, i.e. electricity, heat, bio-ethanol etc.

Typical capacities

The stated capacities are for a single unit or, in case of e.g. solar heating, for a typical system size.

Regulation ability

Description of how the unit can regulate, e.g. a gas boiler is very flexible whereas a solar heating system depends on the solar radiation.

Advantages/disadvantages

Specific advantages and disadvantages relative to equivalent technologies. Generic advantages are ig-nored; e.g. renewable energy technologies mitigate climate risk and enhance security of supply.

Environment

Particular environmental characteristics are mentioned, e.g. special emissions or the main ecological footprints.

The ecological footprints cannot be used to compare technologies. For example, photovoltaic cells have few and small footprints, one of the major ones being radioactive waste. However, this does not mean that there is more radioactive waste from solar electricity than coal-fired electricity. It only means that radioactive waste is one footprint from photovoltaic cells which is more important than other footprints from the same technology.

The energy payback time or energy self-depreciation time may also be mentioned. This is the time re-quired by the technology for the production of energy equal to the amount of energy that was consumed during the production of the technology.

Research and development

This is a very brief listing of the most important current challenges, often from a Danish perspective.

Examples of best available technology

A brief mentioning of recent technological innovations in full-scale commercial operation.

Additional remarks References

1.3

Quantitative description

To enable comparative analyses between different technologies, it is imperative that data are actually comparable. As an example, economic data must be stated at the same price level. Also, it is important to compare technologies at equal footing, e.g. either gross generation capacity or net capacity (gross mi-nus own consumption).

It is essential that data are given for the same years. Year 2015 is the base for the present status of the technologies (best available technology commissioned in 2015), whereas data for expectations to future developments are given for the years 2020, 2030 and 2050.

Below is shown a typical data sheet, containing all parameters used to describe the specific technolo-gies. For several technologies and in particular the technologies regarding energy transport, the data sheets have been adjusted to suit the specific characteristics.

Table 1.1 Typical datasheet for individual heat production technologies

Technology Name of technology

2015 2020 2030 2050 Note Ref

Energy/technical data

Heat production capacity for one unit (kW)

Expected share of space heating demand covered by unit (%)

Expected share of hot tap water demand covered by unit (%)

Total efficiency, annual average, net (%) Technical lifetime (years)

Environment

SO2 (g per GJ fuel)

NOX (g per GJ fuel)

CH4 (g per GJ fuel)

N2O (g per GJ fuel)

Particles (g per GJ fuel)

Financial data

Specific investment (1000€/kW) Specific investment (1000€/unit) - hereof equipment (%)

- hereof installation (%)

Possible additional specific investment (1000€/unit) Fixed O&M (€/kW/year)

Variable O&M (€/GJ) References: 1 2 Notes: A

All data in the data sheets are referenced by a number in the utmost right column (Ref), referring to source specifics below the table.

Please be aware, before using the data, that essential information may be found in the notes below the table.

1.3.1 Energy/technical data Heat production capacity for one unit

The stated capacities are for a single unit or, in case of solar heating, for a typical system size.

The capacity is given as net generation capacity in continuous operation, i.e. gross capacity minus own consumption (if any).

In general, the unit kW is used for both heat capacity, electric capacity (e.g. consumption in heat pumps) and fuel capacity.

Energy efficiencies

The total fuel efficiency for heat production technologies equals the net delivery of heat divided by the fuel consumption. The efficiency is stated in per cent at ambient conditions; air 15 °C and water 10 °C. For heat pumps, a fuel efficiency of e.g. 300 % represents a COP of 3.

If nothing else is stated in the technology description, the fuel efficiency reflects the total fuel efficiency covering both space heating and hot tap water.

The efficiencies reflect annual average efficiencies as experienced by the consumer, assuming that the heat installations are installed correctly. The boundary of annual efficiency is shown in the figure below.

Figure 1.1 Boundary for annual efficiency

O u tp u t: H e a t f o r d o m e st ic h o t w a te r Heat generator Storage tank Pumps for distribution and domestic hot water production O u tp u t: H e a t f o r sp a ce h e a tin g Boundary for annual efficiency In p u t: F u e ls o r e le ct ric it y fo r h e a t g e n e ra tio n

Input: Auxilliary electricity for heat generation: control, burner, etc. Shower Taps Heat emitters O u tp u t: E le ct ric it y To the grid

For energy transport technologies, the network loss is stated instead of the fuel efficiency.

1.3.2 Environment

CO2 values are not stated, as these only depend on fuel, not on the technology.

SOx: grams per GJ fuel input.

NOx: grams per GJ fuel input. NOx equals NO2 + NO, where NO is converted to NO2 in

weight-equivalents.

Greenhouse gases: CH4 and N2O in grams per GJ fuel input.

The emissions of CH4 and N2O can be converted to CO2-equivalents by multiplying the CH4 emission

by 21 and the N2O emission by 310.

Aspects related to the technologies' possible use of rare minerals/metals (when manufactured) as well as the overall environmental footprint of the technologies have not been included in detail in the technolo-gy descriptions.

1.3.3 Financial data

Financial data are all in Euro (€) and in fixed 2011 prices.

Several data originate in Danish references. For those data, a fixed exchange rate of 7.42 DKK per € has been used.

For conversion of prices from one year to another, the general inflation rate as published by the Danish Energy Agency is used1.

Investment costs

The investment costs include the total costs for the consumer of establishing the technology. Where pos-sible, the investment cost has been divided (in percentage) on equipment cost and installation cost. Where relevant, also a line with possible additional specific investment costs have been included. This is for instance relevant in connection with fluid-to-water heat pumps in city areas where it is necessary to establish vertical tubes (by use of drilling holes) instead of horizontal tubes.

The investment costs reflect consumer prices, e.g. the price for a household of establishing a new gas boiler. The prices are excluding VAT, subsidies and taxes.

An overall assumption in the catalogue is that the technologies described are of a "reasonable quality". The cheapest and non-serious boilers and heat pumps that also exist on the market are not included. Regarding the forecast of investment costs, it has been assumed that mature technologies without an ex-pected technology leap have the same investment cost during the period. This is based on an assumption

1

Forudsætninger for samfundsøkonomiske analyser på energiområdet. Energistyrelsen. April 2011. / Assumptions for socio-economic analyses within the energy area. The Danish Energy Agency. April 2011

that costs of materials (e.g. steel prices) are also the same during the period (in fixed prices). If the costs of materials develop in one or another direction, it will most likely influence the technology costs.

Operation and maintenance (O&M) costs

The fixed share of O&M (€/kW/year) includes all costs that are independent of how the unit is operated, e.g. administration, operational staff, property tax, insurance, and payments for O&M service agree-ments. Re-investments within the stated lifetime are also included.

The variable O&M costs (€/GJ heat production) include consumption of auxiliary materials (water, lub-ricants, fuel additives), spare parts, and repairs (however not costs covered by guarantees and insur-ance).

If it is not possible to differ between fixed and variable costs, the total O&M cost is stated instead. Fuel costs are not included in the O&M costs. Furthermore, electricity consumption for heat pumps and for electric heating is not included.

It should be taken into account that O&M costs often develop over time. The stated O&M costs are therefore average costs during the entire lifetime of the technology.

2

Technology sheets

2.1

Solar-assisted gas boiler

Brief technology description

Combined solar heating and gas boiler systems have been used in Europe (including Denmark) for dec-ades and constitute a proven concept for energy supply in houses. There are a number of different sys-tem configurations on the market, and in Denmark these have traditionally been designed and assembled by the solar heating companies. However, with the increasing focus on energy-efficient heating, many boiler manufacturers have entered the market for combined systems at full speed. Most systems in Denmark are designed for solar contribution for preparation of hot water, but some systems are also in-tended for solar space heating.

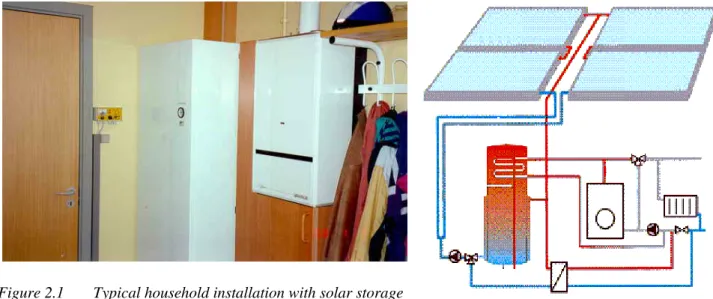

A typical system configuration is illustrated on the figure below (figure 5.7), showing a tank with two heat exchangers, which are connected to the gas boiler and the solar collectors, respectively. In order to save fossil fuel, combined systems will always use solar energy for heating of the storage tank as first priority. Usually, the solar collector system has its own pump and a closed circuit filled with an anti-freeze fluid. The solar loop is circulating as long as there is a net flow of energy to the tank and the tank temperature is below its maximum setting. In most systems, the gas boiler heats the top of the water tank as first priority, then space heating.

Figure 2.1 Typical household installation with solar storage tank and gas boiler

The main components of a hybrid gas/solar system are described in the following:

• The gas boiler is usually a condensing, balanced type with low water content (Figure 2.4 - system A). If the boiler is a separate unit, low thermal mass is preferable because the capacity losses would otherwise compromise the overall efficiency. If the boiler is an integrated part of the storage tank (Figure 2.4 - system C) , it may have a very high thermal capacity as the “lost” energy is captured in the tank. The ability to run at low load becomes less important with this construction due to the thermal mass and longer runtime. If a combi boiler is used together with solar water

preheat-ing(Figure 2.4 - system B), it must be able to accept high inlet temperature. In the Netherlands, there is a special label for this type of boiler named “Gazkeur NZ” [13].

• The solar collectors can be either of the flat-plate or the evacuated tube type. The latter is becoming more and more popular due to the lower cost by large-scale low-cost production (mainly in China) and the higher efficiency at elevated temperature. Some vacuum tubes apply the heat pipe principle, which allows high stagnation temperature of the absorber without boiling in the fluid circuit. The lifetime of vacuum tubes versus the traditional solar collectors is a subject for ongoing discussion, but at least 15 years have been documented for both types.

• The storage tank can either be of sanitary (DHW) water or heating water type. In order to maximize the solar storage capacity, the volume heated by the gas boiler is usually limited to the upper third of the tank by thermal stratification. During the summer months, the boiler is only activated if the solar heat supply is insufficient to reach the desired tank temperature and if the system control timer calls for heat from the boiler.

• Control systems are usually based on the ordinary boiler controller with menu-oriented setting of a broad range of parameters. The solar loop is normally controlled by a simple differential thermostat integrated in the same housing. In some cases, there is a delay-function, so that the solar loop will be allowed sufficient time to heat the tank without using gas as back-up. This is important when running in summer mode when the boiler may be inactive during long periods of time.

A number of boiler manufacturers have fully configured and well-documented solar/gas system solu-tions in their product portfolio, for example Viessmann, Vaillant and Buderus,Weishaupt, Bosch and Solvis. They have in particular been developed for European markets like Germany and the Nether-lands, where gas heating is very common, and where the environmental consciousness is generally high. Space heating with solar energy is possible in some systems, where an additional heat exchanger is add-ed to the solar collector loop or the storage tank. However, in Danish climatic conditions it is very diffi-cult to rely on solar energy in the heating season (see figure 5.9), otherwise the solar collectors and the storage tank should be huge. The best compromise between investment and savings seems to be systems of relatively small size for a single family house:

• Solar collector: 4-15 m2 • Storage tank: 200-600 l • Gas boiler typically: < 20 kW.

In some standard systems, the gas boiler is directly integrated in the storage unit, as illustrated in Figure 2.2

Figure 2.2 Compact solar storage with gas boiler (Rotex).

For single-family houses, it is thus easy to find marketed gas and solar systems that are suitable for most situations, but for large buildings, it is often necessary to design the system from case to case with help from a solar energy specialist.

In typical Danish single-family houses, there is usually very little space available for technical installa-tions, so the consumer will often prefer systems that occupy a small floor area. This is one of the con-straints towards solar heating systems with a higher solar fraction of the energy demand. The disad-vantage of the very compact designs is that service and maintenance become more difficult, and it is difficult to have sufficient insulation on the storage tank.

Figure 2.3 Typical monthly solar heat contribution for a DHW and a combined DWH/space heating system The total solar fraction of annual heat demand is rarely more than 10-20 % in Denmark, except in passive houses or similar where energy for DHW is dominant.

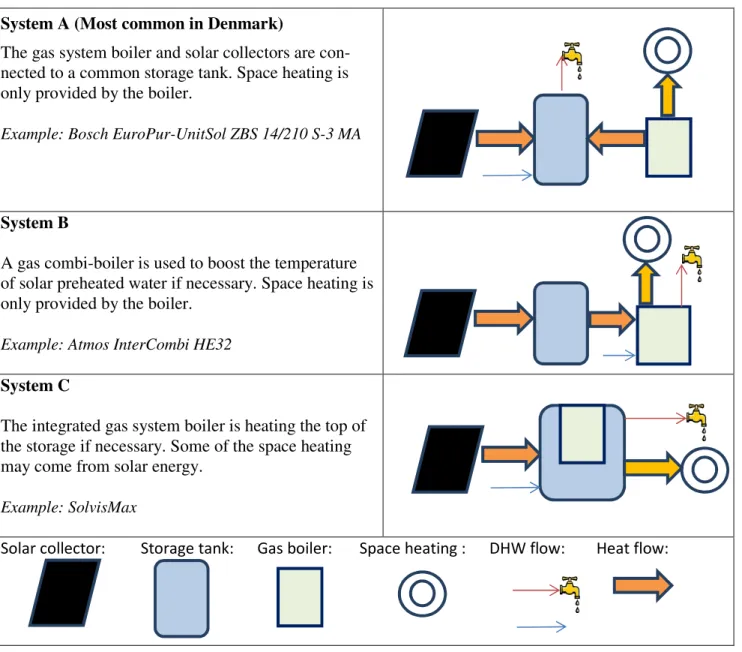

System A (Most common in Denmark)

The gas system boiler and solar collectors are con-nected to a common storage tank. Space heating is only provided by the boiler.

Example: Bosch EuroPur-UnitSol ZBS 14/210 S-3 MA

System B

A gas combi-boiler is used to boost the temperature of solar preheated water if necessary. Space heating is only provided by the boiler.

Example: Atmos InterCombi HE32

System C

The integrated gas system boiler is heating the top of the storage if necessary. Some of the space heating may come from solar energy.

Example: SolvisMax

Solar collector: Storage tank: Gas boiler: Space heating : DHW flow: Heat flow:

Figure 2.4 Figure of the most common principles in hybrid solar/gas systems

Apart from the relatively complex and expensive combined standard systems, there are two system vari-ations that can be mentioned as interesting options for market development in the individual dwelling sector:

1 PV solar-electric system with immersion heater in standard gas heated hot water tank. This solution is so far offered from MetroTherm (though without the gas boiler).

2 Thermo-siphon systems with gas instantaneous water heater. This type is interesting in vacation houses or other houses with low or irregular hot water consumption. The Australian solar manufac-turer, Solahart, offers a gas-fired booster for this type of system. [www.solahart.com.au].

Input

The primary energy input for a hybrid system is solar radiation, gas and a small amount of electricity for the pump. Typically, gas will cover 80-90 % and solar heating 10-20 % of the annual heating demand; however, it depends on the specific configuration (see example on figure 5.10). The present market products in Denmark are mostly configured for a low solar fraction, as this has proven to be the best

compromise between investment and solar collector yield. In other countries, there is a tradition for larger solar fractions. In some cases, the input of electric energy by an immersion heater is added, espe-cially if low-cost electricity is available during night time.

Figure 2.5 Typical solar fraction as a function of total heating demand.

Output

The output is thermal energy at moderate temperature, typically 20-80 °C, depending on operation con-ditions, gas boiler and solar collector type. In summer time, the solar collectors can operate at high tem-peratures and deliver the full demand, whereas the gas boiler is used to boost the temperature level rest of the year. The actual ratio between solar and gas boiler output is determined by factors such as: • Hot water demand and draw off pattern

• Heat loss from circulation pipes, mainly in large buildings • Heat loss from tanks and pipes, thermal bridges

• Floor heating demand in summer months • Start/stop losses for the boiler.

Typical capacities

Traditionally, the system size is given in m2 collector surface and kW boiler output. For single-family homes, the typical range is from 4 m2 in case of a small DHW system to 15 m2 for a combined space heating and DHW system. Usually, it is recommended to have 1-1,5 m2 solar collector area per inhabit-ant in a DHW system. In order to compare with other technologies, IEA have decided that 0,7 kW of nominal thermal power can be used as an equivalent to 1 m2 collector surface, but of course this is a simplification because collectors and operating conditions can be very different.[11]. The capacity of the gas boiler may be less than 10 kW in low-energy houses or more than 25 kW in larger/less efficient homes. The storage tank will typically have a volume of 40-50 litre per m2 solar collector. (200-600 l).

Regulation ability

The thermal power for a given hybrid solution is largely determined by the solar irradiance, and the ac-tual operating temperature relative to ambient. In solar/gas factory-made systems, it is usual to have the solar loop control as an integrated part of the boiler controller, but for add-on solar it has a separate con-trol.

Advantages/disadvantages

Advantages

Advantages of hybrid solar/gas solutions are:

• E.g. very good combination of the non-flexible solar energy with gas units which are very flexible in operation and can start up with high efficiency and low response time.

• The solar collectors can be integrated in the urban environment and may substitute a part of the building envelope.

• Large energy savings are often possible if the gas boiler can be completely switched off during the summer, so that standby losses can be substantially reduced.

• Might be able to use biogas/green gas in the future.

Disadvantages

Relatively expensive installation, except for very large systems. Mismatch between heating demand and solar availability. Requires sufficient area on the roof with appropriate orientation, may compete with photovoltaic systems for the same area. Requires more space in the house than a regular boiler installa-tion.

Environment

A solar heating/gas system mainly contains metals and glass that require energy in manufacturing. Al-most all the materials can be recycled.

The fluid used in most solar heating systems shall be disposed as low-toxic chemical waste.

Research and development

The most relevant R&D needed for further development of solar thermal / gas systems are: • Compact and cost-effective storage systems for thermal energy

• Further development of optimum system control and automatic fault detection • Further development of low-cost installations.

Examples of best available technology

The sector is characterized by step-by-step improvements, and some of the most important improve-ments in the last 10 years have been:

• Perfection of stratified storage tanks and system control • Efficient gas combi boilers with a wide regulation range • Hot water heat exchanger modules for Legionella prevention • Integration of solar tank and gas boiler

Additional remarks

This study is restricted to solar and gas heating systems without exchange of energy with other buildings than the one where the solar collectors are installed. Only domestic hot water and space heating is con-sidered, not solar cooling.

References

3 Solvarme faktablade / www.altomsolvarme.dk 4 Solvarme handlingsplan, Jan Erik Nielsen, okt. 2011

5 Energiteknologier – tekniske og økonomiske udviklingsperspektiver, Teknisk baggrundsrapport til Energistrategi 2025, 2005

6 Bygningsintegreret energiproduktion. Det økologiske råd, juni 2011

7 INSPIRATIONSKATALOG Forsynings- og infrastruktur-teknologier for bæredygtig byudvikling, COWI januar 2011

8 Komponentkrav, konkurrence og eksport. En kortlægning af innovation i byggekomponenter, DTU februar 2011

9 Solar Heat Worldwide 2011 statistics. IEA Solar Heating and Cooling programme. 10 Tænk, december 2009

11 www.batec.dk 12 www.sonnenkraft.dk

13 Recommendation : Converting solar thermal collector area into installed capacity (m2 to kWth). Technical note, IEA SHC 2004

14 Notat til projektet 731-10 Energimærkningsmodel for sol/gas-kedelunit. Ianina Mofid, Dansk Gas-teknisk Center

15 Eco-Design guidelines for water heaters

16 Basisnotat vedr. Solvarmeøkonomi. Jan Erik Nielsen, 2006

Data sheets:

Only one family houses, no systems found for multi family dwellings

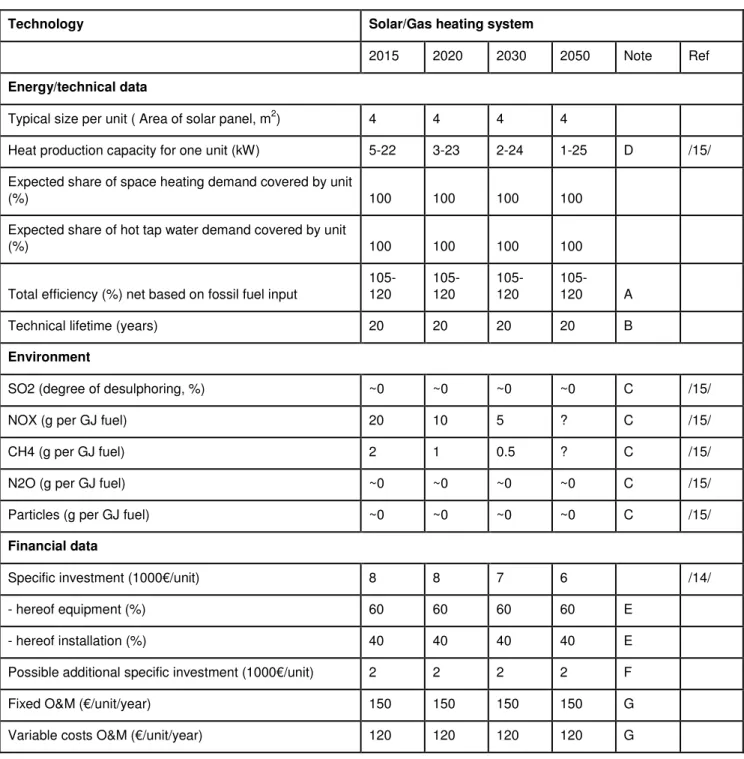

Table 2.1 One family house, existing or new buildings

Technology Solar/Gas heating system

2015 2020 2030 2050 Note Ref

Energy/technical data

Typical size per unit ( Area of solar panel, m2) 4 4 4 4

Heat production capacity for one unit (kW) 5-22 3-23 2-24 1-25 D /15/

Expected share of space heating demand covered by unit

(%) 100 100 100 100

Expected share of hot tap water demand covered by unit

(%) 100 100 100 100

Total efficiency (%) net based on fossil fuel input

105-120 105-120 105-120 105-120 A

Technical lifetime (years) 20 20 20 20 B

Environment

SO2 (degree of desulphoring, %) ~0 ~0 ~0 ~0 C /15/

NOX (g per GJ fuel) 20 10 5 ? C /15/

CH4 (g per GJ fuel) 2 1 0.5 ? C /15/

N2O (g per GJ fuel) ~0 ~0 ~0 ~0 C /15/

Particles (g per GJ fuel) ~0 ~0 ~0 ~0 C /15/

Financial data

Specific investment (1000€/unit) 8 8 7 6 /14/

- hereof equipment (%) 60 60 60 60 E

- hereof installation (%) 40 40 40 40 E

Possible additional specific investment (1000€/unit) 2 2 2 2 F

Fixed O&M (€/unit/year) 150 150 150 150 G

Variable costs O&M (€/unit/year) 120 120 120 120 G

References

/14/ Basisnotat vedr. Solvarmeøkonomi. Jan Erik Nielsen, 2006

Notes:

A Depends highly on actual solar fraction B Estimated average for main components C Assuming same data as for a stand alone boiler D Simultaneous power range from solar+gas E For uncomplicated standard installation

F Installation of a gas service line (grid connection). The price may change depending on the marketing of the gas dis-tribution companies. For non-domestic appliances, the same price as for domestic is assumed. Only to be paid if the natural gas is not yet supplied to the house.

G As for gas unit alone + 10-20%

Technology Solar/Gas heating system

2015 2020 2030 2050 Note Ref

Energy/technical data

Typical size per unit (( Area of solar panel, m2) 7 7 7 7

Heat production capacity for one unit (kW) 5-24 3-25 2-26 1-27 D /15/

Expected share of space heating demand covered by unit

(%) 100 100 100 100

Expected share of hot tap water demand covered by unit

(%) 100 100 100 100

Total efficiency (%) net based on fossil fuel input

110-140 110-140 110-140 110-140 A

Technical lifetime (years) 20 20 20 20 B

Environment

SO2 (degree of desulphoring, %) ~0 ~0 ~0 ~0 C /15/

NOX (g per GJ fuel) 20 10 5 ? C /15/

CH4 (g per GJ fuel) 2 1 0.5 ? C /15/

N2O (g per GJ fuel) ~0 ~0 ~0 ~0 C /15/

Particles (g per GJ fuel) ~0 ~0 ~0 ~0 C /15/

Financial data

Specific investment (1000€/unit) 10 10 9 8 /14/

- hereof equipment (%) 60 60 60 60 E

- hereof installation (%) 40 40 40 40 E

Possible additional specific investment (1000€/unit) 2 2 2 2 F

Fixed O&M (€/unit/year) 150 150 150 150 G

References

/14/ Basisnotat vedr. Solvarmeøkonomi. Jan Erik Nielsen, 2006

/15/ Technology data for individual heat production and energy transport. 2012

Notes:

A Depends highly on actual solar fraction B Estimated average for main components C Assuming same data as for a stand alone boiler D Simultaneous power range from solar+gas E For uncomplicated standard installation

F Installation of a gas service line (grid connection). The price may change depending on the marketing of the gas dis-tribution companies. For non-domestic appliances, the same price as for domestic is assumed. Only to be paid if the natural gas is not yet supplied to the house.

2.2

Gas boiler with electric heat pump or electric immersion heater

Hybrid heating systems consisting of both a gas and an electric heat generator offer a number of oppor-tunities for the consumer and, in the future, also for the grid operator. This type of hybrid system has just recently entered the heating market and is mainly offered in packages. The most common design is a gas boiler combined with an electric heat pump or thermal solar systems, the last type is described in another section. Moreover, a gas boiler combined with an electric immersion heater is another solution. The gas/electric hybrid system, as described here, makes it possible to change between gas and electric heating and thus provides a more fuel flexible option. This makes these systems interesting in the per-spective of designing a smarter energy system for the future, where significant amounts of fluctuating renewable energy sources, e.g. solar and wind, presuppose a more flexible energy system where e.g. gas and electricity grids are interacting.

Hybrid systems as packages for single-family houses will be introduced in Denmark during 2013.

2.2.1 Hybrid system design 1: Gas boiler and electric heat pump Brief technology description

These hybrid systems often consist of a gas boiler and usually an air-to-water heat pump, either sold in two separate parts or as an integrated product. But there are other energy source options for the heat pump, e.g. the ground (brine-water heat pump), or ventilation exhaust air. The gas boiler is a standard condensing gas boiler, while the electric heat pump has a smaller capacity compared to other heat pump installations sold as standalone. Hot water is normally produced using the gas boiler to avoid high tem-peratures from the electric heat pump.

Several control strategies can be used for hybrid system operation to decide when the heat pump or the gas boiler is to be in operation. Some hybrid systems allow the customer to choose between two or more control options. These options include:

a) Heat pump operation until the heating demand exceeds the heat pump’s capacity. The ambient tem-perature may also restrict the heat pump operation.

b) Operation to minimize the heating cost. c) Operation to minimize the CO2 emissions.

For control/regulation option a), the heat pump capacity will cover the heating demand as long as the outdoor temperatures allow it, i.e. during times with moderate or high outdoor temperature. Only in the case of very low outdoor temperature during winter, the heating demand will be covered by the gas boiler alone. The heat pump and the gas boiler are used simultaneously in an intermediate period. The operation of the heat pump depends on the efficiency/COP and the lowest ambient temperature allowed for operation. The latter can differ considerably, from -5 °C to for example -15 °C for heat pumps adapted to the low winter temperatures in Scandinavia.

The two last options b) and c) require preset values for gas and electricity prices, alternatively the price ratio, and the CO2 emission factors for gas and electricity. The control system calculates the cost or CO2

emission and chooses the appliance to be used in order to minimize the consumer energy cost or the overall CO2 emission in an optimising algorithm. These factors are inputs given by the installer or

con-sumer and are fixed until new factors are given as input. In a not too distant future, it will be possible to control the operation through for example real-time electricity prices, or even external control of the hy-brid system operation.

These hybrid systems are delivered with the heat pump and the gas boiler as separate parts or as a single package. An existing gas boiler can be converted into a hybrid system through an added heat pump and a control system for the hybrid system operation. The boiler manufacturers often state that the boiler models that can be efficiently used in a hybrid system. The amount of electricity used for the heat pump and gas for the heating boiler depends on the heating demand, heat pump size, COP and control strate-gy. For a Danish standard house, the gas consumption is estimated to be 40-60% of the gas and electrici-ty consumption for heating and hot water /8/.

Hybrid systems offered today are designed for single-family houses. However, currently there are no hybrid systems for single-family houses installed in Denmark; but it is expected that such package solu-tions will be introduced on the market during 2013.

There is no “ready to install “package known today (2012) for apartment blocks; combining large gas boiler and electrical heat pump. Yet there is no technical barrier to assemble the two appliances in-situ (of any size) in a larger building and combine these with hardware to control the two units. There are no data available about the no. of such systems; but numbers are probably very low.

The present document treats “package” solutions.

Input

The hybrid systems described here use gas and electricity, and in case of a heat pump also free energy from ambient air, ground or exhaust ventilation air. Although brine-to-water heat pumps can also be used in hybrid system, the products on the market today almost exclusively use air-to-water heat pumps. In the following text, only this option is described.

Gas boilers in such hybrid appliance can be used with natural gas and LPG gases, but also with new “green gases”. Appliances that are certified for natural gas can cope with a large variation of natural gas specifications, including natural gas/upgraded biogas (natural gas equivalent) mix, as long as the speci-fications of the mixture conform to specispeci-fications of the natural gas. Note that upgraded biogas is almost pure methane and will therefore also be able to be used directly (without mixing with natural gas). For natural gas/hydrogen mixture, the technologies using fully premix burners should be able to cope with mixtures containing up to 10 to 20% hydrogen (vol).

Output

Hybrid systems’ output is thermal energy for heating and hot water production.

Typical capacities

Hybrid systems offered today are typically designed for single-family houses. The heat pump capacity for the hybrid systems on the market is between 2 kW and 7 kW. The gas boiler output is in the 15-25 kW range. No systems for larger installations such as apartment blocks have been found on the market.

Regulation ability

The gas boiler output in hybrid systems does not differ from the output of other gas boilers, for example modulating between 6 and 24 kW. The exact operation mode of the small heat pumps used in hybrid systems is not known.

Advantages/disadvantages

Correctly sized and installed, hybrid systems offer the consumer a number of advantages.

The main advantage for the user is the optimisation of the energy saving and heating cost by using two different technologies and fuels. However, the comparative advantage of the system is dependent on the market design, i.e. the possibility for the owner to take advantage of fluctuating energy prices and/or emission content.

The main disadvantage is financial, as a hybrid system requires an additional investment, where the payback time would greatly depend on the heat demand, energy costs and investment cost. It is expected that the cost of such hybrid systems will decrease in the future.

The advantage for society is to bring more flexibility to the heating market by allowing the electricity consumption to respond to the fluctuating character of the renewable electricity production. In periods of full production of green electricity, priority can be given to the heat pump, whereas the gas boiler can take over when the green electricity production cannot supply enough energy to the market.

The disadvantages are to a great extent the same as mentioned for gas boilers and electric heat pumps. Since the hybrid technology is new in Denmark, there may be some unknown issues regarding optimisa-tion.

Environment

The environmental impact from hybrid systems is equal to the impact from gas boilers and electric heat pumps.

Research and development

Hybrid systems consisting of condensing gas boilers and electric heat pumps are based on well-known and mature technologies. The research and development may be focussed on integrating the parts and designing the operation control, so that the system becomes an integrated part of the smart grid concept.

Examples of best available technology

Several products comprising a gas boiler and an electric heat pump for hydronic heating systems are already on the European market. In this section, two appliances are shown, representing two different designs. Vaillant introduced a hybrid system in 2012. It consists of a 3 kW heat pump and a 15 or 25 kW gas boiler in separate cabinets. The source energy to the heat pump can be ambient air, ground or ground water. Figure 5.9 shows an installation with heat pump, gas boiler and hot water tank.

Figure 2.6 Vaillant geoTHERM hybrid system with heat pump, gas boiler and hot water tank

(Source: Vaillant)

Figure 2.7 Junkers/Bosch hybrid heating system CerapurAero indoor unit, including heat pump and gas boiler

(Source: Junkers/Bosch)

In 2012, Junkers presented two hybrid systems, CerapurAero and Supraeco SAS Hybrid. Junkers is marketed under the Bosch name in Denmark.

The CerapurAero hybrid system has the heat pump and condensing boiler in a shared single cabinet. The heat pump uses outdoor air as heat source. Heat pump output is approximately 2 kW and COP = 3.5 (at 7 °C source temperature/35 °C flow temperature. The gas boiler has either 14 or 24 kW nominal output. The manufacturer claims an overall efficiency, which is 12% higher than for the gas boiler alone, i.e. 100-104%.

Several boiler manufacturers claim that an electric heat pump can be added to an existing gas boiler in-stallation. The gas boiler has then to be fairly new in order to integrate the heat pump and boiler control systems. One example is the hybrid system Buderus WPLSH, where the heat pump alone can be added to gas boiler installations. A few boiler models are mentioned as possible for the heat pump addition.

2.2.2 Hybrid system design 2: Gas boiler and electric immersion heater

Another way of combining gas and electricity heating is an immersion heater located either in the return flow to the boiler or in a storage tank. An immersion heater in the return line makes it possible to re-place gas consumption by electricity, while the latter option makes it possible also to store electric ener-gy for heating purposes. The enerener-gy can be stored for a few hours, and it is also the only system com-mercially available on the EU market using electric immersion heaters and gas boilers.

This hybrid solution may be suitable in the future for use of low-cost surplus electricity. Today, such a system would be more affordable to the user (compared to the boiler electrical heat pump solution), but the running cost will of course be higher, primarily because of the higher electricity price. Therefore, the economic balance will depend on several factors such as appliance and installation cost, energy cost and control strategy (ratio of gas boiler/electrical heating running hours).

Brief technology description

Even though electric immersion heaters have been used for decades in Scandinavian installations to-gether with oil or wood fired boilers, the intention has not been to integrate the operation with the need of the larger energy system. The intention has been to allow the consumer to choose the most economi-cal heating option through manual settings, for example electric heating of hot water in the summer. Heating the storage tank would typically be for hot water production, while heating directly upstream the boiler would be for heating.

Input

Hybrid gas boiler systems with immersion heaters use gas and electricity.

Output

The output from hybrid systems with a gas boiler and an electric immersion heater is thermal energy for heating and domestic hot water production.

Typical capacities

A hybrid system for single-family houses may typically have a condensing gas boiler in the 5-25 kW range and an electric heater of approximately 1-5 kW. The heater output is significantly lower than the gas boiler output. The immersion heater capacity is partly dependent on the electric capacity in the house. A hybrid system of this kind and size is best suited in the existing building stock.

Regulation ability

The gas boiler in the system will have the same characteristics as the gas boiler as stand-alone including the modulation range.

The immersion electrical heater output will typically work in on/off mode, there the control system de-cides the priority and "on" is electricity mode, while "off" prescribes the use of gas). The control sys-tems will be able to use price signals as well in the future when those are made available to the custom-ers.

Advantages/disadvantages

Costs for the end user

Potentially, the technology will be a low-cost and affordable solution if an immersion heater is located directly in the heating system return line, but the technology is not developed for gas boilers today. The challenge may be integration of the boiler control system and the heater. A storage tank solution has the advantage of storing low-cost electric heat during a short time for heating at a later time (within the next few hours). The main disadvantage for Danish conditions is that the electricity price has to be very low to compete with gas heating, and with the current Danish tariff structure it is not feasible for the time being. But as for the previous technology, the advantage for society is a better flexibility on the heating market. In periods when the electricity is based on renewable sources, priority can thus be given to the

immersion heater, whereas the gas boiler can take over when the green electricity production is not suf-ficient to supply electricity to the market.

Therefore, this product will only develop if, someday, there will be another tariff structure and hence cheap electricity available when there is an over-production with renewables on the market. In this case, an advantage for the user is the optimisation of the heating cost by using two different

technolo-gies/fuels.

Other considerations

The size of the appliances using electricity directly will not differ very much from the original boiler, though the storage will certainly be bigger, but all in all this will bring less constraints compared to gas boiler + electrical heat pumps.

Depending on the capacity of the electrical heater, the user may reach the limit of total power allowed for his existing installation capacity.

Environment

The environmental impact using hybrid systems including electric immersion heaters does not differ from the use of gas heating and electric heating. In case the immersion heater is operated on surplus wind power or other renewable electricity, the CO2 will be reduced compared to heating with natural gas

only.

Research and development

It seems that there is no direct need for research and development of the technical design of hybrid sys-tems with immersion heaters. Only the control system, both for external control of the hybrid system in case of a smart-grid function and on-site added immersion heater, needs to be developed regarding the integration between the system parts and operation.

Examples of best available technology

Gas boiler and a separate immersion heater integrated

There is no example of marketed gas boiler solution with an integrated immersion heater in Denmark.

There are, however, boilers with several fuel options (oil, wood, electricity etc.) that have a hot water tank integrated in the boilers. These are neither intended for use with natural gas, nor suitable for gas heating in Denmark due to the low efficiency compared to the state-of-the-art condensing gas boilers.

Water tank and a separate immersion heater integrated

Hot water storage systems with an electrical immersion heater exist in many countries and are available as a common product in e.g. UK. Water tanks are nowadays mostly hybrid and equipped both with a heat exchang-er (to get the heat from the gas boilexchang-er) and an electric immexchang-ersion heatexchang-er that is used in the summer time (to avoid start/stop of the boiler) /11/. It is also a backup when there is no gas or if the boiler fails /11/. The tech-nology is sold with a control system that controls the boiler and heater in the tank.

Figure 2.8 Example of hybrid storage for a gas boiler in UK /12/

Such hot-water systems can also be purchased in Denmark /13/, but they are not yet a common technol-ogy as are standard packages with gas boilers (boiler/water tank).

Additional remarks -

References

1 M. Näslund, Hybrid systems and smart grids. System design and operation. Market status, DGC December 2012

2 EU Commission Task Force for Smart Grids. Expert Group 4. Smart Grid aspects related to Gas, June 2011

3 M. Larsen, K V Frederiksen, Regulerkraft til villakedelområdet. Overskuds-el fra vindmøller til naturgaskedler, DGC August 2011.

4 Technology data for individual heat production and energy transport. 2012

5 Annual efficiency calculation method for domestic boilers. SAVE Contract XVII/4.1031/93-008. 6 Internal note on HNG Statistics on replacement of gas boilers.

7 Study "Eco-design of Boilers and Combi-boilers (VHK) for the European Commission, DG Transport and Energy (DG TREN). Task 4 Section 3.1.

8 Internal DGC calculations, 2013

9 Start stop emissions of domestic appliances. H. Hüppelshäuser and F. Jansen. Ruhrgas. IGRC 1998. 10 HMN: http://salg.naturgas.dk.

11 Advisor Factsheet. November 2008 Hot Water Systems. Energy saving trust. UK

12 http://www.glow-worm.co.uk/homeowner/products-1/cylinders-1/unvented-hot-water-cylinders/ 13 http://www.billigvvs.dk/search-metrocombi.html

Data sheets:

Part 1: Gas boiler and electric heat pump

Table 2.2 Hybrid system – gas boiler and electric heat pump.

Existing single-family house and new single family houses (No hybrid systems for apartment blocks are pres-ently marketed as packages.)

Technology Hybrid system – gas boiler and electric heat pump

2015 2020 2030 2050 Note Ref

Energy/technical data

Heat production capacity for one gas boiler (kW) Heat production capacity for one heat pump (kW)

5-20 2-7 3-20 2-7 2-20 2-7 1-20 2-7 Expected share of space heating demand covered by

unit (%) 100 100 100 100

Expected share of hot tap water demand covered by

unit (%) 100 100 100 100

Total efficiency, annual average for gas boilers, net (%) Total efficiency, annual average for heat pump, net (%)

100-104 300 100-104 330 100-104 370 100-104 400 B /4/

Technical lifetime (years) 20 20 20 20 C

Environment

The data are for the gas boiler only. For the electrical hat pump, emissions depend on the electricity origin. Emission factors for electricity in Denmark can for instance to be found in the socio economic assumptions for energy projects published by the Danish Energy Authority (www.ens.dk -> Fremskrivninger ->Samfundsøkonomiske beregnings-forudsætninger).

SO2 (g per GJ fuel) ~0 ~0 ~0 ~0

NOX (g per GJ fuel) 20 10 5 ? D,E

CH4 (g per GJ fuel) 2 1 0,5 ? F /9/

N2O (g per GJ fuel) ~0 ~0 ~0 ~0

Particles (g per GJ fuel) ~0 ~0 ~0 ~0

Financial data

Specific investment (1000€/kW) NA NA NA NA K

Specific investment (1000€/unit) 13,2 12,2 12,2 12,2

- equipment (%) 76% 74% 26% 74% 26% 74% 26% J - installation (%) 24% G

Possible additional specific investment (1000€/unit) 2 2 2 2 A /10/

Fixed O&M (€/unit/year) 300 300 300 300 H

References:

4 Technology data for individual heat production and energy transport. 2012

9 Start stop emissions of domestic appliances. H. Hüppelshäuser and F. Jansen. Ruhrgas. IGRC 1998. 10 HMN: http://salg.naturgas.dk.

Notes:

A: Possible installation of a new gas service line grid connection= 2000 €; for new installation only (see /4/ p 31). B: Efficiency of gas boiler expressed in % net. Data for heat pumps directly from Annual efficiency calculated from

test data at DGC /4/ and using the model BOILSIM /5/. The efficiency of the heat pump is from /4/. It is ex-pressed as the ratio heat produced/electricity used by the heat pump. It is therefore not taking into account the pos-sible primary energy needed to produce the electricity needed.

C: The lifetime of a boiler is 22 years (statistics HMN averaged on selected recent technologies.) The lifetime of a heat pumps (air-water) is 20 years according to /4/

D: ECOdesign limit for gas boilers = 70 mg/kWh = 70/3.6 = approx. 20 g/GJ fuel based on Hs.

E: The authors consider that NOx emission will decrease as an average. The level proposed for 2030 is already

achievable today.

F: /5/ gives 5 mg/kWh, This is less than 2 g/GJ.

G: There is not very much data available as the technology is new. HMN standard installation including the appliance is 37,500 DKK including VAT = 5000€ (4000€ without VAT); the installation is 55% = 2200€ (without VAT). /4/ says 15% of 13.000€ for an air-to-water heat pump installation, which equals 1950€. We expect the installation of a hybrid appliance to be somewhere between the cost of installing the boiler alone and the boiler + an air-water heat pump; so we suggest to use a figure of 3200€ for the installation until more experience/data is available for this technology.

H: There is not very much data available as the technology is new. Therefore the authors have considered the follow-ing:

a) For the gas boiler part, the authors use the same as for gas boilers /4/. The unit proposed initially (€/kW/year) is not very adapted to express the reality of the price on the market that is not depending on the appliance ca-pacity. The service contracts on domestic gas appliances are by appliances independently of the caca-pacity. Therefore we suggest here to use (€/appliance/year). The most recent information for boilers is today about 300 Euro/year including VAT (so 240 Euro without VAT). Note however that the service is not mandatory for all appliances.

b) for the heat pump part the existing data from /4/ states 135€ /year

c) We end up with theoretical total of =375€ per unit/year; however it is realistic to consider that the service on gas appliance will be done in the same time as on the electric heat pump so that the total cost is reduced and we consider that 300 € per unit/year is probably closer to the reality.

I: HMN service and maintenance statistics 2006.

J: Cost is given (appliance + appliance installation). Specific investment is given as appliance alone based on inter-view with one manufacturer (appliance estimate ca 12.000 Euros incl. VAT, rounded at 10.000 Euros without VAT. Note that there is no public price given at the time of the investigations.

K: 100% of the investment cost is here given per unit and thus not depending on kW (the technologies known have very similar capacities; so it is not possible to make a linear cost model).

Part 2 Gas boiler + direct electric heater

To our knowledge, there is no standard package with a boiler and hybrid tank on the market, but this may emerge as soon there is a market.

The performance and emissions are equal to those of gas boilers. The investment cost is estimated to be 500 Euros higher than for an installation with only a gas boiler.