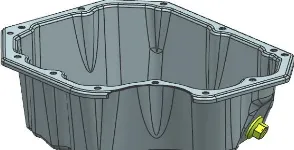

Research on Numerical Simulation for Multi position Progressive Stamping of Car Oil Pan

Full text

Figure

Related documents

Likewise, a higher percentage of late- stage cases of certain cancers is associated with a higher or lower rate of the latter factors independ- ently of socioeconomic

Engine oils have been cooled to below zero temperatures and under controlled temperature regulation, kinematic viscosity (m 2 .s −1 ) have been measured in the range of

This chapter presents a discussion of the findings of this study with regard to the modelling approach, the model development process, the effect of the contributing

rate of KA from the KA-CS-MNPs and KA- PEG-MNPs nanocomposites are obviously slower than that from the physical mixture as shown in the Figure 7B, indicating that

Therefore, this study determined the level of acceptability and factors associated with immediate PPIUCD use among women who gave birth at Bale zone health facilities,

The key to the success of the program can be found in the interpersonal relationships between staff members (clerical included), between patients , and between

Auch die Beobachtung einer reduzierten Gesamt-Acetylierung von H3 bei den EPLC-Zellen nach Gabe von Cisplatin gefolgt von einem HDAC-Inhibitor (Natriumbutyrat, vor

It has been reported (Ref. 31) that high angle grain boundaries and fine packet size as well as the interweave AF microstructure showed good impact toughness and finer cleavage