UDK 535-374

Oblika pulznih laserskih sledi

The Shape of Pulsed Laser Traces

GORAZD RAKOVEC - JANEZ MOŽINA

Za določitev različnih vrst sledi, ki nastanejo pri označevanju s pulznimi laserskimi izvori sta vpeljana dva nova parametra, relativna gostota laserskih pulzov G in relativna gostota kraterjev Gk r . Na tej podlagi je izpeljan model superpozicije kraterjev, s katerim je poleg laserskega označevanja mogoče na nov način opisati tudi druge pulzne laserske obdelovalne procese. Opravljene meritve premera, globine in hrapavosti laserskih sledi potrjujejo uporabnost modela. Z modelom, ki privzema posamezni krater kot glavno procesno enoto, se odpirajo nove možnosti za nadzor in optimizacijo pulznih laserskih obdelovalnih procesov.

Two new parameters, relative density of laser pulses G and relative crater density Gkrt have been introduced in order to define various kinds of laser traces obtained in pulsed laser marking. In addition to the description of laser marking, the model of crater superposition which was derived on this basis also enables one to describe other pulsed laser manufacturing processes. The measurements of diameter, depth and roughness of laser traces were performed to confirm the applicability of the proposed model. Assuming a single laser crater as a fundamental process unit, new possibilities have been opened for monitoring and optimizing pulsed laser processes.

0. UVOD

Laserske sledi je mogoče definirati kot raz lične trajne spremembe, ki se pojavijo v materialu po prehodu laserskega žarka. Lahko jih delimo na sledi z odvzemanjem materiala in brez njega. Za sledi brez odvzemanja materiala so značilne pred vsem kemične in mikrostrukturne spremembe materiala, ki so podlaga za toplotno obdelavo in nekatere vrste označevanja. Pri večjih intenzite tah vpadle laserske svetlobe pa se naštetim spre membam pridružijo še geometrijske spremembe površine materiala, ki nastajajo zaradi lokalnega taljenja in izparevanja materiala. Tovrstne spre membe so podlaga številnim laserskim obdeloval nim procesom, kakršni so vrtanje, rezanje, gravi ranje ipd. Najpogostejša je delitev na pulzne in zvezne laserske procese. V tem prispevku se ome jujemo na pulzne laserske procese, pri čemer pa izbrani način omogoča tudi opis zveznih procesov.

Laserski obdelovalni procesi so v literaturi izčrpno obdelani 111, 121, 131. Pri tem pa je zani mivo, da je o geometrijskih lastnostih laserskih sledi najti le malo podatkov. S tem prispevkom posegamo na to področje in želimo definirati geo metrijske lastnosti laserskih sledi in njihove po vezave z obdelovalnimi parametri. Takšen način naj bi v naslednji fazi omogočil novo klasifikacijo laserskih obdelovalnih pocesov in odprl tudi nove možnosti za njihovo krmiljenje 141, 151.

0. INTRODUCTION

Laser traces can be defined as various per manent changes occuring in a material after the passage of a laser beam. A distinction can be made between those with and those without the ablation of material. Chemical and microstructu- ral changes in the material, which form the basis for heat treatment and some types of marking, are characteristic of traces without material ablation. With high peak intensities of incoming laser light, these changes are coupled with geo metrical changes in the material surface as a consequence of localized melting and vaporization. Such changes are the basis for numerous laser manufacturing processes, such as drilling, cutting and engraving. Most frequently, a distinction is made between pulsed and continuous laser pro cesses. This paper is limited to pulsed laser pro cesses; however, the chosen approach also makes it possible to describe continuous processes.

1. OZNAČBE 1. SYM BOLS

As m razdalja med dvema zaporednima As m distance between two successive

kraterjema, craters,

Dk m premer kraterja, Dk m diameter of crater,

J energija laserskega pulza, E, J energy of laser pulse,

J povprečna energija sledi, J mean energy of trace,

f s~1 frekvenca pulzov, f s -1 pulse frequency,

G relativna gostota laserskih pulzov, G relative density of laser pulses,

G0 statična relativna gostota laserskih Go static relative density of laser

pulzov, pulses,

Gk globina kraterja, Gk depth of crater,

CN m globina sledi, CN m depth of trace,

Ckr relativna gostota kraterjev, ?k r relative density of craters,

A W /m 2 povprečna intenziteta laserskega A W /m 2 mean intensity of laser pulse,

pulza,

Am W /m 2 povprečna intenziteta sledi, Am W /m 2 mean intensity of trace,

N število laserskih pulzov, N number of laser pulses.

Pt W povprečna moč laserskega pulza, P, W mean power of laser pulse,

W povprečna moč sledi, r n W mean power of trace,

m srednje odstopanje profila, R a m standard deviation of profile,

R m m največja višina odsekov neravnin, R m m max. height of sectional unevenness

Rt m največja višina neravnin, R t m maximum height of unevenness,

t s čas, t s time,

A t s čas trajanja laserskega pulza, At s duration of laser pulse,

to s čas med dvema zaporednima pulzo to s time between two successive

ma, pulses,

A t0 s časovna perioda vlaka laserskih A t0 s time period of train of laser pulses, pulzov,

S m2 prerez laserskega žarka, S m2 laser beam cross-section,

Sk m2 površina kraterja, Sk m2 surface area of crater,

V k m višina kraterja, V k m height of crater,

V m /s relativna hitrost med obdelovancem v m /s relative speed between workpiece

in žarkom, and beam,

Ax m širina laserskega žarka v smeri x, Ax m width of laser beam along the x-axis,

A x0 m presledek med dvema zaporednima A x0 m shift between two successive

pulzoma v smeri x, pulses along the x-axis,

VK m /s relativna hitrost v smeri x. VX m /s relative speed along the x-axis.

1.1 Kratice 1.1 Acronyms

LP laserski pulz, LP laser pulse

TLP vlak laserskih pulzov. TLP train of laser pulses

2. K R A TER 2.1 Laserski pulz

Laserski žarek v splošnem ponazarjamo s prostorsko in časovno porazdeljeno intenziteto I(x, y, t), kjer sta x in y radialni koordinati. Z integracijo intenzitete po prerezu laserskega žarka S dobimo trenutno moč:

2. C R A T E R 2.1 Laser pulse

A laser pulse is generally described by spatially and temporally distributed intensity

/ (.V, y, t), where .v and y are radial coordinates. By integrating the intensity over the laser beam cross-section S, we obtain power at a given time:

Pit) = J J/C v , y, t)dy d.v

S

(2.1).

Za opis laserskih procesov v mnogih primerih zadošča poznavanje energije posameznega pulza:

Eì =

J j

J / (at, y, t)dy d.v <it = J P(t)dt (2.2. )A t x A t

in frekvence pulzov f. Povprečna moč laserskega žarka P je v tem primeru enaka:

P = V praksi se pogostno uporablja časovno neod visna povprečna moč laserskega pulza Pv določena z enačbo:

and the pulse frequency f. The mean power of a laser beam P is in this case equal to:

Ey f (2.3).

Frequently applied in practice is the tim e-in- dependent mean power of the laser pulse P ,, which is defined as:

A t A t

(2.4).

Analogno lahko določimo povprečno intenziteto /,, neodvisno od časa:

The mean intensity /i independent of time as:

is analogously defined

E,

S A t (2.5).

Pri pulznih procesih sta intenziteta oziroma moč sestavljena iz zaporedja med seboj časovno ločenih bliskov — pulzov. Zaporednje večjega šte vila pulzov imenujemo vlak laserskih pulzov (TLP). 2.2 R elativna gostota laserskih pulzov — C

Kot parameter laserskih obdelovalnih procesov bomo definirali relativno gostoto laserskih pulzov

(7(61. Pri gibanju v smeri A' je gostota Gx defini rana z enačbo:

Ay

G X = A X A A'n

In pulsed processes, the intensity or the po wer is composed of a sequence of flashes - pulses separated by time. A sequence of a larger number of pulses is called a train of laser pulses (TLP).

2.2 R elative d ensity of laser pulses — G As a parameter of laser manufacturing pro cesses, the relative density of laser pulses G (61 will be defined. When moving along the x-axis, density Gx is defined by the equation:

Aa

-vxAf0 (2.6) .

Če obdelovanec miruje glede na žarek (vx = 0), je treba uporabiti drugačno definicijo relativne go stote pulzov. V tem primeru definiramo statično gostoto laserskih pulzov G0 kot število laserskih pulzov N, ki se popolnoma prekrivajo:

beam ( If the workpiece is stationary relative to the vx = 0 ) a different definition of relative density of pulses should be applied. In this case, the static density of laser pulses G0 is defined as the number of laser pulses N which overlap com pletely:

Gn = N (2.7).

Gostota G vlaka laserskih pulzov je vedno manjša od statične gostote G0, ker vlak laserskih pulzov pri gibanju zavzame večjo dimenzijo v sme ri radialne hitrosti.

The density C of a train of laser pulses is al ways lower than the static density G0, since the train of laser pulses has a greater magnitude in the direction of the radial velocity.

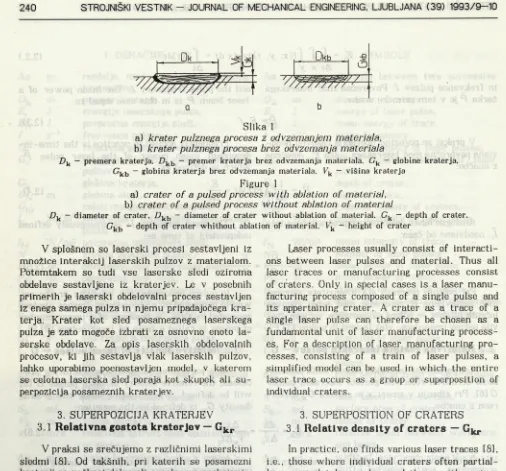

2.3 O b lika k r a te r ja

Sled, ki nastane z vpadom posameznega laser skega pulza na površino materiala, imenujemo krater. Oblika kraterja je v splošnem odvisna od parametrov laserskega pulza in lastnosti obsevane ga materiala (71. Za poenostavljen opis oblike kra terja je primerno izbrati njegov premer Dk in glo bino Gk (sl. 1). Premer in globino je mogoče pri pisati za procese z odvzemanjem (sl. la) in brez odvzemanja materiala (sl. Ib).

2.3 Shape of c r a te r

Slika 1

a) krater pulz nega procesa z odvzemanjem materiala, b) krater pulznega procesa brez odvzemanja materiala

D k — prem era k raterja, D k h — prem er k rate rja brez odvzemanja m ateriala. C k - globine kraterja, Gkb ~ globina k rate rja brez odvzemanja materiala. Vk - višina k rate rja

Figure 1

a) crater of a pulsed process with ablation of material, b) crater of a pulsed process without ablation of material

D k — diam eter of crater, Z)kb — diam eter of crater w ithout ablation of material, Gk — depth of crater, C kb - depth of crater w hithout ablation of material. V’k - height of crater

V splošnem so laserski procesi sestavljeni iz množice interakcij laserskih pulzov z materialom. Potemtakem so tudi vse laserske sledi oziroma obdelave sestavljene iz kraterjev. Le v posebnih primerih je laserski obdelovalni proces sestavljen iz enega samega pulza in njemu pripadajočega kra terja. Krater kot sled posameznega laserskega pulza je zato mogoče izbrati za osnovno enoto la serske obdelave. Za opis laserskih obdelovalnih procesov, ki jih sestavlja vlak laserskih pulzov, lahko uporabimo poenostavljen model, v katerem se celotna laserska sled poraja kot skupek ali su- perpozicija posameznih kraterjev.

3. SUPERPOZICIJA KRATERJEV

3.1 R elativna gostota kraterjev — Gkr

V praksi se srečujemo z različnimi laserskimi sledmi 181. Od takšnih, pri katerih se posamezni kraterji po večkrat delno ali popolnoma prekrivajo, do takšnih, pri katerih so posamezni kraterji med sebojno povsem razmaknjeni. Vse te sledi lahko enotno kolikostno opišemo tako, da vpeljemo rela tivno gostoto kraterjev Gkr kot količnik med pre merom kraterja Dk in relativnim premikom As obdelovanca glede na laserski žarek v času med dvema zaporednima laserskima pulzoma:

Relativna gostota kraterjev ima velik pomen za opis laserskih obdelovalnih procesov. Z njo je mogoče na povsem nov način ne samo karakterizi rati različne vrste laserskih sledi, ampak na pov sem nov način klasificirati pulzne laserske obdelo valne procese. V posebnem primeru, ko je relativ na hitrost enaka nič, kar pomeni, da laserski pulzi vpadajo na isto mesto, definiramo statično relativ no gostoto kraterjev, ki je enaka številu vpadlih pulzov:

Laser processes usually consist of Interacti ons between laser pulses and material. Thus all laser traces or manufacturing processes consist of craters. Only in special cases is a laser manu facturing process composed of a single pulse and its appertaining crater. A crater as a trace of a single laser pulse can therefore be chosen as a fundamental unit of laser manufacturing process es. For a description of laser manufacturing pro cesses, consisting of a train of laser pulses, a simplified model can be used in which the entire laser trace occurs as a group or superposition of individual craters.

3. SUPERPOSITION OF CRATERS 3.1 R elative density of craters — Gj„.

In practice, one finds various laser traces 181, i.e., those where individual craters often partial ly or completely overlap, and those with craters completely separated. All these traces can be uni fied in a quantitative description if the relative density of craters Ckr is introduced as a quotient of the crater diameter Dk and the motion As of the workpiece relative to the laser beam in the period of time between two successive laser pulses:

(3.1).

The relative density of craters is of great importance for the description of laser manufac turing processes. It enables one not only to cha racterize various types of laser traces but also to approach the classification of all pulsed-laser ma nufacturing processes in a new way. In a special case, when the relative velocity vanishes, which means that the laser pulses fall on the same spot, one can define the relative static density of craters, which equals the number of incoming pulses:

' k r o N (3.2).

Tako kakor gostota pulzov, je tudi gostota kraterjev enakega vlaka laserskih pulzov vedno manjša od statične gostote kraterjev. Relativna gostota kraterjev je manjša od relativne gostote pulzov, ker je premer kraterja manjši od premera laserskega pulza, statični gostoti kraterjev in la serskih pulzov pa sta enaki.

Pri obravnavi laserske sledi na materialu nas zanima, koliko energije v povprečju pride na enoto površine materiala <Sk. V ta namen uporabimo relativno gostoto laserskih pulzov G in zapišemo:

The crater density of a train of laser pulses is, like the density of pulses, always lower than the static density of craters. The relative density of craters is lower than the relative density of pulses, since the diameter of the crater is smaller than the diameter of the laser pulses, whereas the static densities of the craters and the laser pulses are equal.

When considering laser traces in the mate rial, we are interested in the mean quantity of energy per unit of material surface area S k . For this purpose, we use a relative density of laser pulses G and write:

(3.3), En = GE\

kjer je i?N energija laserske sledi. Analogne enač be veljajo tudi za P N in / N. S spreminjanjem G torej spreminjamo količino energije na površini sledi laserskega žarka in s tem določamo lastnosti in vrsto sledi. Z gostoto G preslikamo energijske razmere procesa pri enem — enotskem pulzu v energijske razmere celotne laserske sledi. Vse sledi laserskega žarka pa lahko enotno razvrstimo z relativno gostoto kraterjev.

Za procese odvzemanja materiala lahko Gkr prikažemo kot povprečno globino sledi, izraženo v številu globin enega kraterja. Vrednosti G kr so pri procesu odvzemanja teoretično ponazorjene z idealiziranim modelom naslikah 3 in 4. Teoretični model je močno idealiziran zato, da smo lahko vsaj približno nakazali superpozicijo kraterjev. Le ta je v splošnem zapletena, tako da je analitični način vsaj za prakso neuporaben. Prikazane so sledi vla ka pravokotnih pulzov (sl. 2) po procesu odvzema nja materiala, z idealno pravokotnim laserskim pulzom; z veliko globinsko ostrino, z idealnim pro cesom uparjanja homogenega materiala in s pravo kotnim profilom intenzitete.

P

R ... ... ...

where EN is energy of the laser trace. Analogous equations are also applied to P N and / N. Therefore, by modifying G, we modify the quantity of energy on the surface of a laser beam trace, thus deter mining the properties and type of trace. Energy conditions of a process at one unit pulse are ap plied with density G to the energy conditions of the entire laser trace. With the assistance of the relative density of craters, we were able to classi fy all traces of the laser beam in a unified manner. In processes with ablation of material, Gkr can be presented as the mean depth of trace, expressed in terms of the number of depths of crater. G kr values are, in ablative processes, theoretically illustrated by an idealized model in fig. 3, 4. The theoretical model is greatly idea lized, so that we could, at least approximately, indicate the superposition of craters, which is generally complicated, thus preventing the appli cation of a practical analytical approach. Figure 2 shows a train of rectangular pulses with an ideally rectangular laser pulse; with a great depth sharpness, with an ideal vaporization process of homogeneous material and with a rectangular profile of intensity.

* j g

i l w b

A l i A l i „ ___aJL

SI. 2. Vlak pravokotnih laserskih pulzov. Fig. 2. Train of rectangular laser pulses. 0 < Gkr < 1 — pri teh vrednostih se posamezni

kraterji ne prekrivajo. Imamo pikčasto označevanje z odvzemanjem materiala. Globina sledi se giblje od 0 do 1 globine kraterja. Sled je pikčasta. Maksimal na globina sledi je enaka globini enega kraterja. Površina vzdolžnega prereza sledi ima obliko stop ničastega profila (sl. 4a).

Gkr = 0,5 — razdalje med robovi kraterjev (pik) so enake premeru enega kraterja.

0 < Gkr < 1 — at these values, single craters do not overlap. There is dotted marking with abla tion of material. Depth of trace varies from 0 to 1 of the depth of crater. The trace is dotted. The maximum doptli of trace equals the depth of one crater. The surface of a longitudinal cross-section of trace has the shape of a graded profile (fig 4a).

Sl. 3. Statična relativna gostota kraterjev: , ? ~ _ Fig. 3. Static relative density of craters: 0 ’ 0

SI. 4. Relativna gostota kraterjev vlaka pravokotnih laserskih pulzov: a) 0 < Gkr = 1. b) Ckr = 1. c) 1 < Gkr < 2. d) Gkr = 2

Fig. 4. Relative density of craters of a rectangular pulsed laser train: a) 0 < Gkr = 1. b) C kr = 1. O 1 < C kr < 2. d) Ckr = 2

£ kr = 0,33 — razdalje med robovi kraterjev so enake dvema premeroma kraterja.

Gkr = 1 — sled postaja zvezna. Globina sredine sledi je enaka globini enega kraterja in ima naj večjo mogočo ravnost na tej globini. Debelina sledi ni enakomerna (sl. 4.b).

1 < Gkr < 2 — zvezno označevanje s stopniča stim vzdolžnim profilom. Od tu naprej je sled zvez na. Debelina sledi je enakomernejša. Globina sledi se giblje od 1 do 2 v stopničastem profilu (sl. 4c).

Gkr = 2 —zvezno označevanje z gladkim vzdol žnim profilom. Globina sledi je enaka približno dve ma globinama kraterja in ima največjo mogočo ravnost na tej globini. Debelina sledi je enakomerna (sl. 4d), kakovost sledi je v tem primeru najboljša.

2 < Gkr < 3 — globina sredine sledi se giblje od 2 do 3 v stopničastem profilu. Debelina sledi je enakomerna.

£ kr = 0.33 — distances between the edges of craters equal two diameters of one crater.

Ckr = 1 — The trace is becoming continuous. The depth in the middle of the trace is equal to the depth of one crater and has the greatest pos sible evenness at this depth. The thickness of the trace is not even (fig. 4b).

1 < Gkr < 2 — Continuous marking with a graded longitudinal profile. From here onwards, the trace is continuous. The thickness of the trace is more even. The depth of the trace varies from 1 to 2 in the graded profile (fig. 4c).

Gkr — Continuous marking with a smooth longitudinal profile. The depth in the middle of the trace equals appproximately two depths of a crater and has the greatest evenness possible at this depth. The thickness of trace is even (fig. 4d). In this case, the quality of the trace is the best.

Gkr = 3 — globina sledi je približno enaka trem globinam kraterja in ima največjo ravnost na tej globini; debelina sledi je enakomerna.

Na podlagi nadaljnjega analognega opisovanja sledi lahko izvedemo klasifikacijo laserskih sledi z relativno gostoto kraterjev, npr.:

0 < Gkr S 1 — pikčasto označevanje, 1 < Gkr ^ 2 — nezvezno označevanje, 2 < Gkr S 4 — zvezno označevanje, 4 < Gkr ž 6 — graviranje,

6 < Gkr — globoko graviranje ali rezanje ob- delovanca.

Največja globina sledi v tem modelu je:

Gkr = 3 — the depth of the trace equals ap proximately three depths of a crater and has the greatest evenness at this depth. The thickness of the trace is even.

On the basis of further analogous descriptions of the trace, one can classify laser traces with the assistance of the relative density of craters, for example:

0 < Gkr š 1 — dotted marking,

K C k r S2 — discontinuous marking, 2 < G k r š 4 — continuous marking, 4 < Gkr š 6 — engraving,

6 < Gkr — deep engraving or cutting of a workpiece.

The maximum depth of trace in this model is:

C N “ G o G k (3.4).

Poleg vrste obdelav je s številom Gkr mogoče določiti ali sklepati o: obliki prereza sledi, hrapa vosti sledi, globini sledi, premeru kraterja, refe renčni hitrosti laserskega obdelovalnega procesa, adaptivni hitrosti pri adaptivnem krmiljenju 141, 191, razporeditvi energije po sledi itn.

3.2 Poimenovanje laserskih sledi z Ckr

terjev je mogoče dobiti več značilnih razporeditev kraterjev oziroma laserskih sledi na površini. Različne sledi, ki imajo skupni imenovalec v re lativni gostoti kraterjev Gk r, smo razmejili in njihove značilnosti združili pod različnimi imeni 161. Imena smo skušali določiti tako, da je vsaka vrsta sledi s čimmanj besedami čimbolj enopo mensko določena in hkrati tudi opisana.

Za pulzne procese definiramo naslednja imena: — sled vlaka LP (sl. 4, 5): sprememba ma

teriala zaradi obsevanja z vlakom LP, — krater (sl. 3a): sled enega LP; G0 = 1, — luknja (sl. 3b): prekrita sled vlaka LP,

C0 > i,

— pikčasta sled (sl. 4a): neprekrita sled vlaka LP; 0 < G <1,

— verižna sled (sl. 4b—d): delno prekrita sled vlaka LP; Gkr ^ 1.

4. PREIZKUSI

Veljavnost zamisli relativne gostote kraterjev smo skušali potrditi tudi s preizkusi. Opravljene so bile predvsem meritve verižnih sledi, izdelanih pri izbranih parametrih f, At in Ev Vsi preizkusi so bili izvedeni v enakem zaporedju:

In addition to a variety of manufacturing pro cesses, the number Gkr enables us to define or infer: the shape of the trace cross-section, the roughness of the trace, the depth of the trace, the diameter of the crater, referential speed of the laser manufacturing process, adapted speed at adaptive control [4], 191, distribution of energy along the trace, etc.

3.2 Denotine of laser tra ces by £7kr

With the help of the described model of crater superposition, it is possible to acquire several ty pical allocations of craters or laser traces on the surface. Different traces which have a common denominator in the relative density of craters Gkr were separated and their properties were combi ned under various names 161. We tried to choose names which have the smallest number of words, only one meaning and which at the same time are also descriptive.

For pulsed processes, the following names are defined:

— trace of an LP train (analogous to figs. 4, 5): change in the material due to irradia tion with an LP train,

— crater (fig. 3a): trace of one LP; G0 = 1, — hole (fig. 3b): an overlapped trace of an

LP train; G0 > 1,

— dotted trace (fig. 4a): not an overlapped trace of an LP train; 0 < Gkr < 1,

— chain trace (fig. 4b-d): partially over lapped trace of an LP train; Gkr è 1.

4. EXPERIMENTS

— obdelava preizkušancev, — izvedba merilnih postopkov in — analiza rezultatov.

Za merjenje je bila izbrana verižna sled. Kot preizkušanec je bila uporabljena finozrnata jeklena pločevina (zrnat cementit v feritni osnovi) z 0,2- odstotnim deležem ogljika, ki se odlikuje tudi z veliko absorptivnostjo (okrog 35 %) svetlobe laser skega izvora Nd-YAG.

Izdelava laserskih sledi je potekala na laser skem sistemu Nd-YAG, ki daje laserske pulze z naslednjimi karakteristikami: At = 0,23—25 ms, fmaks = 4,5—40 Hz in P, = 2,8—28 J. Z opisanim sistemom so bile narejene sledi v industrijskem okolju. Verižne sledi so bile izdelane pri konstant ni frekvenci laserskega izvora ob spreminjanju hitrosti koordinatne mize.

Parametre sledi smo merili z napravo za mer jenje hrapavosti. Fotografije so bile posnete na vrstičnem elektronskem mikroskopu.

4.1 Dimenzije verižnih sledi

Za meritve hrapavosti verižne sledi je bi[a z vlakom laserskih pulzov TLP(Af = 0,5 ms, Pi = = 3000 W, f = 60 Hz) izdelana verižna sled v me rilnem območju merilnika hrapavosti. Izmerki so prikazani na sliki 5, kjer je potrjeno, da je pri manjših hitrostih hrapavost verižne sledi manjša.

Druga serija preizkusov je bila izvedena s pa rametri TLP (0,13 ms, 3850 W, 3Hz). Pri teh pa rametrih laserskega žarka je znašal povprečni premer kraterja 300 pm, globina pa okrog 600 pm. Moč je bila za 22 odstotkov večja kakor v prvi se riji. Kraterji so skoraj neodvisni drug od drugega. Z večanjem gostote kraterjev se veča tudi globina verižne sledi, ki v končni fazi prebije 1,3 mm de belo pločevino (sl. 6). Značilni primeri tako nasta lih sledi so prikazani na fotografijah, ki smo jih posneli z elektronskim mikroskopom.

— processing of samples,

— performance of measurement procedures, — analysis of results.

A chain trace was chosen as the object of measurement. For the sample, we used a fine- -granulated steel plate (granulated cementite in ferrite base) with 0.2 percent of carbon, which is notable for its high absorbtion (around 35%) of the Nd-YAG laser light.

Traces were made with Nd-YAG system, which renders laser pulses with the following properties: At = 0.23—25 ms, /Vnax = 4.5—40 Hz and P, = 2.8—28 J. With the described system, traces were made in an industrial environment. Chain traces were made with constant frequency of the laser source while changing the speed of the coordinate table.

The parameters of the trace were determined with a device for roughness measurements. Photo graphs were taken with a scanning electron mi croscope.

4.1 Dim ensions of chain traces

For the measurements of the roughness of a chain trace, a chain trace was made with a train of laser pulses TLP (At = 0.5 ms, P = = 3000 W, f = 60 Hz) in a measurement range of the roughness meter. The results of the measurements are shown in Fig. 5, where it is confirmed that at lower speeds, the roughness of chain trace decreases.

The second series of experiments was carried out with parameters TLP (0.13 ms, 3850 W, 3 Hz). With these parameters, the mean diameter of a crater was 300 pm, while the mean depth was around 600 pm. In comparison with the first se ries, the power was 22% higher. Craters are al most independent of each other. An increase in the relative density of craters causes an increase in the depth of chain trace which, in the final phase, pierces through a 1.3 mm thick steel plate (fig. 6). Typical examples of traces formed in this way are presented in photographs taken with an electron microscope.

SI. 5. Hrapavost vzdolžnega profila verižne sledi v odvisnosti od hitrosti.

+ - P t : * - f i m ; ° - R a

Sl. 6. Globina verižne sledi v odvisnosti od relativne gostote kraterjev. Fig. 6. Depth of chain trace dependent on relative density of craters.

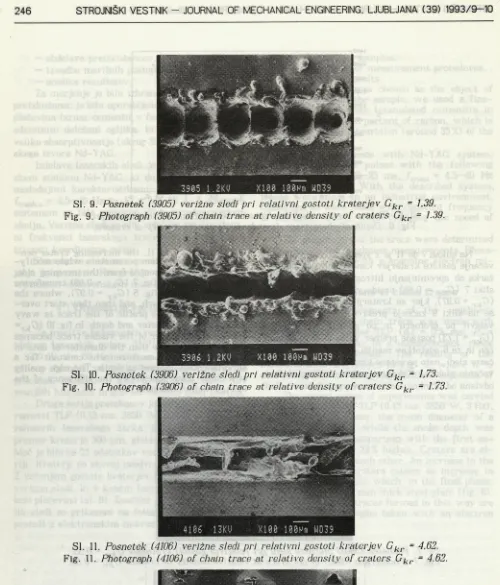

Naslikah 7 do 11 je z vpadne strani prikazano večanje gostote kraterjev konstantnih parametrov žarka ob spreminjanju hitrosti. Pikčasta sled na sliki 7 (Gkr = 0,88) preide v verižno na sliki 8. (Gkr = 0,97), kjer se kraterji le dotikajo, nato pa se na sliki 9 začnejo prekrivati. Profil sledi je valovit po premeru in po globini. Na sliki 10 (Gkr = 1,73) postane premer vidne sledi enakome ren in za 6 odstotkov manjši od premera pik pik časte sledi, nato pa ostane konstanten ob hkratnem večanju globine. Kakovost robov verižne sledi je odvisna od učinkovitosti izmetavanja taline.

In figures 7 to 11, the increasing crater den sity for constant beam parameters while modify ing the speed is presented from the incoming side. The dotted trace in fig. 7 (Gkr = 0.88) transforms into a chain one in fig. 8 (Gkr = 0.97), where the craters only just touch, and then they start over lapping in fig. 9. The profile of the trace is wavy

with regard to diameter and depth. In fig. 10 (Gkr= = 1.73), the diameter of the visible trace becomes even and 6% smaller than the diameter of dots in the dotted trace, then it remains constant for a simultaneously increasing depth. The edge quality of a chain trace depends on the efficiency of the ejected molten material.

SI. 7. Posnetek (39021 pikčaste sledi pri relativni gostoti kraterjev Gkr = 0,8S. Fig. 7. Photograph (3902) of dot trace at relative density of craters Gkr = O.SS.

4Ì0S 13KW K i 80 M i

SL 9. Posnetek (3905) verižne sledi pri relativni gostoti kraterjev Ckr = Fig. 9. Photograph (3905) of chain trace at relative density of craters Gkr

SI. 10. Posnetek (3906) verižne sledi pri relativni gostoti kraterjev Gkr = Fig. 10. Photograph (3906) of chain trace at relative density of craters Gkr

SI. 11. Posnetek (4106) verižne sledi pri relativni gostoti kraterjev Gkr = Fig. 11. Photograph (4106) of chain trace at relative density of craters Gkr

SI. 12. Posnetek (4001) prereza verižne sledi s slike 11. Fig. 12. Photograph (4001) of the profile of chain trace from fig. 11.

1,39. = 1.39.

1,73. = 1.73.

Z večanjem globine se pojavi zmanjšanje izmetavanja taline, ki v nekaterih delih zalije prerezano sled. Globina narašča z večanjem Gkr prav do preboja pločevine, ki je prikazan na slikah 11 in 12 (Gkr = 4,62). Kakovost robov je tu naj večja. Naraščanje globine prikazuje tudi diagram na sliki 6. Odstopa le ena vrednost globine pre reza, ki je verjetno dobljena na zalitem delu, preostale dimenzije pa nakazujejo linearno zvezo med Gkr in globino verižne sledi. Globina pikčaste sledi 600 pm je dvakrat manjša od teoretične vrednosti, kar je mogoče razložiti s tem, da gre za Gaussov profil žarka. Ugotovljeno je tudi naraščanje globine sledi z večanjem relativne gostote kraterjev Gk r.

5. SKLEP

Relativna gostota kraterjev Gkr kot razmerje treh laserskih parametrov (hitrosti, frekvence pulzov in premera kraterja) pomeni učinkovit pa rameter za določanje vrste, globine, premera in hrapavosti pulznih laserskih sledi. Izhaja iz rela tivne gostote pulzov G, ki določa razporeditev energije po laserski sledi in s tem postaja temelj za klasifikacijo laserskih obdelav. Z gostoto G je mogoče hitro preslikati energijske razmere enega laserskega pulza v proces nastanka celotne sledi. Gostota kraterjev Gkr omogoča razmejitev in s tem poimenovanje vseh vrst pulznih laserskih sledi. Za osnovno enoto laserskih pulznih obdelav smo uporabili krater, ki sestavlja vse druge sledi: pikčasto in verižno sled ter pulzno luknjo. Pri tem je izdelana poenotena definicija kraterja za pulzne laserske procese z odvzemanjem in brez odvzema nja materiala. Ta omogoča tudi poenoteno obravna vo drugih vrst laserskih sledi z relativno gostoto kraterjev.

Opravljene so bile meritve premera, globine in hrapavosti laserske verižne sledi. Z njimi je bila potrjena uporabnost vpeljane relativne gostote kraterjev. Potrjeno je naraščanje hrapavosti ve rižne sledi z večanjem hitrosti med laserskim žarkom in površino materiala ter naraščanje glo bine verižne sledi z večanjem relativne gostote kraterjev, pri čemer se premer sledi bistveno ne spremeni.

Opisane raziskave nakazujejo nadaljnje raz iskave v smeri določanja dimenzij posameznih kraterjev kot osnovnih enot laserskih obdelovalnih procesov. Takšno orodje omogoča oblikovanje dato teke tehnoloških parametrov, s katerimi je mogoče na podlagi relativne gostote kraterjev optimirati parametre pulznih procesov z metodami adaptivne ga krmiljenja.

With an increasing depth, there is a decrease in ejected molten material, which in some parts flushes the trace which has been cut. The depth increases with the Gkr until it pierces through the steel plate as shown in figs. 11 and 12 (Gkr = 4.62). Under these circumstances, the edge quality is the best. An increase in depth is shown in the graph in fig. 6. Only one value of cross-section depth is not consistent. It is pro bably acquired in the flushed part, since other dimensions indicate a linear relationship between Gkpand the depth of a chain trace. The depth of dotted trace 600 pm is half the theoretical value, which can be explained by the Gaussian profile of the beam. An increasing trace depth was discovered in the case of an increasing relative density of craters Gk r.

5. CONCLUSIONS

The relative density of craters Gkr as a proportion of three laser parameters (speed, pulse frequency and diameter of crater) is useful for defining the type, depth, diameter and roughness of pulsed laser traces. The relative density of craters is derived from the relative density of pulses G, which determines the distribution of energy along the laser trace, thus becoming the basis for the classification of laser manufacturing processes. With a density G, it is possible to convey the energy conditions of single laser pulse to the formation of the entire trace. The relative density of craters Gkr enables us to distinguish and denote all types of pulsed laser traces. As an elementary unit of pulsed-laser manufacturing processes, we used a crater which shows all other types of trace: dotted, chain trace and pulse hole. In this way, a unified definition of a crater for pulsed-laser processes with and without ablation of material was formulated. This enables a unified treatment of the remaining types of laser traces with the aid of the relative density of craters.

Measurements of diameter, depth and rough ness of a laser chain trace were taken. They confirmed the applicability of the crater relative density. The increasing roughness of a chain trace is verified where we have an increasing speed between the laser beam and the material surface, while the increasing depth of a chain of trace is verified where we have an increasing relative density of craters, whereby the diameter of the trace is not significantly changed.

6. LITERATURA 6. REFERENCES

II) Duley. W.W.: Laser Processing and Analysis of Materials. Plenum Press. New York. London. 1983.

(21 Ready. J.F.: Industriai Applications of Lasers. Academic Press. New York, 1978.

131 Možina. J.: Some Prospects for Pulsed Laser Manufacturing Processes. Robotics & Comp.. Int. Manuf.. Voi. 4. 1988/1-2. 233-239.

141 Peklenik, J.: Avtomatski obdelovalni sistemi. Univerza, Ljubljana. 1981.

151 Herziger. G.: Laser als industrielle Werkzeuge. Zeitschrift für werkschaftliche Fertigung. Carl Hanser Verlag, München. Voi. 38. 1988/8. 404.

161 Rakovec, G.: Lasersko označevanje v maloserijski proizvodnji. Magisterij. Fakulteta za strojništvo Univerze v Ljubljani, Ljubljana 1991.

171 Eyett. M.-Baeuerle. D.: Influence of the Beam Spot Size on Ablation Rates in Pulsed Laser Processing. Applied Physics Letters. Voi. 24. 1987/51. 2054-2055.

18) Rakovec, G.-Možina. J.: Uporaba laserske tehnike v strojegradnji. Poročilo za ZPS. Fakulteta za strojništvo Univerze v Ljubljani. Ljubljana, februar 1989.

191 Möller, H.-Rau. A.: Steuerung für CO, Laser. Zeitschrift für werkschaftliche Fertigung. Carl Hanser Verlag. München. Voi. 84. 1989/6. 349-351.

Naslov avtorjev: mag. Gorazd Rakovec, dipl. inž. Authors' Address: Mag. Gorazd Rakovec. Dipl. Ing. prof. dr. Janez Možina, dipl. inž.

Fakulteta za strojništvo Univerze v Ljubljani Aškerčeva 6.

Ljubljana. Slovenija

Prof. Dr. Janez Možina, Dipl. Ing Faculty of Mechanical Engineering University of Ljubljana

Aškerčeva 6 Ljubljana, Slovenia

Prejet0: 11.6.1993 Received: