Division II

SENSITIVITY ANALYSIS ON INPUT PARAMETERS OF

PROBABILISTIC FRACTURE MECHANICS CODE, PRO-LOCA

Sun-Hye Kim1, Sang-Min Lee1, Jeong-Soon Park1, and Yong-Beom Kim2

1 Senior Researcher, Korea Institute of Nuclear Safety, Republic of Korea

2 Principal Researcher, Korea Institute of Nuclear Safety, Republic of Korea

ABSTRACT

PRO-LOCA is a probabilistic fracture mechanics code, and it is being developed continuously through PARTRIDGE, the international co-operative research program which is derived by Battelle. It can calculate the probability of pipe break caused by fatigue or SSC. The members of Korean Consortium performed sensitivity analyses to validate PRO-LOCA version 4.0. The target case is the rupture in pressurizer surge nozzle resulting from PWSCC, and the target input parameters are the crack depth, crack length, J-resistance, leak detection rate and inspection interval. The sensitivity analyses showed that the PRO-LOCA could provide a trend consistent with the expected crack growth and pipe failure

behavior. Especially, the availability of the new KI and COD solutions developed by Korean Consortium

for non-idealized through-wall cracks was proven from this study.

INTRODUCTION

The PARTRIDGE (Probabilistic Analysis as a Regulatory Tool for Risk-Informed Decision GuidancE) program is an international cooperative research project led by the Battelle. The objectives of this program are the further development of the PRO-LOCA (PRObabilistic Loss Of Coolant Accident) code considering the advanced computational method, enhanced deterministic modules and quality assurance (QA) support to the xLPR (eXtremely Low Probability of Rupture) code. PRO-LOCA code is a kind of probabilistic fracture mechanics code which can be used as a tool for evaluating the pipe break frequency of nuclear power plants. The PRO-LOCA code was developed for the U.S. NRC as part of its Large Break Loss of Coolant Accident (LOCA) program. PRO-LOCA code was originally intended to augment, or periodically re-evaluate the expert elicitation for estimating LOCA frequency, which was the technical basis for the U.S. NRC’s proposed rule change to the emergency core cooling system (ECCS) requirements in 10 CFR 50.46 [1, 2]. The PRO-LOCA code was developed as part of an international cooperative research project led by Battelle called MERIT (Maximizing Enhancements in Risk-Informed Technology) program [3]. The revised version of PRO-LOCA has been developed as part of PARTRIDGE program since 2012. On the other hand, the xLPR code is being developed by U.S.NRC and EPRI as a means of demonstrating compliance with the 10CFR50 Appendix A, General Design Criterion 4 (GDC-4) requirements that the primary system piping exhibit an extremely low probability of rupture [4].

The members of PARTRIDGE program are U.S. NRC, EPRI, CANDU Energy Inc., Swedish Radiation Safety Authority (SSM), Institute of Nuclear Energy Research in Taiwan, and Korean Consortium. KINS, KHNP-CRI, and KEPCO-E&C established a Korean Consortium to take part in the PARTRIDGE program and have provided not only financial but also a technical contribution to it. As a part of the technical contribution, Korean Consortium has developed the new solutions for Mode I stress intensity

factors (KI) and crack opening displacements (COD, δ) for non-idealized through-wall cracks (TWC)

parameters have the greatest effect on the predicted break probabilities. This paper presents the enhancements made to PRO-LOCA code during PARTRIDGE program and the interim results of Korean Consortium’s technical activities.

PRO-LOCA CODE

The PRO-LOCA code can address the failure mechanisms of pre-existing cracks, fatigue associated with initiated cracks, IGSCC (Intergranular Stress Corrosion Cracking), and PWSCC (Primary Water Stress Corrosion Cracking). The outcome of the PRO-LOCA code is a sequence of failure frequencies which presents the probability of surface crack developing, a through-wall crack developing, six different sizes of crack opening areas corresponding to different leak flow rates or LOCA categories, and pipe rupture. Therefore, it can be potentially used for assisting with leak-before-break (LBB), or extremely low probability of rupture assessments as a general purpose PFM code, helping to evaluate the failure probability of a piping system once a flow is detected in service, and helping the prioritization of plant maintenance activities. However, the current state of development is considered to be more of research code than a regulatory tool.

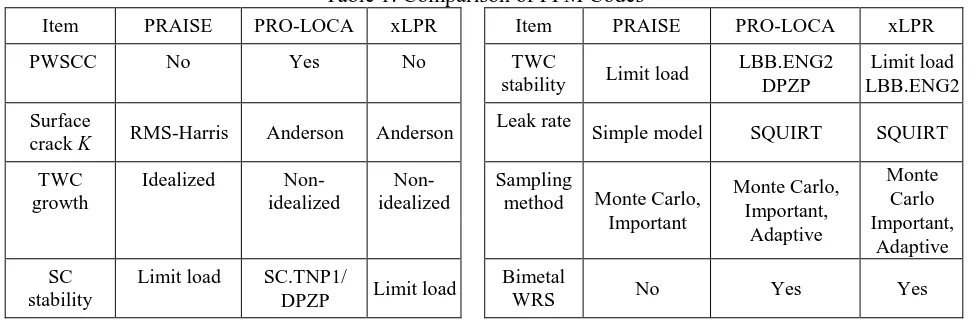

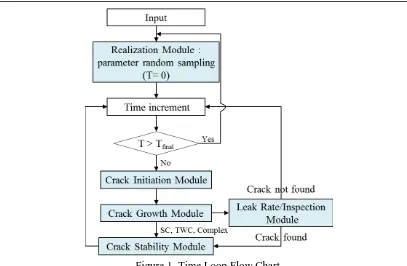

Fig. 1 shows the time loop flow chart of PRO-LOCA code. In realization module, the sampling process is addressed by using Monte Carlo, discrete probability distribution (DPD) important sampling, and adaptive sampling methods on the random variable such as material properties, weld residual stress, crack growth coefficients, crack morphology, fatigue initiation crack size, and leak detection limit can be defined by constant, uniform, normal, Log-normal, and Weibull distributions. The crack initiation module includes: (1) fatigue initiation models developed by Argonne Nat’l Laboratory (ANL) [5], (2) SCC initiation model developed from service history as data fit Weibull distribution [6], and Poisson arrival rate model, (3) distribution describing the time to crack initiation (4) multiple crack initiation model based on service history [7]. The crack growth module is based on the K-solutions from Anderson [8] and it includes: (1) pre-programmed fatigue crack growth laws (Forman laws [9], Paris laws, Walker laws [10], NUREG-CR/6986 model [11], NUREG-CR/6674 model [12] and Nuclear and Industrial Safety Agency (NISA)/ Japan Society of Mechanical Engineering (JSME) model [13] (2) SCC crack growth laws with distribution based on MRP-115 [14] data, (3) crack coalescence model based on ASME B&PV Code Sec. XI, Article IWA-3000. The crack stability module is based on the J-estimation scheme, and it includes: (1) the Dimensionless Plastic Zone Parameter (DPZP) for simply checking stability (2) SC. TNP1 analysis method for surface crack stability (3) LBB.ENG2 analysis method for through-wall crack stability. The leak rate/inspection module includes (1) SQUIRT 3.0 for leak rate prediction, (2) user selected inspection period. The critical differences between PRAISE, PRO-LOCA and xLPR codes are described in Table 1.

Table 1: Comparison of PFM Codes

Item PRAISE PRO-LOCA xLPR Item PRAISE PRO-LOCA xLPR

PWSCC No Yes No TWC

stability Limit load

LBB.ENG2 DPZP

Limit load LBB.ENG2 Surface

crack K RMS-Harris Anderson Anderson

Leak rate

Simple model SQUIRT SQUIRT TWC

growth

Idealized Non-idealized

Non-idealized

Sampling

method Monte Carlo, Important Monte Carlo, Important, Adaptive Monte Carlo Important, Adaptive SC stability

Limit load SC.TNP1/

DPZP Limit load

Bimetal

Figure 1. Time Loop Flow Chart.

The change made to PRO-LOCA 4.0 through PARTRIDGE program includes: (1) implementing the adaptive sampling method, (b) incorporating the new combined pressure and bending crack-opening

displacements (COD) solutions being developed by Battelle, (c) Implementing the new solutions for KI

and COD for non-idealized TWC, (d) incorporating the modified SQUIRT 3.0 code considering new interpolation routine, (e) implementing an alternative approach using the universal weight function method (UWFM) for handling the distribution of weld residual stresses (WRS) in thickness direction, (f) developing a graphical user interface.

SENSITIVITY ANALYSES ON PRO-LOCA CODE

Pressurizer surge nozzle DM weld in PWRs

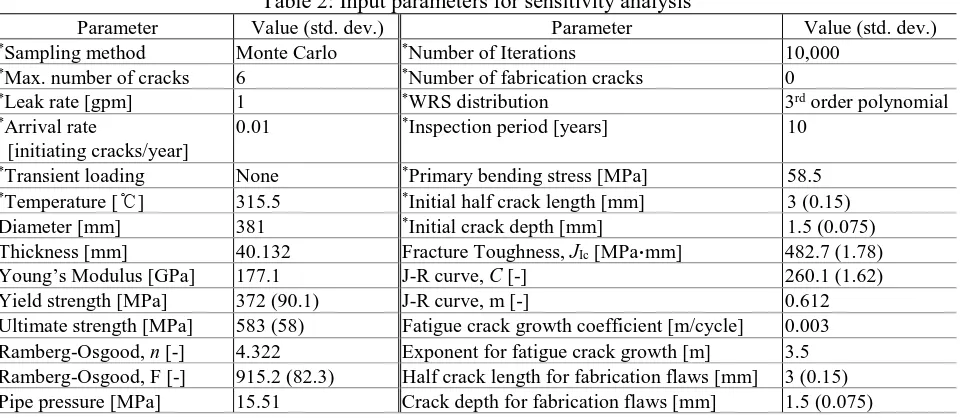

Table 2: Input parameters for sensitivity analysis

Parameter Value (std. dev.) Parameter Value (std. dev.)

*Sampling method Monte Carlo *Number of Iterations 10,000

*Max. number of cracks 6 *Number of fabrication cracks 0

*Leak rate [gpm] 1 *WRS distribution 3rd order polynomial

*Arrival rate

[initiating cracks/year]

0.01 *Inspection period [years] 10

*Transient loading None *Primary bending stress [MPa] 58.5

*Temperature [℃] 315.5 *Initial half crack length [mm] 3 (0.15)

Diameter [mm] 381 *Initial crack depth [mm] 1.5 (0.075)

Thickness [mm] 40.132 Fracture Toughness, JIc [MPa∙mm] 482.7 (1.78)

Young’s Modulus [GPa] 177.1 J-R curve, C [-] 260.1 (1.62)

Yield strength [MPa] 372 (90.1) J-R curve, m [-] 0.612

Ultimate strength [MPa] 583 (58) Fatigue crack growth coefficient [m/cycle] 0.003 Ramberg-Osgood, n [-] 4.322 Exponent for fatigue crack growth [m] 3.5 Ramberg-Osgood, F [-] 915.2 (82.3) Half crack length for fabrication flaws [mm] 3 (0.15) Pipe pressure [MPa] 15.51 Crack depth for fabrication flaws [mm] 1.5 (0.075)

*Variable parameters for sensitivity analysis

Simulation method

The adaptive sampling method newly implemented in PRO-LOCA 4.0 is a sampling technique to adapt to the calculated responses and adjust the discrete probability distribution to focus the sampling on the regions of interest. This method allows the PRO-LOCA code to determine which combination of inputs may lead to pipe rupture within a reasonable amount of simulations and apply important sampling on those variables. The precision of adaptive sampling method is high, but the related artificial sampling parameters should be carefully adjusted for accuracy and efficiency. Fig. 2(a) shows the trend of TWC and rupture probabilities calculated by considering the Monte Carlo method and adaptive sampling method with 10,000 iterations and real calculation time are 3 and 4 minutes, respectively. The TWC probabilities are similar to each other, but the rupture probabilities calculated by using adaptive method have considerably low values and steeply increases with time. Furthermore, the probabilities calculated by using Monte Carlo method with 100,000 iterations have a more stable trend, and slightly low values at an initial stage compared to that with 10,000 iterations, but it takes 34 minutes for calculation.

PRO-LOCA code has been developed to provide the capability for running and handling to 5∙106 iterations.

(a) Sampling method and iteration number (b) Weld residual stress distribution

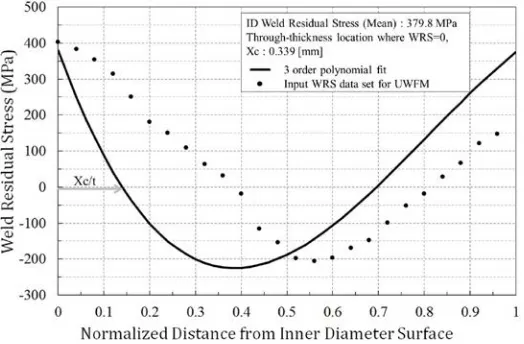

In PRO-LOCA 3.0, the WRS distribution through the pipe thickness is assumed to be axis-symmetric, and the conventional least squares method is used for fitting the polynomial equation to discrete data points of WRS, but that polynomial fit is not always an optimum fit to stress distributions with large gradients or discontinuities. Especially, the 4th order polynomial model is excluded because of unrealistic WRS distribution, and the universal weight function method (UWFM) is newly included in PRO-LOCA 4.0. The 3rd order polynomial fit was derived from the inner and outer diameter WRS stresses as well as

the point Xc where the WRS first crosses over from tensile to compressive stress, and these three values

were considered to be random to account for uncertainty in WRS. Fig. 3 shows the representative example of WRS distribution. On the other hand, the UWFM does not require a polynomial fit, and it follows the actual WRS profile like the data set presented in Fig. 3. In this method, a piece-wise cubic

variation of stress between discrete locations where stresses are known are used to calculate the KI [16,

17]. The UWFM has a significant effect on the TWC probabilities and causes relatively high probabilities as shown in Fig. 2(b).

Figure 3.Representative example of weld residual stress distribution.

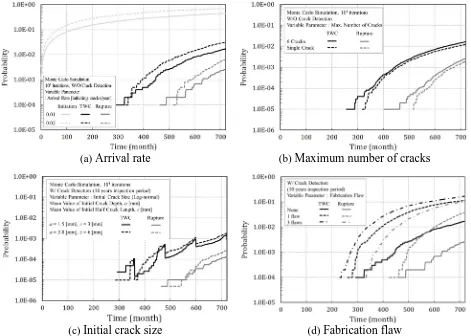

Flaw feature

Crack initiation model is one of the most important drivers to predict failure probability in the piping system. Although the phenomenology on PWSCC has been well characterized, there is difficulty in developing a PWSCC initiation model because no consensus has formed on the PWSCC initiation mechanism. The Poisson arrival rate model is one of the PWSCC initiation models in PRO-LOCA 4.0, and it can introduce multiple initiated cracks into the analysis. It is assumed that the probability of crack initiation, P, a Poisson’s distribution as follows [18]:

) ( ) ( , ! / ) ( )

(k e k k N t N t

P = −λτ λτ k = +τ − (1)

Where {N(t + τ) - N(t)} is the number of events in the time interval (t, t + τ), and τ, λ, k is a time interval, arrival rate, and the number of cracks, respectively. This distribution allows the probability of multiple crack initiations to be developed as a function of time. It defines crack initiation from the arrival rate, the number of cracks per year, and the distribution type along with means and standard deviations for both the initial crack lengths and depths.

a maximum number of cracks on the failure probabilities. A large number of cracks cause high failure probabilities as expected. Fig. 4(c) depicts the doubling initial crack size (length and depth) on the failure probabilities. The large initial crack size causes high failure probabilities as expected except some of the initial stages. The crack detection may cause the different probability trends at the initial stage so that additional evaluation is underway to find the specific causes of the different trends at the initial stage. Fig. 4(d) depicts the effect of fabrication flaws on the failure probabilities. The fabrication flaw is defined not to be considered in the probability of crack initiation in PRO-LOCA code. Fabrication flaw causes high failure probabilities and the failure probabilities remarkably increase with the increase of fabrication flaw. Especially, the rupture probability increases close to the TWC probability in case of three fabrication flaws. It means that fabrication flaw is one of the significant parameters affects the failure probabilities.

(a)

Arrival rate

(b)Maximum number of cracks

(c)

Initial crack size

(d)Fabrication flaw

Figure 4. Effects of flaw features

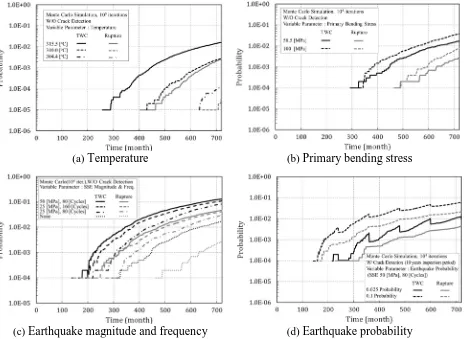

Loading and operating conditions

Fig. 5(a) depicts the effect of operating temperature on the failure probabilities. The TWC and rupture

probabilities considerably decrease with decreasing the temperature of 5oC and extremely decrease with

decreasing the temperature of 10oC. As already known the PWSCC initiation and growth is defined by

circumferential direction of pipe in PRO-LOCA code and it has a signification effect on the failure probabilities because it affects the crack initiation and growth characteristics. The additional evaluation is underway to find the specific causes of different probability trends at the early stage.

Fig. 5(c) shows the effect of magnitude and frequency of safety shutdown earthquake (SSE) loading on the failure probabilities. The SSE loading was defined as a fully reversed loading with constant amplitude and fixed frequency. This SSE load was added to the normal operating loading based on superposition principle, and the low cycle fatigue aspect of earthquakes was considered. The failure probabilities slightly increase with the increase of amplitude and frequency of SSE loading as shown in Fig. 5(c). The reason is that earthquakes were assumed to affect not only fatigue crack initiation and growth but also crack stability. Fig. 5(d) depicts the effect of earthquake occurrence probability for a year on the failure probabilities. The failure probabilities considerably increase with four-times increasing of earthquake probability.

(a)

Temperature

(b)Primary bending stress

(c)

Earthquake magnitude and frequency

(d)Earthquake probability

Figure 5.

Effects of loading and operating conditions

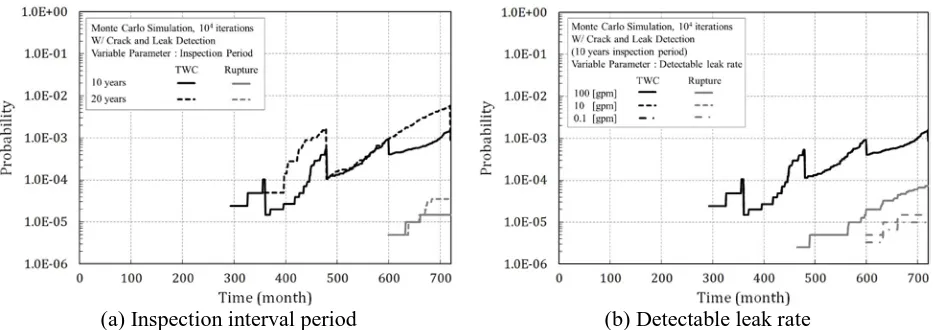

Inspection and leak rate

and the end of the life is reached. Fig. 6(a) depicts the effect of inspection interval on the failure probabilities. Two different inspection interval periods (10 or 20 years) for detecting cracks and leakage were considered in this sensitivity analysis. The short inspection interval causes the decreasing of failure probabilities as expected except some of the initial stages. The crack detections have effects on the TWC probability but not for rupture probability. In contrast, the leak detections have effects on the rupture probability but not for TWC probability. The crack detection may cause the different probability trends at the initial stage, but additional evaluation is underway to find the specific causes of the different trends at the initial stage. Fig. 6(b) shows the effect of detectable leak rate on the failure probabilities. The SQUIRT 3.0 is incorporated in PRO-LOCA 4.0 for predicting leak rate, but the convergence problem can occur when the leak rate is too high. The low limit of detectable leak rate causes the low rupture probabilities as expected.

(a) Inspection interval period (b) Detectable leak rate

Figure 6. Effect of inspection and leak rate.

CONCLUSION

Korean Consortium, KINS, KHNP, and KEPCO E&C, performs LEFM analyses for developing the new

KI and COD solutions for non-idealized circumferential through-wall cracks as part of the in-kind

contribution to the international research program called PARTRIDGE. The new solution was incorporated into the crack transition module of the probabilistic fracture mechanics codes, PRO-LOCA and xLPR. Korean Consortium also conducted sensitivity analyses on the surge line nozzle in PWRs to identify coding errors and check which input parameters have the greatest effect on the failure probability. As a result of sensitivity analyses, the failure probabilities are considerably affected by operating temperature, WRS module, fabrication flaw, and inspection conditions under PWSCC failure mechanism. The stress ratio and rise time have a significant effect on the failure probability under fatigue failure mechanism. However, additional improvement is needed to address the problems such as the instability of adaptive sampling method and the unexpected trend of failure probabilities at the initial stage of crack growth in PRO-LOCA 4.0.

ACKNOWLEDGEMENT

REFERENCES

1. Code of Federal Regulations, “Acceptance Criteria for Emergency Core Cooling Systems for Light-Water Nuclear Power Reactors,” 10 CFR 50.46, 2007.

2. Tregoning, R., Abramson, L., and Scott, P., “Estimating Loss of Coolant Accident (LOCA) Frequencies through the Elicitation Process,” NUREG-1829, 2008.

3. Paul S., Robert K., Andrew C., Rick O., David R., “Development of the PRO-LOCA Probabilistic Fracture Mechanics Code,” Merit Final Report, 2010:46, 2010.

4. xLPR Computational Group, “xLPR Version 1.0 Report: Technical Basis and Pilot Study Problem Results,” 2011.

5. Keisler, J., Chopra, O.K., Shack, W.J., “Fatigue Strain-life Behavior of Carbon and Low-alloy Steels, Austenitic Stainless Steels, and Alloy 600 in LWR Environments,” NUREG/CR-6335, 1995.

6. Shack, W.J., Chopra, O.K., “Statistical Initiation and Crack Growth Models for Stress Corrosion Cracking,” Proceeding of the ASME Pressure and Piping Conference, PVP2007-26731, San Antonio, USA, July 17-21, 2007.

7. Xu, H., Rudland, D.L., Wilkowski, G., Scott, P., “Statistical Characteristics Analysis and Simulation of Circumferential IGSCC Cracks for a BWR Plant,” Proceeding of the ASME Pressure and Piping Conference, PVP2006-ICPVT11-93966, Vancouver, Canada, July 23-27, 2006.

8. Anderson, T.L., Thornwal, G., Revellle, D.A., Lanaud C., “Stress Intensity Solutions for Surface Cracks and Buried Cracks in Cylinders, Spheres, and Flat Plates,” Structural Reliability Technology Final Report to the Materials Property Council, 2000.

9. Forman, R.G., Kearney, V.E., Engle, R.M., “Numerical Analysis of Crack Propagation in Cyclic-loaded Structures,” Transections of ASME, Journal of Basic Engineering, Vol. 89, pp.459-464, 1967. 10. Beden, S.M., Abdullah, Ariffin, A.K., “Review of Fatigue Crack Propagation Models for Metallic

Components,” European Journal of Scientific Research, Vol. 28, No. 3, pp. 364-397, 2009.

11. Khaleel, M.A., Jackson, D.A., Norris, W.E., “Evaluations of Structural Failure Probabilities and Candidate Inservice Inspection Programs,” NUREG/CR-6986, PNNL-13810, 2009.

12. Khaleel, M.A., Simonen, F.A., Phan, H.K., Garris, D.O., Dedhia, D., “Fatigue Analysis of Components for 60-Years Plant Life,” NUREG/CR-6674, PNNL-13227, 2000.

13. Itoh, H., Li, Y., Osakabe, K., Onizawa, K., Yoshimura, S., “Benchmark Analysis on PFM Analysis Codes for Aged Piping of Nuclear Power Plants,” Journal of Mechanical Science and Technology, Vol. 26, No. 7, pp. 2055-2058, 2012.

14. EPRI, “Crack Growth Rates for Evaluating Primary Water Stress Corrosion Cracking of Alloy 82, 182, and 132 Welds,” MRP-115, 2004.

15. EPRI, “Materials Reliability Program: Advanced FEA Evaluation of Growth of Postulated Circumferential PWSCC Flaws in Pressurizer Nozzle Dissimilar Metal Welds,” MRP-216, Rev.1, 2007.

16. Scarth, D.A., Xu, S.X., “Universal Weight Function Consistent Method to Fit Polynomial Stress Distribution for Calculation of Stress Intensity Factor,” Journal of Pressure Vessel Technology, Vol. 134(6), 061204-1-11, 2012.

17. Shim, D.J., Xu, S., Kerr, M., “Effect of Weld Residual Stress Fitting on Stress Intensity Factor for Circumferential Surface Cracks in Pipe,” Proceeding of the ASME Pressure and Piping Conference, PVP2012-78180, Toronto, Canada, July 15-19, 2012.