The Mystery of Gemstone Polish Part 1

By Stephen W. Attaway, Ph.D.March, 1999. Introduction

If you are a new facetor, then you may be confused by the conflicting theories that abound for polish. Just remember that in order to drive your car, you do not have to know how the transmis-sion works. The same is true of polishing theories. The question of what causes polish has inter-ested faceters for a long time and has been the subject of numerous debates. Polishing theories generally fall into three categories:

• Finer scratch theory: The surface is removed with smaller and smaller scratches until the scratches cannot be seen.

• Flow theory: The surface deforms and flows to fill in and level the surface.

• Chemical polish theory: The surface is removed atom by atom through chemical reactions. For me, a good polish theory should be able to explain why it is hard to polish quartz with dia-mond, yet easy to polish quartz with cerium oxide. Why is it that sometimes the lap makes all the difference in the world, and, at other times, it seems to make no difference at all? Why is it that the stone waits until the last facet to crack or scratch? Does it somehow ‘know’ that you are work-ing on the last facet? Some laps are as soft as butter (corian, lucite, and wax), while others are as hard as a rock (ceramic and meehanite iron). Should I use water or oil when polishing? How much polish should I use? Some things are just common sense: you should keep your laps clean, have good flat facets, and have a very good pre-polish that removes the damage from the coarse grind-ing before you begin to polish.

One of the obstacles to understanding polish is that it is very hard to design experiments that will reveal what is really happening during polish. In reality, polishing occurs on a very, very small scale. The surface is actually inaccessible during the polishing process. No one has yet designed a sensor that can be used to make measurements during the polishing process. There-fore, what is known about polish is often inferred from indirect experiments and observations.

In this article, I will try to present some of the experiments that have been used to characterize the behavior of glass, and I will review some of the inferences that the researchers have made from these experiments, which we can relate to gemstone polishing. Although gemstones do not always behave like glass, some good ideas and new insights may be generalized from the work done on glass polishing.

The Grit Size Paradox

Before looking at polish, let us examine some experiments that will tell us about material behavior. There are several experiments that indicate a change in material behavior can occur at very small loading scales.

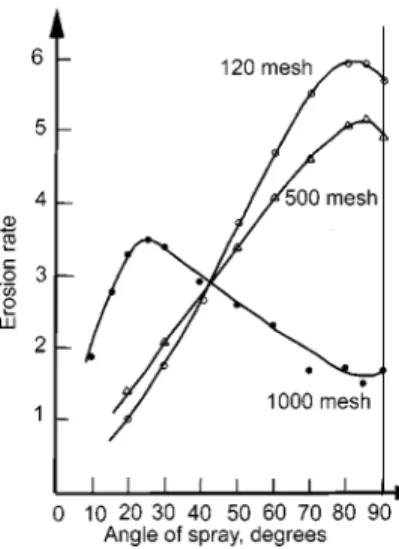

The first experiment to consider measured the amount of glass eroded by a spray of silicon carbide particles impacting the glass1. This experiment determined the angle of impact that maxi-mized the amount of material removed by a high speed jet of particles. The results of these tests

are shown in the Figure 1. Three different grit sizes were used in the test: 120-mesh, 500-mesh, and 1000-mesh. For the coarser abrasives, the fastest material removal rate occurred when the spray was aimed almost directly down upon the glass. The maximum removal rate was at about 10 degrees off axis from vertical for the 120-grit and the 500-grit abrasive, with a removal rate for the 120-grit being greater than the 500-grit.

The surprising result was that for the finer 1000-mesh abrasive, the maximum removal rate was at an impact angle of approximately 30 degrees. The 1000-mesh abrasive actually removed more material at 30 degrees than did the 120-mesh abrasive. The 1000-mesh removal rate at 30 degrees was over twice the removal rate of the 120-mesh.

What is going on here? There appears to be some sort of size effect on the strength of the glass. Why should the smaller grit remove more material than the larger grit at any angle? Based on this experiment, one would be tempted to conclude that the change in behavior is based upon the grit size. Below a certain size, the glass certainly demonstrates a drastic change in its behavior. Scratch Size

In addition to the sand blasting experiment described above, other researchers have made observations of changing glass behavior for very small sizes. Opticians have observed scratches in glass, where the behavior of the material seems to be dependent upon the depth of the scratch. For very shallow scratches, the glass seems to behave like ploughed ground, with material pushed

Figure 1. Results of sandblasting experiment by Oh1.

out of the way as the grit moves over the surface. For deeper scratches, fractures start to radiate out from the scratch.

Malkin et. al.2performed experiments that measured the behavior of a scratch as a function of the depth. They studied scratches using a single-point diamond tool, where the cutting tool was moved across an inclined surface. For this experiment, the normal force was increased with dis-tance. The normal force was measured as the tool was dragged across the surface. At first, the tool simply slid across the surface with friction. As the depth increased, the normal force also

increased and resulted in a scratch. At still deeper cutting depths, the normal force began to fluc-tuate, indicating fractures.

Their scratching experiment showed evidence of material flow, lateral cracking, chipping on the groove, and crushing beneath and ahead of the tool. For depth of cut less than one micron, only material flow was observed. As the depth increased, both cracks and material flow were observed in the grooved surface. At larger depths of cut up to about 10 microns, lateral cracks developed radially from the groove. At still larger depths, large-scale chipping and crushing occurred. (See Figure 2)

Malkin reported on several other researchers’ efforts that also showed a relation between the depth of a scratch and the glass material behavior. He stated that, in addition to load, this

transi-Figure 2. Results of single point diamond as a func-tion of depth of cut2.. a) no cracking only plastic flow, b) some scale like cracks, c) cracking, chip-ping, and subsurface cracks.

tion also depends upon machine stiffness, tool radius, rake angle, crystallographic orientation, and cutting direction.

Zdenek Bazant3has performed tests on concrete, sea ice, steel, and other engineering materi-als. He concluded that many materials can undergo a transition between ductile and brittle behav-ior based on a characteristic length that is a property of the material. He presents a general theory of fracture in his book entitled Fracture and Size Effect in Concrete and Other Quasi-brittle Materials, where he lays out the fundamental laws governing fracture of brittle materials. The Twyman Effect

In the early 1900s, an Englishman by name of Twyman made an interesting observation regarding the grinding of thin glass plates4.. He discovered that the grinding process introduced a thin compressive layer in the surface of the glass. He found compressive stress was induced in grinding and caused the plate to assume a convex form. It is now generally believed that the sur-face stress induced in grinding was the result of permanent deformation of the ground material. Clearly, if fractures are introduced in the surface, then the material will not fit in the same space.

The amount of deformation resulting from this thin layer of damaged and strained material on the grinding surface can be measured very accurately with an interferometer. To do this, one mea-sures the curvature of the glass before and after grinding. Basically, the ground glass behaves as if the grinding process introduces a layer of compressive stress. This compressive stress can cause the ground plate to deform slightly. This effect was known to exist by opticians since Twyman’s time, although few investigators have studied the actual physics governing the Twyman effect.

Sample Preparation In order to measure the Twyman effect, a round glass disk is ground to shape. Usually, a very thin disk is used. Hydrofluoric acid can be used to remove any stresses that may be left from the shaping process. Because some polishing processes also remove all stresses from the fine grinding, an optical flat can be put on one side of the disk.

Twyman Experiment After the initial curvature of the disk is measured, the acid-etched sur-face can be ground using different grits. The resulting change in the curvature can be measured very accurately using an interferometer. The amount of change in curvature resulting from grind-ing stress is related to the properties of the glass and to the amount of stress induced durgrind-ing the grinding process. Once the diameter and plate thicknesses are known, a mathematical model can then be used to estimate the stress produced during the grinding process.

Test Results Podzimek5found that plates are bent more with larger abrasives, and that the bending decreases with abrasive size. He found that as the abrasive size decreased, the depth of the stress decreased. The depth decreased linearly with the size of the abrasive. The depth of the stressed layer depends upon the abrasive size and has been observed to vary from tens of microns down to tenths of a micron. The maximum surface stress, however, increased with decreasing grit size. Basically, as the grit size decreased, so did the size of the microcracks.

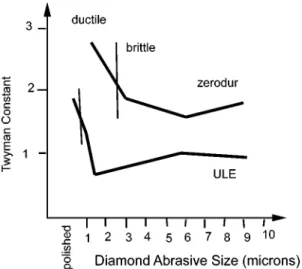

Everyone assumed that the stress would decrease as the grit size became smaller (finer scratch theory). However, in 1991, Donald Golini and Stephen Jacobs6studied the Twyman effect for very small grit sizes. To their surprise, their results showed that as the grit size was reduced below one or two microns, the surface stress increased dramatically.

Figure 3 shows a plot of the Twyman constant, a measure of the surface stress for different diamond abrasive size. Golini and Jacobs observed that the stress decreased for larger grit sizes, but then jumped higher at the smaller grit sizes. They also found that, for polished surfaces (pitch with cerium), the stress was almost zero.

Interpretation Golini and Jacobs postulated that when the grit size becomes very small, the surface is no longer fractured. Instead, the material behaves in a plastic manner. For this type of grinding, they found little subsurface damage. They believe that the ductile surface deformation is the result of glass removal through shearing. A high degree of permanent deformation occurs in this ductile behavior. Apparently, this ductile behavior results in extremely high surface stresses, much higher than in brittle grinding.

What causes size dependent material behavior?

We are all familiar with the terms ductile and brittle. Here, I will try to define these common terms in a scientific sense. Before we define ductile and brittle behavior, we need to talk about

elastic and plastic behavior. We say that a material is elastic if, during the process of loading, the

atoms are strained such that they do not break their bonds and snap back into place when the load-ing is removed. Basically, the bonds between the atoms are stretched, but not stretched too much. A good example of elastic behavior is a rubber band. When it is unloaded, it returns to its original un-stretched position.

Typically, two material constants are needed to describe the elastic properties of a material:

Young’s Modulus and Poisson’s Ratio. The stress in an elastic material is proportional to the

Figure 3. Twyman constant for different small diamond abrasive sizes6. The Twyman constant is a measure of stress on the surface of the glass. Note how the stress increases for small grits and is near zero for surfaces polished with cerium oxide.

Young’s Modulus times the strain. Young’s Modulus reflects how much energy is stored as a material is stretched.

Plastic behavior occurs when a material is loaded to the point that the strains are great enough

to cause the atoms to slide past each other and result in permanent deformation. When unloaded, the atoms do not return to their original position. A good example of plastic behavior is clay.

Most materials will behave elastically for small loads. Once a critical stress is exceeded, plas-tic behavior may occur. The criplas-tical stress needed to cause a material to behave plasplas-tically is known as the Yield Stress. The value of the Yield Stress for glass is typically about one half the Vickers’ hardness9..

A material is called brittle if it fails before it deforms plastically. If a brittle material is loaded, then it will behave elastically until it fails. For a ductile material, some plasticity will occur before the material fails. Everyone typically associates glass with brittle behavior. Good examples of ductile behavior are metals like gold, platinum, and copper.

The mechanics of fracture are such that even a ductile material can fail from fracture. If a crack is introduced into a structure, then the sharp edge of the crack can cut though the structure that would normally behave plastically. If you have ever tried to open bag of peanuts or potato chips, then you know what I am talking about. Unless there is a starting tear in the bag, it can be almost impossible to open. One small flaw, though, and the bag seems to open by itself.

Fracture Mechanics

Fracture mechanics is a failure theory that determines if enough strain energy exists to cause a crack to grow. Cracks make for great mathematical challenges. The sharp tip of a crack leads to very high stresses and makes it almost impossible to model with mathematics. Even so, fracture mechanics is commonly applied in failure analysis of metal structures, especially in aerospace, naval, and nuclear engineering. The stresses at a crack tip can be very high, even when the struc-ture is only lightly loaded.

Just as material constants like Young’s modulus and Yield stress can be measured for a given material, the Fracture Toughness can also be measured for a material. The Fracture Toughness is related to the energy needed to break the bonds at a crack tip and start an existing crack to grow.

An odd phenomenon of fracture is that the stress required for crack growth is controlled by both the crack size and the material properties. The criteria for crack growth depends upon the fracture toughness and the square root of the crack size. This means that bigger structures are more easily failed by fracture. An interesting consequence of the size effect on the strength of brittle materials is that if they are loaded on smaller and smaller regions, then the stress required for a crack to grow may eventually exceed that required for plastic yielding.

Plastic process zone

Below a certain size, a crack will not grow. Instead, plasticity will dominate. By deforming plastically, a transition to ductile behavior may occur. Bazant3points out that the transition between ductile and brittle behavior is often governed by the size of something known as the

frac-ture process zone. This is a very small zone around a crack tip that determines whether the crack

will behave in a brittle or ductile manner. For something like concrete, the fracture process zone may be on the order of inches. For gemstones, the fracture process zone will be very, very, very

small. One of the fundamental ideas that Bazant presents is the idea that the size of the fracture process zone is an important material property, just like hardness. It can control the behavior of the material.

An estimate of the size of the fracture process zone can be made using the fracture toughness, Kc, and the Vickers hardness, H. The size of the plastic zone for a given material is independent of the crack size. However, when the crack size from grinding approaches this plastic zone size, a brittle to ductile transition could occur. Atluri8estimates the size of the plastic process zone as

where Kc is the fracture toughness, and T is the yield stress.

Lambropoulos9,10,11defined a similar ratio that he called the ductility index.

where H is the Vickers hardness.

This index has the dimensions of length, and a close analysis of this index indicates that it is related to the size of the fracture process zone derived by Atluri. In experiments, Lambropoulos found that ground glass surface roughness and subsurface damage were dependent upon the duc-tility index.

We generally have an idea of the fracture toughness of gemstones that we deal with. However, for us to rate one stone relative to another, we would need to measure the fracture toughness and hardness for different gemstones. Hardness is easy. Almost any gemstone data book will list hard-ness values. Published values for fracture toughhard-ness, on the other hand, are more difficult to find.

For the sand blasting experiment, the researchers made an estimate of the fracture process zone size for the glass1. They found that plastic yielding would occur before fracture if the load area fell somewhere around 2-20 microns. Recall that 1000-grit is about 8-11 microns in diameter. Beilby was close, but for the wrong reasons

If gemstones exhibit ductile behavior, then one can see how the Beilby theory7could explain some aspects of polishing. Beilby observed what he thought was glass flowing during polish. He thought that under frictional heating, a viscous liquid is produced that flowed over the surface. He believed that surface tension forces caused the molten liquid to form a smooth surface. Beilby may have been partly correct, in that he believed that the material flowed on the surface. By closer examination of the mechanics of fracture and plasticity, researchers today do not believe that the material actually melts but simply behaves plastically.

Does this explain polish? Is a modification of the Beilby theory all that is needed to under-stand polish?

Golini and Jacobs believe that ductile mode grinding is a purely mechanical process. They verified that material was actually removed during ductile mode grinding by weighing and acid etching the specimens.

R 1 2 ---π Kc T --- 2 = D Kc H --- 2 =

By measuring the Twyman effect for small grit sizes, Golini and Jacobs showed that surface stresses increased dramatically in the transition from brittle to ductile mode grinding. They believe this is due to the results of increased subsurface deformation in the ductile process. They also believe that both ductile and brittle grinding can occur simultaneously. They observed that grinding with small abrasives resulted in brittle fracture, accompanied by some degree of ductile behavior.

Golini and Jacobs concluded: “This work has suggested a clear distinction between grinding and polishing processes. Brittle and ductile mode grinding are purely mechanical processes. The removal mechanisms in grinding include fracture, chipping, and shearing. Both brittle and ductile mode grinding result in some degree of permanent deformation and an accompanying surface stress. Polishing, on the other hand, is a chemomechanical process, which involves a chemical bonding of glass with polishing compounds. The polishing compounds are embedded in a soft tool, and the chemically weakened glass bonds are then pulled apart mechanically on an atomic level. The relatively small stress level that is introduced to the glass in polishing verifies that the level of mechanical shearing is minimal.”6

Three Polish Theories

As you know, gemstones do not always behave like glass. Even so, the discoveries made from the careful observation of the Twyman effect provide strong evidence that three different types of phenomena may be occurring when we polish gemstones.

Everyone understands that a grinding layer could produce subsurface damage with material removal through fracture. One polish theory is that as smaller grits are used, the scratches or frac-tures just become finer and finer until they cannot be seen.

Ever since the introduction of the Beilby theory of polish, the debate has raged in the faceting community concerning the existence of a flow layer. The problem with this theory was that it had trouble explaining how soft compounds could produce fine polished surfaces. Another problem with the Beilby theory was the belief that the surface somehow melted and flowed into place. We now believe that the surface does not really melt but instead flows plastically, much like a clay flows under the strain of the artist’s hands.

More recently, the idea of a chemical effect in polishing has been introduced. The idea of a chemical tooth that can remove portions of the surface atom by atom has gained some credibility.

Golini and Jacobs suggest that all three mechanisms, finer scratch, ductile flow, and chemical polishing may be at work. Their stress measurements, using the Twyman effect, certainly point to evidence that three different mechanisms are at work during polish.

Is this just for glass?

Sinkankas comments in his article, What is Polishing12, on the curious phenomenon that every experienced facetor meets. He noted that stones like almandine garnet and tourmaline develop what seems to be a harder surface just after polish, compared to the same surface just prior to polishing. Thus, for some materials, in order to change a facet, it is best to go back to a coarse grit to rework the facet. The existence of a highly stressed surface layer would certainly explain this phenomenon.

Based on polishing characteristics of the many gemstones that we cut, my suspicion is that not all gemstones exhibit all three modes of polish. I am sure that some gemstones are very resis-tant to chemical attack. These could be problematic to polish, since the only mechanism for pol-ishing would be ductile or brittle grinding. Other stones may have mechanical properties such that a ductile mode grinding and the associated high surface stresses may never develop.

Quartz behavior

Anyone who has tried quartz polish with a fine grit diamond and compared the behavior to that of cerium oxide knows how much easier the polishing is with cerium. You can obtain a polish on quartz with 50,000 diamond, but you really have to work at it. You often get scratching and an odd surface pattern, too. Could a brittle-ductile transition explain the behavior of quartz?

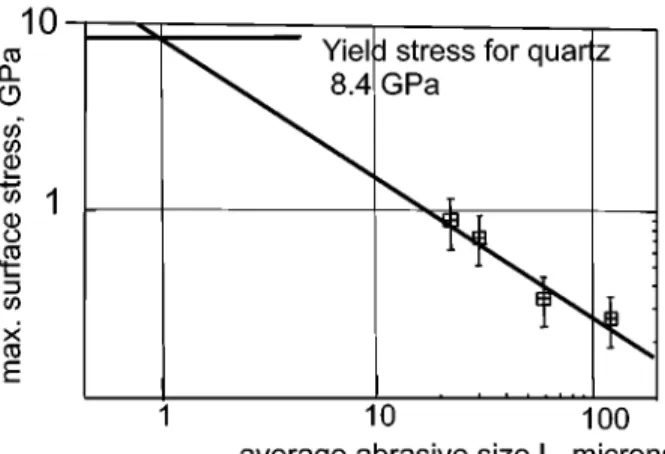

While there is very little data for gem stones, there dose exist some data for quartz which indi-cate that a brittle-ductile transition may occur for grit sizes under one micron (14,000 mesh)10. Figure 4 shows the maximum stress from the Twyman effect for different grit sizes. Note that the plot is shown on log/log paper. If the data is extended to grit sizes below one micron, then the maximum stress in the surface would exceed the yield stress. Based on this data, we should see a different material behavior for quartz in the range of one micron.

Sapphire behavior

Some experiments have been performed on sapphire that show it may also undergo a brittle to ductile transition. Smith13used the Twyman effect as a tool for measuring the stress in different polishing processes for sapphire. While a polish could be obtained with either ¼ micron diamond or colloidal silica, the ¼ micron diamond polish generated a very high stress, while the colloidal silica polish generated almost no stress. Since sapphire’s strength depends upon the crystal direc-tion, they had to be extra careful in their experimental setup. They found that the stress generated during polishing with ¼ micron diamond was roughly equal to the yield strength of the material,

Figure 4. Twyman stress data for quartz and fused silica10.. The grinding stress depends on the square root of the average abrasive size. As the abrasive size becomes smaller, the grinding stress may exceed the yield stress.

10.4 Gpa for the c-plane (0001). They found a polished stress layer about 0.12 microns deep for 0.25 micron diamond and a stress layer about 0.01 microns deep for colloidal silica polish.

Smith’s work on sapphire shows that there may be more than one path to polish. In this case, it appears that both a mechanical and a chemical polish are possible.

Ramifications

One might think that it would be best to avoid generating a highly stressed surface layer, espe-cially if you are dealing with a fragile stone like an emerald. If, indeed, all three mechanisms of polish were at work, then it might be faster to avoid very small grits, and thus avoid this ductile grinding mode and the associated high stresses. Ideally, one would like to use brittle grinding fol-lowed by chemical polish to obtain the fastest removal rate with the least amount of stress.

I am reminded of the fear that one particular facetor struck in our hearts when he described an emerald repair job he did some years ago. After he re-polished the table, he put the stone away for the night. When he came back the next morning, the stone was split nicely down the middle. Could high surface stresses associated with a Twyman effect cause this fracture? We will never know, but it does give you something to think about before you tackle expensive repair jobs. Iden-tifying if a chemical polish exists for a stone could certainly be useful in cases like this, where we need to minimize the stresses.

Summary

We have only scratched the surface when it comes to understanding the physics and chemistry involved in polishing. Each stone may behave very differently. The presence of small micro cracks throughout certain gemstones could drastically change their behavior when considering the small scales that are involved in polishing.

Let us review what we have:

• Experimental evidence for size effects in glasses and other materials. • Experimental evidence for two modes of grinding: ductile and brittle.

• We inferred that size effects control the transition between ductile and brittle grinding. • Experimental evidence (Twyman effect) that grinding introduces stress in the surface.

• Experimental evidence that grinding with very small grit generates more stress than grinding with larger grits.

• From the stress measurements using the Twyman effect, we inferred that a thin plastic defor-mation layer leads to high stress under ductile grinding.

• Experimental evidence shows that polishes like Linde-A and cerium oxide leave a stress-free surface.

• For glass, three modes of material removal may be at work, brittle, ductile or chemical. • We have some evidence that some gemstones may have three modes of material removal.

Four material properties have been identified that might control the ‘mechanical’ aspects of polish: Young’s Modulus, Poisson’s Ratio, fracture toughness, and Vickers hardness (yield stress). You may find it interesting to know that these same properties also play a role in the cutting and

polishing of metals. As far as I know, no one has measured these properties for a wide variety of gemstones. The chemical aspects of polish are much less understood. More testing will be needed to fully understand the subtle aspects of chemical polishing.

In Part II of this article, I will review some of the ongoing work in chemical polish theories.

References

1. Oh, H.L, Oh, K.P.L, Vaidyanatham, S. and Finnie, I. “On the shaping a brittle solids by

ero-sion and ultrasonic cutting,” The science of ceramic machining and surface finishing, NBS

Special publication 348, 1972.

2. Malkin S. and Hwang T. W., “Grinding Mechanisms for Ceramics”, Vol 45/2, 1996 pp 569-580.

3. Bazant, Z.and Planas, J.to, Fracture and Size Effect in Concrete and Other Quasi-brittle Materials, CRC Press, New York, 1998.

4. Dalladay, A. J. “Some Measurement of the Stress Produced at the Surfaces of Glass by Grind-ing with Loose Abrasives,” Trans. Opt. Soc. London 23, 170-173 (1922).

5. Podzimek, O., “Deformation Energy Under Optical Surfaces,” Proc. Soc. Photo-Opt. Instrum. Eng. 801, 221-225 (1987).

6. Golini, D. and Jacobs, S. D. “Physics Of Loose Abrasive Micro-Grinding,” Applied Optics, Vol 30. No. 19 pp 2761-2777, 1991.

7. Beilby, G.T. Aggregation and flow of solids, Macmillan and Co. London. (1912). 8. Atluri, S. N., Structural Integrity and Durability, Tech Science Press, 1997.

9. Lambropoulos, J.C., Fang, T., Funkenbusch P.D., Jacobs S. D., Cumbo M. J. and Golini D., “Surface microroughness of optical glasses under deterministic microgrinding,” Applied Optics, Vol, 35, No. 2, pp 4448-4462, 1996.

10. Lambropoulos, J. C., Xu, S., Fang, T, and Golini, D., “Twyman effects mechanics in grinding and microgrinding,” Applied Optics, Vol. 35, No. 28, 1996.

11. Lambropoulos, J. C., Xu, S., and Fang, T, “Loose Abrasive Lapping Hardness of Optical Glasses and its Interpretation,” Applied Objects, Vol 36, No. 7, 1997.

12. Sinkankas, J. “What is Polishing,” Lapidary Journal, Vol. 52, No. 11. pp 51-56, Feb. 1999. 13. Smith, M. B., Schmid, K., Schmid, F., Khattak, C. P. and Lambropoulos, J. C. “Controlling