Statistical Process Control In Future Production

Full text

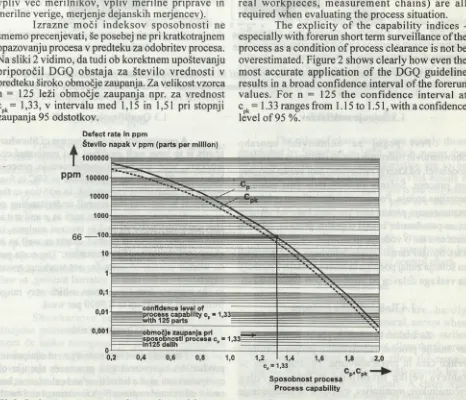

Figure

Related documents

Although close to the 95% point, there was no significant difference in the percentage of time the heart was active for over the salinities tested (p = 0.054) (Figure 6.7),

determine how well a molecule can permeate cells [133], however for the purpose of this experiment, Vega calculations are used to determine the heat capacity of the complex as

Cincturing in comparison with PCPA in this trial tends to increase the fresh and dried fruit yields of Zante currant, suggesting that the increase in currant production in the

Based on survey responses, are the responses for how frequently a student would use a social media tool to sell books online between students in his or her department

The effects of extrusion cooking on the nutrient and anti-nutrient composition of raw and extruded blends of pigeon pea and unripe plantain flours were evaluated.. Pigeon pea seeds

1 from 14 pièces pour flûte et piano Selected Flute Exam Pieces 2008–13, 2 Pam Wedgwood Hot Chilli: from Really Easy Jazzin’ About for Flute Grade 1 (ABRSM).. 3 John Widger Fun

international law systems and the problems this creates. Other difficulties are caused by the use of nationality as a connecting factor to determine personal capacity, and the

Sub−endothelial matrix destruction further increases ROS production and initiates smooth muscle cell migration, prolifera− tion, and phenotypic changes, thus propagating the