2019 International Conference on Computational Modeling, Simulation and Optimization (CMSO 2019) ISBN: 978-1-60595-659-6

The Effect of the Tool Dimensions on the Formability of High

Strength Steel

Jian-wei YANG

1,2,3, Wen-yu MA

1,2,3,*, Xue-bin ZHENG

1,2,3,

Yong-qiang ZHANG

1,2,3, Shao-nan DU

1,2,3and Hong-wei E

1,2,31Research Institute of Technology of Shougang Group Co., Ltd., China

2Beijing Key Laboratory of Green Recycling Process for Iron & Steel Production Technology, China

3Beijing Engineering Research Center of Energy Steel, China

*Corresponding author

Keywords: Formability, High strength steel, Tool dimension, Springback.

Abstract. In this paper, the influence of the toolset size on the formability of the high strength steel formability was analyzed. The formability indexes include the thinning rate and springback. The toolset size analyzed in this study includes die corner size and punch corner size. To analyze the above relationship efficiently, the test design and the FE simulation were employed. At the same time, the optimization method was also used. The response surface method can be used to show the effect of the tool size on the formability clearly. It can be seen from the results that the springback increases with the increase of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the springback. The radius of the toolset punch corner is more sensitive for the springback than the radius of the toolset die corner. The thinning increases with the decrease of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the thinning, the thinning increases with the increase of the radius of the toolset die corner. In terms of the thinning, the punch corner is more sensitive than the die corner, especially when the radius of the toolset die corner is high.

Introduction

The FE Model

[image:2.595.202.385.191.257.2]There are four main parts in the FE model. They are punch, die, blank holder and blank. The width of the blank is 50 mm and the length of the blank is 550 mm. The material is DP780. The model used the Y-U material hardening model. The Poisson’ Ratio of the material is 0.3, and the Young’s Modulus is 2.1e5 MPa. The yield stress is 548 MPa, at the same time the tensile strength is 805 MPa. The blank holder force is set as 50 kN, and the punch velocity is 40 mm/s. The thickness of the blank is 1.5 and the depth of the stamping is 50 mm.

Figure 1. The FE model.

The Design for the Effect Test

The design factors including radius of the toolset punch corner and radius of the toolset die corner were considered. To analyze the effect of the design factor efficiently, the test design method, i.e. Central Composite Design was employed. A range of the design factor was chosen and the employment of the test design can help establish the response surface. The test factors and their levels were shown in the Table 1.

Table 1. The test factors and their levels.

Low High -alpha +alpha Mid

A radius of the toolset punch corner

5 11 3.8 12.2 8

B radius of the toolset die corner

5 11 3.8 12.2 8

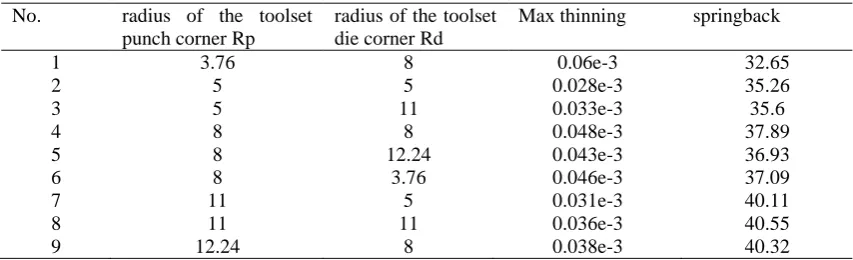

The design of tests was conducted according to the table 2, and the corresponding results were also shown in the table 2.

Table 2. The design of tests and the corresponding results.

No. radius of the toolset punch corner Rp

radius of the toolset die corner Rd

Max thinning springback

1 3.76 8 0.06e-3 32.65

2 5 5 0.028e-3 35.26

3 5 11 0.033e-3 35.6

4 8 8 0.048e-3 37.89

5 8 12.24 0.043e-3 36.93

6 8 3.76 0.046e-3 37.09

7 11 5 0.031e-3 40.11

8 11 11 0.036e-3 40.55

9 12.24 8 0.038e-3 40.32

Results and Discussion

[image:2.595.84.511.529.659.2]Figure 2. The response surface for the springback against tool dimensions (Unit: mm).

It can be seen from the figure that the springback increases with the increase of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the springback. The radius of the toolset punch corner is more sensitive for the springback than the radius of the toolset die corner. The mathematical formula for the effect of the radius of the toolset die corner and radius of the toolset punch corner on the springback was shown in the following formula.

S=26.9+1.58Rp+0.28Rd+2.78e-3 Rp* Rd-0.05 Rp^2-0.017Rd^2 (1)

Where, S is for springback; Rp is for radius of the toolset punch corner; and Rd is for radius of the

toolset die corner.

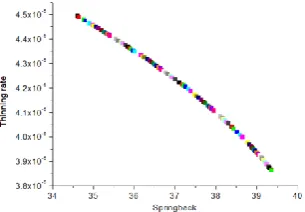

[image:3.595.209.410.397.499.2]According to the test results, the response surface for the effect of the radius of the toolset die corner and radius of the toolset punch corner on the thinning rate was established, which is shown in the Fig. 3.

Figure 3. The response surface for the thinning against toolset dimensions (Unit: mm).

It can be seen from the figure that the thinning increases with the decrease of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the thinning, the thinning increases with the increase of the radius of the toolset die corner. In terms of the thinning, the punch corner is more sensitive than the die corner, especially when the radius of the toolset die corner is high.

The mathematical formula for the effect of the radius of the toolset die corner and radius of the toolset punch corner on the thinning rate was shown in the following formula.

t=4.9e-5-1.05e-6 Rp+2.4e-7 Rd+2.9e-21 Rp* Rd (2)

Where, t is for thinning rate.

radius of the toolset die

corner radius of the toolset punch corner

p

Sri

n

gb

ak

Spri

ng

ba

ck

radius of the toolset die

corner radius of the toolset

punch corner

Thi

nni

ng

ra

[image:3.595.222.375.662.768.2]To optimize the formability indexes, the optimization toolset was employed and applied in determining the relationship between the thinning and springback. It can be seen from the figure that with the increase of the springback, the thinning rate decreases. The line in the figure is the Pareto frontier for the thinning and springback with different toolset sizes. It can be seen that these two indexes are contradictory.

Experimental Validation

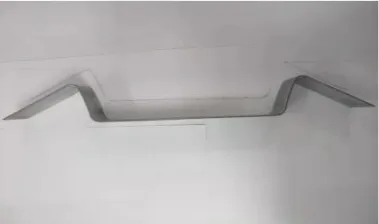

[image:4.595.204.394.274.386.2]The experiment was conducted using the radius of the toolset die corner of 8 mm and the radius of the toolset punch corner of 8 mm. And the experimental part after springback is shown in the following figure and the springback value is measured. The experimental springback value is 44 for the left and 43 for the right. The following simulated result was also measured, and the springback value is 37.89 for the left and 37.33 for the right. The deviation between the experimental result and simulated result is 13.89% for the left and 13.91% for the right, which shown a good predictability of the FE (FE) simulation.

Figure 5. The experimental result after the stamping and springback using the radius of the toolset die corner of 8 mm and the radius of the toolset punch corner of 8 mm.

Figure 6. The simulated result after the stamping and springback using the radius of the toolset die corner of 8 mm and the radius of the toolset punch corner of 8 mm.

Conclusion

1) The springback increases with the increase of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the springback. The radius of the toolset punch corner is more sensitive for the springback than the radius of the toolset die corner.

2) The thinning increases with the decrease of the radius of the toolset punch corner. And the effect of the radius of the toolset die corner shows slight effect on the thinning, the thinning increases with the increase of the radius of the toolset die corner. In terms of the thinning, the punch corner is more sensitive than the die corner, especially when the radius of the toolset die corner is high.

[image:4.595.187.414.421.532.2]References

[1] Wen-yu MA, B.W.L.F., Effect of friction coefficient in deep drawing of AA6111 sheet at elevated temperatures. Trans. Nonferrous Met. Soc. China, 2015. 25: pp. 2342-2351.

[2] Wenyu Ma, Jianwei Yang, Xuebin Zheng., The effect of Bauschinger related parameters 20181030. 2019. pp. 8-12.

[3] Ding Hao, D.H., et al., Formability of TRIP/TWIP Steel Containing Manganese of 18.8%. Journal of Iron and Steel Research, International, 2011. 18(1): pp. 36-40.

[4] Wenyu Ma, B.W.J.Z., Multi-objective optimization of hot stamping of aluminum alloy blank. Journal of Harbin Engineering University, 2015. 36: pp. 1-6.

[5] G. Ingarao, R.D.L.F., Analysis of stamping performances of dual phase steels: A multi-objective approach to reduce springback and thinning failure. Materials and Design, 2009. 30: pp. 4421-4433.