Plasma Electrolytic Oxidation of AZ91 Mg Alloy in the Sodium Stannate Electrolyte

Full text

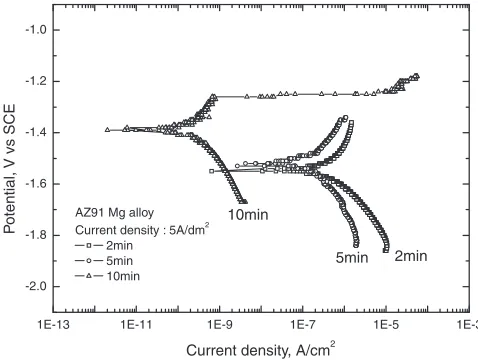

Figure

Related documents

The results of the rotating bending fatigue tests carried out on the untreated sand cast EV31A Mg alloy with different surface roughness (S0.3 and S0.8 samples), and on the

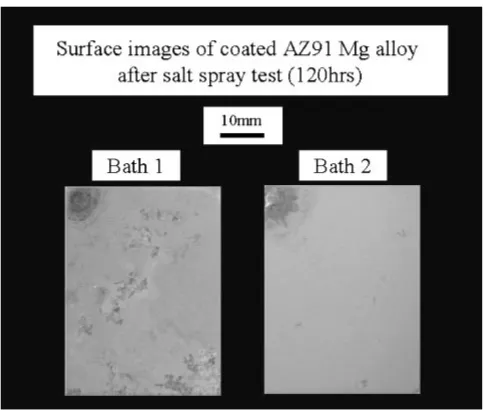

Corrosion Behavior of AM60 Magnesium Alloy Based Composites Corrosion Behavior of AM60 Magnesium Alloy Based Composites with and without Plasma Electrolytic Oxidation Coating..

substrate, furthermore, PEO coatings shown much higher polarization resistance compared with bare magnesium alloy, indicating the oxide films fabricated through PEO

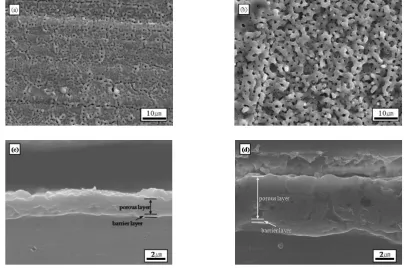

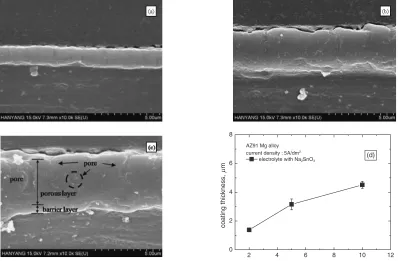

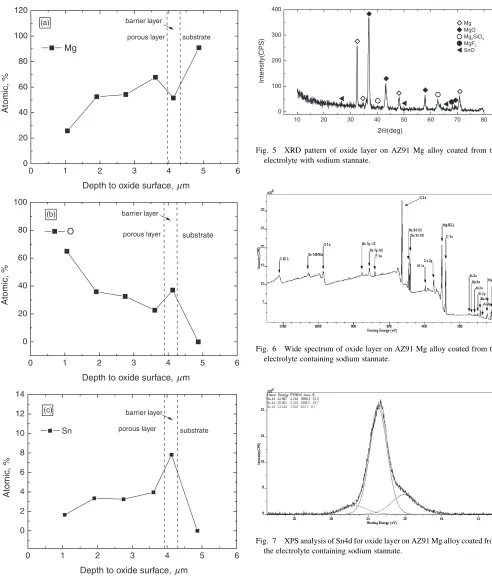

The composition of electrolyte plays a key role in determining the structure and properties of the ceramic coatings by the prepared plasma electrolytic oxidation

Northwood, The effect of current mode and discharge type on the corrosion resistance of plasma electrolytic oxidation (PEO) coated magnesium alloy AJ62, Surf. Gnedenkov, Effect of

But in the micro arc oxidation process for preparing biocoating of on titanium alloy surface, the composition of formed coating is greatly affected by the electrolyte

The result was achieved using plasma electrolytic oxidation with modi fied electrolyte to introduce carbon ions into the oxide thus inducing defects in the crystalline structure of

Şahin, “Effects of pulse duration on structure and surface characteristics of micro-arc oxidation coatings formed on aluminum alloy,” Acta Phys.. Belozerov et al., “Effect